Solatube Energy Care Optima 160 DS User manual

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

1

Solatube® Brighten Up® Series

Solatube® 160 DS Daylighting System

Solatube® 290 DS Daylighting System

Installation Instructions

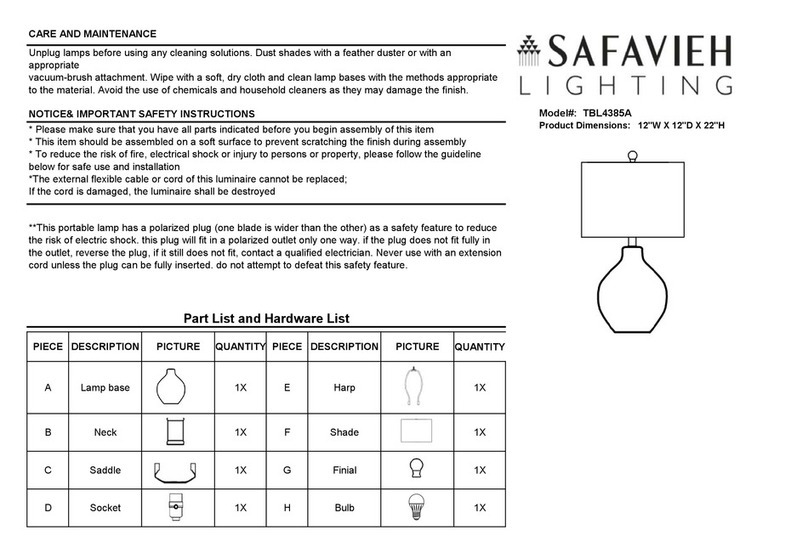

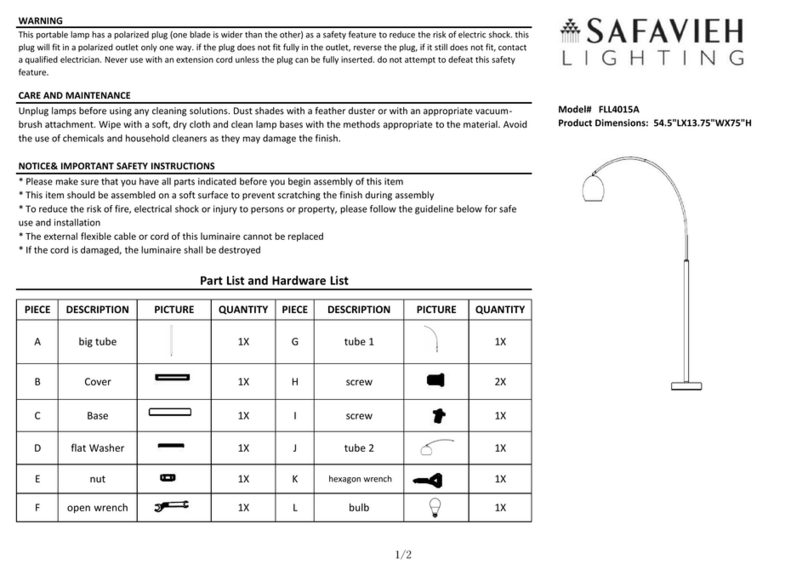

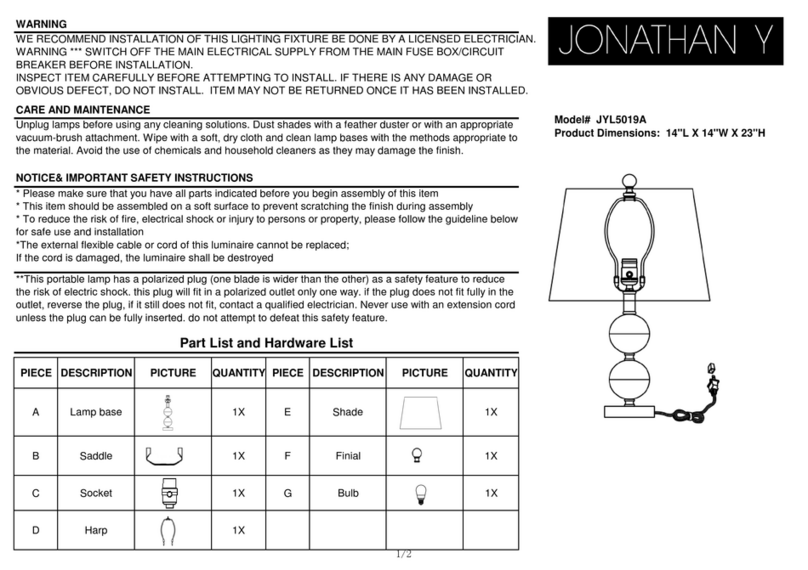

Parts List * Quantity

1

Dome with Raybender® 3000 Technology (1)

a. Shock Inner Dome*†

2Roof Flashing (pitched or no pitch) (1)

3

Top Tube Assembly including: Dome Ring, Dome

Ring Seal, Spectralight® Innity Top Tube with

Angle Adapter.

(1)

4Spectralight® Innity 16 in (400 mm) Extension

Tube (not included in some kits, see label on box) (2)

5

Bottom Tube Assembly including: Spectralight®

Innity Bottom Tube with Angle Adapter, Ceiling

Ring

(1)

6Effect Lens (1)

7Diffuser (1)

Seal and Fasteners

a. Dome Ring Screws - #8 X 1 in (25 mm) (5)

8

b. LightTracker™ Reector (1)

c. Flashing Screws - #10 X 2 in (51 mm) (8)

d. Roof Sealant (1)

e. Expansion Joint Seal (1)

f. Tube Screws - #8 X 9/16 in (14 mm) (10)

g. Foil Tape - 2 in (51 mm) X 18 ft (5.5 m) roll (1)

h. Drywall Screws - #6 X 1 5/8 in (40 mm) (4)

3

Required Tools:

Keyhole Saw

Saber or Reciprocating Saw

Hammer

Flat Bar

Utility Knife

Tape Measure

Caulking Gun

Screw Gun with Phillips Head

Lumber Crayon

Magnetic Compass

Required Safety Equipment

4

5

2

7

6

8f

8d

8b

8e

8a

8c

1a

1

8h

*†High Velocity Hurricane Zones: Shock Inner Dome must be installed

with dome. To meet HVHZ requirements, use a six inch no pitch

ashing or a pitched ashing with a four inch turret extension.

8g

*Components shown not included in all kits, see label on box.

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

2

WARNING

Daylighting Systems Installation Tips

These instructions are a step-by-step guide for the installation of a Solatube Daylighting System in the following conditions.

For other roof types, please contact your Solatube International representative for additional information.

Built Up Flat Roof - Single Ply/Membrane - Asphalt Shingle - Low/No Pitched - Pitched -

Prefabricated Curbs - Metal Roof Panels

Please refer to the installation tips for the appropriate product below:

Do not proceed with the installation until you have read the entire instructions, including these warnings.

(Use of materials or methods not authorized by Solatube International will result in an invalid warranty.)

Solatube International, Inc. (seller) assumes no responsibility or obligation whatsoever for the failure of an architect, contractor, installer, or building

owner to comply with all applicable laws, ordinances, building codes, electrical codes, energy codes, re and safety codes and requirements, roof

warranties and adequate safety precautions. Installation of this product should be attempted only by individuals skilled in the use of the tools and

equipment necessary for installation. Protect yourself and all persons and property during installation. If you have any doubt concerning your competence

or expertise, consult a qualied expert before proceeding.

Install at your own risk!

