Sparta CENTURY Series User manual

www.SteamPoweredRadio.Com

TECHNICAL

MANUAL

CENTURY

SERIES

Models 4510, 45·

15

,

4520

and

4525

Tape Cartridge Reproducers

PROPRIETARY

NOTI

CE

Sparta Electronic

Corpor

ation

proprietary

data

is

contained

herein.

Neither

this

document

nor

the

information

contained herein shall be disclosed

to

others

for

manufacturing

or

any

other

purpose except

as

authorized in

writing

by

Sparta Electronic Corporation.

~1973

098-4510

$5.00

~

;g[p~~lf~

~

ELECTRONIC

CORPORATION

!5851

FLORIN·PERKINS

ROAD

SACRAMENTO,

CALIFORNIA

9582

8

A

DIVISIO

N

or

COM

P

UTE

R EQ

UI

PM

ENT

CORPORA

TIO

N

www.SteamPoweredRadio.Com

I . . . .

\ ·..

.

Dear

Customer:-

.

,

Careful

attcnt1011

to

Qu::ility

Control

is

another

important

clement

in

our

daily

effort

to

provide

y

ou.

vilh

excellence

of

product

and

service.

At

SPARTA

each

piece

of

equipment

and

sub-assembly

:receives

numerous

insp

e

ctions

and

tests

in

the

process

of

production.

The

final

results

·must

mcastirc

·

within

our

ex.acting

requi

re

ments

before

it

is

shipped

to

you.

Listed

bclo,~

are

just

a

few

of

the

major-

;:c

heck

points

am!

tests

this

partic\1br

piece

of

equipment

has

received

before

being

prepared

for

shi7)·· .

;:.:

ncnt.

Should

you

note

any

discrep

an

cy

in

the

appearance

or

operation

of

your

SPARTA

Product

or

if

yo

:h

ave

any

general

comments

as

to

how

we

might

be

of

greater

service.

your

sugge

_

stions

will

be

greatly

:a

ppreciated..

. · .

.

.

..

CENTURY

SERIES .

..

MODEL

NO:

._f'~/~ - .

:PURCHASER .

l(e.4~

.

----

.

__

·.

_DATE:

_±~

-~/ -

-

7

✓

- -

- -

-

_

:S

ERIAL

NO..

//73

CALID.

BY

~-

~

--

_:__

•

____________

✓

_

-

_Intc.mal

Mech.

&

Soldering

···-

-

~·

--·

.·.

.

..

.

FREQ:

RESPONSE

v

Mech.

oper?,tion

&

Press

Roller

Adj.

MONO LEF'T

CHA

NN

EL

--------------

v

Fuce

&

Power

Supply

Volt

ag

e

(Playback)·

-------------,-

.

50Hz

-~S--

db

75Hz

1J

db

150

Hz

+, b

db

✓

Azimuth

Adj.

(Play

Back)

--------------

v-

Equalization

set

(Play

back)-

··

· •·

,....

IL__

...,__~

t;J

- ~

--d-b_m_R

__

_

___

_

dbrn.

Output

!-evcl

(600

ohms)'

•_·

~L

__:S--6

'JJt!5,

R

Si

g

nal/Noise

.

.

-··

ow

&

Flutter--

·

_:

;··

·-

LL~

w

.

✓

c

✓

T

ue

Amp.

Sensitivity

.:-.

one

Output

· · ·• ·

;:

✓

R

emote

Contr

ol

Start

&

Stop

-:..

✓

.

15

0

Hz

. .

End

.

of

M

es

sa

ge

&J

nd.

Lamp

•

use+

Power

Su

pp

ly

Voltage

(Record)

-

as

Trap

Adj.

(Record)

'

as

Trap

Adj.

fCµe

) _.,

_':·.:

- . : ·

.......-

F

✓

Bi

v

Bi

......--

Bi

as

·Curr\.;nt

Adj.

(Rc~ord)

1,.,-""'

Bi

as

Current

Adj.

(Cue)

V A

300

Hz =

4.00

Hz

~

600

Hz

-,

£

. l

KHz

szS

db

db

·

db

db

_

2.

