Southbend GH10CCH User manual

Manual 1177596 Rev 3 (02/23)

$21.00

Marathoner Gold Half-Size Gas

Convection Ovens

Manual Section CO

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this

manual for the life of the equipment:

Model #:

___________________________

Serial #:

___________________________

Date Purchased:

_____________________

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury

or death. Read the installation, operating and maintenance instructions thoroughly before installing or

servicing this equipment.

Model GH/10TC

Marathoner Gold Half-Size

Gas Convection Ovens

GH/10CCH, GH/10SC, GH/10TC

GH/20CCH, GH/20SC & GH/20TC

Installation & Operation Manual

SOUTHBEND

A Middleby Company

1100 Old Honeycutt Road Fuquay-Varina, North Carolina 27526 USA

www.southbendnc.com

Model GH/20SC

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 2 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sure everyone involved in its operation is fully trained and aware of

precautions. Accidents and problems can be caused by failure to follow fundamental rules and precautions.

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the operator,

service personnel, or to the equipment.

CAUTION

WARNING

NOTICE

This symbol warns of immediate hazards that will result in severe injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury, product

damage, or property damage.

This symbol refers to information that needs special attention or must be fully

understood, even though not dangerous.

DANGER

Copyright © 2023 by Southbend. All rights reserved. Published in the United States of America.

SPECIFICATIONS

WARNING

FIRE HAZARD

FOR YOUR SAFETY

Keep area around appliances free and clear of combustibles.

Purchaser of equipment must post in a prominent location detailed instructions to be followed in the event the

operator smells smoke.

NOTICE

Be sure this Operator’s Manual and important papers are given to the proper authority to retain for future reference.

NOTICE

This product is intended for commercial use only. NOT FOR HOUSEHOLD USE.

NOTICE

WARNING

EXPLOSION HAZARD

FOR YOUR SAFETY

Immediately call the emergency phone number of your gas supplier.

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

WARNING

ventilation air to and from your cooking equipment.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23) PAGE 3 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Table of Contents

........................................................................................................................ 4

Installation............................................................................................................................. 9

Operation .............................................................................................................................. 21

Operation for Touchscreen Models Only ................................................................................... 29

Cooking Hints........................................................................................................................ 39

Cleaning................................................................................................................................ 42

Adjustments .......................................................................................................................... 44

Troubleshooting .................................................................................................................... 45

Parts...................................................................................................................................... 56

TC

You will find that your new equipment, like all Southbend equipment, has been designed and manufactured to

meet the toughest standards in the industry. Each piece of Southbend equipment is carefully engineered and

designs are verified through laboratory tests and field installations. With proper care and field maintenance, you

will experience years of reliable, trouble-free operation. For best results, read this manual carefully.

Read these instructions carefully before attempting installation. Installation and initial startup should be performed by a

experienced in and knowledgeable with the installation of commercial gas an/or electric cooking equipment) then the terms

and conditions on the Manufacturer’s Limited Warranty will be rendered void and no warranty of any kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, write to:

Southbend Technical Service

1100 Old Honeycutt Road

Fuquay Varina, North Carolina 27526 USA

The serial plate is located on the interior side of the lower front panel, as shown below.

plate located at the base of the front panel, between the door and the control panel. Letters in the model number are

described below.

PREFIX: G- GAS H- HALF-SIZE

SUFFIX: SC - STANDARD CONTROLS CH - COOK & HOLD CONTROLS TC - TOUCH CONTROL

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 4 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

NOTICE

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association, Inc.

states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to installation

requirements for equipment. Therefore, installations should comply with all local codes.

the buyer to corresponding changes, additions, or replacements for previously purchased equipment.

This product is intended for commercial use only, not for household use.

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGA-B149.2,

as applicable, including:

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi

WARNING

There must be adequate clearance between the left side of the ovens and combustible construction..

racks and for serviceability.

Although no clearance is required behind the motor on the rear of the oven, care must be taken to provide adequate

air circulation to prevent the motor from overheating.

Do not locate the oven adjacent to any high heat or grease-producing piece of equipment, such as a range top,

DO NOT MOUNT ABOVE OTHER COOKING EQUIPMENT.

MINIMUM CLEARANCES

Minimum Clearance from

Combustible Construction

Minimum Clearance from

Non-Combustible Construction

Minimum Clearance from heat

producing appliance

Back 0” 0” 6”

Right Side 0” 0” 6”

Left Side 2” 0” 6”

Floor 0” 0” 6”

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23) PAGE 5 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

The serial plate is located behind the combustion cover panel, below the oven door. It is on the right side, attached to

the base of the oven. It indicates the type of gas the unit is equipped to burn. All Southbend equipment is adjusted at the

factory. Check type of gas on serial plate.

pressure regulator which is set for 4.5” W.C. on high fan, 2.5: W.c. manifold pressure on low fan for natural gas or 10.5”

W.C. manifold pressure on high fan, 7” W.C. manifold pressure on low fan for propane gas. Use 1/8” pipe tap on the top of

the burner manifold for checking pressure.

An optional gas connection is available through the bottom of the oven base. If the incoming gas line needs to connect

through the bottom of the oven, refer to page 6 for optional gas connection.

If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in accordance with

local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1, Natural Gas Installation

Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGA-B149.2, as applicable.

This appliance should be connected ONLY to the type of gas for which it is equipped.

A 3/4” NPT line is provided at the rear for the gas connection. An adequate gas supply is imperative. Undersized or low

pressure lines will restrict the volume of gas required for satisfactory performance. Fluctuations of more than 25% on

An adequate gas supply line to the unit should be no smaller than the inside diameter of the pipe from the unit to which it

is connected.

Purge the supply line to clean out any dust, dirt, or other foreign matter before connecting the line to the unit. Each unit

joint compound which is suitable for use with LP gas on all threaded connections. Test pipe connections thoroughly for

gas leaks. USE SOAPY WATER ONLY FOR TESTING ON ALL GASES. NEVER USE AN OPEN FLAME TO CHECK

FOR GAS LEAKS. ALL CONNECTIONS MUST BE CHECKED FOR LEAKS AFTER THE UNIT HAS BEEN PUT IN

OPERATION. Test pressure should not exceed 14” W.C.

