SOLID STATE SECURITIES SS90 User manual

SS90-WPS MODEL A/B INSTALLATION MANUAL

GENERAL DESCRIPTION: S/N____________________

The Solid State Securities “SS90" World Power Series Time Delay Release Devices are designed for use on rolling doors,

single-slide and center parting level and inclined track doors. All models are normally energized Fail-Safe Releasing

Devices incorporating state of the art electronic control circuitry. The "SS90" Series Release Devices respond to emergency

conditions generated by manual or automatic normally closed initiating devices and shall be used in conjunction with a

temperature fuse link system.

The "SS90" Series Release Device *features include; world power source capability allowing the same unit to be used on

24VDC, 24VAC or 120VAC 50 or 60HZ., separate adjustable time delays for alarm and power loss, motor voltage sensing,

form-C relay output, proximity/door edge input and trouble diagnostic capabilities. Models A and B can be wired for two

or four wire configuration. *Check model label on unit to be installed to verify applicable features.

CAUTION: Review all installation instructions, procedures, cautions and warnings contained within this manual

prior to installing and/or servicing this product. As with all releasing device systems, maximum fire protection is

provided when installed in accordance with factory specifications and used with fuse link systems.

Fail-safe operation can only be provided with input power applied. DO NOT install this unit without fuse links.

TEST SYSTEM AT LEAST ONCE EVERY 90 DAYS TO ASSURE PROPER OPERATION.

Installation and testing to factory specifications shall be performed by factory authorized personnel for

proper operation in accordance with all of the latest National Fire Protection Association (NFPA),

Underwriters Laboratories (UL), National Electrical Code (NEC), local, state, county, district and/or other

applicable building and fire standards, guidelines, regulations and codes including, but not limited to, all

appendices and amendments and the requirements of the local authority having jurisdiction (AHJ).

TECHNICAL SUPPORT (570) 455-0577 © 1999 SSSI, PATENTS PENDING ALL RIGHTSRESERVED

HAZLETON, PENNA 18201 P/N: REV1.a

1

*

P

A

T

E

N

T

P

E

N

D

I

N

G

SS

S

S

S

S

OLID

T

A

T

E

E

C

U

R

I

T

I

E

S

,

I

N

C

SS90

S

O

L

I

D

S

T

A

T

E

F

A

I

L

-

S

A

F

E

U

N

I

T

L

I

S

T

E

D

9

9

Y

9

R

E

L

E

A

S

I

N

G

D

E

V

I

C

E

U

L

R

E

S

E

T

THE "SS90" SERIES

RELEASE DEVICES

SOLID STATE SECURITIES, INC.

MADE IN THE U.S.A.

INSTALLATION INSTRUCTIONS - To be performed by factory authorized personnel only.

The following installation procedures must be followed to assure performance of the release device to factory standards.

