Sony D-555 User manual

Other Sony CD Player manuals

Sony

Sony DEJ017CK - Walkman Portable CD Player User manual

Sony

Sony CDX-F5510X User manual

Sony

Sony CDX-GT560 User manual

Sony

Sony MZ-M10 User manual

Sony

Sony MDP-650 User manual

Sony

Sony CDX-GT690UI User manual

Sony

Sony CDP-CX450 - Compact Disc Player User manual

Sony

Sony XR3F-19B160 User manual

Sony

Sony CFD-V25 - Cd Radio Cassette-corder User manual

Sony

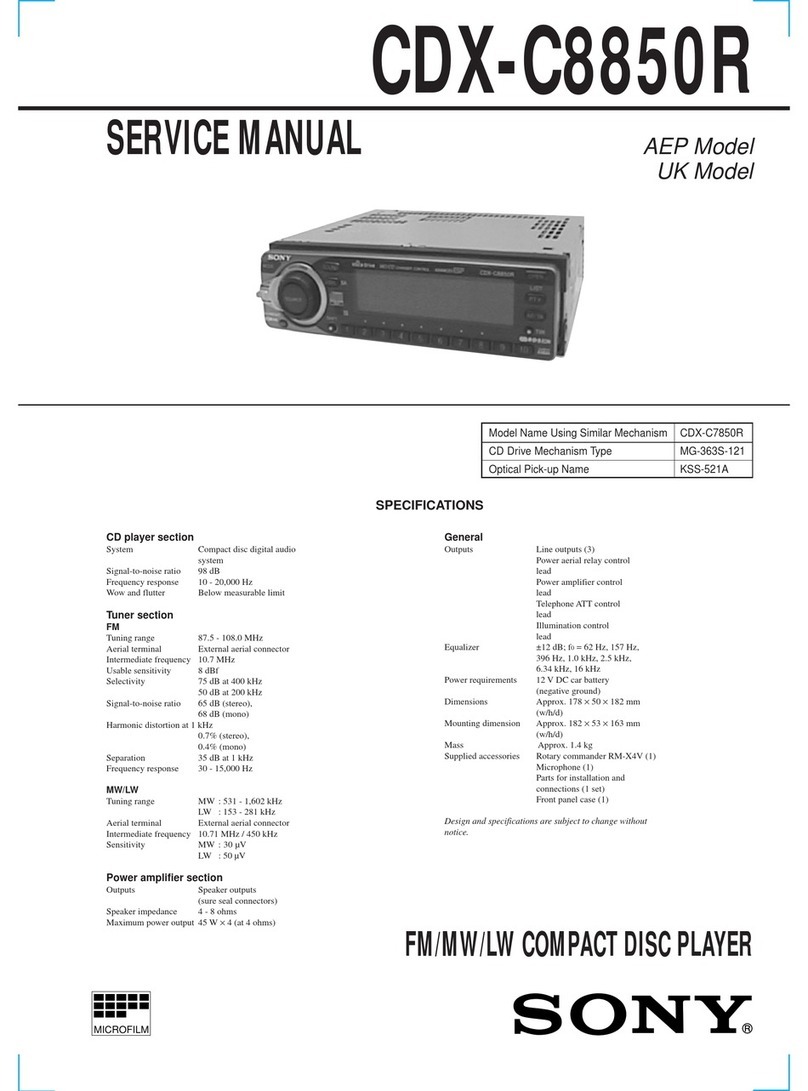

Sony CDX-C8850R User manual

Sony

Sony Discman D-180AN User manual

Sony

Sony CDP-502ESII User manual

Sony

Sony SCD-XA9000ES - Es Super Audio Cd Player User manual

Sony

Sony MDS-E12 User manual

Sony

Sony D-NE710 - ATRAC3/MP3 CD Walkman Portable Disc... User manual

Sony

Sony CDX-G3200UV User manual

Sony

Sony CFD-S250L User manual

Sony

Sony Discman D-E905 User manual

Sony

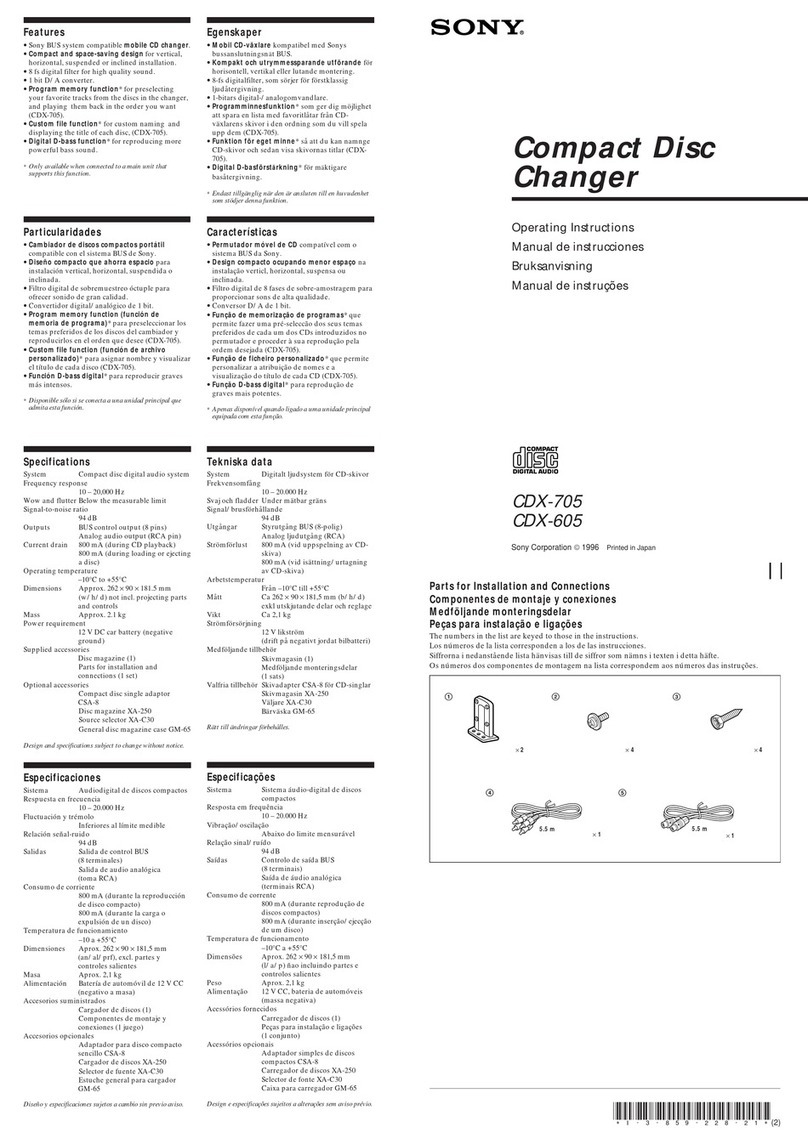

Sony CDX-705 - Compact Disc Changer System User manual

Sony

Sony MZ-R70 Analog PCLink User manual