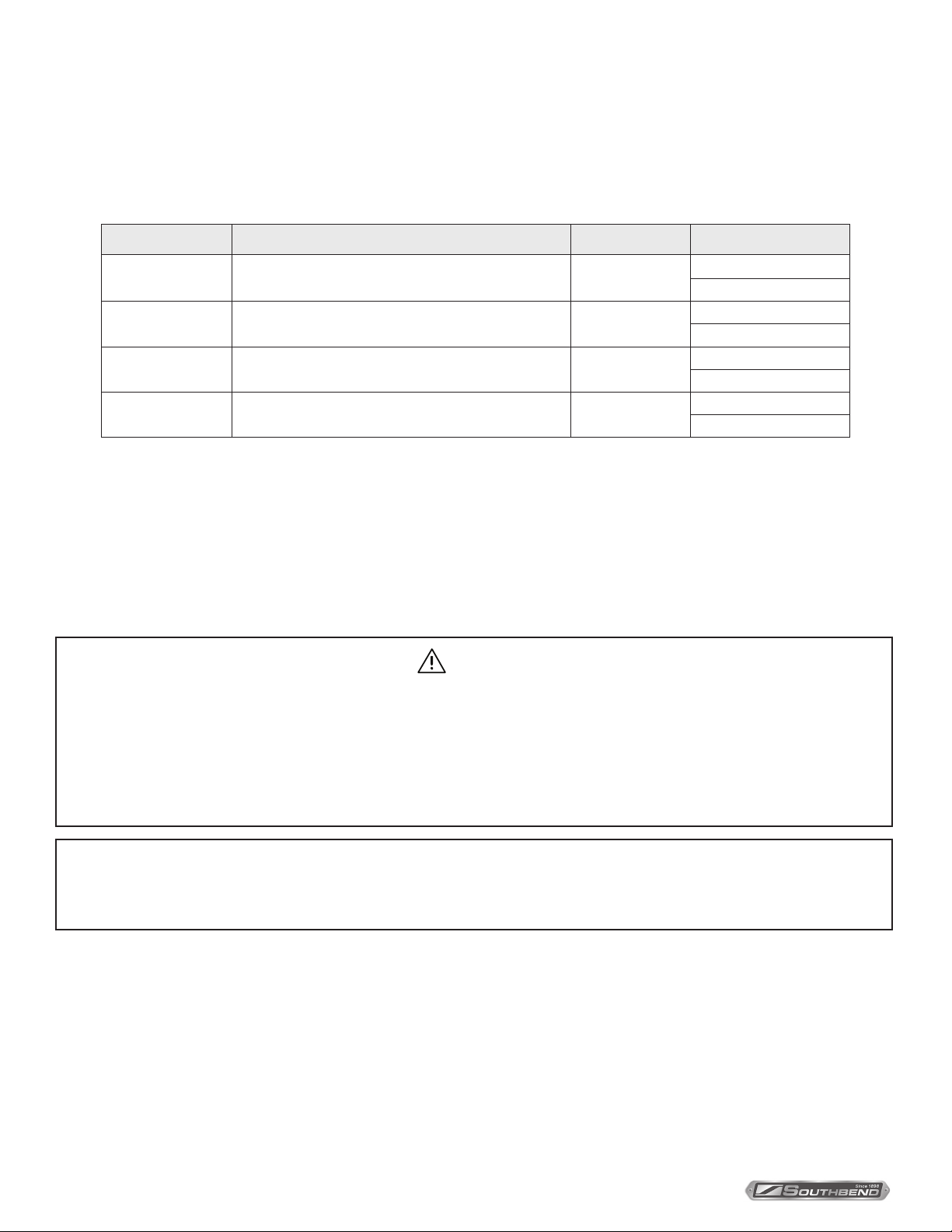

Model Number # of Ovens Total BTU Type of Gas Orice Size

GH-10… Single-Deck 30,000

Propane 60

Natural Gas 53

GH-20… Double-Deck 60,000

Propane 60

Natural Gas 53

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 6 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

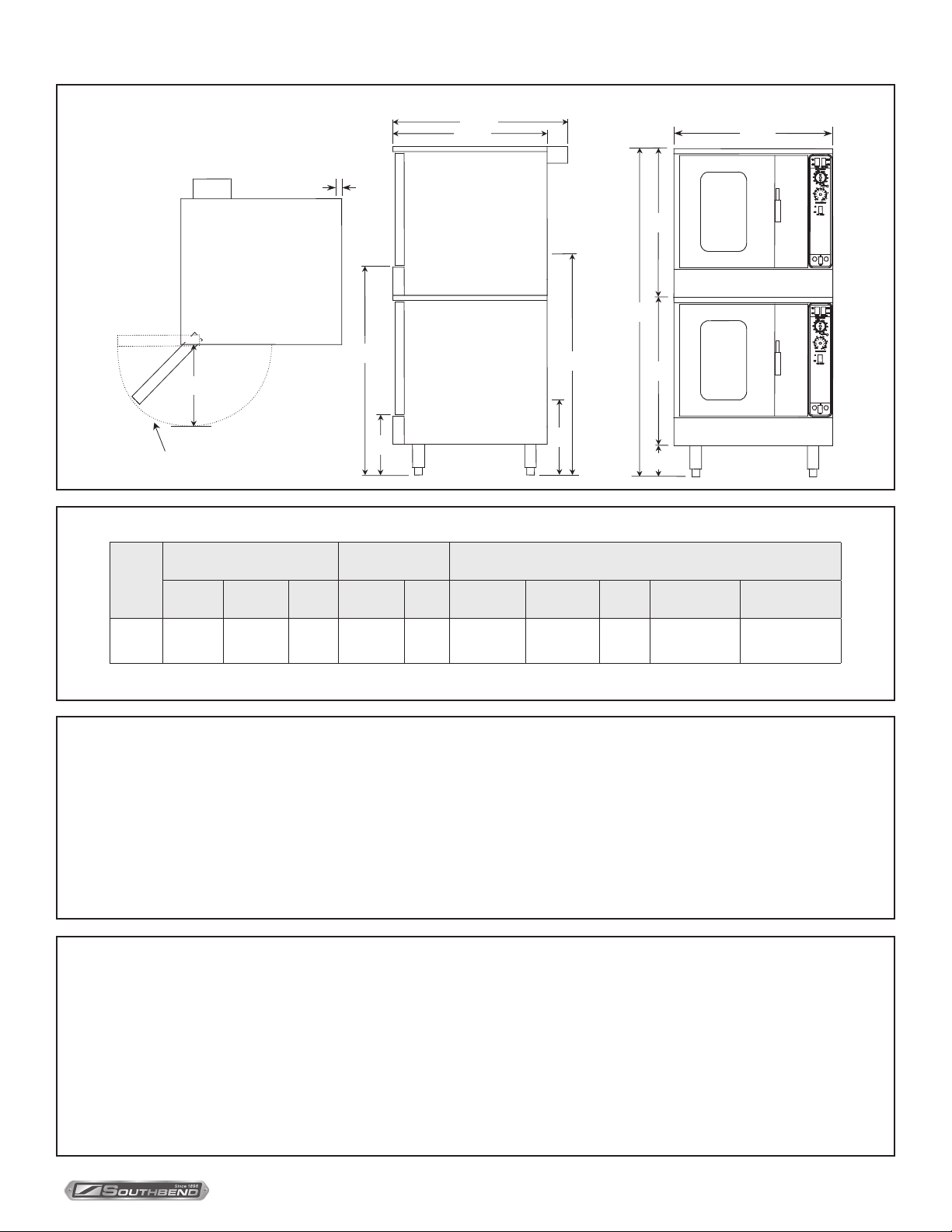

DIMENSIONS

MISCELLANEOUS

Note:

UTILITY INFORMATION

and must comply with ANSI Z 21.69.