Solatube product installations may be dangerous and include the potential for death, personal injury and property damage. The hazardous

conditions include but are not limited to the following:

During installation, the Solatube Daylighting System’s reective tubes may focus sunlight, causing intense heat or re. Remove

protective lm only after the parts have been installed. Prior to and during installation, do not leave tubes in contact with

combustible materials or unattended, especially near direct sunlight. Avoid skin burns.

Solatube Daylighting System and Solar Star products may have sharp edges. Always wear leather or canvas gloves while handling and installing

products.

Solatube product installations require climbing and working at dangerous heights, including on ladders, scaffolding, roofs and in attic spaces.

Risk of death, personal injury and property damage may result from a fall, or from falling objects. Use extreme caution to minimize risk of

accidental injury, including, but not limited to the following procedures:

Clear area below your work space of all people, animals and other items.

Avoid working on surfaces that are slippery or wet.

Use foot-wear with excellent traction.

Use only strong, well supported ladders.

Work only in calm dry weather.

When in the attic, ensure that your weight is supported at all times with structurally sound framing; drywall material is not designed to

carry a person’s weight.

To reduce the risk of re, electric shock, and personal injury, basic safety precautions should always be followed when using electric tools,

including always wearing safety goggles or other suitable eye protection, and ensuring work area is clear of all electrical wires, gas pipes, water

pipes, and other obstacles.

When working in the attic or other dusty areas, use of a mask or respirator is recommended to avoid lung irritation. Attic spaces may be dark,

conned, and subject to extreme temperatures. Beware of sharp protruding objects. Do not attempt installation without having someone within

range of your voice or close enough to come to your aid if necessary.

Solatube products are not designed to withstand the weight of a person, tools or other objects. Walking or placing objects on the system could

cause personal injury and property damage. If the product is damaged, the structural capacity may be weakened; therefore the system should

be repaired immediately. For safe installation and use, do not deviate from these installation instructions.

Additional support is recommended for long vertical and all horizontal tube runs. Review local building requirements and consult with

appropriate building code ofcial for proper material and placement of additional support. Avoid galvanic reaction (corrosion) if dissimilar metals

are used.

Electrical Components

Before installing, servicing, or cleaning unit, switch power off at service panel and lock service panel to prevent power from becoming switched

on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device such as a tag to the

service panel.

Re-Roong

Solatube products require special care if removed for re-roong. In order to ensure proper removal and re-installation, please contact your

Solatube International representative.

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

3

Solar Star Attic Ventilation Installation Tips

Keep Solar Star solar panels covered until product is mounted and sealed to roof. Cover solar panel whenever motor, fan, or unit is to be

serviced. Fan blade is controlled by the solar panel and may become operational when panel is exposed to sunlight.

Solar Star products are designed for general ventilation purposes only. Do not exhaust any hazardous materials or gases such as ammable,

explosive or incendiary materials.

Solar Star products have an unguarded fan blade. Do not use Solar Star products in areas that are easily accessible.

Caution

Carbon monoxide may be drawn into a house or attic space with the operation of Solar Star products if fuel-burning equipment is not

serviced or monitored regularly. Carbon monoxide (CO) is a colorless, odorless gas that can be hazardous to your health and may cause

death. Fuel-burning equipment must have proper ventilation, Solar Star products are not designed to provide ventilation for fuel-burning

products.

Light Add-On Kit Installation Tips

This product is to be installed by qualied electricians only. Disconnect power before installation.

“FOR USE IN NON-FIRE-RATED INSTALLATIONS ONLY.”

Thermally protected “TYPE IC” (insulation may contact housing).

“ACCESS ABOVE CEILING REQUIRED.”

“SUITABLE FOR DAMP LOCATIONS.” Use only as a component of Solatube Daylighting System products.

“MIN. 60°C SUPPLY CONDUCTORS.”

Intended for installation with ½ in (12.7mm) minimum spacing from the xture to cavity surfaces (side wall and overhead building member)

and 1 in (25.4mm) minimum spacing to adjacent xtures.

