Spacek SE-33 User manual

Spacek s.r.o. | Lesní 25 | 695 01 | Hodonin | Tel: +420 605 409 539 | [email protected] | www.sdplanes.com

OPERATO;RS MANUAL

ENGINE SE-33

OPERATORS MANUAL FOR ENGINE SE-33

2

Engine type: SE - 33

Manufacturer: SPACEK s.r.o.

S/N:

Issue date: 25.11.2017

WARNING

Engine must be operated in compliance with the information and

limitations stated in this manual as it contains important safety relevant

information. Read this Operators manual before first start of the engine.

Failure to do so may result in personal injuries or death.

All data and the information in this manual are the property of Spacek s.r.o., Lesni 25, 691 01

Hodonin, Czech Republic, and shall not, without prior written permission of Spacek s.r.o., be disclosed

in whole or in part to third parties. This legend shall be included on any reproduction of these data, in

whole or in part. The Manual must remain with the engine/aircraft in case of sale.

OPERATORS MANUAL FOR ENGINE SE-33

3

LIST OF REVISIONS AND REPAIRS

Revision

Nr.

Document Nr. - bulletin

Related to pages Nr.

Date

Signature

OPERATORS MANUAL FOR ENGINE SE-33

4

Table of Contents

1. Description........................................................................................................................5

1.1 Important information................................................................................................................. 5

1.2 Safety symbols........................................................................................................................... 5

1.3 Safety information...................................................................................................................... 6

2. Engine description...........................................................................................................8

2.1 Technical data............................................................................................................................ 8

2.3 Direction of rotation.................................................................................................................... 9

2.4 Engine Instruments.................................................................................................................. 10

3. Operation ........................................................................................................................10

3.1 Oil system.................................................................................................................................. 10

3.2 Fuel system............................................................................................................................... 12

3.3 Engine start............................................................................................................................... 13

4. Maintenance....................................................................................................................15

4.1 Oil change................................................................................................................................. 16

4.3 Oil Check / Add Oil................................................................................................................... 16

4.4 Spark Plug replace................................................................................................................... 17

4.5 Cleaning of air intake mesh.................................................................................................... 18

4.6 The Fuel Filter replace ............................................................................................................ 18

4.7 Air Cooling System clean........................................................................................................ 18

4.8 Nikki Carburetor........................................................................................................................ 18

4.9 Maintenance specification ...................................................................................................... 19

5. Abnormal function, troubleshooting.............................................................................19

NOTE This Operator Manual contains basic information on the safe

operation of the engine.

Read this Operators manual before first start of the engine.

In any doubt or if any content or passages of this manual is unclear or

in case of any questions, please do not hesitate to contact

manufacturer Spacek s.r.o. or any local dealer.

OPERATORS MANUAL FOR ENGINE SE-33

5

1. Description

This Operator Manual contains basic information on the safe operation of the engine and familiarize

the user with basic operation, use and care of the engine.

This manual contains safety information to make you aware of the hazards and risks associated with

engine and how to avoid them.

Save these original instructions for future reference.

For more information about specific engine installation refer to the aircraft manufacturer’s

documentation.

1.1 Important information

ATTENTION

This product is not liable to be approved by any Aviation authority, and it

is operated exclusively at someone’s own risk.

1.2 Safety symbols

The following information applies to warnings, cautions, attention and notes used in the Operator

Manual.

Alert symbols and signal words indicate the likelihood and the potential severity of injury and may be

used to represent the type of hazard.

Always apply common workshop safetyrules.

WARNING

Means that non-observations of the corresponding procedure leads to an

immediate or important degradation of flight safety.

CAUTION

Means that non-observations of the corresponding procedure leads to a

minor or to a more or less long term degradation of the flight safety.

ATTENTION

Identifies any important and instruction notes. Not following these notes

or instructions may lead to damage of the engine or breach of air law.

NOTE

Draws the attention to any special item not directly related to safety but

which is important or unusual.

OPERATORS MANUAL FOR ENGINE SE-33

6

1.3 Safety information

WARNING

Never fly the aircraft equipped with this engine at locations, air

speeds, altitudes or in other situations which do not allow a successful

engine out landing after sudden engine stoppage.

Not following of this warning can result in serious injuries or death and

breach of air law!