• Clearances from combustibles: Top - 0”, bottom - 0”, right side - 0”

and left side - 2”

• Recommend - install under vented hood

• If the unit is connected directly to the outside flue, an A.G.A

approved down draft diverter must be installed at the flue outlet

of the oven

• Oven cannot be operated without fan in operation

NOTICE:

Southbend has a policy of continuous product research and

product design without notice. Such revisions do not entitle the buyer

to corresponding changes, improvements, additions or replacements

for previously purchased equipment.

MODEL

GH/10 15.80”

21.30”

20”

13”

21”

57.50”

45”

68.1 cu. ft.

420 lbs.

GAS: •

• One 3/4” male connection

• Required minimum inlet pressure:

- Natural gas 7” W.C.

- Propane gas 11” W.C.

ELECTRIC: Standard: 120/60/1 phase, furnished with 6’ cord w/3-

with terminal block located at rear. Total maximum amps 4.3 per deck.

with terminal block located at rear. Total maximum amps 3.8 per deck.

with terminal block located at rear. Total maximum amps 6.0 per deck.

4.0"

(102)

29.0"

(737)

33.0"

(838)

30.0" (762)

26.0"

(660)

29.0"

(737)

55.0"

(1397)

18.6"

(473)

2.0" (51)

7.0"

(178)

26.65" (676)

29.65" (753)

10.5"

(267)

Oven

Bottom

utility

connection

utility

connection

Full 180° Opening

* All units shipped single phase.

Single phase can be easily converted to three phase.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23) PAGE 7 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

DIMENSIONS

UTILITY INFORMATION

MISCELLANEOUS

3/4” and must comply with ANSI Z 21.69.

• Clearances from combustibles: Top - 0”, bottom - 0”, right side -

0” and left side - 2”

• Recommend - install under vented hood

of the oven

• Oven cannot be operated without fan in operation

NOTICE:

Southbend has a policy of continuous product research and

product design without notice. Such revisions do not entitle the buyer

to corresponding changes, improvements, additions or replacements

for previously purchased equipment.

MODEL

GH/20 15.8”

21.30”

20”

13”

21”

57.50”

45.50”

81.5”

68.1 cu. ft.

850 lbs

GAS: •

• One 3/4” male connection

• Required minimum inlet pressure:

- Natural gas 7” W.C.

- Propane gas 11” W.C.

ELECTRIC: Standard: 120/60/1 phase, furnished with 6’ cord w/3-

with terminal block located at rear. Total maximum amps 4.3 per deck.

with terminal block located at rear. Total maximum amps 3.8 per deck.

with terminal block located at rear. Total maximum amps 6.0 per deck.

* All units shipped single phase.

Single phase can be easily converted to three phase.

13.0"

(330)

26.65" (676)

29.65" (753)

16.5"

(419)

Utility Connection

Oven Bottom

42.0"

(1067)

Oven Bottom

45.5"

(1156)

Utility Connection

30.0" (762)

29.0"

(737)

29.0"

(737)

64.0"

(1626)

6.0"

(152)

18.6"

(473)

2.0" (51)

utility

connection

Full 180° Opening

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 8 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

WARNING

cause headaches, drowsiness, nausea, or could result in death.

Provisions for adequate air supply must be provided. Do not obstruct the front or rear of the unit as combustion air

enters through these areas.

Be sure to inspect and clean the ventilation system according to the ventilation equipment manufacturer’s instructions.

NOTICE

Proper ventilation is the owner’s responsibility. Any problem due to improper ventilation will not be covered by the

warranty.

Convection ovens require connection to a supply of electricity. The appliance, when installed, must be electrically

grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.2, as applicable. An electrical diagram is located on the

on page 48.

Ovens ordered with the 120V power option are equipped with one or two power cords with a standard 120V single-phase

plug with a ground prong. Single-deck ovens will have one power cord; double-deck ovens will have two.

order. Ovens with other power options have a terminal block on the rear of the oven that must be wired to the power supply.

Depending on how the power supply is connected to the terminal block, the oven can operate on either single-phase of

three-phase power.

120/60/1 120 Volts, 60 Hz, Single Phase Single-Deck

Double-Deck

7.9

15.8

208/60/1or3 190-219 Volts, 60 Hz, Single or Three Phase Single-Deck

Double-Deck

4.3

8.6

240/60/1or3 220-240 Volts, 60 Hz, Single or Three Phase Single-Deck

Double-Deck

3.8

7.5

240/50/1or3 208-240 Volts, 50 Hz, Single or Three Phase Single-Deck

Double-Deck

6.0

12.0

If a ventilation canopy is used, it is recommended that a canopy extend 6” past the appliance and that the bottom edge

fan tends to create a vacuum in the room and may interfere with burner performance. Fresh air openings approximately

equal to the fan area will relieve such a vacuum. In case of unsatisfactory performance on any appliance, check the

appliance with the exhaust fan in the “OFF” position. Do this only long enough to check equipment performance. Then

turn the exhaust fan back on and let it run to remove any exhaust that may have accumulated during the test.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23) PAGE 9 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

NOTICE

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association, Inc.

states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to installation

requirements for equipment. Therefore, installations should comply with all local codes.

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGA-B149.2,

as applicable, including:

2. The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If damaged equipment is received, either apparent or concealed, a claim

must be made with the delivering carrier.

Apparent damage or loss must be noted on the freight bill at the time of delivery. The freight bill must then be signed

the necessary forms.

A request for inspection must be made to the carrier within 15 days if there is concealed damage or loss that is not

apparent until after the equipment is uncrated. The carrier should arrange an inspection. Be certain to hold all contents

plus all packing material.

