Spartan Equipment SC2170 User manual

Wood Chipper 4.5”

For

Mini Skid Steer

Loaders

Operator’s Manual

Set-Up Assembly and

Parts Information

D

Do

o

n

no

ot

t

u

us

se

e

o

or

r

o

op

pe

er

ra

at

te

e

t

th

hi

is

s

m

ma

ac

ch

hi

in

ne

e

u

un

nt

ti

il

l

t

th

hi

is

s

manual has been read and understood.

Read the Operation & Maintenance Manual entirely. When you see this

symbol, the subsequent instructions and warnings are serious –follow

without exception. Your life and the lives of others depend on it!

IMPORTANT

If this machine is used by an employee or is loaned or

rented to others, make certain that the operator(s) prior to

operating:

•

Is instructed in safe and proper use.

•

Reviews and understands the operation and main-tenance

manual(s) pertaining to the machine.

Remember, the operator is responsible for the safe

operation and maintenance of the machine. Most accidents

can be prevented. Good safety practices not only protect

you, but also the people around you.

NOTE: Spartan Equipment reserves the right to make improvements

in design or changes in specifications at any time without notice and

without incurring any obligations to install them on units previously sold.

Before You Begin

DEAR SPARTAN EQUIPMENT

CUSTOMER

Thank you for purchasing a Spartan Equipment product. The Spartan Equipment line is designed, tested, and

manufactured to give years of dependable performance. To keep your machine operating at peak efficiency, it is

necessary to adjust it correctly and make regular inspections. The following pages will assist you in the operation and

maintenance of your machine. Please read and understand this manual before operating your machine.

If you have any questions or comments about this manual, please call us toll-free at 1.888.888.1085.

If you have any questions or problems with your machine, please call or write your local authorized Spartan

Equipment

Dealer.

This document is based on information available at the time of its publication. Spartan Equipment is continually

making improvements and developing new equipment. In doing so, we reserve the right to make changes or add

improvements to our product without obligation for equipment previously sold.

PLEASE SEND US YOUR WARRANTY CARD

Awarranty card is included in your owner's kit packaged with your machine. Please take the time to fill in the information

requested on the card. When you send your completed card to us, we will register your machine and start your coverage

under our limited warranty or go to bearcatproducts.com/warranty/warranty-registration/.

FOR MACHINE SERVICE OR PARTS:

For service assistance, contact your nearest authorized

Spartan Equipment dealer or the factory. For parts,

contact your authorized dealer. Your dealer will need to

know the serial number of your machine to provide the

most efficient service. See below for information on how

to identify and record the serial number for your machine.

FOR ENGINE SERVICE OR PARTS:

Forengineservice or

parts,

contact your nearestauthorized

engine dealer. Spartan Equipment does not handle any

parts, repairs or warranties for engines.

ORDERING PARTS

Only genuine Spartan Equipment replacement parts

should be used to repair the machine. Replacement parts

manufactured by others could present safety hazards,

even though they may fit on this machine. Replacement

parts are available from your Spartan Equipment dealer.

Provide the following when ordering parts:

The SERIAL NUMBER or VIN of your machine.

The PART NUMBER of the part.

The PART DESCRIPTION.

The QUANTITYneeded.

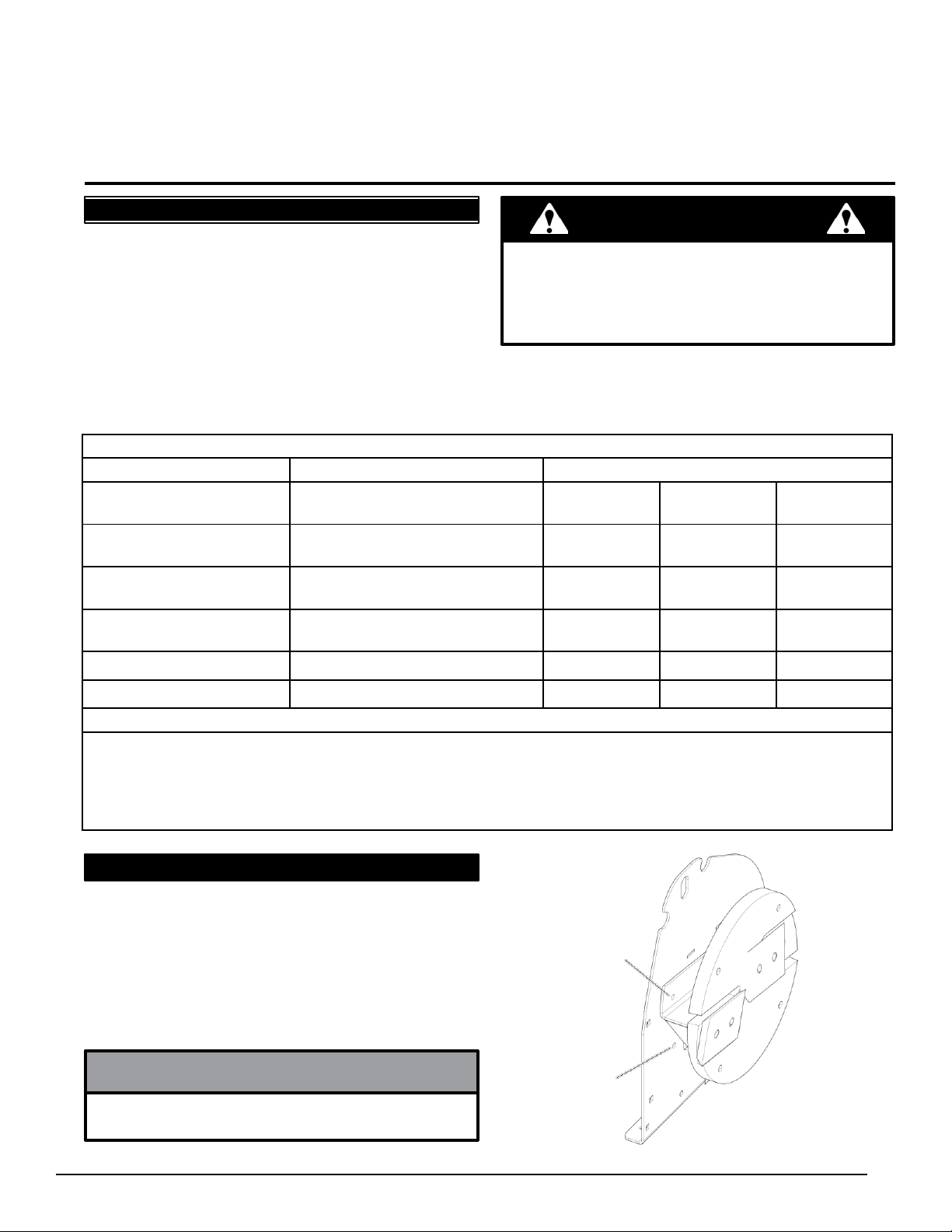

SERIAL NUMBER LOCATION

Please record the serial number in the space provided

and on the warranty and registration card.