5

KHz

-b

<t-

db

5KHz

*db

8'KHz

: db

. lC ,

KHz

db

12

KHz_---'---

__

db

15

KHz

-,

/,

db

RIGHT CBANNE L

STE

lfEO-

vE

t,A

zimuth

Adj.

(Record)

quaHzation

(Record)

·

·.

f

udio

Current

VU

Meter

Calib~

·

.·

· . · S0I·Iz

db

A.

__._

.

:

.

......

J.

.J'7D

v-f'.>

i

st.

Total

System

.

,

·V B

~

C

S"IK

~ -

..

..

. ·

.

Stereo

Un-its

fi}IJ

I "

.

,:

. . . • .

.

£...---"

150

Aux.

Cue

(Record)

emote

Control

.

0{

v1

n

put

Source-

--

.

'

IC:-

~

.,c_

Encoder

R/PB

Crosstalk

Cuc

to

Prog

Meter

Cal:

l·KHz

150

Hz

Bias

R

un

In

.

Channel

Separation

Plwsing

_

..

.

----'l<----

75Hz .

db

-------

. 150Hz

db

--

300

Hz

db

400

Hz

·

db

600.Hz

db

1

KHz

db

2. 5

KHz

db

S KHz dh

8 KHz db

10

KHz

db

~

12

KHz

db

-------

. 15

KHz

clb

..

..

www.SteamPoweredRadio.Com

•

CONTENTS

CENTURY

SERIES

FEATURES

INTRODUCTION ................................

GENERAL

DESCRIPTION ........................ 1

3

SPE

CI

FICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLATION

UNPACKING

ENCLOSURES

•••••••••••••••••••••••••••

0

•••••••

AUDIO &

CONTROL

CONNECTIONS

OPERATION

••••••••••••••••••••••

0

••

CARTRIDGE INSERTION

READY INDICATION ..............................

CARTRIDGE PLAY

CARTRIDGE

STOP

..............................

6

6

7

8

8

8

8

CARTRIDGE

RELEASE

• • • • • • • • • • • • • • • • • • • • • • • • • • •• 9

E.

0.

M. INDICATION ............................ 9

www.SteamPoweredRadio.Com

ELECTRONIC ADJUSTMENTS

AUDIO

LEVEL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

EQUALIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

STOP TONE

SENSITIVITY.....

• • . • • • • • • • • • • • • • . • 10

E.

0.

M.

TONE SENSITIVITY • • • • • • • • • • • • • • • • • • • • 11

MECHANICAL ADJUSTMENTS

(See

Figure

1)

SOLENOID

POSITION..........................

12

PINCH

ROLLER PRESSURE • • • • • • • • • • • • • . • • • • • • • • 12

CARTRIDGE

RELEASE

• • • • • • • . • • • • • • • • • • • • • • • • • • 12

ARMATURE

RETURN STOP • • • • • • • • • • • • • • • • • • • • • • 13

ROTARY

LIFT MECHANISM • • • • • • • • . • • • • • • • • • • • • 13

FLYWHEEL THRUST BEARING • • • • • • • • • • • • • • • • • • • 13

FIG

URE

1 - UPPER VIEW MECHANISM • • • • • • • • • • • 14

SOLENOID ASSEMBLY DRAWING

(P-3

8)

• • • • • • • • • • 14 a

REPLACEMENT & ALIGNMENT OF

TAPE

HEADS

(See

drawing

P-120487)

TRACK

CONFIGURATION.......................

15

HEAD

LOCATION..................

.

...........

15

TRUE

TANGENT.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

HEAD REPLACEMENT • • • • • • • • • • • • • • • • • • • • • • • • • • 16

HEIGHT ADJUSTMENT • • • . • • • • • • • • • • • • • • • • • • • • • 16

ZENITH ADJUSTMENT • • • • • . • • • • • • • • • • • • • • • • • • • 17

AZIMUTH ADJUSTMENT. • • • • • • • • • . • • • • • • • • • • • • • 17

www.SteamPoweredRadio.Com

.,..