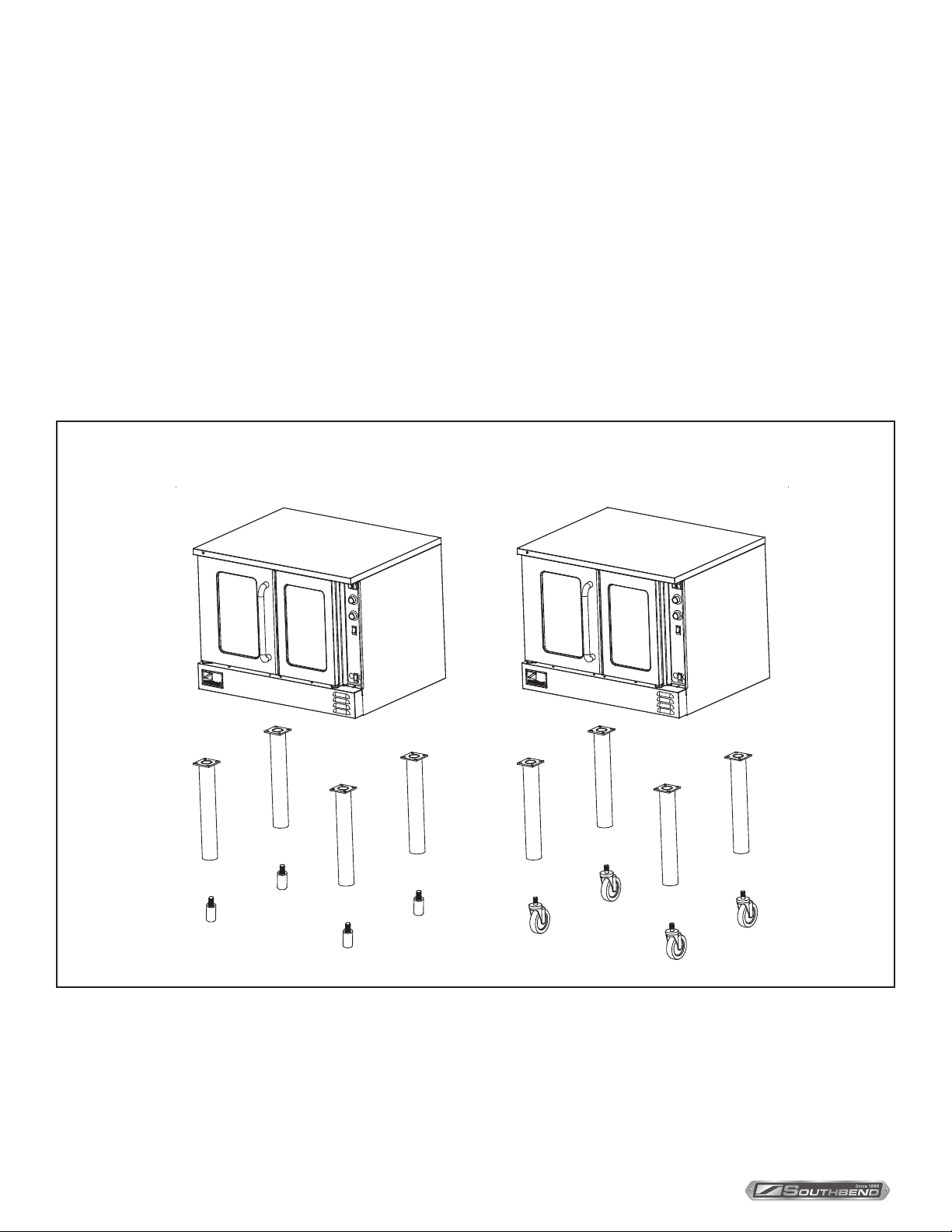

1. Cut banding straps and remove packing material.

2. Cut banding strap holding oven to wooden skid.

3. If you are installing 4” legs on a single-deck oven, go to Step 2a on page 9.

If you are installing 26” legs on a single-deck oven, go to Step 2b on the page 10.

If you are installing a double-deck oven, go to Step 2c on page 11.

means is recommended. For safety, “shore up” and support the oven with an adequate blocking arrangement strong

2. Attach each leg to a bottom corner of the oven by screwing it into the appropriate threaded hole.

3. Lower the oven gently onto a level surface. Never drop or allow the oven to fall.

4. Use a level to make sure that the oven is level. Each leg can be screwed in or out to lower or raise each corner of the

oven.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 10 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

means is recommended. For safety, “shore up” and support the oven with an adequate blocking arrangement strong

Each leg is secured by four screws. The mounting holes are pre-drilled and threaded.