MANUFACTURED IN the U.S.A.

SERIAL NUMBER

SERIAL NUMBER

XXXXXX

LIMITED

WARRANTY

This warranty applies to all Spartan Equipment original owner each new Spartan Equipment product to be free

from defects

in material and workmanship,under normal use and service.The warranty shall extend, from date of purchase,

3 years (U.S. and Canada only (2 years outside U.S. and Canada)) for Consumer use of the product, 1 year

for Commercial applications and 6 months for Rental applications. Replacement parts and accessories are

warranted for (90) days from date of installation.

"Consumer" defined as: complete unit for personal, residential or non-income producing use.

"Commercial" defined as: complete unit for commercial, institutional, property management, agricultural,

horticultural or income producing use.

"Rental" defined as: complete unit for rental purposes to produce income.

*Models SC2170, SC2206 & SC3206 are classified as Consumer grade products and will not qualify for

warranty coverage if used for Commercial or Rental purposes.

The product is warranted to the original owner by either a completed warranty registration on file at Spartan

Equipment, Inc. and/or proof of sale. Warranty coverage begins on the date of purchase. The warranty

registration can be registered on-line by visiting

http://bearcatproducts.com/warranty/warrantyregistration/

or

the paper card completed and returned to Spartan Equipment, Inc.

In the event of a failure, return the product, at your cost, along with proof of purchase to the selling Spartan

Equipment dealer. Spartan Equipment, Inc. will, at its option, repair or replace any parts found to be defective

in material or workmanship. Warranty on any repairs will not extend beyond the product warranty. Repair or

attempted repair by anyone other than an authorized Spartan Equipment dealer as well as subsequent failure

or damage that may occur as a result of that work will not be paid under this warranty. Spartan Equipment,

Inc. does not warrant replacement components not manufactured or sold by Spartan Equipment, Inc.

1. This warranty applies only to parts or components that are defective in material or workmanship.

2. This warrantydoes not cover normalwear items including, butnot limitedto: bearings, belts, pulleys,filters,

chipper blades, shredder flails or knives.

3. This warranty does not cover normal maintenance, service or adjustments.

4. This warranty does not cover depreciation or damage due to misuse, negligence, accident or improper

maintenance.

5. This warranty does not cover damage due to improper setup, installation or adjustment.

6. This warranty does not cover damage due to unauthorized modifications of the product.

7. Engines are warranted by the respective engine manufacturer and are not covered by this warranty.

Spartan Equipment, Inc. is not liable for any property damage, personal injury or death resulting from the

unauthorized modification or alteration of an Spartan Equipment product or from the owner's failure to

assemble, install, maintain or operate the product in accordance with the provisions of the Owner's manual.

Spartan Equipment, Inc. is not liable for indirect, incidental or consequential damages or injuries including but

not

limited to loss of crops, loss of profits, rental of substitute equipment or other commercial loss.

This warranty gives you specific legal rights. You may have other rights that may vary from area to area.

Spartan Equipment, Inc. makes no warranties, representations or promises, expressed or implied as to

the performance of its products other than those set forth in this warranty. Neither the dealer nor any other

person has any authority to make any representations, warranties or promises on behalf of Spartan

Equipment, Inc. or to modify the terms or limitations of this warranty in any way. Spartan Equipment, Inc., at

its discretion, may periodically offer limited, written enhancements to this warranty.

SPARTAN EQUIPMENT, INC. RESERVES THE RIGHT TO CHANGE THE DESIGN AND/OR

SPECIFICATIONS OF ITS PRODUCTS AT ANY TIME WITHOUT OBLIGATION TO PREVIOUS

PURCHASERS OF ITS PRODUCTS.

iv

4.5 INCH HYDRAULIC CHIPPER

TABLE OF CONTENTS

SAFETY.........................................................................

1

1.1 SAFETY ALERT

SYMBOL

........................................

1

1.2 BEFORE

OPERATING..............................................

1

1.3 OPERATION

SAFETY...............................................

2

1.4 MAINTENANCE & STORAGE

SAFETY

..................2

1.5 SAFETY DECAL LOCATIONS

.................................

2

1.6 SAFETY DECALS

.....................................................

3

ASSEMBL

Y

...................................................................

4

2.1 DISCHARGE ASSEMBL

Y

.........................................

4

2.2 CHUTE ASSEMBLY

..................................................

4

FEATURES &

CONTROLS..........................................

5

OPERATION

.................................................................

6

4.1 RECOMMENDED HYDRAULIC FLOW RA

TES

......6

4.2 MOUNTING THE CHIPPER TO A UTILITY

LOADER

...........................................................................

6

4.3 REMOVING THE CHIPPER FROM A UTILITY

LOADER

...........................................................................

6

4.4 CONNECTING COUPLERS

.....................................

7

4.5 STARTING THE CHIPPER

.......................................

7

4.6 STOPPING THE CHIPPER

......................................

7

4.7 OPERATING THE CHIPPER

....................................

8

SERVICE & MAINTENANCE

......................................

9

5.1 MAINTENANCE SCHEDULE

...................................

9

5.2 INSTALLING THE ROTOR LOCK

............................

9

5.3 CHIPPER BLADE MAINTENANCE

.......................

10

5.4 REMOVING THE BLADES

.....................................

10

5.5 SHARPENING THE BLADES

.................................

10

5.6 INSTALLING THE BLADES.....................................11

5.7 SETTING BLADE CLEARANCE .............................11

5.8

LUBRICATION

..........................................................11

5.9 REPLACING ROTOR

BEARINGS .........................

12

5.10 CLEARING A PLUGGED

ROTOR........................

12

TROUBLESHOOTING...............................................

13

SPECIFICATIONS

......................................................

14

BOLT

TORQUE..............................................................

15

P

ARTS

.........................................................................

17

8.1 PARTS ORDERING

INFORMATION .....................

17

8.2 REPLACEMENTS

PARTS ......................................

17

8.3 BASE & HOUSING (SN: E02736 AND BELOW) ... 18

8.3 BASE & HOUSING (SN: E04641 - CURRENT) ..... 20

8.4 ROTOR & HYDRAULICS

........................................

22

8.5

ATTACHMENTS.......................................................

24

8.6 SERVICE PARTS &

OPTIONS

...............................

26

4.5 INCH HYDRAULIC CHIPPER

8

1

Section SAFETY

1

.