RECORD HEAD ALIGNMENT • • • • • • • • • • • • • • • • • • • • • • •

17

STEREO

HEAD ALIGNMENT • • • • • • • • • • • • • • • • • • • • • • • 18

STEREO

CARTRIOOE CONSIDERATIONS

21

MAINTENANCE

CLEANING ......................................

22

HEAD DEMAGNETIZING • •• • •• • • • • • • • • • • • •• • • ••• • • 22

CARTRI.D(;E CARE

•••••......•.•.•.•.•••••.••.....

22

BELT

CHANGE • • • • . • • • . . . . . . . • . • • • • . . . • • . . . . • . • . 23

CIRCUIT DESCRIPTIONS

POWER SUPPLIES (See

drawing

S-154)

• • • • • • • • • • • • • • 24

CONTROL CIRCUIT (See

drawing

S-150)

• • • • • • • • • • • • • 25

CUE TONE

DETECTORS

(See

drawing

S-156).........

26

CUE LOCKOUT (See

drawing

S-150

&

S-156)

PROORAM AMPLIFIER (See

drawing

S-157)

WARRANTY

SCHEMATICS

S-154

POWER SUPPLIES

S-150

CONTROL CIRCUIT

S-156

CUE TONE

DETECTORS

S-157

PROORAM AMPLIFIER

P-34

INTERCONNECTING DIAGRAM

•••••

0

•••

27

28

www.SteamPoweredRadio.Com

INTRODUCTION

The

Century

Series

of

cartridge

reproducers

are

intended

for

broadcast

and

industrial

applications

requiring

continuous

duty

capability

and

highest

quality

performance.

Each

model

meets

or

exceeds

all

applicable

NPiB

Standards.

The

Century

Series

tape

transport

has

been

specifically

designed

to

accept

the

NAB

Type

A

(Model

300)

cartridges,

and

delivers

optimum

performance

with

loads

of

up

to

10

1/2

minutes

of

lubricated

tape.

Monaural

reproducers

use

a

standard

_2

track,

single

head

configuration,

with

the

program

amplifier

connected

to

the

upper

track,

and

the

cue

amplifier

connected

to

the

lower

track.

Stereo

reproducers

use

the

NAB

standard

3

track

head.

The

top

track

is

the

left

program

channel;

the

lower

track

is

for

cue

tones.

In

the

recording

process,

a

1000

Hz

(cycles

per

second)

tone,

of

about

1

second

duration,

is

automatically

recorded

on

the

cue

track

each

time

the

cartridge

transport

is

started

in

the

record

mode.

Each

reproducer

is

furnished

with

a

detector

circuit

which

responds

to

this

tone

by

stopping

the

transport.

This

cues

the

cartridge

to

the

beginning

of

the

announcement.

The

1000

Hz

toPe

is

called

the

primary

cue

tone.

Models

4515

and

4525

have

an

additional

detector

circuit

which

responds

to

the

secondary

cue

tone

frequency

of

150

Hz.

This

tone

is

popularly

called

the

E.

0.

M.

tone,

standing

for

"end-of-message",

and

is

used

in

automation

and

for

other

control

or

signaling

functions.

When

a

150

Hz

tone

is

detected,

a

relay

contact

closure

is

connected

to

terminals

at

the

rear

of

the

reproducer

-(1)

www.SteamPoweredRadio.Com

chassis.

This

signal

can

be

used

to

advance

an

automation

syst

e m

to

the

next

"event"

or

turn

on

a

light

in

a

nearby

studio

as

a

signal

to

an

announcer

to

begin

speaking

etc.

On

Century

Series

Recorders,

the

E.O.M.

tone

can

be

put

on

the

cue

track

during

either

play

or

record

conditions,

making

it

possible

to

audition

a

cartridge

before

placing

the

tone

on

the

cue

track.

Several

mounting

configurations

are

available

for

Century

Series

equipm

e

nt:

Single

table

top,

with

flip

top

cover

Dual

table

top,

with

flip

top

cover

Triple

rack

mount,

with

panel

lock

screws.