WARNING

Fuel and its vapours are extremely flammable and explosive.

Fire or explosion can cause severe burns or death.

When Adding Fuel

•Turn engine off and let engine cool at least 2 minutes before removing the fuel cap.

•Fill fuel tank outdoors or in well-ventilated area.

•Do not overfill fuel tank.

•Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition sources.

•Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if necessary.

•If fuel spills, wipe it down and wait until it evaporates before starting engine.

When Starting Engine

•Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in place and

secured.

•Do not crank engine with spark plug removed.

•If engine floods, set choke (if equipped) to OPEN/RUN position, move throttle (if equipped) to

FAST position and crank until engine starts.

When Operating Equipment

•Do not tip engine or equipment at angle which causes fuel to spill.

•Do not choke the carburetor to stop the engine.

•Never start or run the engine with the air intake wire mesh or the air filter (if equipped)

removed.

When Changing Oil

•If you drain the oil from the engine, avoid to make any spillage.

When Transporting Equipment

•Transport with fuel tank EMPTY or with fuel shut-off valve OFF.

When Storing Fuel or Equipment With Fuel In Tank

•Store away from furnaces, stoves, water heaters or other appliances that have pilot lights or

other ignition sources because they can ignite fuel vapours.

OPERATORS MANUAL FOR ENGINE SE-33

7

WARNING

Flights according to IFR and intentional flights under icing conditions are

prohibited!

•This engine is not suitable for aerobatics flight.

•Basic engine setting is limited to certain flight attitudes.

•Be aware of engine seizure in any time. Avoid flying over congested areas, any areas

or conditions which do not allow safe outlanding.

Engine Logbook

•Keep and maintain engine log book to record every flight, maintenance schedules

and service or repairs carried out.

•Do not fly an aircraft with poorly maintain engine/aircraft logbook.

OPERATORS MANUAL FOR ENGINE SE-33

8

2. Engine description

The SE-33 is simple V-twin OHV 4-stroke ram air-cooled engine with wet oil sump.

The propeller flange is mounted directly on the flywheel.

This standard engine has:

•forged one central crank and rods,

•single magneto ignition for each cylinder.

•vacuum fuel pump

•mechanical internal oil pump.

•exhaust manifolds and muffler

•crankcase oil breather

•regulator and starter solenoid

•electric starter motor

•generator stator

•electric oil pump

•oil pressure switch

•oil temperature sensor

Auxiliary optional equipment:

•electric fuel pump

•CHT rings

2.1 Technical data

Model

SE-33

Displacement

810 cc (49.42 ci)

Bore

83.81 mm (3.300 in)

Stroke

73.41 (2.890 in)

Oil capacity

1.9 –2.0l (66 –68 oz)