1

SAFETY

ALERT

SYMBOL

The Owner/Operator's manual uses this symbol to alert

you of potential hazards. Whenever you see this symbol,

read and obey the safety message that follows it. Failure

to obey the safety message could result in personal injury,

death or property damage.

DANGER

Indicates an imminently hazardous situation that, if not

avoided, will result in death or serious injury.

W

ARNING

Indicates an imminently hazardous situation that, if not

avoided, will result in death or serious injury.

CAUTION

Indicates an imminently hazardous situation that, if not

avoided, will result in death or serious injury.

1

.

2

BEFORE

OPERA

TING

3. Keep safetydecals clean and legible. Replace missing

or illegible safety decals.

4. Obtain and wear safety glasses

and use hearing protection at all

times when operating this machine.

5. Avoid wearing loose fitted clothing.

Never operate this machine while

wearing clothing with drawstrings

that could wrap around or get caught in the machine.

6. Do not operate this machine if you are under the

influence of alcohol, medications, or substances that

can affect your vision, balance or judgment. Do not

operate if tired or ill. You must be in good health to

operate this machine safely.

7. Do not operate this equipment in the vicinity of

bystanders. Keep the area of operation clear of all

persons, particularly small children. It is recommended

that bystanders keep at least 50 feet (15 meters) away

from the area of operation.

8. Do not allow children to operate this equipment.

9. Use only in daylight or good artificial light.

10. Do not run this equipment in an enclosed area. Engine

exhaust contains carbon monoxide gas, a deadly

poison that is odorless, colorless and tasteless. Do not

operate this equipment in or near buildings, windows

or air conditioners.

11. Do not operate machine without shields in place.

Failure to do so may cause serious injury or death.

12. Keep all guards, deflectors, and shields in good

working condition.

13. Before inspecting or servicing any part of this machine,

shut off the machine and make sure all moving parts

have come to a complete stop. Disconnect the battery

and remove the ignition key where applicable.

14. Check that all screws, nuts, bolts, and other fasteners

are secured, tightened and in proper working condition

before starting the machine.

15. Do not transport or move machine while it is operating

or running.

1. Read and understand this owner's manual. Be

completely familiar with the controls and the proper

use of this equipment.

2. Familiarize yourself with all of the safety and operating

decals on this equipment and on any of its attachments

or accessories.

2

4.5 INCH HYDRAULIC CHIPPER

SAFETY

1.3 OPERATION SAFETY 1.4 MAINTENANCE & STORAGE SAFETY

1. Always stand clear of discharge area when operating

this machine. Keep face and body away from feed

and discharge openings.

2. Keep hands and feet out of feed

and discharge openings while

machine is operating to avoid

serious personal injury. Stop

and allow machine to come to

a complete stop before clearing

obstructions.

3. Set up your work site so you are not endangering

traffic and the public. Take great care to provide

adequate warnings.

4. Do not climb on machine when operating. Keep proper

balance and footing at all times.

5. Check cutting chamber to verify it is empty before

starting the machine.

6. Therotorwillcontinue

to

rotate

after

beingdisengaged.

Shut off the machine and make sure all moving parts

have come to a complete stop before inspecting or

servicing any part of the machine. Disconnect the

battery and remove the ignition key if applicable.

1. Before inspecting, servicing, storing, or changing

an accessory, shut off the machine and make sure

all moving parts have come to a complete stop.

Disconnect the battery and remove the ignition key

where applicable.

2. Replace any missing or unreadable safety decals.

Refer to the safety decal section for part numbers.

3. Allow machine to cool before storing in an enclosure.

1

.

5

SAFETY

DECAL

LOCA

TIONS

The numbers below correspond to the decals in Section

1.6. Familiarize yourself with all of the safety and

operational decals on the machine and the associated

hazards. See the engine owner's manual or contact the

engine manufacturer for engine safety instructions and

decals. Make certain that all safety and operating decals

on this machine are kept clean and in good cond4

ition.

Decals that need replacement must be applied to their

original locations.

7. Do not insert branches with a diameter larger than 5 4

the max chipper capacity into machine or machine

damage may occur.

8. When feeding material into machine, do not allow 7

metal,

rocks,

bottles,cans oranyotherforeignmaterial

to be fed into the machine.

9. Ensure debris does not blow into traffic, parked cars,

or pedestrians. 6

10. Keep the machine clear of debris and other

accumulations.

11. Do not allow processed material to build up in the

discharge area. This may prevent proper discharge

and can result in kickback of material through the feed

opening.

12. If the machine becomes clogged, the cutting 2

mechanism strikes any foreign object, or the machine

starts vibrating or making an unusual noise, shut off

machine immediately and make sure all moving parts

have come to a complete stop. Disconnect the battery

and remove the ignition key if applicable. After the

machine stops: A) Inspect for damage, B) Replace

or repair any damaged parts, and C) Check for and

tighten any loose parts. 1

13. Onelectric startmodels, disconnectcables from battery

before doing any inspection or service. Remove key.

14. Check blade boltsfor propertorque afterevery8 hours 4

of operation. Check blades and rotate or resharpen 3

daily or as required to keep blades sharp. Failure to do

so may cause poor performance, damage or personal

injury and will void the machine warranty.

4.5 INCH HYDRAULIC CHIPPER

1

0

SAFETY

1.6 SAFETY DECALS

See Section 1.5 for decal locations. Familiarize yourself with all of the safety and operating decals on the machine

and the associated hazards. See the engine owner's manual or contact the engine manufacturer for engine safety

instructions and decals. Make certain that all safety and operational decals on this machine are kept clean and in good

condition. Decals that need replacement must be applied to their original locations.

1 PN 12169 4 PN 12175

KEEP HANDS AND FEET OUT OF

INLET

AND

DISCHARGE

OPENINGS

WHILE MACHINE IS

OPERATING TO

AVOID

SERIOUS

PERSONAL

INJURY. STOP AND ALLOW MACHINE TO

COME TO A CO

MPLET

E

STO

P

BEF

O

RE

CLEARING OBSTRUCTIONS.

KEEP HANDS AND FEET OUT OF INLET AND DISCHARGE

OPENINGS WHILE MACHINE IS OPERATING TO AVOID SERIOUS

PERSONAL INJURY. STOP AND ALLOW MACHINE TO COME TO A

COMPLETE STOP BEFORE CLEARING OBSTRUCTIONS.

2 PN 12172 5 PN 12250

READ AND UNDERSTAND THIS

OWNER/OPERATORS MANUAL.

BE COMPLETELY FAMILIAR

WITH THE CONTROLS AND

THE PROPER USE OF THIS

EQUIPMENT.