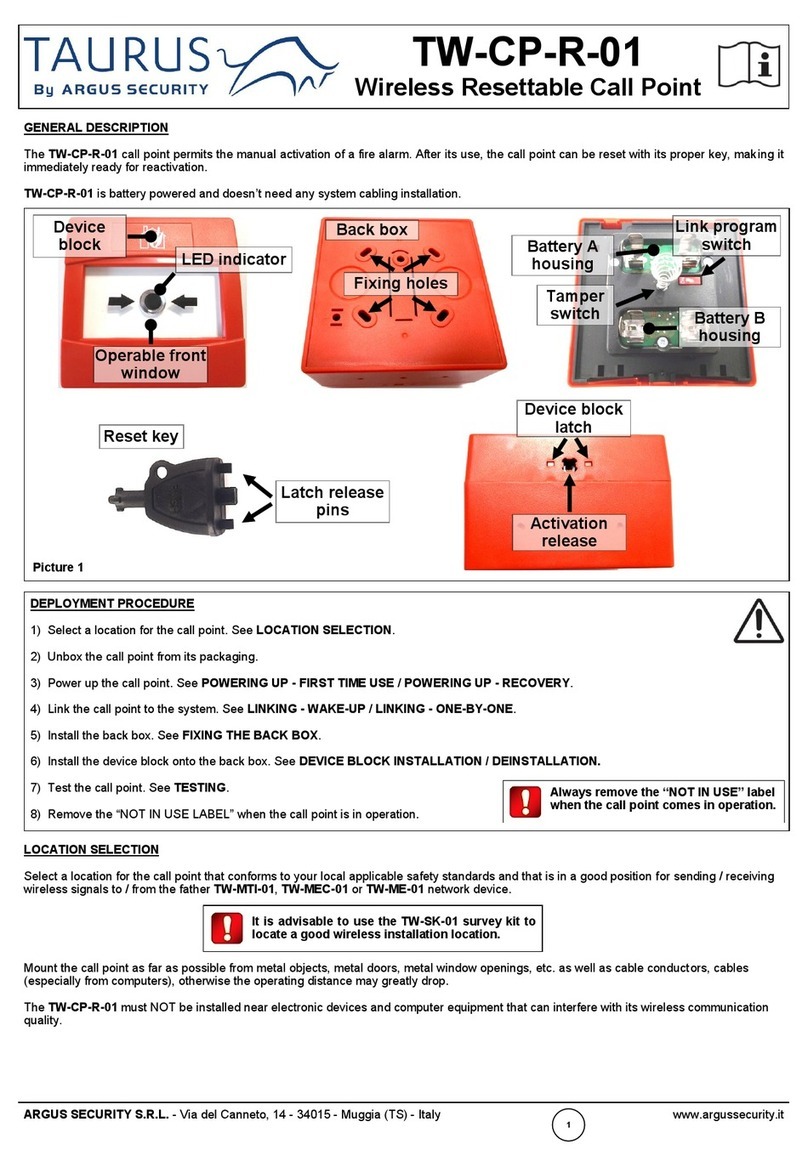

SECTION A. MOUNTING PROCEDURE (Figure 1)

1. The release device shall be mounted on a vertical surface with chain end link exiting side of enclosure as illustrated in

figure 3. The unit may be rotated 90 degrees CW for a direct vertical pull.

2. Release device enclosure shall be mounted with minimum #10 size fastening screws or bolts for securing to structures

other than masonry. Masonry applications shall utilize 1/4" or greater anchors or studs as required to insure proper

mounting strength.

3. Release device and associated hardware [sash chain or 1/16 cable, eyebolts, fuse links (DO NOT install this unit

without fuse links), turnbuckles] shall be installed as per door manufacturers recommendations (figure 3 typical

installation configuration). Note should be taken that the end link direction of pull is perpendicular to the enclosure

side. An eyebolt installed at a distance of 18 to 24 inches from the release device should adequately redirect sash chain

pull as illustrated in figure 3.

4.Complete hardware installation by connecting fuse links, sash chain, S-hooks and turnbuckles as required. Push reset

lever in direction of arrow on label to allow insertion of end link through release device side opening. Push end link

completely in and release reset lever to latch end link. Remove sash chain slack by adjusting turnbuckle.

Do Not exceed 40 lbs. maximum pull rating on release device.

SECTION B. Smoke Detectors.

When installing smoke detectors with this unit refer to NFPA 72-1993 and NFPA 80, for instructions concerning proper

placement and detection coverage. End of line devices (relays) must be installed in accordance with U.L. 864. See

electrical connections figure 4. Verify detector placement with Final AHJ.

SECTION C. ELECTRICAL CONNECTIONS - All models (Figure 4 - 4 wire operation, figure 4A - 2 wire operation)

Installation of all wiring and connections shall be performed in accordance with, but not limited to, the latest NFPA,

U.L. and N.E.C. standards. In addition, all installations subject to Canadian standards shall be performed in accordance

with the Canadian Electrical Code, Part I, with respect to wiring material, wiring gauge related to power capacity

requirements and circuit length and wiring methods.

The following wiring instructions can configure the unit for independent delay on alarm and power loss using four wires or

a single adjustable delay using only two wires. Use steps 1-2-3-4 for 4 wire operation. *Use 1-2-3 for 2 wire operation.