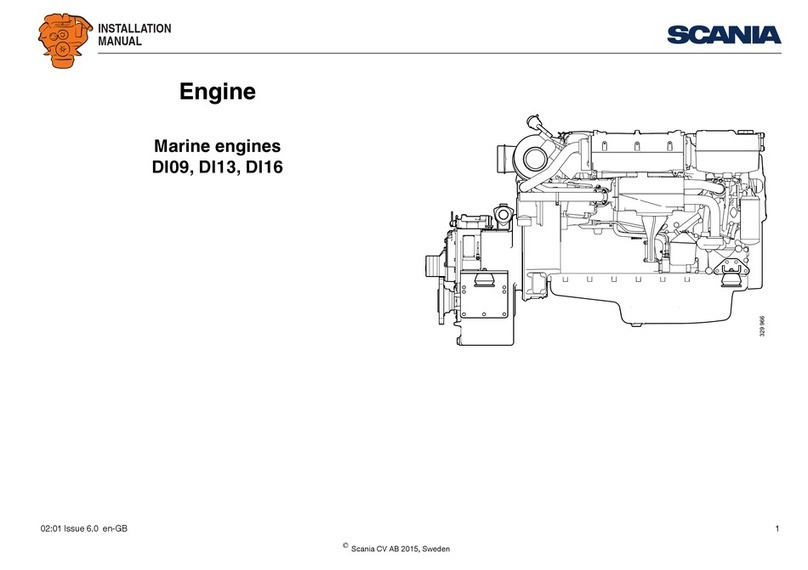

Picture 1.: Top and left side view

OPERATORS MANUAL FOR ENGINE SE-33

9

2.2 Operating limits

Max. continuous power…………………25kW@3600 rpm

Max. take off power……………………..22kW@3100 rpm

Recommended idle speed……………..900 –max. 1100 rpm

Min. CHT…………………………………60°C

Max. CHT……………………………......240 °C

Min. oil temp……………………………..25 °C

Max. oil temp…………………………….140 °C

Oil. pressure……………………………..0,3-2,5 bar –normally indicated by red light

Oil. quantity………………………………cca 1.9 –2.0l

Operating outside air temperature…….-10°C / +40°C

Fuel consumption………………………..max. 8 l/hr @ 3600 rpm

Fuel consumption in cruise ……………4.8 l/hr

Charging………………………………….3600rpm 20 volts AC minimum for 10 & 13 amp 30

volts AC minimum for 16 amp

2.3 Direction of rotation

Propeller direction of rotation –clockwise –

- viewed from the front

Picture 2.: Right side and front view

Picture 3.: Direction of rotation