OBTAIN AND WEAR SAFETY

GLASSES AND USE HEARING

PROTECTION AT ALL TIMES

W HEN O P E RA TI N G T HI S

MACHINE.

B

EF

O

RE

I

NS

PE

CT

I

NG

O

R

SERVICING ANY PART OF THIS

MACHINE, SHUT OFF POWER

SOURCE, DISCONNECT SPARK

PLUG WIRE FROM

SP

ARK

P

LUG

A

ND M

A

K

E

S

URE

A

LL

MOVING PARTS HAVE COME TO

A COMPLETE STOP.

CHECK BLADE

BOL

TS

FOR PROPER

T

ORQUE

AFTER EVERY 8 HOURS

O

F

O

P

ERA

T

I

O

N. CHECK

BLADES AND ROTATE OR

RESHARPEN DAILY OR

AS REQUIRED

T

O KEEP

BLADES SHARP. REFER

TO OWNERS MANUAL FOR

I

NSTRUCT

IO

NS

.

F

AILURE

TO DO SO MAY CAUSE POOR PERFORMANCE, DAMAGE OR

PERSONAL INJURY AND WILL VOID THE MACHINE WARRANTY.

6 PN 13890-00

3 PN 12173

KEEP HANDS AND FEET OUT OF INLET AND DISCHARGE

OPENINGS WHILE MACHINE IS OPERATING TO AVOID SERIOUS

PERSONAL INJURY. STOPAND ALLOW MACHINE TO COME TO A

COMPLETE STOP BEFORE CLEARING OBSTRUCTIONS.

7 PN 14942-00

DO NOT

OPER

ATE THIS

EQU

IPMEN

T IN THE

VICIN

ITY OF

BYSTANDERS. DO NOT ALLOW CHILDREN TO OPERATE THIS

EQUIPMENT. ALWAYS STAND CLEAR OF DISCHARGE AREA

WHEN

OPERATING

THIS MACHINE. KEEP

FACE

AND

BODY

AWAY

FROM DISCHARGE AREAS.

READ AND UNDERSTAND YOU OWNERS MANUAL BEFORE

OPERATING. IF OWNERS MANUAL WAS NOT INCLUDED OR

YOU HAVE ANY QUESTIONS, PLEASE CALL 800.247.7335 OR

701.282.5520 (U.S.A.)

2

Section

ASSEMBLY

4

4.5 INCH HYDRAULIC CHIPPER

4.5 INCH HYDRAULIC CHIPPER

1

2

W

ARNING

If any bolts or nuts are dropped in the machine, be sure

to remove them before starting the machine.

2

.

1

DISCHARGE

ASSEMB

LY

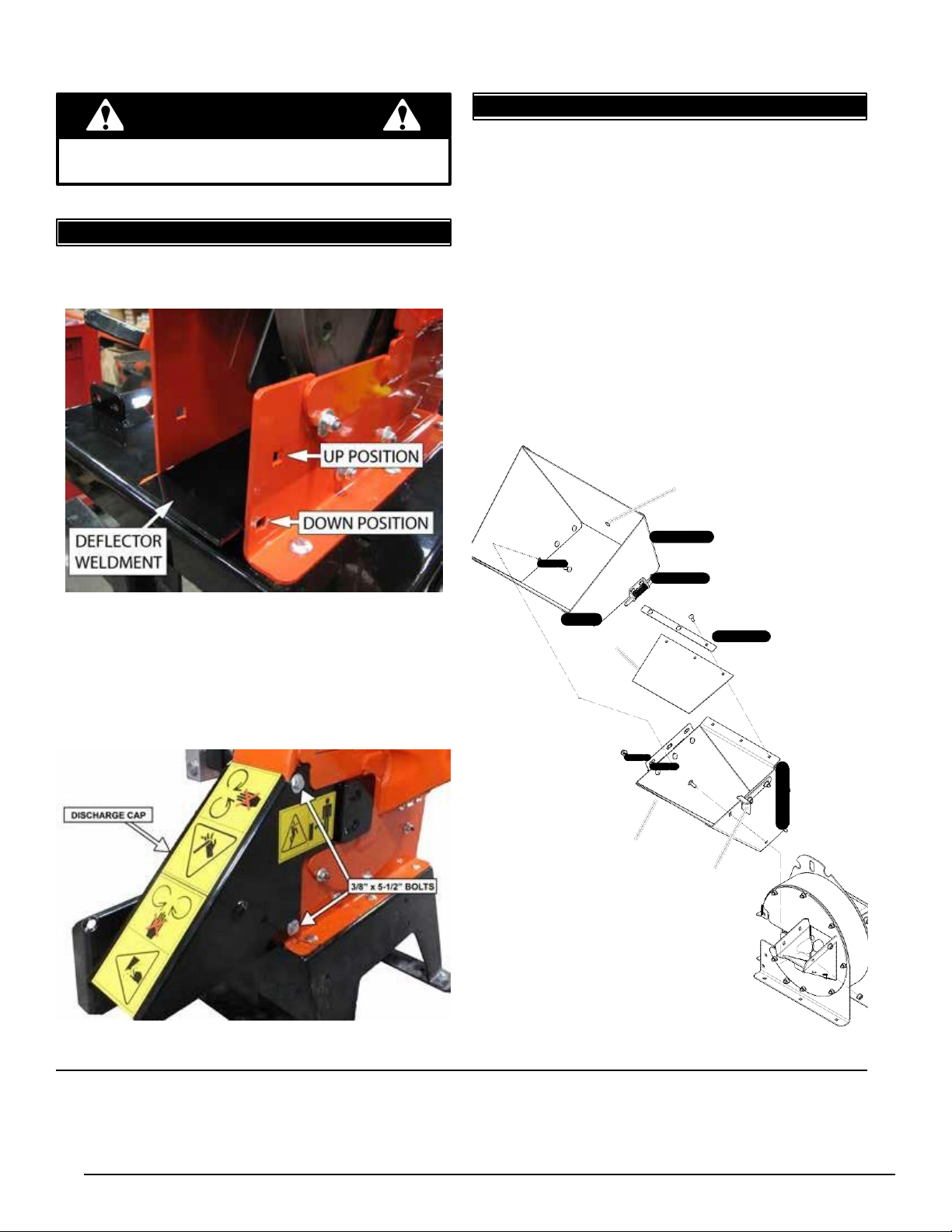

1. Move the chipper deflector weldment located inside

the chipper housing to the down position (Figure 2.1).

2

.