See Figure 4, page 3A for 4 wire dual delay wiring and Figure 4A, page 3B for 2 wire single delay wiring

1. Turn off power supply before beginning.

2. Verify voltage rating of release device to power source being utilized.

3. Connect 24 volt power source inputs to WPS circuit board, screws 1 & 2. On 24VDC units observe proper polarity by

placing positive (+) wire to screw 1. 120 VAC use TB3. TB3 screw 3 shall be utilized for earth ground where applicable.

4. Normally closed initiating devices (smoke detectors)- remove jumper from screws 1 & 2 (Alarm loop will not function

if jumper is not removed). Connect wiring from N/C initiating device alarm loop to TB1 screws 1 & 2 (see NFPA 72-

1993 and NFPA 80 for proper placement of smoke detectors). NOTE: Alarm loops cannot be series or parallel

connected between TB1 of multiple release devices. Contact tech support for wiring instructions where multiple doors

must close from a single initiating device.

OPTIONS: SS90-B-WPS only.

*Close Limit Detection (Lower limit/Proximity switch) -This option interfaces to electrical contact type lower limit

sensing devices and/or magnetic proximity type switches. If the electrical contact has toggled states from its N/O condition

to a closed condition (TB1-5&6) indicating the door edge has made contact with desired down position, the release device

logic will prevent the solenoid from energizing on alarm, thereby eliminating any damage which may result to the door

from the release device attempting to close the already lowered door. This option only works as long as power is available

to unit. Fail-safe operation shall be maintained under all operating conditions.

Continued on page 3 2

* TYPICAL INSTALLATION FIGURE 1

* Actual configuration may differ. This unit may be rotated 90 degrees CW for a vertical pull. See door

manufacturer recommendations and NFPA 80 for use of this product with specific door. DO NOT install

this unit without fuse links.

2A

INSIDE VIEW SS90-WPS FIGURE2

TB3

END LINK

TB2

TB1-1 LOGIC BOARD

WPS

Board

*PA

T

E

N

T

PE

N

D

ING

S

S

SS

S

S

OLID

TATE

ECURITIES,INC

SS90

S

O

L

IDS

T

A

T

E

FAIL-S

AFEUNIT

L

I

S

T

E

D

99Y9

RELEASINGDEVICE

U

L

RESET

Fuselink

Endlink

Ceiling

Fuselink

Thruwallconduit

Sash chain or cable

RELEASE DEVICE

TROUBLE RELAY (TB1-8,9&10) The trouble relay toggles immediately upon a power loss or alarm condition and may be

used for turning on signalling appliances (horns,strobes,etc.) or other external signalling functions requiring a dry contact

open or closure. Figure 4 illustrates contacts with no power to unit. With power applied TB1-9&10 are closed and toggle in

alarm and power loss.

Optional wiring - Verify that all operating voltage is off before continuing.

5. Normally open lower limit/proximity switch (closes in down limit). Connect wiring from *Aux. electrical loop to

TB1 screws 5 & 6. Leave jumper in TB1-6&7. Remove jumper & use TB1-6&7 for a N/C which opens in down limit.

6. Trouble Relay - Connect wiring to common TB1-9 and either N/O contact TB1-10 or N/C contact TB1-8.

* Note: Electrical loop must be provided as dry contacts and may not be used in conjunction with the simulta-

neous switching of a motor control or any other voltage through the same contacts. Connections of this type will

result in immediate damage to the release device.

Verify all connections made within unit. Close hinged cover and secure screw on lid after all connections are made.

DO NOT LEAVE COVER OPEN AFTER CONNECTIONS ARE MADE!