Quad

custom

cabinet,

with

walnut

grain

finish.

Bottom

plates

with

no-mar

rubber

feet

are

provided

with

table-top

configurati

o

ns,

and

must

be

removed

for

use

in

the

triple

rack

mount

or

quad

cabinet.

Each

module

can

slide

forward

in

the

rack

mount

and

quad

cabinet

for

convenient

access

to

all

adjustments

and

for

head

cleaning.

Additionally,

the

rack

mount

has

front

panel

lock

screws

to

secure

the

modules,

and

removable

tabs

on

the

rear

of'

the

p.

c.

board

covers,

to

prevent

the

modules

from

being

inadvertently

removed

from

the

rack.

Record

modules

are

the

same

size

as

the

reproducer

modules

and

can

mount

in

any

of

the

multiple

module

housings.

When

a

record

module

is

used,

it

is

attached

to

the

right

side

of

a

reproducer

module

(as

viewed

from

the

front)

with

hardware

provided,

and

the

two

modules

slide

in

and

out

of

their

housing

as

one

unit.

(2)

www.SteamPoweredRadio.Com

GENERAL

DESCRIPTION

Four

basic

models

are

available:

4510

-mono

reproducer,

with

standard

1

kHz

stop

tone

detector.

4515

-mono

re

producer,

with

added

150

Hz

EOM

tone

detector.

4520

-

stereo

reproducer,

with

standard

1

kHz

stop

tone

detector.

4525

-

stereo

reproducer,

with

added

150

Hz

EOM

tone

detector.

All

electronics

for

audio

reproduction

and

tone

detection

are

on

a

single

plug-in

printed

circuit

board,

as

is

the

power

supply

regulator.

Thus,

each

model

uses

the

same

basic

p.c.

board,

less

unneeded

circuit

components.

All

electronic

adjustments

are

accessible

through

the

p.

c.

board

cover.

Integrated

circuits

have

been

used

in

both

the

program

and

cue

amplifiers,

to

provide

best

performance,

while

minimizing

the

number

of

components

required.

The

IC's

are

interchangeable

between

all

circuits

and

are

plug-in,

for

ease

of

trouble

shooting

in

case

of

a

malfunction.

A 1700 rpm

hysteresis

syncronous

motor

is

utilized

in

Century

Series

reproducers,

and

runs

only

when

a

cartridge

is

inserted.

The

inherently

smoother

high

speed

motor

is

coupled

to

the

flywheel-driven

capstan

via

dual

flutter-filter

belts,

resulting

in

unsurpassed

flutter

and

wow

characteristics,

plus

cool-running

operation.

Monaural

reproducers

can

be

field-converted

to

stereo

operation,

if

desired.

All

units

are

wired

for

stereo

operation,

and

require

only

the

stereo

p.c.

board,

stereo

head,

an

additional

output

transformer,

and

a 2

channel

LCR

to

replace

the

single

channel

LCR

used

for

audio

switching.

(3)

www.SteamPoweredRadio.Com

Each

reproducer

is

also

factory

wired

for

later

connection

to

a

record

module,

in

case

additional

record

capacity

is

required.

The

price

of

the

record

module

includes

a

record

head

and

head

mount.

The

record

modules

are

available

in

four

basic

models.

4710

-

mono

record,

with

standard

1000

Hz

stop

tone

generator.

471

S -

mono

record,

with

added

1

SO

Hz

EOM

tone

generator

4720 -

stareo

record,

with

standard

1000

Hz

stop

tone

generator.

4725

-

stereo

record,

with

added

150

Hz

EOM

tone

generator.

Remote

Control

of

start/stop

functions

is

available

on

the

barrier

strip

at

the

rear

of

each

reproducer

module.

Audio

outputs

are

also

taken

from

the

barrier

strip.

Additionally,

an

amplified

cue

channel

output

is

provided,

which

can

be

used

to

check

cue

tones,

as

well

as

connect

to

an

automatic

logging

system

for

automation

applications.

If

the

optional

150

Hz

EOM

tone

detector

is

included,

its

contact

closure

appears

at

barrier

strip

terminals

also.