2

CHUTE

ASSEMB

LY

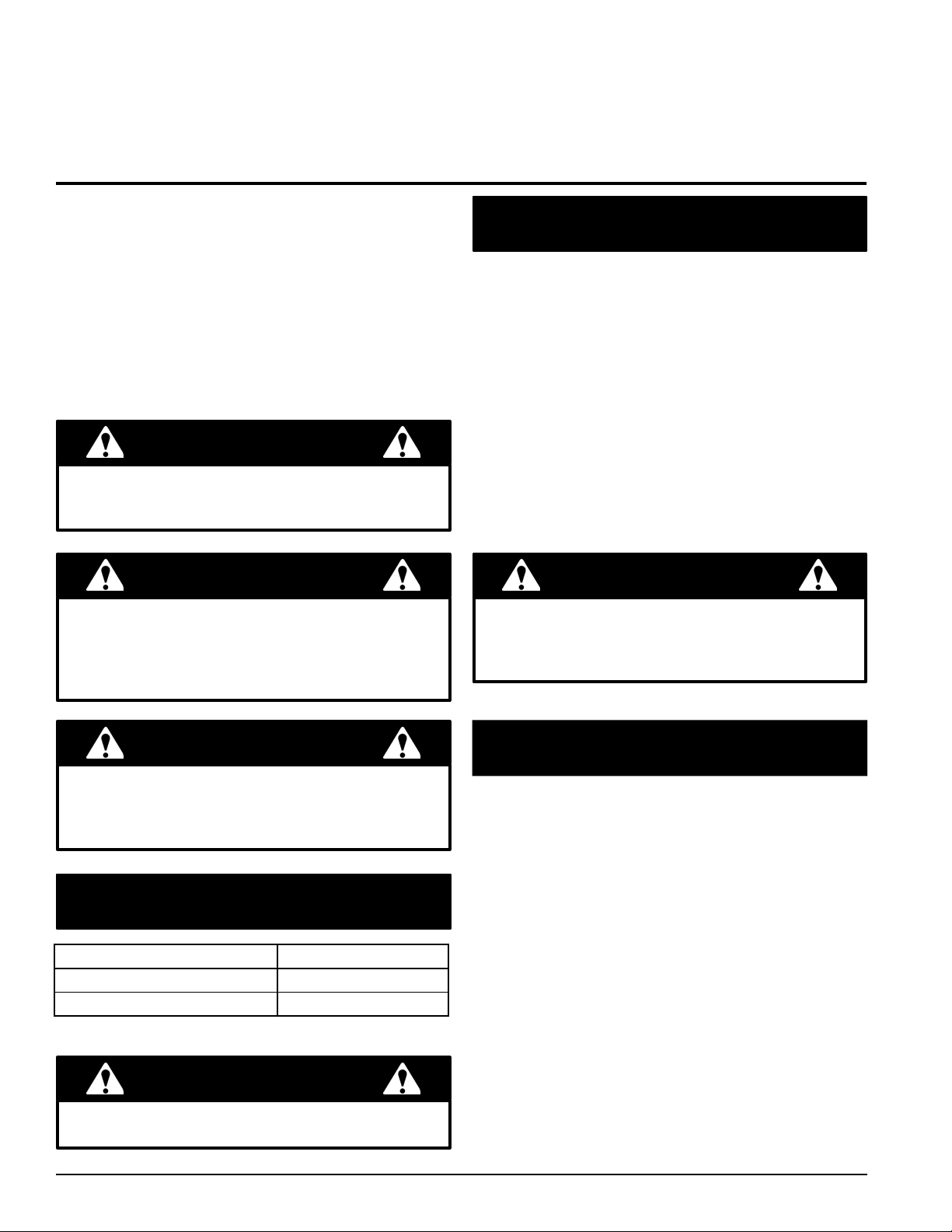

1. Attach the chipper chute to the chipper using four (4)

3/8 x 1" carriage bolts, 3/8" washers and 3/8" nuts.

Use two bolts on each side. Install with nuts on the

outside.

2. Attach the chute extension to the chipper chute using

three (3) 3/8 x 1" carriage bolts, 3/8" washers and 3/8"

nuts. Install with nuts on the outside.

3. Use the lanyard to attach the chute extension to the

middle hole on the chipper chute.

4. Attach chute flap and flap strip to the chipper chute

as shown below with the three (3) 5/16 x 1" carriage

bolts, 5/16" washers, and 5/16" nylock nuts.

5. Latch the chute extension to the lock plate on the

chipper chute.

LANYARD ATTACHES HERE

CHUTE EXTENSION

LATCH

FIGURE 2.1, CHIPPER DEFLECTOR WELDMENT

2. Slide the discharge cap onto the chipper housing

(Figure 2.2).

3. Insert two (2) 3/8" x 5-1/2" bolts into the bolt holes on

the chipper housing and tighten using 3/8" washers

and 3/8" nylock nuts.