OPERATORS MANUAL FOR ENGINE SE-33

10

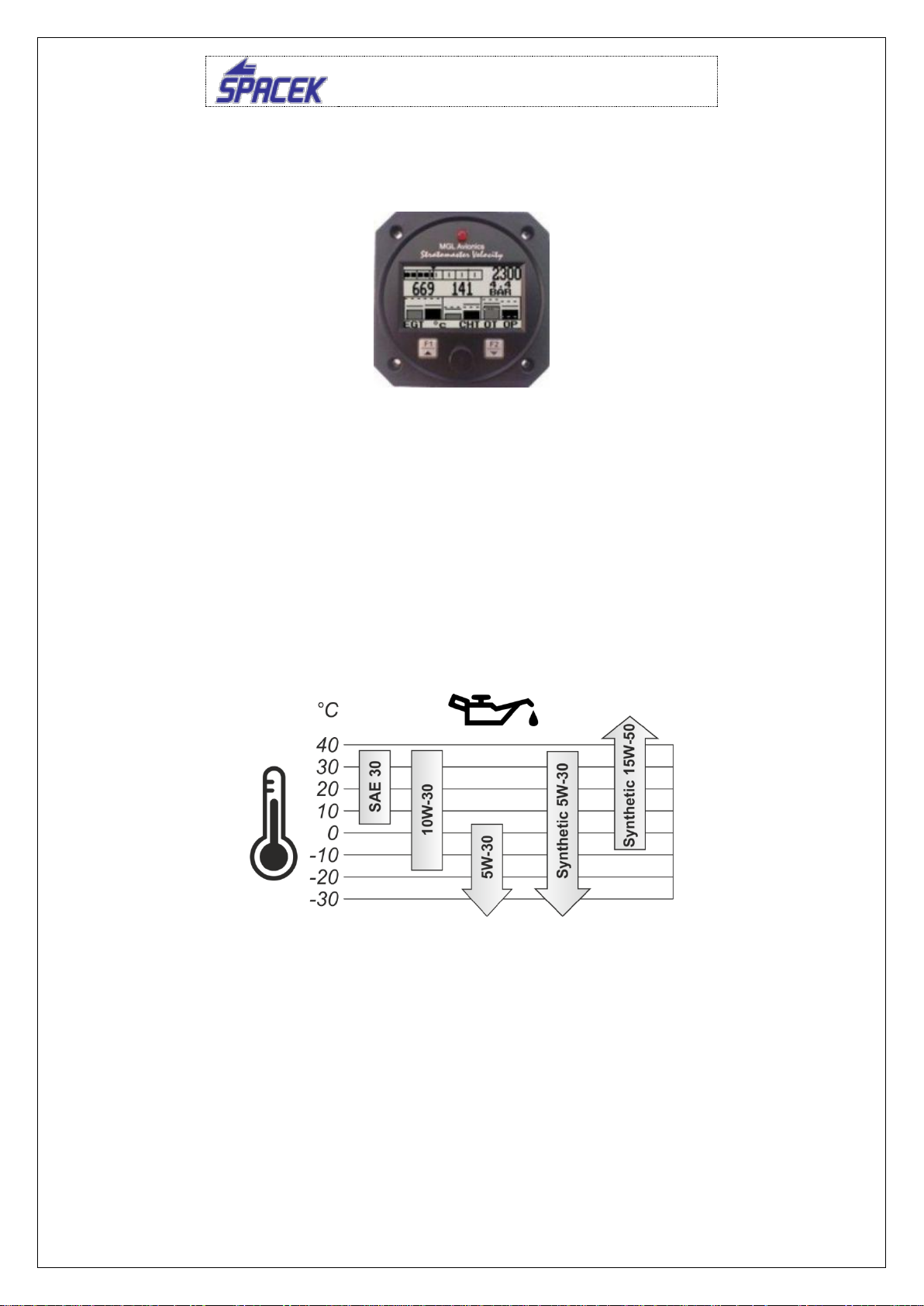

2.4 Engine Instruments

Any suitable electronic engine monitor or analogue gauges can be used.

Example: the most common and convenient engine monitor

MGL E1/E3

3. Operation

3.1 Oil system

High-quality detergent oils are acceptable if classified for service SF, SG, SH, SJ or higher.

Do not use special additives.

Recommended viscosity: 10W30

Oil capacity: 1.9 –2.0l –use dipstick to determine correct level.

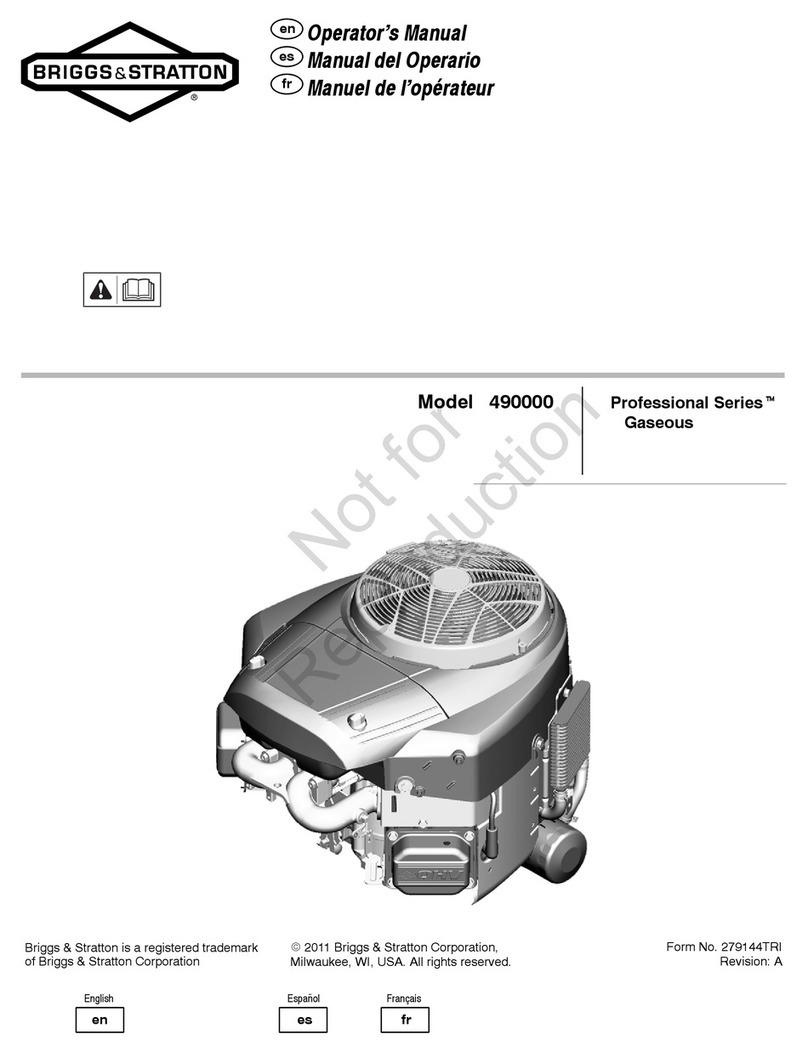

Outdoor ambient temperatures determine the proper oil viscosity for the engine. Use the

chart to select the best viscosity for the outdoor temperature range expected.

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W-30 may cause increased oil consumption. Check oil

level more frequently.

Oil Check / Add Oil

Before adding or checking the oil

•Move the aircraft/engine to level position.