Blinking light may indicate improper lamp wattage or type, or insulation is too close to xture, or other condition causing overheating.

Caution

Risk of re and electrical shock. Most dwellings built before 1985 have supply wire rated 60° C.

To reduce the risk of re, use only:

Fluorescent Lamps, Medium Base - 23 Watt Maximum, Maximum Overall Length (MOL) 4 3/4 in (120 mm)

Compact Fluorescent (4 Pin Quad Tube) 26 Watt only

Minimum thickness of metal tubing is 0.018 in (0.47mm)

Daylighting Systems Installation Tips (Continued)

Allow at least 2-3 hours for the installation, particularly if this is your rst installation.

During the day, turn off all the lights in the room to see how much natural light comes in through the windows, and determine the best position for the

Solatube Daylighting System. To light a specic area, place the system over the area, not in the center of the room. This will prevent the desired

area from being shaded by tall objects in the room.

Measure the distance between the roof and the ceiling. If you don’t have enough tubing, contact your Solatube International representative

for additional tubing.

Avoid roof locations shaded by trees, ridges and chimneys, or near water channels or valleys. Also avoid roof areas with obstructions such

as re sprinklers, HVAC equipment, gas, water or drain pipes, air ducts or ues and make sure that the roof is adequate to endure an

installation without damaging its waterproong properties or weakening the building structure.

All adhesives, seals and tapes are recommended to be applied to a clean and dry surface at a minimum of 70°F (21°C) for maximum

performance.

Foil tape contains a pressure sensitive adhesive and pressure must be applied at all seams for proper bonding. Foil tape is not intended for

use as structural support of the extension tubes. For structural integrity use manufacturer supplied fasteners on all overlapping extension

tube joints.

Uninstalled product that is stored and exposed to excessive heat and or humidity can experience damage. Store product prior to installation

in a cool dry place.

Daylight Dimmer Installation Tips

Install Solatube Daylight Dimmer only on a properly aligned Solatube Daylighting System.

Use only UL recognized components approved for this listing.

Ventilation Add-On Kit Installation Tips

See Ventilation Add-On Kit installation instructions for tips.

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

4

1/2 in (12.7 mm)

Roof Underlayment

4Remove Roof Shingles

Center on Nail and Trace Inside Flashing Base

Roof Underlayment

5

Mark Ceiling and Roof Location Between Joists and Rafters Using Nails. Cut Ceiling Hole.

Minimum clearance of 5 3/8 in (140 mm) for 160 DS and 7 3/8 in (190 mm) for 290 DS between nail hole center

and joist.

2

1

3Cut Roof Opening

Set Flashing

Nail

Nail

Nail

Cut Line; 1/2 in

(13 mm) Outside

Traced Line

Traced Line

ac

b

b

160 DS

Ø 10 3/4 in (275 mm)

290 DS

Ø 14 3/4 in (375 mm)

Ceiling

Roof

a

Roof Sealant

(3/8 in (10 mm) thick)

160 DS

5 3/8 in (140 mm)

290 DS

7 3/8 in (190 mm)

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

5

7

Align Dome Ring and Flashing Holes

8Align Top Tube Angle with Ceiling Opening

9Remove and Tape Top Tube

Tape all seams.

6Fasten Flashing to Roof and Replace Shingles

Roof Underlayment

10 Fasten Top Tube to Flashing*

*For HVHZ dip screw threads in sealant

11 Dome Installation

Reective side of LightTracker™ Reector faces South in

Northern Hemisphere (North in Southern Hemisphere). Align

and snap dome into place engaging all four snaps.

Shock Inner

Dome for HVHZ

LightTracker™

Reector

Flashing Screw

Dome Ring Screw

a

b

c

a

b

Remove Protective Liner

Remove Protective Liner

b

a

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

6

Insert bottom tube

assembly into top

tube; do not tape

seam.*

Apply pressure to

tape for proper

bonding

Minimum Overlap

at Tube Seams

1 1/2 in (38 mm)

cd

h

Foil

Tape

Assemble and Install Tube Run

Use notches to create a tapered tube.