CHUTE FLAP

FLAP STRIP

CHIPPER CHUTE

LOCK PLATE

FIGURE 2.2, DISCHARGE CAP

FIGURE 2.3, CHIPPER CHUTE EXTENSION

2

Section

ASSEMBLY

4

4.5 INCH HYDRAULIC CHIPPER

3

Section

FEATURES & CONTROLS

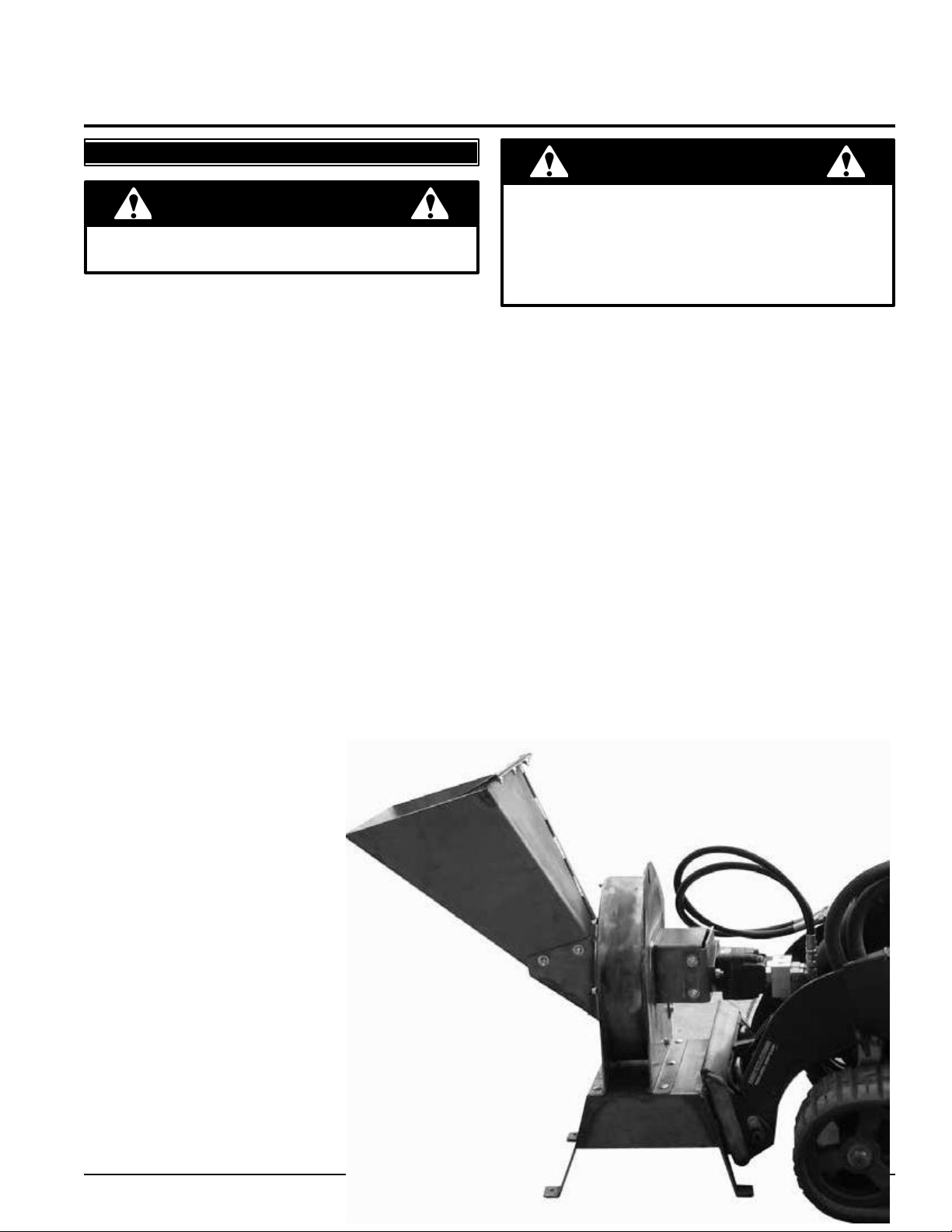

Understanding how your machine works will help you achieve the best results when using your machine. The following

descriptions define the features and controls of your machine.

CHIPPER CHUTE

Feed branches no larger than 4.5 inches in diameter into the chipper chute.

CHIPPER DEFLECTOR

Chipped material exits out the chipper deflector and onto the ground.An optional chipper discharge tube is also available

(PN 74634-00).

CHUTE EXTENSION

An additional safety feature to keep the operator from touching or being pulled into the chipper blades. The extension

should be unlatched and rotated open on its hinge when transporting the chipper.

FEMALE COUPLER/MALE COUPLER

Connect the couplers to the

appropriate connectors on the utility

loader. Note that there is a zip tie

around the pressure hose.

UTILITY LOADER MOUNT

Use this mount to secure and

transport the chipper with a utility

loader.

CHUTE EXTENSION

FEMALE

COUPLER

(PRESSURE)

MALE

COUPLER

CHIPPER

CHUTE

CHIPPER

DEFLECTOR

UTILITY

4.5 INCH HYDRAULIC CHIPPER

1

4

LOADER

MOUNT

4

Section

OPERATION

6

4.5 INCH HYDRAULIC CHIPPER

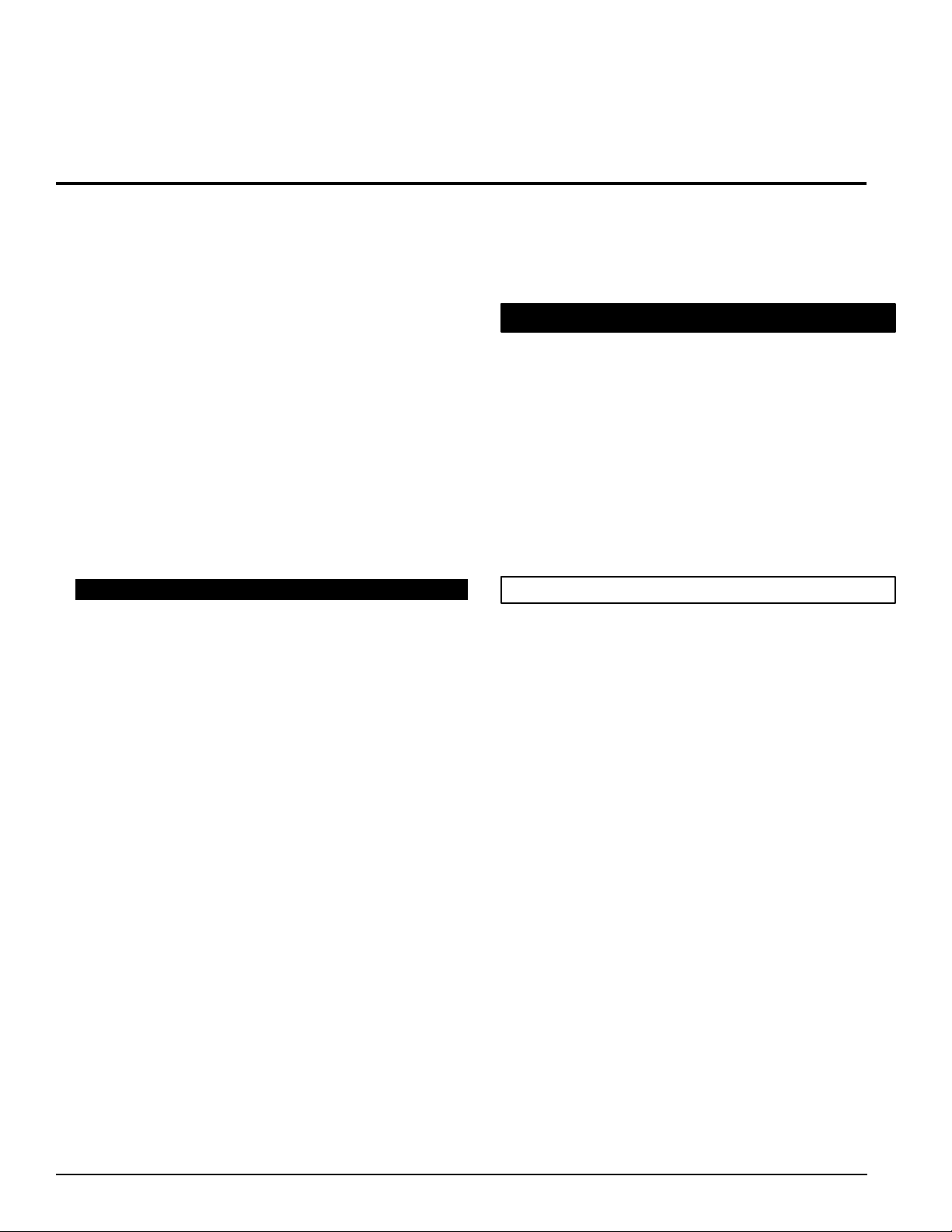

As with any other piece of outdoor equipment, getting the

feel for how your machine operates and getting to know

the best techniques for particular jobs are important to

overall good performance.