•Clean the oil fill area of any debris.

1. Remove the dipstick (D) and wipe with a clean cloth (Figure 2, p.17).

2. Insert and tighten the dipstick.

Picture 4.: Temperature range

OPERATORS MANUAL FOR ENGINE SE-33

11

3. Remove the dipstick and check the oil level. It should be at the FULL mark (E) on the

dipstick.

4. If low, add oil slowly into the engine oil fill (F). Do not overfill. After adding oil, wait one

minute and then recheck the oil level.

5. Replace and tighten the dipstick.

ATTENTION

If low, add oil slowly into the engine oil fill (dipstick pipe). Do not overfill!

After adding oil, wait one minute and then recheck the oil level.

NOTEOil level should be in the upper half between 50% and MAX. mark and should

never be under MIN. mark.

Oil Pressure

Low oil pressure is indicating by red LED diode on the instrument panel and simple oil

pressure switch (B) is used near oil filter. (Figure 1), (X, Figure 2)

Oil pressure has to build up within 10 sec. after start up and red light has to go off.

Min. oil pressure: 0.3 bar

Max. oil pressure: 2.5 bar

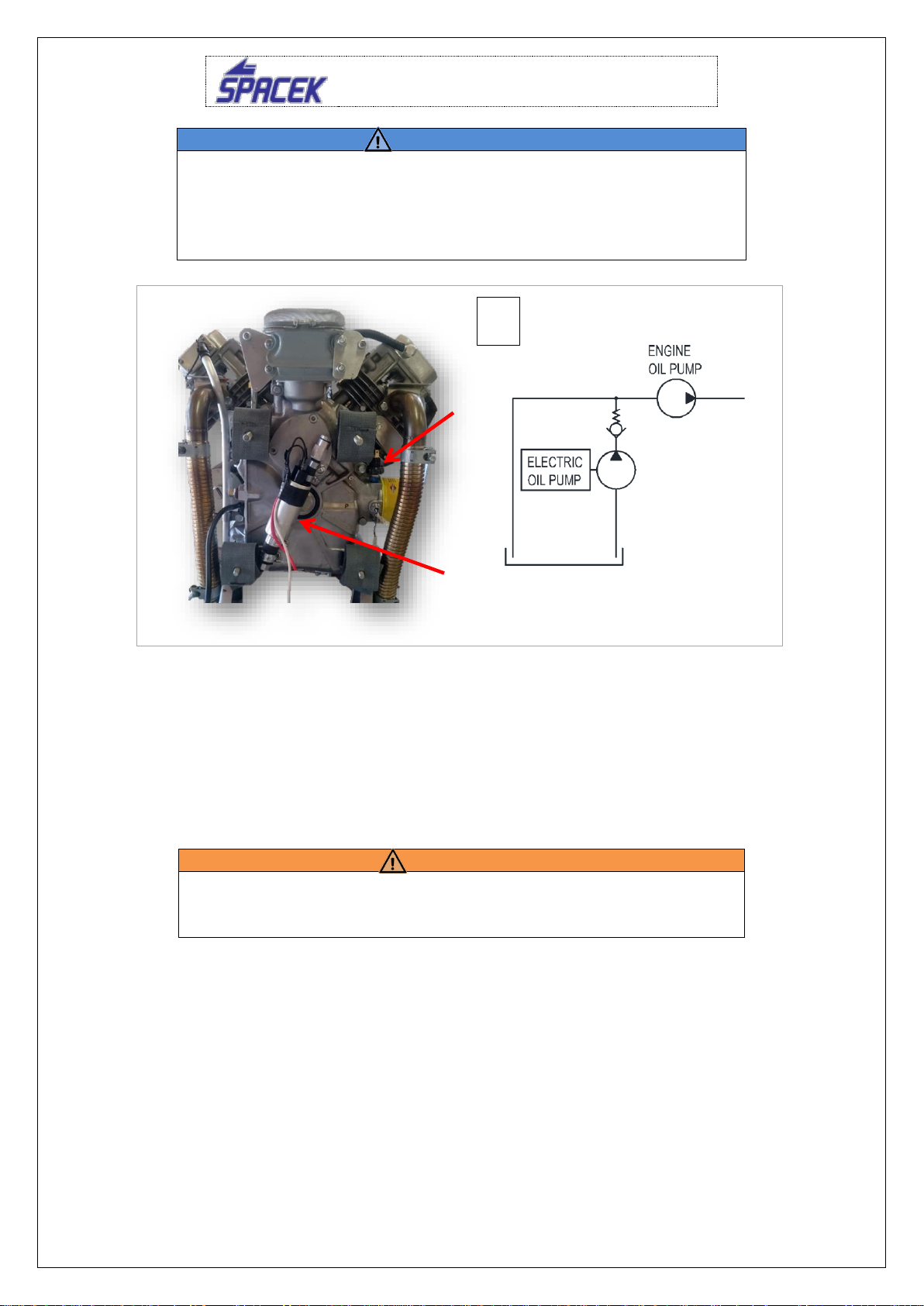

Priming oil system (C, Figure 1)

The standard engine is equipped with electric oil pump (A). This el. oil pump serves as

priming oil system and flooding internal mechanical oil pump. (Figure 1)

•After first installation and before first start up, oil system and mechanical oil pump

should be flooded using el. oil pump.

•When the engine is not being used for longer time, switch el. oil pump on for 5 sec.

and then switch off before start up.

With el. oil pump on low pressure indicator should go off even with no engine running.

In case of indication of low pressure after start up switch the el. oil pump on for a couple

seconds while engine running and the shut the el. oil pump off. If this not help and low

pressure indicator is still on immediately shut the engine off and check the oil level with the

dipstick.

If the oil level is BELOW minimum mark, add oil until it reaches MAX mark.

If the oil level is between min. and max. mark, repeat the step above ‘Priming oil system’. In

case this does not help please contact your dealer or manufacturer.

Use el. oil pump just for priming. Do not use el. oil pump for normal flying operation.

Auxiliary oil pressure sender (optional)

It is possible to use oil pressure sender such as VDO instead of pressure switch. In that case

low pressure indicator is not being used but analogue or digital instrument (e.g. MGL E1/3,

VDO analogue gauge etc..)

OPERATORS MANUAL FOR ENGINE SE-33

12

ATTENTION