(4)

www.SteamPoweredRadio.Com

Frequency

Response:

Noise:

Distortion:

Wow

&

Flutter:

Equalization:

Audio Output:

Cue

Signals:

Tape

Speed:

Playing

Time:

Remote

Control:

Mounting:

Dimensions:

Power:

Weight:

SPECIFICATIOl'S

50-15,

000

Hz±

2db

55db

or

more

below

saturation

recording

(mono)

52db

or

more

below

saturation

recording

(stereo)

2%

or

less

0.2%

or

less

NAB

(adjustable)

600

ohms

balanced,

+6

dbm

nominal,

+16

dbm

maximum

NAB

primary

cue

(stop) l KHz

standard;

second

-

·

ary

cue

(EOM) 150 Hz

optional;

EOM

signal

provided

as

Form

A

contact

closure.

(5)

7.

5

ips;

shielded

hysteresis

synchronous

motor;

non-magnetic

dynamically

balanced

flywheel;

multiple

belt

flutter-filter

drive

system.

2

seconds

to

10-1/2

minutes,

NAB

size

A

cartridge

All

functions

available

Single

desk,

dual

desk,

7"

rack

mount

adaptor

for

3

modules,

custom

walnut

grain

cabinet

for

4

modules

(15" H x

14"

W x 15

1/2"

D)

Playback

module

and

record

amplifier

module

each

6"

H x

5-3/4"

W x

14"

D

117

volts,

60Hz

(available

for

other

power

line

standards

on

special

order)

16

lbs,

including

lid

www.SteamPoweredRadio.Com

INSTALIATION

UNPACKING:

After

removing

the

equipment

from

the

shipping

container,

carefully

inspect

it

for

shipping

damage.

If

damage

is

discovered,

make

a

written

request

to

the

carrier

for

inspection,

and

retain

all

cartons

and

fillers.

The

carrier

is

responsible

for

any

damage

incurred

in

shipping,

but

the

claim

must

be

promptly

filed

by

the

receiver.

ENCLOSURES:

Table

top

units

are

shipped

with

lids

installed.

fiowever,

Triple

Rack

Mounts

and

Quad

Cabinets

are

shipped

separately

from

the

transport

modules.

The

modules

slide

in

from

the

front,

and

in

the

Triple

Rack

Mount

can

be

fastened

in

place

by

turning

the

front

panel

lock

screws

clockwise.

There

is

a

tab

on

the

rear

of

the

p.

c.

board

cover

on

rack

mounted

units

which

can

be

turned

upward

to

prevent

accidental

removal.

( 6)