"SS90" SERIES RELEASE DEVICE ELECTRICAL AND MECHANICAL CHARACTERISTICS

OPERATING VOLTAGES

MODEL

SS90A-WPS ............. 24VDC +10% /-15% 24VAC +10% /-15% 120VAC +10% /-15%

SS90B-WPS ............. 24VDC +10% /-15% 24VAC +10% /-15% 120VAC +10% /-15%

CURRENT REQUIREMENTS

-------------------------------- Operating Voltage ---------------------------------

24VDC 24VAC 120VAC

Current rating SUPERVISORY/ALARM SUPERVISORY/ALARM SUPERVISORY/ALARM

Model

SS90A-WPS .025A/.045A .075A/.130A .300A/.650A

SS90B-WPS .025A/.045A .075A/.130A .300A/.650A

INITIATING LOOPS -

CAUTION: All initiating devices shall be dry contact type only

Maximum loop resistance: 100 Ohms

Maximum current: Not to exceed .002A

Maximum voltage: 15Vdc

FORM C OUTPUT (MAXIMUM CONTACT RATING) FUSE RATINGS

2A/15Vdc 30 Watt DC Resistive Load Only Model A/B PC Board - 0.75 AMP @250V

2AG FAST ACTING TYPE

3

WPS PC BOARD

F1 2A @ 250v, 2AG Fast Acting, high voltage input

F2 1A @ 250v, 2AG Fast Acting, low voltage input

F3 1A @ 250v, 2AG Fast Acting, low voltage output

MECHANICAL- LOAD RATING DIMENSIONS

Support and release: 40LB. MAXIMUM 7 1/2" x 8 " x 4" (H x W x D)

Break wire for proper

supervision. Do not loop

wire around terminals

End of line relay (4)(8)

Per U.L. 864

(2) Initiating Device

(Smoke detector, etc.)

WPS PC Board

24VAC/DC ONLY

Observe polarity

for DC supply

(+)

(-)

Chassis ground

Proximity switch

option Model B

only

Model A/B

PC MOUNT

TB1

(1)(4)(6)

}

Model B Only

PC MOUNT

TB2 Motor sense

TROUBLE RELAY

Model B Only

(unit de-energized)

(1) Dotted line indicates factory jumper which must be removed when connecting the N/C device.

(2) See NFPA 80 and NFPA 92-1993 for proper placement.

(3) Verify input voltage to model being used.

(4) Maximum loop resistance 100 ohms. Verify contact rating of End of Line Relay.

(5) Jumper must remain installed for two wire installation (figure 4A).

(6) Jumper must remain installed if not using this option.

(7) All fuses 2AG Fast Acting. See page 5, figures 5 &5A for proper ratings

(8) End of line relay as per U.L. 864 See smoke detector installation instructions for proper End of Line Relay p/n and contact ratings.

Installation of all wiring and related connecting hardware must be performed in accordance with the latest NFPA, U.L., and N.E.C. standards and codes. In

addition, all installations subject to Canadian standards shall be performed in accordance with the Canadian Electrical Code, Part I, with respect to wiring material

type,wiringgaugerelatedtopowercapacity requirements and circuit lengthand

wiringmethods. 3A

ELECTRICAL CONNECTIONS (TYPICAL) - FIGURE 4

FOUR WIRE- INDEPENDENT ALARM & POWER LOSS DELAYS 02/16/98

Referto Section C - ElectricalConnections pages 2&3 for completeSS90 wiring instructions. Reference all footnotesbelow foradditional installation

information.

(3) Input power

Down Limit Detection

(1)(4)(6)

(4)(5)(8)

TB3

CHASSIS MOUNT

120VAC only

USE TB3 CHASSIS

MOUNT

120Vac only

OR

low voltage to WPS

PC Board

02/16/98

FIGURE 4A - TWO WIRE/SINGLE DELAY

High voltage connections

ModelA/B

PC MOUNT

WPS Board

PC MOUNT

WPS PC MOUNT

NOT USED

Initiating Device (Smoke detector, etc.)

24VAC or DC

Inputpower

(1)

(2)

(3)

(+)

(-) 24VAC/DC ONLY

Observepolarity on

DCunits

CHASSIS MOUNT

NOT USED

120VAC

Inputpower

(1) See NFPA 80 and NFPA 92-1993 for proper placement.

(2)Verify inputvoltage tomodel being used.