Oil pressure has to build up within 10 sec. after start up and red light has

to go off. In case of indication of low pressure after start up switch the el.

oil pump on for a couple seconds while engine running. If this not help

and low pressure indicator is still on immediately shut the engine off and

check the oil level with the dipstick.

3.2 Fuel system

Fuel requirements:

•Use clean, fresh, unleaded fuel.

•A minimum of 87 octane / 87 AKI (91 RON). High altitude use, see below.

•MOGAS with up to 10% ethanol (gasohol) or up to 15% MTBE (methyl tertiary butyl

ether) is acceptable.

CAUTION

Do not use unapproved gasolines, such as E85. Do not mix oil in gasoline or

modify the engine to run on alternate fuels. This will damage the engine

components.

NOTE

Risk of vapour formation if using winter fuel for summer operation.

High Altitude

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane/85 AKI (89 RON) gasoline

is acceptable. To remain emissions compliant, high altitude adjustment is required. Operation

without this adjustment will cause decreased performance, increased fuel consumption, and

increased emissions.

Operation of the engine at altitudes below 2,500 feet (762 meters) with the high altitude kit is

not recommended.

1

A

B

C

OPERATORS MANUAL FOR ENGINE SE-33

13

3.3 Engine start

WARNING

Ensure that spark plug, muffler, fuel cap and air cleaner (if equipped) are in

place and secured.

Do not crank engine with spark plug removed.

If engine floods, set choke to OPEN/RUN position, move throttle to FAST

position and crank until engine starts.

WARNING

Engines give off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause nausea, fainting or death.

Start and run engine outdoors.

Do not start or run engine in enclosed area, even if doors or windows are open.

ATTENTION

This engine was shipped from the manufacturer without oil. Before you start the

engine, make sure you add oil according to the instructions in this manual. If you

start the engine without oil, it will be damaged beyond repair and will not be

covered.

Cold start:

1. Check the engine for any oil leaks, cracks, good connections and security.

2. Check the oil level. See 3.1 Oil system section.

3. Fuel valve –open –

4. Master –on –

5. Switch el. fuel pump for a couple seconds, then switch off (if fitted)

6. Prime oil system if necessary. See 3.1 Oil system section.

7. Move the choke control to –open –position.

8. Set the throttle lever to 50%.

9. Magnetos switch –on –

10. Starter button –actuate –

ATTENTION

Do not actuate start button switch for more than 10 sec. and as long as

the engine running.