www.SteamPoweredRadio.Com

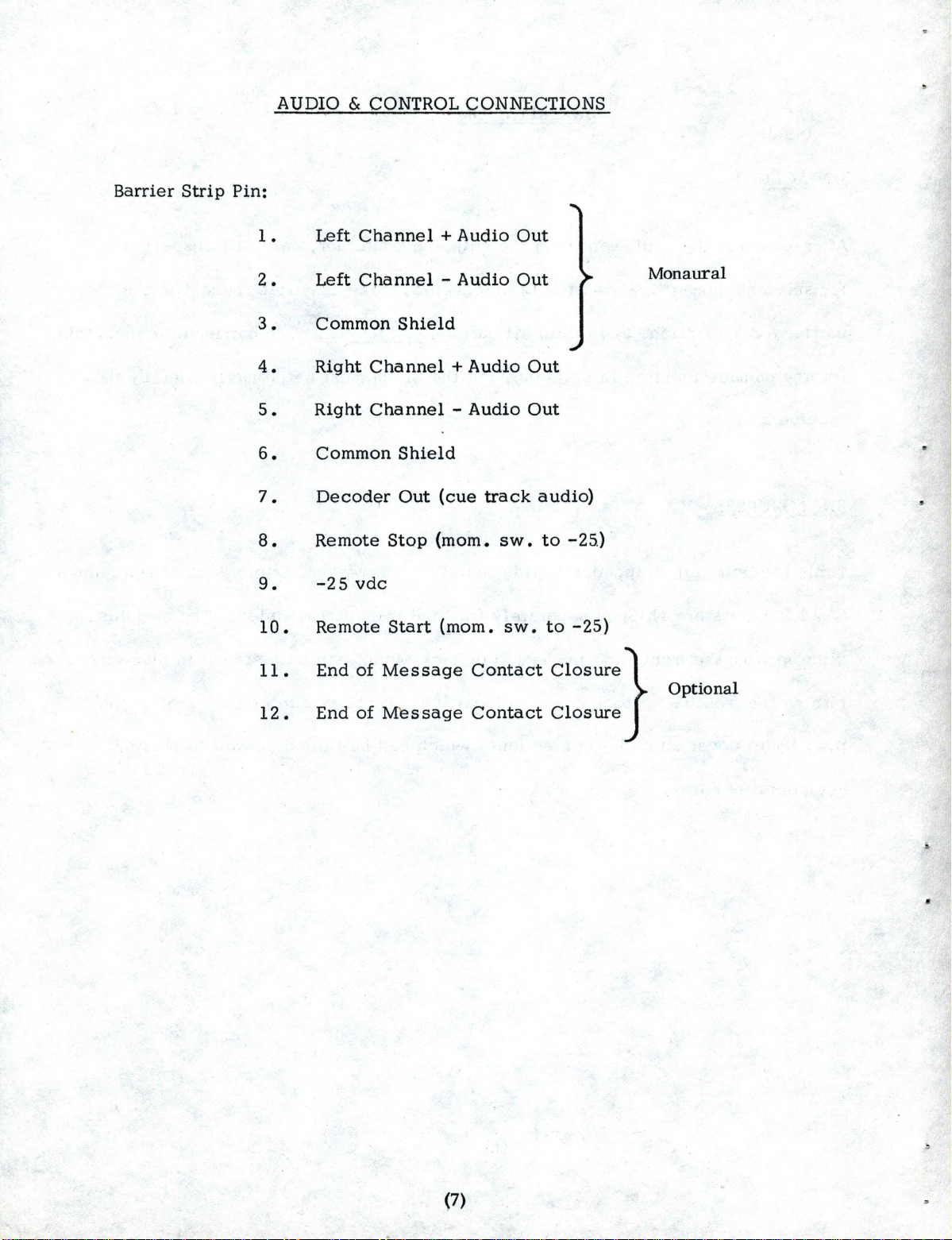

AUDIO & CONTROL

CONNECTIONS

Barrier

Strip

Pin:

1.

Left

Channel

+

Audio

Out

2.

Left

Channel

-

Audio

Out

Monaural

3.

Common

Shield

4.

Right

Channel

+

Audio

Out

5.

Right

Channel

-

Audio

Out

6.

Common

Shield

7.

Decod~r

Out

(cue

track

audio)

8.

Remote

Stop

(mom.

sw.

to

-25

.) ·

9.

-2

5

vdc

10.

Remote

Start

(mom.

sw.

to

-25)

End

of

Message

Contact

Closure}

Optional

End

of

Message

Contact

Closure

12.

(7)

www.SteamPoweredRadio.Com

CARTRIDGE

INSERTION:

READY

INDICATION:

CARTRIDGE Pl.A

Y:

CARTRIDGE

STOP:

OPERATION

The

cartridge

should

be

inserted

firmly

so

as

to

bring

the

pinch

roller

fully

into

position.

The

cartridge

pushes

the

contact

arm

only

about

3/8"

and

this

limited

motion

is

translated

into

nearly

90

degrees

rotation

of

the

pinch

roller

shaft,

thus

a

certain

amount

of

force

is

required.

When

a

cartridge

is

inserted

the

Touchbar

glows

red

on

the

left

side,

indicating

a

"ready"

condition.

The

motor

starts

when

the

cartridge

is

inserted

and

requires

approximately

2

1/2

seconds

to

reach

operating

speed.

Depress

the

right

side

of

the

Touchbar

to

start

the

cartridge.

The

bar

will

glow

green,

indicating

a

"play"

condition.