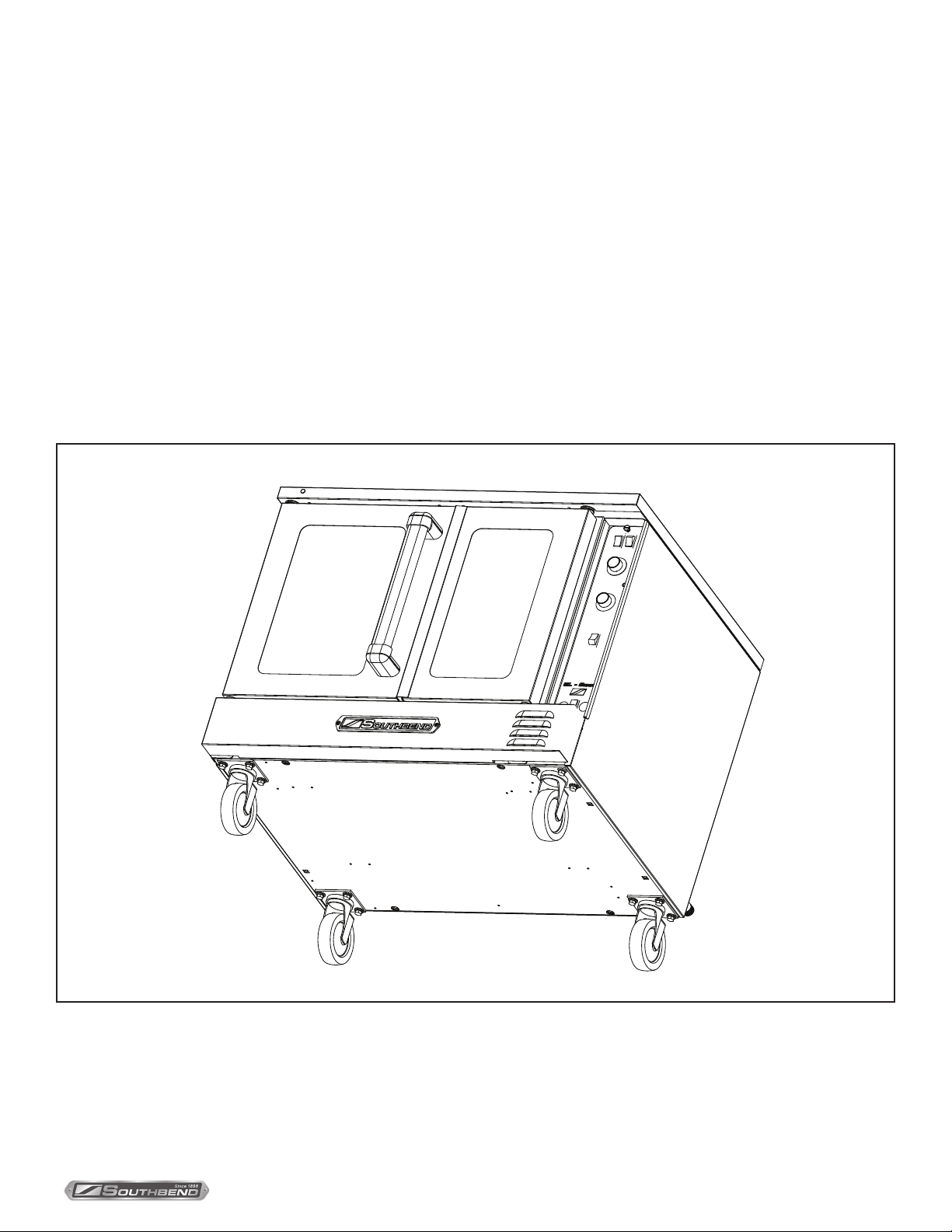

attaching casters, the two casters with brakes should be attached to the front legs.

4. Lower the oven gently onto a level surface. Never drop or allow the oven to fall.

5. Use a level to make sure that the oven is level. The adjustable feet can be screwed in or out to lower or raise each

corner of the oven.

6. If casters were installed, go to Installation Step 3, otherwise go to Step 4.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23) PAGE 11 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

Double-deck oven can be shipped either already bolted together, or as two separate ovens to be bolted together after

of the oven. Do the following:

means is recommended. For safety, “shore up” and support the oven with an adequate blocking arrangement strong

attaching casters, the two casters with brakes should be attached to the front leg pads.

3. Lower the oven gently onto a level surface. Never drop or allow the oven to fall.

4. Use a level to make sure that the oven is level. The adjustable legs can be screwed in or out to lower or raise each

corner of the oven.

5. If casters were installed, go to Installation Step 3, otherwise go to Step 4.

SCALE 3/8

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 12 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

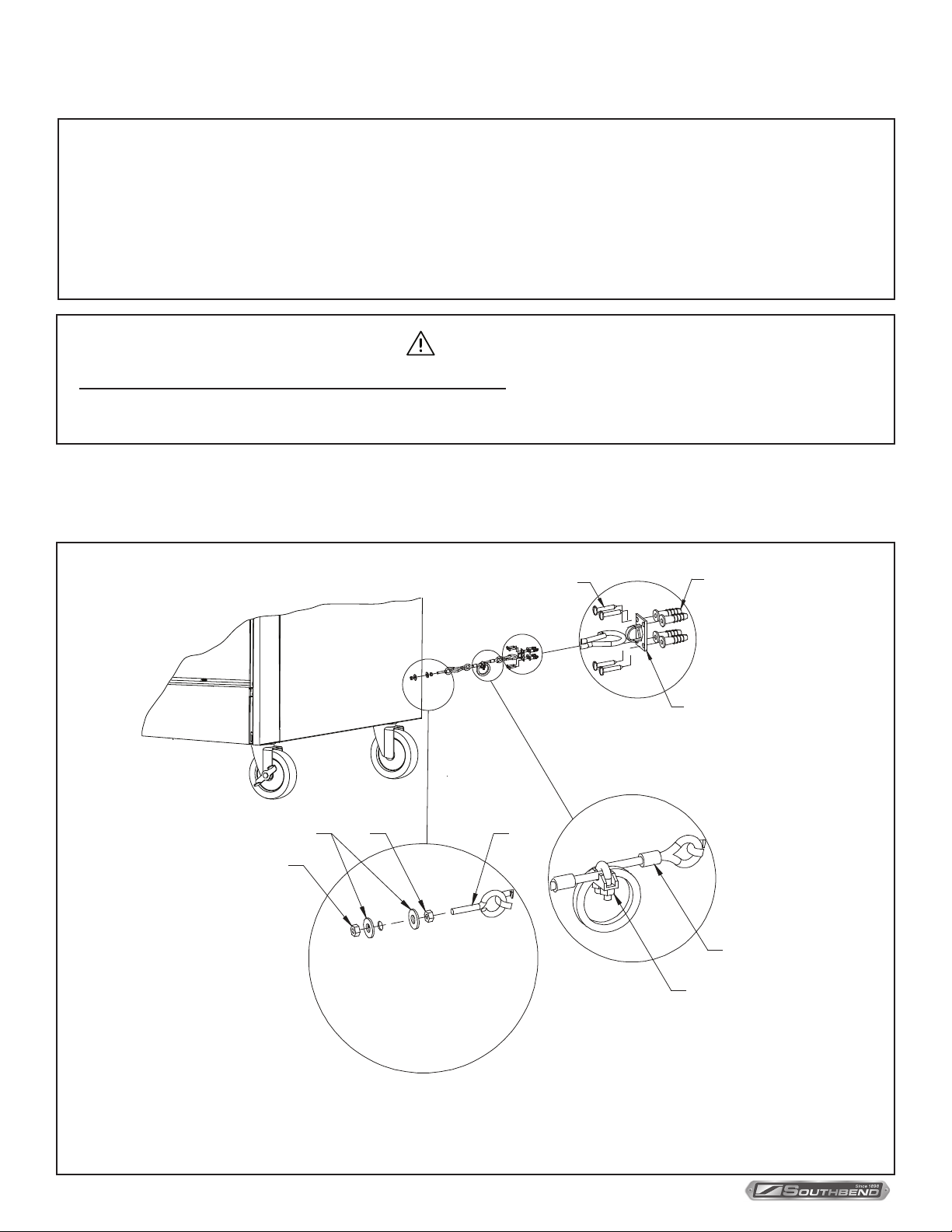

NOTICE

Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 or Connectors for Moveable Gas Appliances,

CAN/CGA-6.16, and a quick-disconnect device that complies with the Standard for Quick-Disconnect Devices for

Use With Gas Fuel, ANSI Z21.41, or Quick Disconnect Devices for Use with Gas Fuel, CAN1-6.9

means must be provided to limit the movement of the appliance without depending on the connector and the quick-

attached to a frame member on the back of the unit.

WARNING

To avoid accidental gas disconnection and potential explosion:

If disconnection of this restraint is necessary to move the appliance for cleaning, etc., reconnect it when the

appliance is moved to its originally installed position.

F

G

H

I

B

C

E

D

A

Note: Kit can be purchased from Southbend

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23) PAGE 13 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

member for adequate clearance, drill a 1/4” hole through the frame member.