In case of re-start let the starter motor to cool down for approx. 1-2mins.

Warm start:

1. Check the engine for any oil leaks, cracks, good connections and security.

2. Check the oil level. See 3.1 Oil system section.

3. Fuel valve –open –

4. Master –on –

5. Switch el. fuel pump for a couple seconds, then switch off (if fitted)

6. Set the throttle lever to idle position.

7. Magnetos switch –on –

8. Starter button –actuate –

OPERATORS MANUAL FOR ENGINE SE-33

14

After start up:

1. As soon as engine running –set the throttle to approx. 2000 rpm –

2. Oil pressure –check oil pressure indicator or values –pressure has to build up within

10 sec.

ATTENTION

Oil pressure has to build up within 10 sec. after start up and red light has

to go off. In case of indication of low pressure after start up switch the el.

oil pump on for a couple seconds while engine running. If this not help

and low pressure indicator is still on immediately shut the engine off and

check the oil level with the dipstick.

3. Continue warming up the engine with approx. 2000 rpm to reach the lowest

vibrations.

4. Move the choke control slowly to –close –position.

5. Warming the engine up until the oil temperature reaches min. 25°C. But 50°C oil

temp. is highly recommended before applying the full rpm.

Take off:

1. Switch el. fuel pump –on –(if fitted)

2. Apply full power and check full rpm approx. 3100 rpm is reached.

3. Climb with full power and check operating temperatures. See 2.2 Operating limits.

4. Switch the fuel pump –off –approx. 500ft (150m) AGL or just before level off.

Cruising:

•Maximum continuous 3600 rpm.

•Recommended cruise rpm 3000-3300 rpm.

See 2.2 Operating limits section.

Engine shut-off:

•Engine is normally cooled down in descending and can be shut off after landing.

•In case higher operating temperatures let it cool down for a couple minutes before

engine shut-off.

OPERATORS MANUAL FOR ENGINE SE-33

15

4. Maintenance

Maintenance Chart

First 5 Hours

•Oil change

•Check for any leaks

Every 8 Hours or Daily

•Check oil level

•Check for any leaks or cracks, damage

•Check control throttle / choke cables

•Check exhaust system

•Check air intake wire mesh for good

security

Every 25 Hours or Annually

•Clean air intake wire mesh

•Check fuel lines for perishing or wear

•Check exhaust system

100 hr or Annually

•Change engine oil

•Replace oil filter Replace spark plugs

•Replace air filter (if fitted)

•Replace fuel filter

•Clean air cooling system

•Check valve clearance *

*Not required unless engine performance problems are noted.

WARNING

When testing for spark:

•Use approved spark plug tester.

•Do not check for spark with spark plug removed.

WARNING

Before performing adjustments or repairs:

•Disconnect the spark plug wire and keep it away from the spark plug.

•Disconnect battery at negative terminal (only engines with electric

start.)

•Replacement parts must be of the same design and installed in the

same position as the original parts. Other parts may not perform as

well, may damage the unit, and may result in injury.

•Use only correct tools.

Unintentional sparking can result in fire or electric shock.

Unintentional start-up can result in entanglement, traumatic amputation,

or laceration.

OPERATORS MANUAL FOR ENGINE SE-33

16

4.1 Oil change (Figure 2)

Used oil is a hazardous waste product and must be disposed properly. Do not discard with

household waste. Check with your local authorities, service centre, or dealer for safe

disposal/recycling facilities.

Remove Oil

1. Warm the engine up to 50°C.

2. Remove top and bottom cowling.

3. Disconnect the spark plug wire (A) and keep it away from the spark plug.

4. Remove the dipstick (D).

5. Remove the oil drain plug (B). Drain the oil into an approved container.

6. After the oil has drained, install and tighten the oil drain plug.

4.2 The Oil Filter change

For replacement intervals, see the Maintenance chart.

1. Drain the oil from the engine. See

2.

3.

4.

5.

6. 4.1 Oil change section.