The

Touchbar

should

not

be

tapped

to

start

a

cartridge,

as

the

spring

tension

of

the

switch

contacts

may

cause

the

bar

to

bounce

back

and

actuate

the

stop

contacts

momentarily.

Since

a

stop

tone

is

automatically

recorded

at

the

beginning

of

each

announcement,

the

cartridge

will

stop

itself

after

playing,

cued

to

the

beginning

of

the

announcement.

It

is

also

possible

to

stop

the

cartridge

manually

by

moment-

arily

depressing

the

left

side

of

the

Touchbar.

www.SteamPoweredRadio.Com

CARTRIDGE RELEASE :

E.O.M.

INDICATION:

To

remove

the

cartridge,

push

the

Release

Button

located

to

the

side

of

the

cartridge

slot.

This

retracts

the

pinch

roller

and

allows

the

cartridge

to

be

withdrawn.

On

later

models

the

cartridge

can

also

be

released

by

lifting

the

.

end

of

the

cartridge

that

extends

through

the

front

panel.

Pause

momentarily

to

let

the

pinch

roller

retract

before

withdrawing

the

cartridge.

The

cartridge

cannot

be

released

while

being

played.

On

reproducers

equipped

with

the

optional

secondary

cue

tone

detector

(end-of-message

signal)

a

visual

indication

of

the

presence

of

the

tone

is

provided.

When

the

tone

is

detected,

the

left

side

of

the

Touchbar

glows

red

for

the

duration

of

the

tone.

(9)

www.SteamPoweredRadio.Com

AUDIO

LEVEL:

EQUALIZATION:

ELECTRONIC ADJUSTMENTS

The

ou~put

level

of

the

program

amplifier

(s)

is

factory

set

to

+6dbm.

At

time

of

installation

it

may

be

necessary

to

change

this

setting.

R24

is

the

left

channel

(mono)

gain

control;

R6

is

the

right

chartnel

gain

control.

Both

can

be

reached

through

the

access

hole

in

the

p.

c.

board

cover.

Do

not

disturb

the

setting

of

the

equalization

control(s).

The

program

amplifier(s)

have

been

adjusted

to

conform

\!Vi.th

the

NAB

Standard

Reprodu

c

ing

Characteristic.

No

further

adjustment

should

be

required

until

considerable

head

wear

.

has

occurred.

The

control(s)

should

then

be

adjusted

for

flattest

response

during

playback

of

a

frequency

response

test

cartridge.

If

no

test

cartridge

is

available,

the

equalization

should

be

set

to

produce

natural

sounding

high

frequencies.

R23

is

the

left

channel

(mono)

equalizati

on

control.

Both

can

be

reached

through

the

access

hole

in

the

p.

c.

board

cover.

STOP TONE SENSITIVITY:

The

1000

Hz

primary

tone

detector

sensitivity

is

adjusted

by

RS.

This

control

is

factory

set

to

operate

the

stop

circuit

with

a

tone

l0db

lower

than

the

NAB

specified

tone

level.

The

control

can

be

reached

through

an

access

hole

in

the

p.

c.

board

cover,

if

adjustment

is

necessary.

(10)

www.SteamPoweredRadio.Com

E.

0.

M.

TONE SENSITIVITY:

The

150

Hz

secondary

tone

detector

sensitivity

is

adjusted

by

R4.

This

control

is

factory

set

to

close

relay

KZ

with

a

tone

l0db

lower

than

the

NAB

specified

tone

level.

The

control

can

be

reached

through

an

access

hole

in

the

p.c.

board

cover,

if

adjustment

is

necessary.

An

accessory

a-c

outlet

is

provided

on

the

rear

of

each

reproducer

module,

so

that

a

single

power

cord

can

supply

operating

voltage

to

a

group

of

modules.

Each

module

is

simply

plugged

into

its

neighbor,

and

the

power

cord

from

the

last

one

plugs

into

the

wall

outlet.

The

accessory

outlets

are

not

fused

or

switched.