CHIPPING OPERATION

The chipping operation takes place on the front of the

machine, where hardened steel chipper blades are

mounted on a rotating rotor assembly. Material fed into

the chipper chute is sliced into small chips and propelled

out through the chipper deflector.

WARNING

Move machine to a clear, level area outdoors before

starting. Do not operate in the vicinity of bystanders.

Make sure cutting chamber is empty before starting.

WARNING

Before operating your machine, be sure you read and

understand all

safety, controls and operating

instructions

in this owner's manual and on your machine. Failure to

follow these instructions can result in serious injury or

property damage.

4.2 MOUNTING THE CHIPPER TO A

UTILITY LOADER

Consult the owner's manual for your utility loader

before mounting the chipper!

1. Position the chipper on a level surface.

2. Ensure that the mount plates are free of dirt or debris.

3. Start the engine on the utility loader.

4. Direct the loader mount plate into the upper lip of the

chipper receiver plate.

5. Raise the loader arms while tilting back the mount

plate.

6. Stop the engine.

7. Engage loader pins to ensure the chipper is securely

mounted.

IMPORT

ANT

If the pins do not rotate to the engaged position, the

mount plate is not fully aligned with the holes in the

chipper receiver plate. Check the chipper plate and

clean it if necessary.

W

ARNING

If your loader creates back pressure greater than 250

psi, a case drain will have to be added to prevent

damage to the seal on the chipper rotor motor. Contact

your dealer for more information.

4.1 RECOMMENDED HYDRAULIC FLOW

RATES

Minimum flow rate

10 gal/min

Maximum flow rate

14 gal/min

Standard hydraulic pressure

3000 psi

W

ARNING

Exceeding the recommended flow rates can cause

severe damage and void the chipper warranty!

4.3 REMOVING THE CHIPPER FROM A

UTILITY LOADER

1. Lower the chipper to the shipping pallet or base of

similar size. (30" x 50")

2. Stop the engine.

3. Disengage the pins.

4. Relieve pressure on the hydraulic couplers (see your

owner's manual).

5. Rotate the ball sleeve so the grooves are aligned with

the pins in the female coupler.

6. Retract the sleeve on the female coupler until the

couplers disconnect.

7. Repeat for the male hose.

8. Attach the chipper to the pallet using the four holes

located in the skids of the chipper base.

9. Start the engine, tilt the mount plate forward, and back

the loader away from the chipper.

4.5 INCH HYDRAULIC CHIPPER

1

6

WARNING

4

.

4

CONNECTING

COUPLERS

WARNING

OPERATION

Handle pressurized hydraulic fluid carefully. Escaping

pressurized hydraulic fluid may penetrate your skin

Hydraulic lines may be under pressure due to testing

done at the factory.

Consult the owner's manual for your utility loader

before mounting the chipper!

The chipper is equipped to attach to flush face couplers.

The chipper is shipped with -10 size hydraulic couplers

fitted on the hoses. If your utility loader is fitted with

anything other than -10 sized flush face couplers on the

main lines, you must replace the couplers supplied with

the chipper.

Atie wrap is used to indicatethe pressure line. Be sure

to connect the hydraulic hoses to the proper ports.

TO CONNECT:

1. Stop the engine on the utility loader.

2. Remove dirt and debris from the surface of the

couplers.

3. Visually check the couplers for damage; replace if

damage is found.

4. Relieve the hydraulic pressure in the utility loader (see

your owner's manual).

5. Push the chipper male coupler into the loader female

coupler. Full connection is made when the ball release

sleeve slides forward on the

female coupler

.

6. Turn the sleeve so that it is

rotated away from the locking

pin to prevent accidental

disconnection.

7. Push the chipper female

coupler into the loader male

coupler.

TO DISCONNECT:

1. Lower the chipper to the

ground.

2. Stop the engine.

3. Relieve pressure on the

hydraulic couplers (see your

owner's manual).

4. Rotate the ball sleeve so the

grooves are aligned with the

pins in the female coupler.

5. Retract the sleeve on the

female coupler until the

couplers disconnect.

6. Repeat for the male hose.

4

Section

OPERATION

6

4.5 INCH HYDRAULIC CHIPPER

causing serious injury. This fluid may also be hot

enough to burn. Serious infection or reactions can

develop if immediate proper medical treatment is not

administered.

4.5 STARTING THE CHIPPER

Running the utility loader chipper is a one- or two-person

operation. If the loader requires an operator in the

driveseat, two people are needed. The chipper engages

with the hydraulics of the utility loader.

1. Set parking brake.

2. Engage the hydraulics of the utility loader to supply

power to the unit. The chipper will start to spin.

3. Bring the unit up to speed.

4. The chipper is ready to chip.

4

.

6

STOPPING

THE

CHIPPER

Slow down the engine of the utility loader to idle and after

several seconds disengage the utility loader hydraulics.

4.5 INCH HYDRAULIC CHIPPER

1

8

OPERATION

4

.

7

OPERA

TING

THE

CHIPPER

CAUTION

●Obtain and wear safety glasses at all times when

operating the machine.

● Do not wear loose fitting clothing.

●The operator should always wear heavy boots,

gloves, pants and a long-sleeved shirt.

●Use common sense and practice safety to protect

yourself from branches, sharp objects, and other

harmful objects.

W

ARNING

●Never lean over the chipper chute to push objects

into the cutting device. Use a push stick or brush

paddle.

●Never use shovels or forks to feed brush. They can

cause extensive damage if they contact the blades.

In addition, metal pieces can be ejected from the

chipper chute and cause serious injury or death.

● Never feed brush into the chute with your feet.

●Never use hands or feet to clear materials that

build up in the chute.

W

ARNING

Read and follow all safety instructions in this manual.

Failure to operate the machine in accordance with

the safety instructions MAY RESULT IN PERSONAL

INJURY!

The machine chips a variety of materials into a more

readily decomposed or handled condition. The following

guidelines will help you get started.

1. Run unit at full operating speed before starting to

chip material.

2. Limbs fed in to the chipper chute must be 4.5

inches (11.4 cm) in diameter or less. Trim side

branches that cannot be bent enough to feed into the

chipper chute. Hold small diameter branches together

in a bundle and feed in simultaneously.