12 Insert Bottom Tube

Align and measure tube run.

Minimum Overlap

at Tube Seams

1 1/2 in (38 mm)

Minimum Overlap

at Tube Seams

1 1/2 in (38 mm)

Tube length

measurements

should be equal.

Tube Screw Expansion Joint

Seal

a

b

ef

g

a

b

*Tape seam for commercial install with suspended ceiling.

Remove

Protective Liner

13

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

7

Fasten to Ceiling

Use drywall screws if fastening clamps do not engage ceiling.

For cold weather climates, apply latex caulking to ceiling ring

to minimize air transfer.

15 Install Effect Lens and Diffuser

14

Drywall screw if

necessary

Fastening Clamp

Cold Weather Option

Now you can enjoy the benets of your Solatube Daylighting System and

the high performance, natural lighting it provides.

16

ac

bd

a

b

c

Remove Protective Liner

Effect Lens

Diffuser

Please refer to the following section for a list of

alternative ashings and accessories.

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

8

Curb by Others (allow

for counter ashing

roong material)

1Apply Sealant to Curb

Install Cap on Curb

a

3Fasten Flashing to Curb

*For HVHZ apply 4 more screws to curb cap.

b

Curb Mounted Flashing Installation Instructions Appendix

Parts List Quantity

1290 DS (14 in/350 mm) Curb Mounted Flashing

(Inside Dimension 27 in (685 mm) X 27 in (685 mm)) (1)

Additional Materials and Tools Quantity

1Roof Sealant (1)

2Flashing Screws #10 X 2 in (50 mm) (8)

27 in (685 mm)

inside dimension

27 in (685 mm)

inside dimension

Flashing Screw

2

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

9

1Apply Sealant to Underside of Curb Cap

2Install Insulation

Apply Foil Tape to Seams

Curb Cap Flashing Insulation

Installation Instructions Appendix

Parts List Quantity

1290 DS (14 in/350 mm) Curb Insulation (4)

Additional Materials and Tools Quantity

1Roof Sealant (1)

2Foil Tape (1)

b

Apply matte side of

insulation to Curb

Cap surface.

3

a

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

10

3Set Base Flashing

a

Roof Sealant

(3/8 in (10 mm) thick)

b

1Remove Tiles. Center on Nail and Trace Inside

Flashing Base.

Nail

2

Traced Line

Nail

Cut Line; 1/2 in

(13 mm) Outside

Traced Line

4Fasten Flashing to Roof

b

a

Flashing

Screw

Universal Tile Flashing Installation Instructions Appendix

(with Base Flashing)

Parts List Quantity

1Tile Flashing (Pitched or No Pitch version) (1)

2Base Flashing (Pitched or No Pitch version) (1)

2Aluminum “L” bracket (4)

3#8 X 1/4 in (6 mm) screws (8)

Additional Materials and Tools Quantity

1Roof Sealant (1)

2Flashing Screws—#10 X 2 in (50 mm) screws (8)

3Tile Grinder (1)

Note: These instructions are for non-HVHZ areas only. Contact a Solatube

International representative for recommendations in HVHZ areas.

Caution: The use of Portland Cement based mastic, grout, or alkaline

materials will cause damage to the aluminum ashing.

Cut Roof Opening

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

11

Set Universal Tile Flashing

Bend front edge of Universal Tile Flashing to t shape of roof

tiles.

5

6Fasten Universal Tile Flashing to Base Flashing

b

Base

Flashing

#8 X 1/4 in

(6 mm) Screw

Universal

Tile

Flashing

a

8

Secure Flashing to Tile

c

Flashing

Edge

L-bracket

b

a

7Cut and Replace Roof Tiles

#8 X 1/4 in

(6 mm) Screw

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

12

3Apply Sealant to Roof and Flashing

Roof Sealant 3/4

in (20 mm) thick

a

Roof Sealant 3/4

in (20 mm) thick

b

4Set Flashing

2

Cut Roof Opening

Cut Line; 1/2 in

(13 mm) Outside

Traced Line

Flashing

Perimeter

Traced Line

1Center on Nail. Trace Inside and Outside

Flashing Perimeter.

