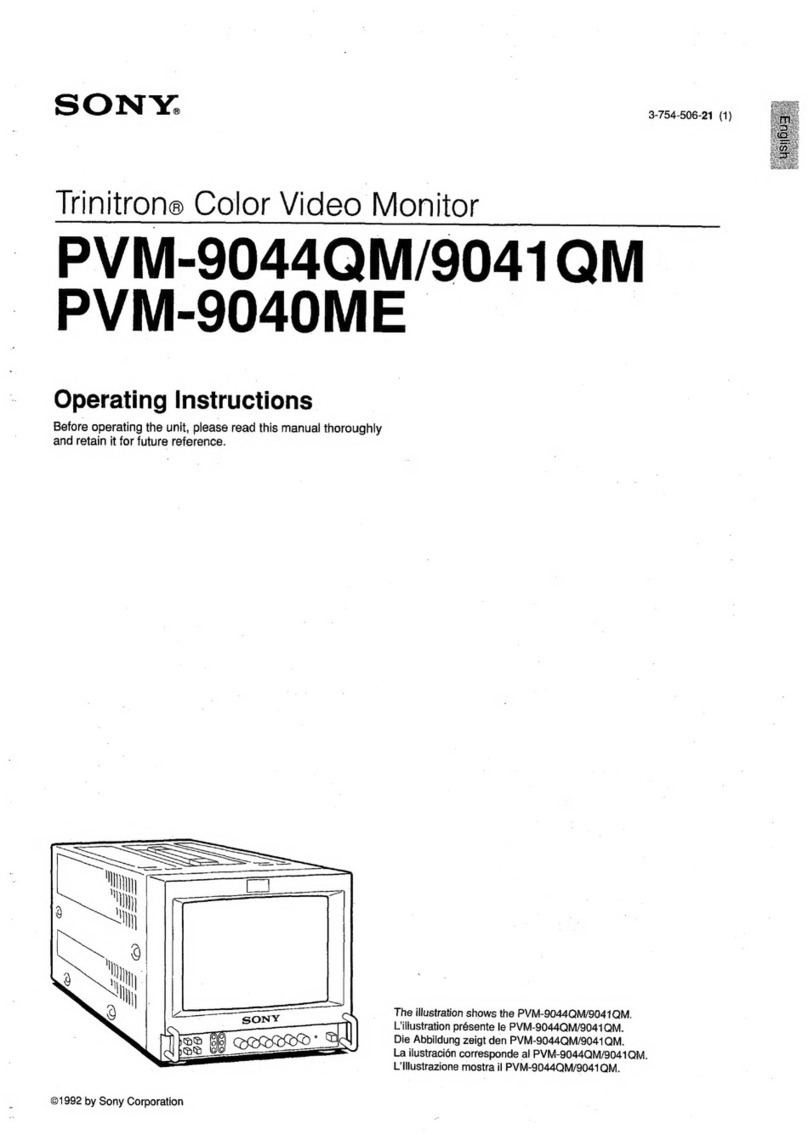

PVIVI-6041QIVI

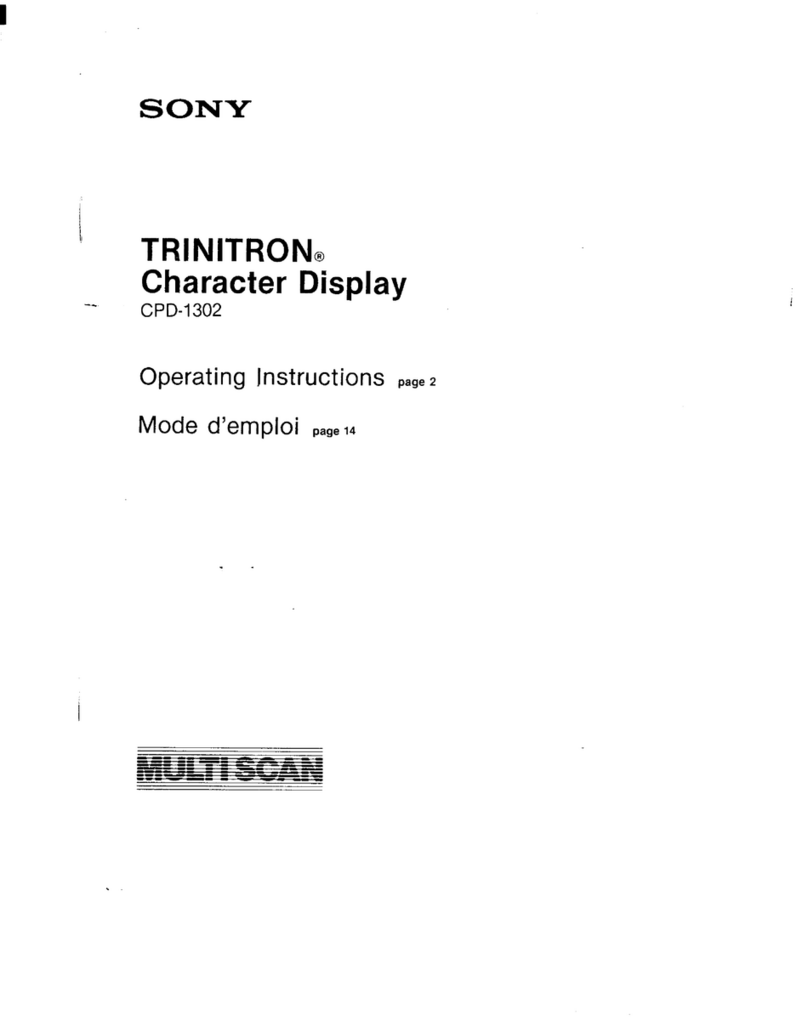

Rear

LINE connectors

SYNC INT/EXT (internal/

external) selector

RGB/COMP (RGB/

component) selector

REMOTE connector

DC 12V IN jack

in] LINE connectors

To monitor the signal ted through these connectors,

keep the LINE/RGB selector on the front panel released

(LINE).

VIDEO IN (BNC); Connect to the video output of a

video camera, VCR or other video equipment.

VIDEO OUT (BNC); Loop-through output of the VIDEO

IN connector. Connect to the video input of aVCR or

another monitor.

AUDIO IN (phono jack): Connect to the audio output of

aVCR or amicrophone (through asuitable

microphone amplifier).

AUDIO OUT (phono jack); Loop-through output of the

AUDIO IN connector. Connect to the audio input of a

VCRor another monitor.

[i2l SYNC INT/EXT (sync internal/external) selector

Select the internal or externa! sync.

RGB/COMP (RGB/component) selector

Select the RGB or component (Y, R-Y and B-Y) signal.

Keep the LINE/RGB input selector on the front panel

depressed (RGB), otherwise the RGB/COMP selector

does not function.

0REMOTE connector (8-pin mini DIN)

Connect to aremote controller. For the pin assignment

of this connector, see “Specifications" on page 5.

[1 DC12ViNjack(XLR,4pin)

Connect the Sony AC-500/500CE AC power adaptor

(not supplied).

01 RGB/COMPONENT input connectors

R/R-Y, G/Y, B/B-Y, (BNC), AUDIO (phono):

To monitor asignal fed through these connectors,

depress the LINE/RGB selector on the front panel

(RGB).

To monitor the analog RGB signal

Connect to the analog RGB signal outputs of avideo

camera. Set the RGB/COMP selector to RGB.

To monitor the component signal

Connect to the R-Y/Y/B-Y component signal outputs of

aSony Betacam video camera. Set the RGB/COMP

selector to COMP (component).

SYNC (BNC):

To operate the monitor on an external sync, connect the

reference signal from async generator. Set the SYNC

INT/EXT selector to EXT (external).

[il VHOLD (vertical hold) control

Turn to stabilize the picture if it rolls vertically.

0AC IN socket

Connect the supplied AC power cord to this socket and

to awall outlet.

El EJECT button

Press the EJECT button upwards to remove the battery

pack.

[mi BATTERY compartment

insert the NP-1 A/1 Bbattery pack (not supplied).

-6-