4. Using the spring-loaded snap hooks, attach the restraining device to the bracket and the eye-bolt.

the appliance connector.

reconnecting, be sure that the oven is switched OFF.

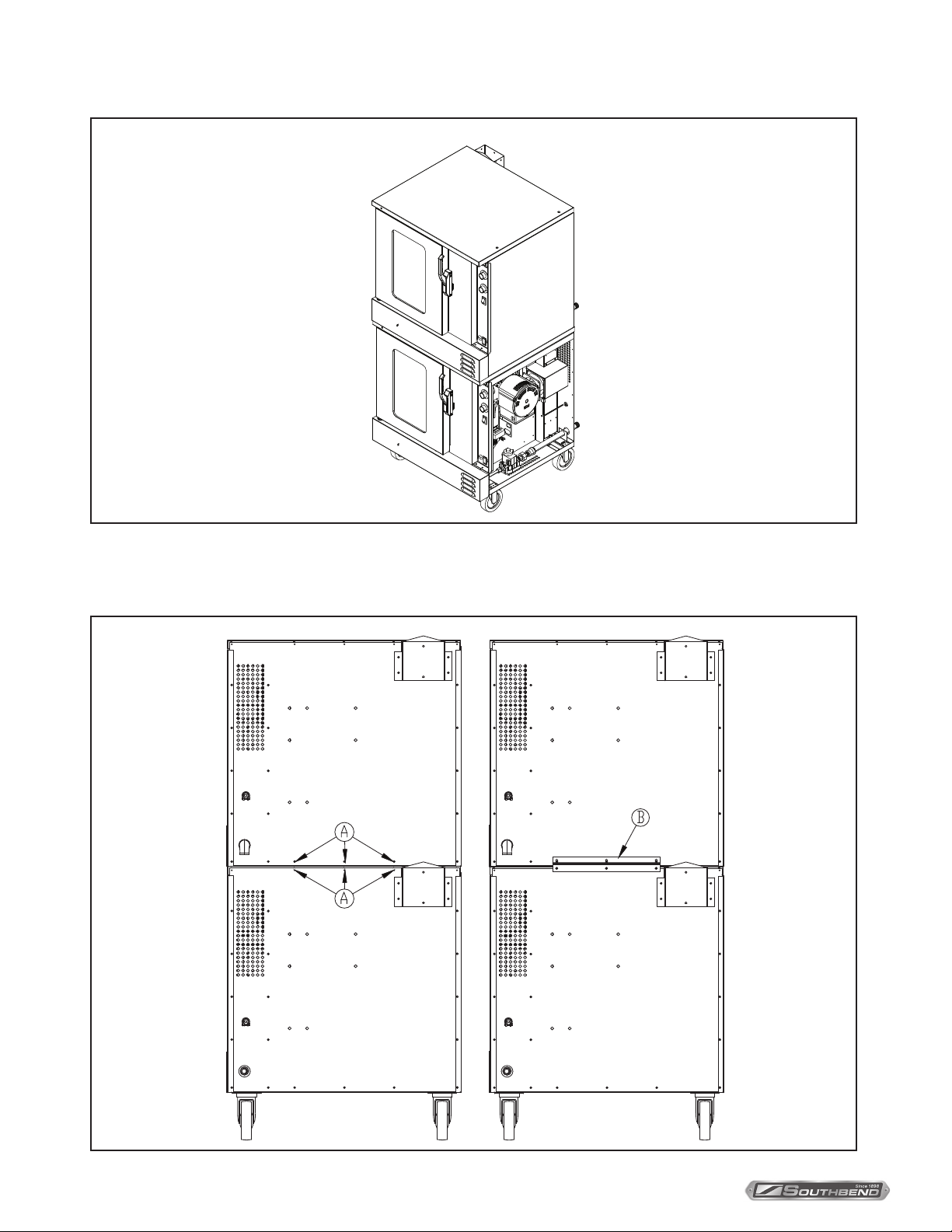

Double-deck ovens can be shipped already assembled, but can instead be shipped as two single-deck ovens to be stacked

This installation step describes the procedure for stacking two single-deck ovens to form a double-deck oven.

2. If the oven that will be the top oven was NOT ordered as part of a double-deck oven, remove the four leg pads from

the bottom of the top oven.

and pull it forward to remove it, then set it aside.

4. Locate and remove the now-accessible screw that secures the lower front corner of the side panel.

Remove the right side panel and insulation and set them aside.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 14 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

6. Lift the top oven and position it on top of the lower oven, as shown in the drawing below.

7. Move to the rear of the ovens and remove the six screws shown as items “A” in the left-hand drawing below. Position

through the holes in the tie bracket, but do not tighten them yet.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23) PAGE 15 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

threaded holes in the bottom of the top oven. Tighten these bolts and the screws that you did not tightened in the

previous step.