(11)

www.SteamPoweredRadio.Com

MECHANICAL ADJUSTMENTS

(See

Figure

3)

The

following

step

by

step

adjustments

apply

only

to

Century

Series

decks

utilizing

the

Push/Lift

Release.

SOLENOID POSITION:

(Normally

required

only

when

replacing

solenoid)

First

loosen

catch

plate

screw,

then

raise

the

pinch

roller

and

engage

the

pivot

arm

with

the

catch

plate.

Move

the

armature

and

plunger

assembly

toward

the

solenoid

until

the

armature

roller

contacts

the

solenoid.

Loosen

the

mounting

screws

and

position

the

solenoid

so

that

the

armature

and

plunger

assembly

are

on

parallel

planes.

Tighten

all

four

screws.

Release

the

pinch

roller

and

check

for

free

movement

of

the

plunger

throughout

its

range

of

travel.

Verify

the

position

after

tightening

the

screws.

PINCH

ROLLER

PRESSURE:

Make

adjustments

in

the

following

sequence.

(a)

Raise

the

pinch

roller

and

operate

start

switch.

(b)

Loosen

the

catch

plate

screw.

(c)

Insert

screwdriver

blade

into

the

notches

in

the

edge

of

the

rocker

arm

and

catch

plate.

(d)

Twist

the

blade

counter-clockwise

to

increase

pinch

roller

pressure.

(e)

Tighten

the

catch

plate

screw

when

the

capstan

indents

the

pinch

roEer

about

1/64"

(indentation

barely

visible).

CARTRIDGE

RELEASE:

Set

the

release

adjust

screw

so

that

the

pivot

arm

is

held

by

the

full

thickness

of

the

catch

plate.

First

loosen

the

lock

nut,

then

turn

the

screw

until

the

pivot

arm

is

even

with

top

surface

of

the

catch

plate.

While

making

the

adjustment,

hold

forefinger

on

top

side

of

lift

release

arm

using

downward

pressure.

This

will

allow

the

adjustment

to

be

made

without

tripping

the

release

mechanism.

Holding

screw

in

adjusted

position,

tighten

the

lock

nut.

(12)

www.SteamPoweredRadio.Com

ARMATURE

RETURN

STOP:

Loosen

the

return

stop

screw

and

position

the

stop

so

that

the

lip

of

the

stop

locks

the

rocker

arm

in

the

down

position

while

the

solenoid

is

energized,

but

clears

the

rocker

arm

completely

when

the

solenoid

releases.

The

armature

travel

length

should

be

about

1/8".

Note

that

the

rocker

arm

must

go

under

the

lip

of

the

armature

return

stop

when

the

armature

is

in

contact

with

the

solenoid

--

this

inhibits

the

push

and

lift

releases

from

operating

while

a

cartridge

is

being

played.

ROTARY

LIFT MECHANISM: Turn

rotary

lift

adjusting

screw

clockwise

until

almost

at

end

of

travel

(within

1/8").

Back

screw

out

in

small

increments

until

a

cartridge

held

against

the

stop

screws

will

barely

pull

tape

(solenoid

turned

off).

Now,

turn

screw

clockwise

1/8

turn.

The

cartridge

should

not

pull

tape

with

this

setting.

Try

several

cartridges

to

confirm

that

adjustment

is

correct.

Recheck

adjustment

of

pinch

roller.

FLYWHEEL THRUST BEARING: The

flywheel

thrust

bearing

is

a

nylon

screw

in

self-

locking

threads

in

the

support

plate

directly

below

the

flywheel.

A

moderate

vertical

force

exerted

on

the

capstan

should

result

in

a

noticeable

movement

of

the

shaft

not

to

exceed

1/3

2

of

an

inch.

If

adjustment

of

the

vertical

play

is

required,

a

large

blade

screwdriver

should

be

used

to

prevent

damage

to

the

nylon

screw.

If

the

nylon

screw

is

screwed

in

just

far

enough

to

remove

all

play

and

then

backed

out

1/4

turn,

satisfactory

operation

should

result.

{13)

•

Other manuals for CENTURY Series

1

This manual suits for next models

4