Nail

a

b

Nail

Flat Roof Installation Instructions Appendix

Parts List Quantity

1Roof Flashing (no pitch) (1)

2Flashing Screws - #10 X 2 in (51 mm) (8)

Additional Materials and Tools Quantity

1Straight Edge (1)

2Roof Sealant (1)

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

13

5Fasten Flashing to Roof

a

b

6Apply Sealant and Spread Evenly Using Straight

Edge

a

b

Roof Sealant 3/4

in (20 mm) thick

Straight Edge

Flashing Insulator Installation Instructions Appendix

Parts List Quantity

1Flashing Insulator (1)

2Foil Tape (8)

Additional Materials and Tools Quantity

1None

1Center Flashing Insulator on Flashing Base.

Apply pressure to

foil tape for proper

bonding.

Flashing Screw

b

2Apply Foil Tape.

a

Warning: Do not expose Flashing Insulator to direct ame.

Return to main instruction set to complete ashing installation.

a

b

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

14

a

Turret Extension Installation Instructions Appendix

Parts List Quantity

1Turret Extension 2 in (50 mm) or 4 in (100 mm) (1)

21/4 in (6 mm) screws (4)

Additional Materials and Tools Quantity

1Roof Sealant (1)

1Apply Sealant to Flashing and Inside of Turret

Extension

a

b

Place Turret Extension over Flashing and Fasten

bc

1/4 in (6 mm)

Screw

2

a

a

b

2Secure Dome Edge Protection Band

With top tube installed, align with dome ring spacers and snap

into place.

Dome Edge Protection Band Installation Instructions Appendix

Parts List Quantity

1Dome Edge Protection Band (1)

Additional Materials and Tools Quantity

1None

Place Dome Edge Protection Band Over Flashing

Bend tabs up prior to

installation

a

b

1

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

15

0-90 Degree Extension Tube Installation Instructions Appendix

Parts List Quantity

10-90 Degree Extension Tube (1)

2Tube Screws - #8 X 3/4 in (10 mm) (4)

3Foil Tape - 2 in (51 mm) X 6 ft (2 m) (4)

Additional Materials and Tools Quantity

1None

1Install 0-90 Degree Extension Tube

Install only between the top tube and an extension tube or two extension tubes.

cab

Foil Tape Tube Screw

Apply pressure

to tape for

proper bonding

Minimum overlap

at tube seams

1 1/2 in (38 mm)

Additional structural support may be required for

horizontal tube runs. Consult local building code.

For the most current Installation Instructions, please visit www.solatube.com/instructions

Solatube International, Inc. | 2210 Oak Ridge Way | Vista, CA 92081-8341 | www.solatube.com | T: 888.SOLATUBE

© 2014 Solatube International, Inc. Part No. 951780 v2.7

16

Not all items available for all markets. Contact your Solatube International representative for availability.

Solatube Brighten Up® Series Accessories

Add more function by upgrading your Solatube Daylighting System with any of these great accessories.

Metal Roof Installation Kit

Order this kit for installation of a Solatube 160 DS or 290 DS ashing onto a standing seam metal roof.

Universal Tile Flashing (for applications without base ashing)

The Universal Tile Flashing integrates seamlessly with most tile proles. The malleable ashing skirt, available with a pitched

or no pitch turret, easily adapts to the shape of the tile.

Light Add-On Kit

When equipped with a light add on kit, the Solatube Daylighting System provides the convenience of a switched light for

night time use. Available in an energy efcient compact uorescent design that meets California Title 24 requirements

and in a universal xture.