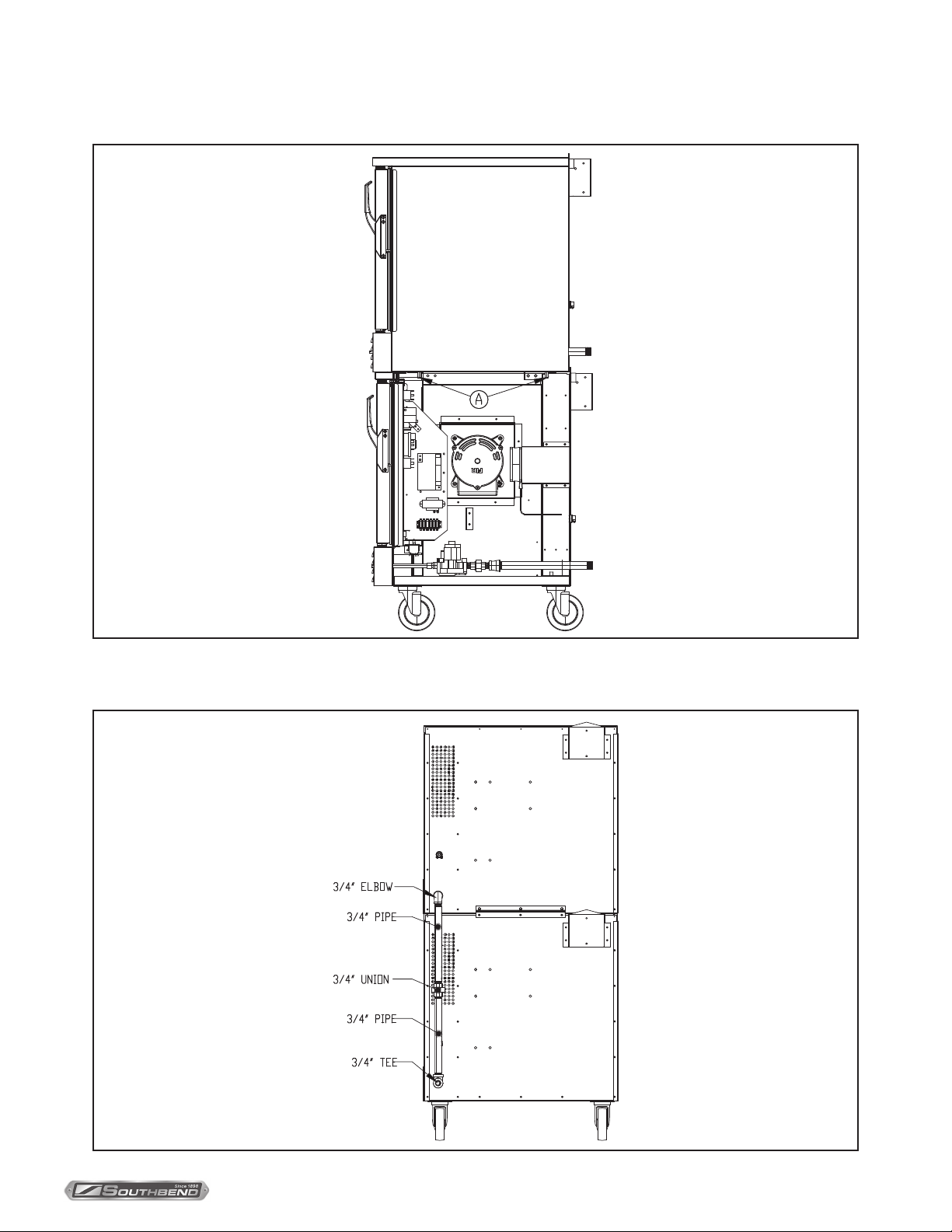

9. Assemble the gas piping shown in the following drawing. Be sure to check all connections for leaks once the oven has

been installed.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 16 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

11. Replace the right side insulation, exterior panel, and lower front panel that you removed in step 4 of this procedure.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23) PAGE 17 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

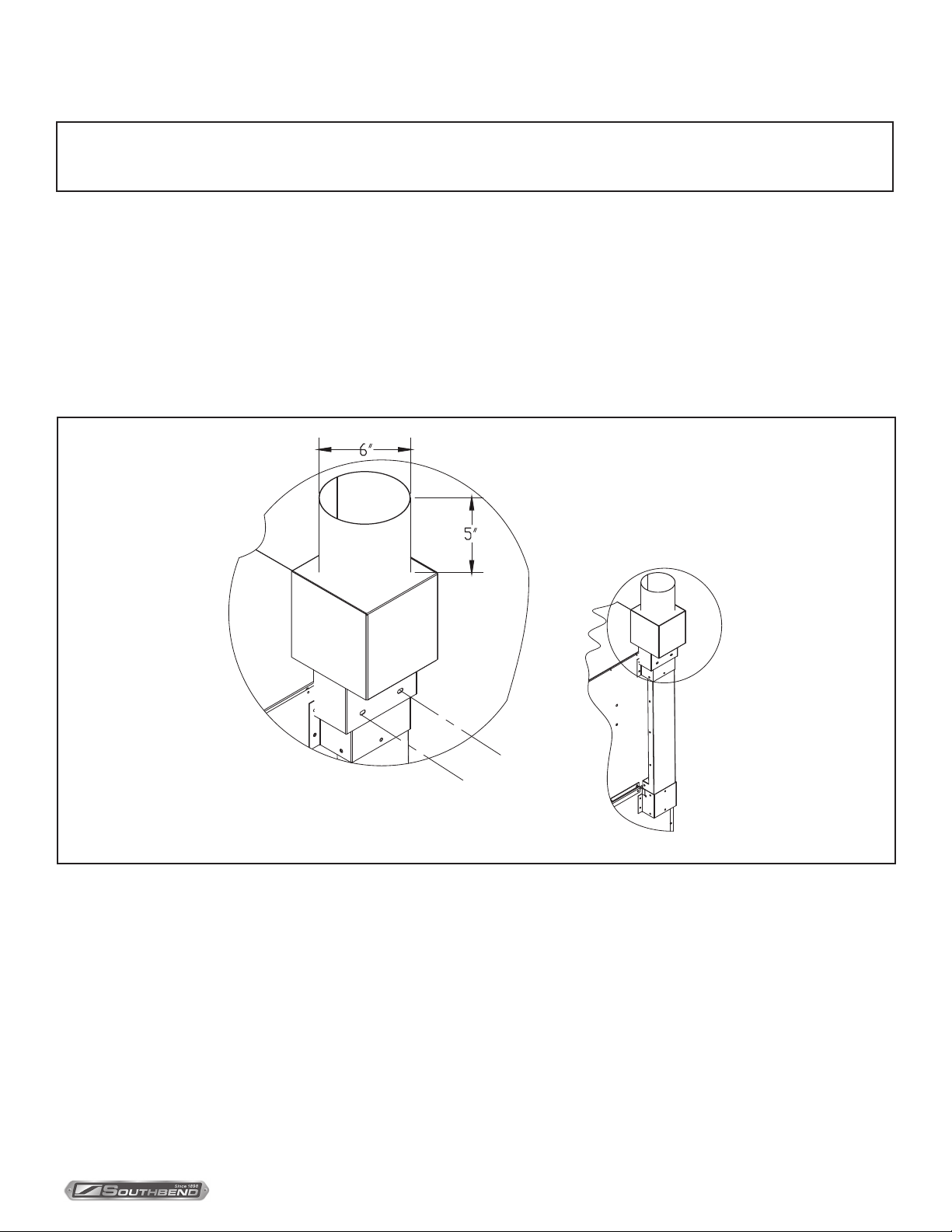

NOTICE

Installation must use approved CSA International down draft diverter supplied by Southbend.

of ventilation pipes through walls and roofs must conform to all local codes. To install the down draft diverter, do the

following:

Allow the diverter to slide down as far as it will go.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 18 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

STEP 6:

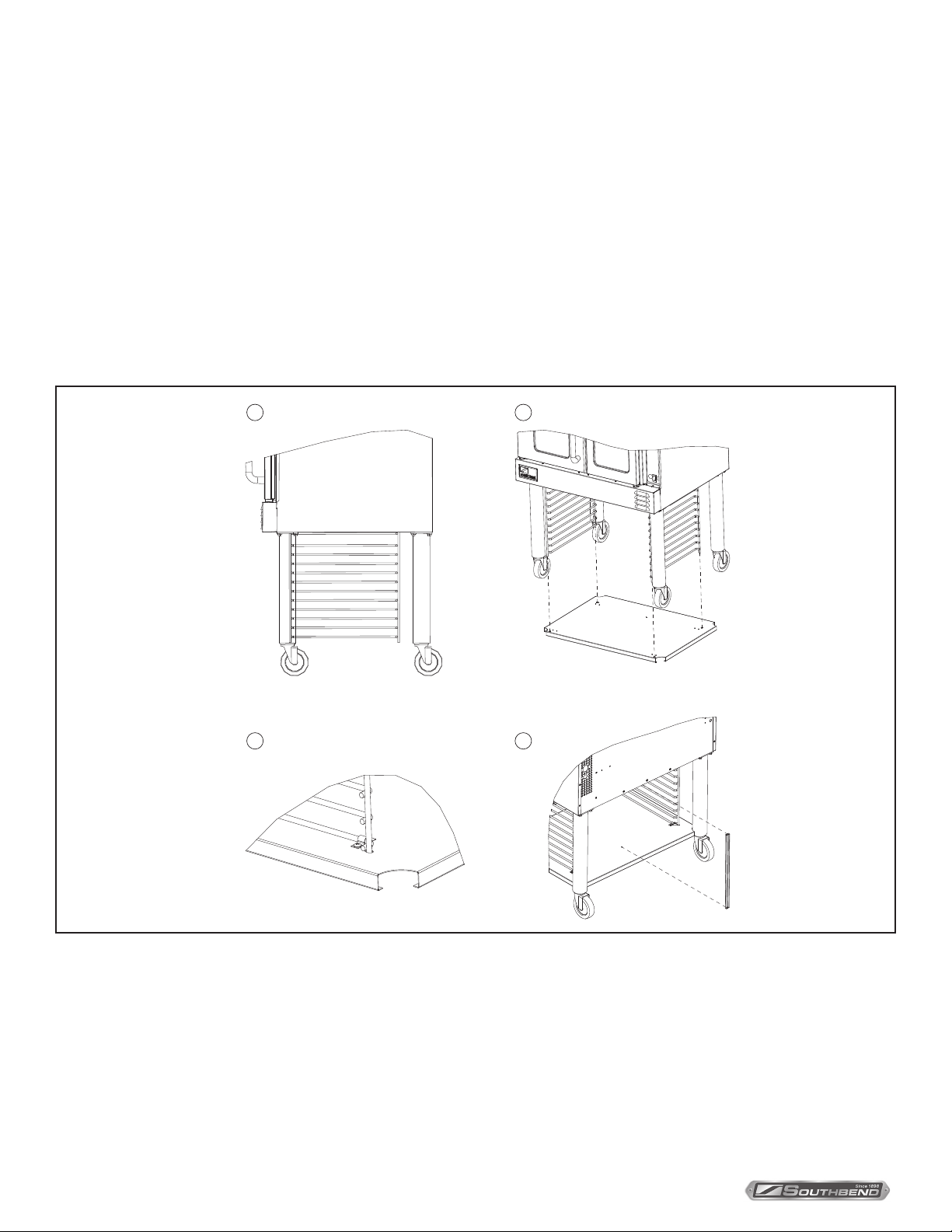

The following describes how to assemble the optional open storage. All holes are pre-drilled for the provided screws.

1. Attach the legs to the oven as described in installation Step 2b on page 10.

below).

3. Position the shelf below the rack guides and lift it so that the bottom ends of the rack guides pass through the holes in

4. Secure the shelf to the rack guides with four clips, each secured by two screws that thread into the threaded holes on

5. Attach the rack-stop using two screws. Attach the top of the rack stop to the bottom of the oven, and the bottom of the

A B

C D

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23) PAGE 19 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

WARNING

ELECTRIC GROUNDING INSTRUCTIONS

hazard and should be plugged directly into a properly grounded three-prong receptacle. Do not cut or remove the

grounding prong from this plug..

NOTICE

This appliance, when installed, must be electrically grounded in accordance with local codes, or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 70 or the Canadian Electrical Code, CSA C22.2, as applicable.

Section). Be sure that the input voltage and phase match the requirements shown on the serial plate, which is located

inside the lower front panel.

Ovens ordered to operate on 120V

Do

NOT have factory installed power cords and must be wired as described below.)

Ovens without a power cord have a terminal block. The electric supply must be brought through the service panel in the

Ovens are factory-equipped with a two-pole terminal block, located behind a cover plate located on the rear of the oven.

To connect the supply wires, remove the cover plate, then route the supply wires and the grounding wire through the strain

screws. Insert the ground wire into the grounding lug and tighten the screw. Re-attach the cover plate.

Three phase units are wired as above, using only two supply wires. The third wire is not used and must be properly

terminated.

be accomplished by referring to phase loading and line amperes chart on wiring diagram for wire size and ampere

requirements.

INSTALLATION & OPERATION MANUAL 1177596 REV 3 (02/23)

PAGE 20 OF 76

Marathoner Gold Half-Size Gas Convection Ovens

NOTICE

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code

CAN/CGA-B149.2, as applicable, including:

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than

A 3/4” NPT line is provided at the rear for the gas connection.

the appropriate authorized Southbend Service Representative or the Southbend Service Department. Failure to install

The serial plate is located inside the front lower panel. It indicates the type of gas the unit is equipped to burn. All

Southbend equipment is adjusted at the factory. Check type of gas on serial plate.

deliver a 4.0” W.C. pressure to the manifold. For propane gas, it is set to deliver 11” W.C.

This appliance should be connected ONLY to the type of gas for which it is equipped. The inlet pressure before the

regulator should be 7-10” W.C. for natural gas or 11-14” W.C. for LP gas.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required for

satisfactory performance. Fluctuations of more than 25% on natural gas or 10% on propane gas will create problems and

An adequate gas supply line to the unit should be no smaller than the I.D. of the pipe from the unit to which it is

connected.

Purge the supply line to clean out dust, dirt, or other foreign matter before connecting the line to the unit.

CAUTION

ALL PIPE JOINTS AND CONNECTIONS MUST BE TESTED THOROUGHLY FOR GAS LEAKS. USE ONLY

SOAPY WATER FOR TESTING ON ALL GASES. NEVER USE AN OPEN FLAME TO CHECK FOR GAS LEAKS.

ALL CONNECTIONS MUST BE CHECKED FOR LEAKS AFTER THE UNIT HAS BEEN PUT INTO OPERATION.

TEST PRESSURE SHOULD NOT EXCEED 1/4” W.C.

1. Check that all screws and bolts are tightened.

2. Move the oven into the position at which it will be operated.

3. Check that the oven is level. If not, adjust the legs.

5. Turn-on supply power and check oven for proper operation.

This manual suits for next models

5

Table of contents

Other Southbend Oven manuals