7. Remove the oil filter (C) and dispose properly. See Figure 7.

8. Before you install the new oil filter, lightly lubricate the oil filter gasket with fresh, clean

oil.

9. Install the oil filter by hand until the gasket contacts the oil filter adapter, then tighten

the oil filter 1/2 to 3/4 turns.

10. Add oil. See 4.3 Oil Check / Add Oil section.

11. Prime oil system (see 3.1 Oil system)

12. Start and run the engine. As the engine warms up, check for oil leaks.

13. Stop the engine and check the oil level. It should be at the FULL mark on the dipstick.

4.3 Oil Check / Add Oil

Before adding or checking the oil:

•Move the aircraft/engine to level position.

•Clean the oil fill area of any debris.

1. Remove the dipstick (D) and wipe with a clean cloth (Figure 2).

2. Insert and tighten the dipstick.

3. Remove the dipstick and check the oil level. It should be at the FULL mark (E) on the

dipstick.

4. If low, add oil slowly into the engine oil fill (F). Do not overfill. After adding oil, wait one

minute and then recheck the oil level.

5. Replace and tighten the dipstick.

ATTENTION

If low, add oil slowly into the engine oil fill (dipstick pipe). Do not overfill!

After adding oil, wait one minute and then recheck the oil level.

NOTE

OPERATORS MANUAL FOR ENGINE SE-33

17

Oil level should be in the upper half between 50% and MAX. mark and should never

be under MIN. mark.

4.4 Spark Plug replace

•Check the gap with a wire gauge. If necessary, reset the gap.

•Install and tighten the spark plug to the recommended torque. For gap setting or

torque, see the 4.9 Maintenance specification section.

2

A

B

C

D

E

min.

F

G

OPERATORS MANUAL FOR ENGINE SE-33

18

NOTE In some areas, local law requires using a resistor spark plug to suppress ignition

signals. If this engine was originally equipped with a resistor spark plug, use the same type

for replacement.

4.5 Cleaning of air intake mesh

Air intake wire mesh is fitted standardly.

•Check and clean any debris and dirt.

•Check for good security.

CAUTION

Never start or run the engine with the air intake mesh or the air filter (if

equipped) removed.

4.6 The Fuel Filter replace

WARNING

Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition

sources.

Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if

necessary.

Before replacing the fuel filter, drain the fuel tank or close the fuel shut-off valve.

Replacement parts must be the same and installed in the same position as the

original parts.

If fuel spills, wait until it evaporates before starting engine.

1. Before replacing the fuel filter (A, Figure 3), if equipped, drain the fuel tank or close

the fuel shut-off valve. Otherwise, fuel can leak out and cause a fire or explosion.

2. Use pliers to squeeze tabs (B) on the clamps (C), then slide the clamps away from

the fuel filter. Twist and pull the fuel lines (D) off of the fuel filter.

3. Check the fuel lines for cracks or leaks. Replace if necessary.

4. Replace the fuel filter with an original equipment replacement filter.

5. Secure the fuel lines with the clamps as shown.

4.7 Air Cooling System clean

NOTEDo not use water to clean the engine. Water could contaminate the fuel system. Use

a brush or dry cloth to clean the engine.

This is an air cooled engine.

Dirt or debris can restrict air flow and cause the engine to overheat, resulting in poor

performance and reduced engine life.

•Use a brush or dry cloth to remove debris from cylinder’s fins area.

3

B

A

C

D

OPERATORS MANUAL FOR ENGINE SE-33

19

4.8 Nikki Carburetor

Never make adjustments to the carburettor. The carburetor was set at the factory to operate

efficiently under most conditions. If any adjustments are required contact your local dealer or

the manufacturer.

4.9 Maintenance specification

Maintenance specification

Spark plug type

Champion RC12YC

B&S 5066

Spark plug gap

0.76 mm (0.030 in)

Spark plug torque

20 Nm (180lb-in)

Oil filter

B&S Oil filter PRO 795890

B&S Oil filter 798576

Armature Air gap

0.20 –0.30 mm (0.008 –0.012 in)

Intake Valve clearance

0.10 –0.15 mm (0.004 –0.006 in)

Exhaust Valve clearence

0.10 –0.15 mm (0.004 –0.006 in)

5. Abnormal function, troubleshooting

If any abnormal function has been found please contact your local dealer or the

manufacturer.

Table of contents