(3)See smoke detector installation instructions for contact ratings. Installation of all wiring and related connecting hardware must be performed

in accordance with the latest NFPA, U.L., and N.E.C. standards and codes. In addition, all installations subject to Canadian standards shall be

performed in accordance with the Canadian Electrical Code, Part I, with respect to wiring material type, wiring gauge related to power capacity

requirementsand circuit lengthand wiring methods.

(4)Jumper must remain installed for two wire installation.

(5) All fuses 2AG Fast Acting. See page 5, figures 5 &5A for proper ratings

3B

(4)

ModelA/B

PC MOUNT (4)

(1)

(2)

(3)

Initiating Device (Smoke detector, etc.)

TB3

CHASSIS MOUNT

Break wire for

propersupervision.

Donot loopwire

aroundterminals

Break wire for

propersupervision.

Donot loopwire

aroundterminals

Low voltage connections

SECTION D. TEST PROCEDURES

TO BE PERFORMED BY FACTORY AUTHORIZED PERSONNEL ONLY! SOLID STATE SECURITIES

RECOMMENDS REGULAR TESTING OF ALL RELEASE DEVICE EQUIPMENT. TESTING SHALL BE

WITNESSED FOR PROPER OPERATION.

Follow step A for electronic testing of Model SS90-A-WPS. Step B refers to Model SS90-B-WPS with Close Limit option.

Step C power loss test may be performed on both models A and B. Testing does not affect normal operation of alarm system

when connected to release device. Testing and normal operation can only be accomplished with power applied to unit.

When power is applied to unit under test the Power LED (red) will be lit on the bottom of the release device. Testing of the

"SS90" release device is independent of, and shall in no way be interpreted as an alternative method of, testing of the

fire alarm system, motorized operator and/or any other system component employed on the fire door or counter fire

door installation.

CLEAR FIRE DOOR OPENING AND PROHIBIT ALL TRAFFIC THROUGH DOOR OPENING DURING

TESTING OF SYSTEM!

Door must be in open position with power applied to unit to begin testing.

A) 1. Depress and continue to hold test button on side of release device (figure 1). After factory adjusted 10 second

alarm verification (10 sec. delay) device will release door. Release test button.

2. Reset and raise door, then reset release device by pushing reset lever in direction of arrow as indicated on device

label. Fully insert end link through release device side opening and release reset lever to latch end link.

B) 1. Using chain hoist, lower door to fully closed position.

2. Reset door, then release device by pushing reset lever in direction of arrow as indicated on device label. Fully

insert end link through release device side opening and release reset lever to latch end link.

3. Verify that Close Limit LED (amber) is lit indicating “the door is closed”. Depress and continue to hold test

button on side of release device for 10 seconds. Active ”Lower Limit” logic will prohibit the release device from

energizing. Release test button.

4. Raise door to fully open position.

C. Power Loss Test.

1. Make sure door is in the fully open position. Turn off “all” power to release device (including motor control

voltage when used on the model B). After approximately 10 seconds of continuous power loss, a mechanical

release will be initiated.

2 Reset and raise door, then reset release device by pushing reset lever in direction of arrow as indicated on device

label. Fully insert end link through release device side opening and release reset lever to latch end link.

After completing all tests, make sure door is in its normally open position and all power required for normal

operation is restored to unit. This unit is designed to operate with power applied.

REMINDER:

Testing of the "SS90" release device is independent of, and shall in no way be interpreted as an alternative method

of, testing of the fire alarm system, motorized operator and/or any other system component employed on the fire door

or counter fire door installation. TESTING SHALL BE PERFORMED AND WITNESSED FOR PROPER

OPERATION.

4

MAINTENANCE REQUIREMENTS

The "SS90" WPS Model release devices have no scheduled maintenance requirements. The unit has been designed and

tested for use in indoor locations. Solid State Securities recommends weekly testing of the unit, but test intervals shall

ultimately be subject to criteria established by the Final Authority Having Jurisdiction (AHJ).

Serviceable fuses are provided for the following: See Figure 5 for fuse locations on release control board. Figure 5A

illustrates fuses on World Power Supply board.