3. Exclude pieces of metal, rocks, bottles, cans, and

other foreign objects when feeding material into the

machine.

4. Feed brush from the side of the chipper chute,

rather than from the front. Step aside to avoid being

hit by the brush moving into the chipper.

5. Place limb, butt end first, into the chipper chute

until it contacts the chipper blades. The actual feed

rate of the limb into the chipper will depend on the type

of material fed and sharpness of the cutting blades.

6. If the engine slows to where it may stall, stop

feeding material and allow the engine to recover.

Feed material more evenly.

7. If the chipper jams, remove the branch and rotate it

before reinserting it into the chute. Alternately insert

and retract the limb or insert continuously at a rate that

will not kill the engine.

8. Alternate greener material with dry material to

lubricate the chipping blades for longer life and better

performance. Chipping dead, dry material will create

heat and dull the chipping blades quickly.

9. Sharpen the chipping blades periodically. Check

the sharpness of the blades every 5-15 hours. Refer to

the Service and Maintenance section for sharpening

instructions.

10. Do not drive the utility loader while chipping.

W

ARNING

To prevent personal injury or property damage: shut

off engine and make sure that all moving parts have

come to a complete stop before, servicing, adjusting or

repairing. Disconnect the battery and remove ignition

key where applicable.

8

4.5 INCH HYDRAULIC CHIPPER

5

Section SERVICE & MAINTENANCE

5

.

1

MAINTENANCE

SCHEDULE

The items listed in this service and maintenance schedule

are to be checked, and if necessary, corrective action

taken. This schedule is designed for units operating under

normal conditions. If the unit is operating in adverse or

severe conditions, it may be necessary for the items to be

checked and serviced more frequently.

SEE ENGINE OWNER'S MANUAL FOR FURTHER

ENGINE MAINTENANCE AND TROUBLESHOOTING

INFORMATION.

WARNING

To prevent personal injury or property damage: shut

off engine and make sure that all moving parts have

come to a complete stop before, servicing, adjusting or

repairing. Disconnect the battery and remove ignition

key where applicable.

SERVICE AND MAINTENANCE SCHEDULE

FREQUENCY

COMPONENT

MAINTENANCE REQUIRED

BEFORE

EACH USE

EVERY 8

HOURS

EVERY 50

HOURS

All internal and external

nuts and bolts

Check tightness

●

Chipper anvil

Check clearance and re-torque to

75 ft-lbs. (1)

●

Chipper blades

Check sharpness and re-torque to

120 ft-lbs. (1)

●

Entire machine

Clean

●

Grease zerks

Lube

●

(1) Perform more frequently when chipping dry or dirty wood.

As the limited warranty states, failure by the owner to perform normal maintenance will void the machine's

warranty. The aggressive, high-speed nature of chipping requires the owner to perform the above listed

normal maintenance. Special consideration to maintain and re-torque the chipper anvil, chipper blades, and

all internal and external nuts and bolts is the sole responsibility of the owner. Failure by the owner to do so

shall be cause for denial of warranty.

5.2 INSTALLING THE ROTOR LOCK

When working on the rotor assembly, use the lock

mechanism at all times (Figure 5.1). Follow the steps

below to install the rotor lock:

1. Rotate the rotor until the hole on the paddle is aligned

with the hole on the chipper housing (Figure 5.1).

2. Install a punch or screwdriver into the holes.

MATCHING HOLE

ON ROTOR PADDLE

CHIPPER

ROTOR

NOTE

One of the 3/8 x 5-1/2" bolts from the chipper deflector

can also be used to lock the rotor.

ROTOR

LOCK HOLE

FIGURE 5.1, ROTOR LOCK

4.5 INCH HYDRAULIC CHIPPER

20

W

ARNING

BEFORE INSPECTING OR SERVICING ANY PART OF THIS MACHINE, SHUT OFF POWER SOURCE

,

AND MAKE SURE ALL MOVING PARTS HAVE COME TO A COMPLETE

STOP.

5.3 CHIPPER BLADE MAINTENANCE 5.4 REMOVING THE BLADES

The chipper blades will eventually become dull, making

chipping difficult and adding extra strain on the machine.

CHECK THE SHARPNESS OF THE BLADES EVERY

5-15 HOURS OF OPERATION AND SHARPEN AS

NEEDED.

Your blades need to be sharpened if:

●Machine vibrates severely when material is fed into

the chipper.

● Small diameter branches do not self-feed.

●Chips discharge unevenly or have stringy tails,

especially when chipping green branches.

Before you sharpen the chipping blades, check for

permanent damage. Replace the blade if:

●There are cracks, broken corners or nicks greater

than 1/8" (see below).

1. Remove the chipper deflector from the chipper

housing.

2. Rotate the rotor until a blade is accessible and install

the rotor lock (Section 5.2).

3. Remove the two hex bolts holding the blade to the

rotor.

4. To access the remaining blade, remove the punch or

screwdriver, reposition the rotor, and return the punch

or screwdriver to the rotor lock hole.

5. Repeat step 2 for the remaining blade.

6. Inspect blades to see if cracks or nicks are visible (see

Section 5.3).

5

.

5

SHARPENING

THE

BLADES

The blades can be ground on a bench grinder or by a

professional.

1. Never sharpen or grind the mounting surfaces of

the blades. This will cause the edge to roll and the

blade will be damaged, resulting in poor chipping

Broken

corner

Crack greater

than 1/8" Nick greater

than 1/8" performance.

2. Regrind the angled edge of the chipping blades to 45

degrees (see below). Make sure some type of fixture

is used to correctly hold the blade at the proper angle.

3. Be careful when grinding so that the blade does

not become overheated and change color. This will

remove the heat-treated properties.

●The base of the cutting edge is worn or has been

re-sharpened so that it no longer extends past the

chipping slot (see below).

4. Use short grinding times and cool with water or some

type of liquid coolant.

5. Remove an equal amount off each blade to maintain

rotor balance.

6. Small imperfections such as nicks and burrs on

Chipper

rotor

New

blade

Chipper

rotor

Chipping slot

Blade is too

short, must

be replaced

Chipping slot

the flat side of the blade will not affect the chipping

performance of the machine.

7. For blades that have been repeatedly sharpened,

ensure that the sharpened surface extends past the

chipping slot opening. If it does not extend past the

opening, the blades should be replaced.

Sharpened

Surface

Mounting Surface

(DO NOT GRIND)

Sharpened

Surface

W

ARNING

The chipping blades are sharp!! Use care when working

on the machine to avoid injury.

45˚

.50"

Mounting Surface

(DO NOT GRIND)

This manual suits for next models

2

Table of contents

Other Spartan Equipment Chipper manuals