Daylight Dimmer

Because you don’t need 100% of the light 100% of the time, the innovative Solatube Daylight Dimmer easily controls the

amount of daylight entering a room with the convenience of a switch. Our patented variable buttery bafe controls the

light output.

Ventilation Add-On Kit

The Solatube 160 DS is available with an optional Ventilation Add-On Kit. When combined with this innovative accessory,

the 2-in-1 ceiling xture minimizes ceiling penetrations for a more attractive look.

Flashing Insulator

This insulating material helps to reduce condensation in cold climates when the ashing is exposed to a humid interior

space. The insulator is afxed to the ashing base and the top tube slips through the opening, which provides a seal

between the interior and metal ashing.

Dome Upgrade Kit

Upgrade an older Solatube product to take advantage of Solatube’s patented Raybender™ 3000 Technology. The dome

upgrade kit is installed without removing previous ashing or tubing.

Re-Roong Recommendations

Solatube products require special care if removed for re-roong. Refer to the Solatube Re-Roong Recommendations to

ensure proper removal and re-installation.

Other manuals for Energy Care Optima 160 DS

2

This manual suits for next models

1

Table of contents

Popular Home Lighting manuals by other brands

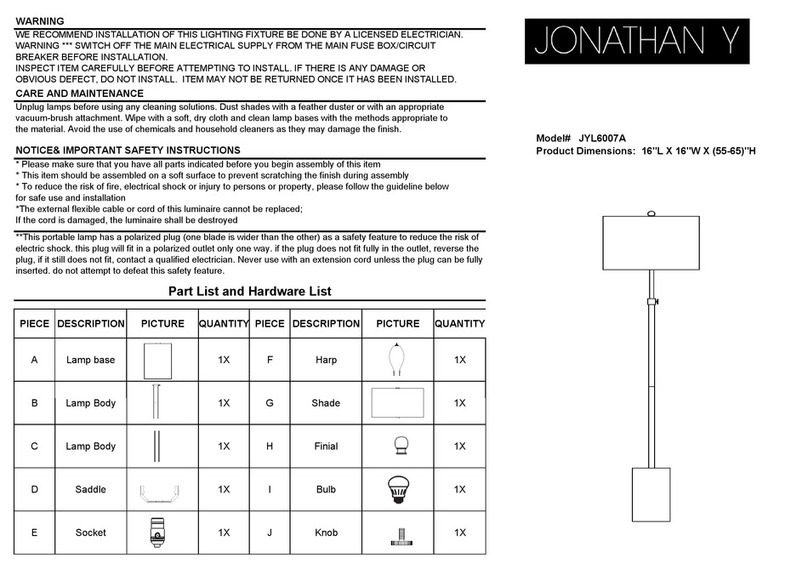

JONATHAN Y

JONATHAN Y JYL6007A quick start guide

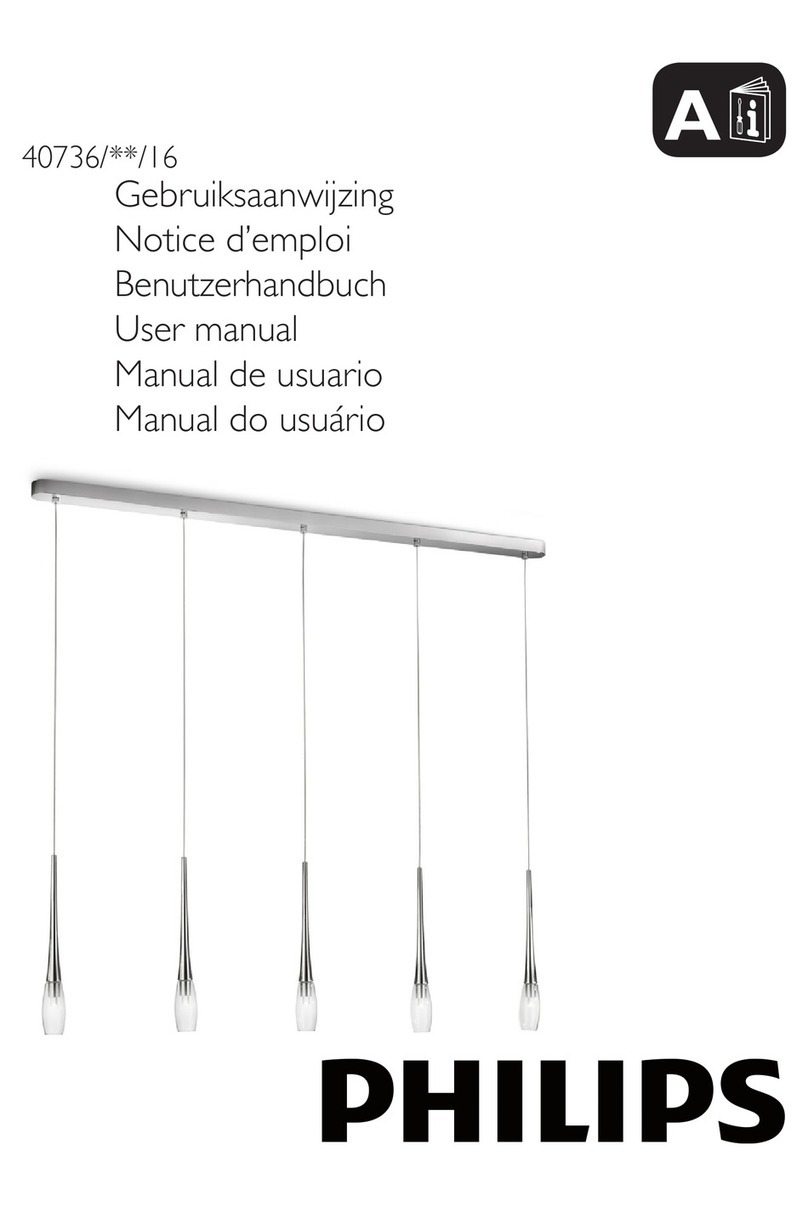

Philips

Philips Ledino 31606/11/16 Specifications

Safavieh Lighting

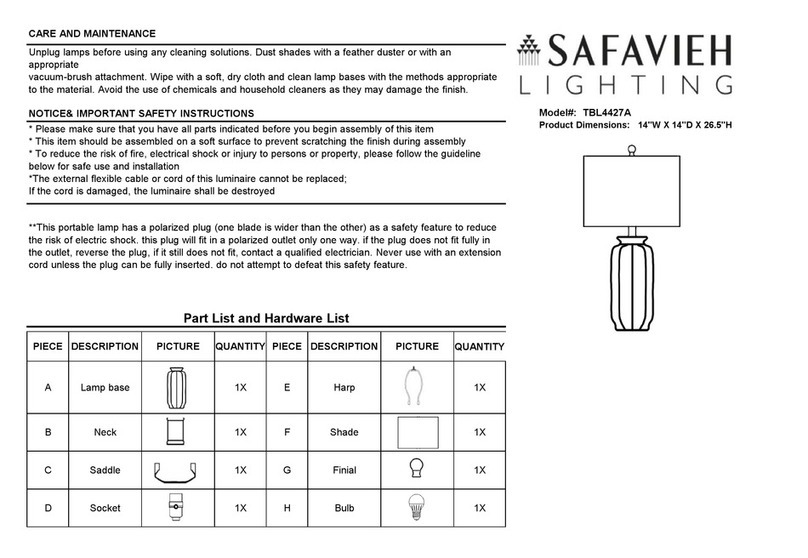

Safavieh Lighting CANDRI TBL4427A manual

Hunter

Hunter Bullet Spotlight Kit Owner's guide and installation manual

Philips

Philips 405441213 user manual

Philips

Philips Halogen Light Brochure & specs