Figure 5 fuses

F1 3/4A @ 250v, 2AG Fast Acting, Logic Board Power Supply

F2 3/4A @ 250v, 2AG Fast Acting, MODEL B ONLY

F3 3/4A @ 250v, 2AG Fast Acting, Power Input

Replacement fuses may be ordered directly from the factory thru the technical support number provided below.

Should servicing of fuses be required, personnel authorized to perform such maintenance shall ensure that; a) all traffic

is prohibited thru door opening, b) door is mechanically released and fully closed, c) all power is disconnected from

unit.

After servicing equipment as required, unit shall be tested and witnessed for proper operation as described in

SECTION D- TEST PROCEDURES, contained herein.

FIGURE 5 fuses SS90 Model A/B circuit board

FIGURE 5A fuses SS90-WPS circuit board

F1 2A @ 250v, 2AG Fast Acting, high voltage input

F2 1A @ 250v, 2AG Fast Acting, low voltage input

F3 1A @ 250v, 2AG Fast Acting, low voltage output

Technical Support (570) 455-0577 6

F1 3/4A @ 250V

F3 3/4A @ 250V

F2 3/4A @ 250V

VR1 - POWER LOSS

VR2 - ALARM

TB1

TB2

1 2 5 6 7 8 9 10

1 2

K1

F1 2A @ 250V

F2 1A @ 250V

F3 1A @ 250V

"SS90" WPS MODELS A & B TROUBLESHOOTING GUIDE

Verify that desired options are available on unit before troubleshooting. Refer to electrical connection information and the

maintenance and service page of this manual for fuse locations. Troubleshooting shall be performed by factory authorized

personnel only. Service and/or installation by unauthorized personnel shall void warranty. Review the following guide prior

to requesting technical support. If technical support is required, unit serial number (found on front of manual and inside

unit), as well as distributor who supplied unit must be supplied.

POSSIBLE TROUBLE

A) Primary power source turned off.

B) Loose connection on TB3 or WPS board

C) Incorrect polarity on D.C. unit

D) Incorrect power source applied. Verify voltage

and check fuses F1 & F2 of both circuit boards.

A) N/C Alarm loop is not connected properly to TB1.

Remove wires from TB1, 1 & 2. Continuity test on wires

should be zero ohms (short) back to initiating device. Place

smoke detector in alarm and verify that dry contacts open on

alarm.

B) Unit is detecting down limit (Model B only). If Down

Limit feature is not being used, jumper must remain in TB1,

6 & 7.

C) Load on release mechanism exceeds 40lbs. Remove sash

chain and test with manual test button for proper release.

D) Damaged unit. Call tech support.

A) Motor control voltage not connected to TB2

B) Motor control is D.C.. Check polarity.

C) Control voltage is above 30V. Check Model B

circuit board fuse F2.

A) Test button is not being depressed long enough. Depress

button continuously for the 10 second delay. Unit must be

powered up for a minimum of 15 seconds before testing.

B) Unit is detecting down limit (Model B only) Make sure

Aux. down limit is connected properly. If N/O down limit is

used, N/C loop (TB1-6&7) must have jumper installed.

C) Possible defective switch. Call tech support.

A) Incorrect power applied. Check unit label. Measure

supply voltage.

B) Unit has sustained damage from transient voltage. Call

tech support.

SYMPTOM

1. Red Power LED does not light.

2. Red LED is on, but unit does not release door after

alarm or power loss delay.

3. Amber Disable LED does not light (Model B)

4. Red LED is on, unit does not respond to manual test

button, but works in alarm.

5) Unit blows fuse when power is applied

UNITSERIALNUMBER___________________ DISTRIBUTOR___________________

TECHNICAL SUPPORT (570) 455-0577 9AM - 5PM EST MON-FRI

6

NOTES/TESTRECORDS

Copy this sheet and attach to manual for additional test data as required. Maintain test records in a secure

location for future reference.

UNITSERIALNUMBER:________________________

TEST DATE PERFORMED BY WITNESSED BY COMMENTS

7

NOTES

Table of contents