Spaw MAGNUM TIG THF 238 PRO User manual

MAGNUM TIG THF 238 PRO

INSTRUCTIONS MANUAL

WARNING! FOR SAFETY REASON PLEASE READ AND UNDERSTAND

THE FOLLOWING INSTRUCTIONS BEFORE FIRST USE OF THE DEVICE.

1.General instructions

Read the operating instructions!

The operating instructions provide an introduction to the safe use of the products. An

incorrectly performed installation can result in material damage and injure persons as a

result. For this reason, we do not accept any responsibility or liability for losses, damages

or costs arising from incorrect installation, improper operation or incorrect usage and

maintenance or any actions connected to this in any way.

• Read the operating instructions for all system components!

• Observe accident prevention regulations!

• Observe all local regulations!

• Confirm with a signature where appropriate.

2. Safety instructions

DANGER!

Electromagnetic fields!

The power source may cause electrical or electromagnetic fields to be produced which

could affect the correct functioning of electronic equipment such as IT or CNC devices,

telecommunication lines, power cables, signal lines and pacemakers.

• Observe the maintenance instructions! (see Maintenance and Testing chapter)

• Unwind welding leads completely!

• Shield devices or equipment sensitive to radiation accordingly!

• The correct functioning of pacemakers may be affected (obtain advice from a doctor if necessary).

Do not carry out any unauthorised repairs or modifications!

To avoid injury and equipment damage, the unit must only be repaired or modified by

specialist, skilled persons! The warranty becomes null and void in the event of unauthorised

interference.

• Appoint only skilled persons for repair work (trained service personnel)!

Electric shock!

Welding machines use high voltages which can result in potentially fatal electric shocks

and burns on contact. Even low voltages can cause you to get a shock and lead to

accidents.

• Do not touch any live parts in or on the machine!

• Connection cables and leads must be free of faults!

• Switching off alone is not sufficient!

• Place welding torch and stick electrode holder on an insulated surface!

• The unit should only be opened by specialist staff after the mains plug has been

unplugged!

• Only wear dry protective clothing!

• Wait for 4 minutes until the capacitors have discharged!

WARNING!

Risk of injury due to radiation or heat!

Arc radiation results in injury to skin and eyes.

Contact with hot workpieces and sparks results in burns.

• Use welding shield or welding helmet with the appropriate safety level (depending on the

application)!

• Wear dry protective clothing (e.g. welding shield, gloves, etc.) according to the relevant

regulations in the country in question!

• Protect persons not involved in the work against arc beams and the risk of glare using

safety curtains!

Explosion risk!

Apparently harmless substances in closed containers may generate excessive pressure

when heated.

• Move containers with inflammable or explosive liquids away from the working area!

• Never heat explosive liquids, dusts or gases by welding or cutting!

WARNING!

Smoke and gases!

Smoke and gases can lead to breathing difficulties and poisoning. In addition, solvent

vapour (chlorinated hydrocarbon) may be converted into poisonous phosgene due to

the ultraviolet radiation of the arc!

• Ensure that there is sufficient fresh air!

• Keep solvent vapour away from the arc beam field!

• Wear suitable breathing apparatus if appropriate!

Fire hazard!

Flames may arise as a result of the high temperatures, stray sparks, glowing-hot parts

and hot slag produced during the welding process.

Stray welding currents can also result in flames forming!

• Check for fire hazards in the working area!

• Do not carry any easily flammable objects such as matches or lighters.

• Keep appropriate fire extinguishing equipment to hand in the working area!

• Thoroughly remove any residue of flammable substances from the workpiece before

starting welding.

• Only continue work on welded workpieces once they have cooled down.

Do not allow to come into contact with flammable material!

• Connect welding leads correctly!

Risk of accidents if these safety instructions are not observed!

Non-observance of these safety instructions is potentially fatal!

• Carefully read the safety information in this manual!

• Observe the accident prevention regulations in your country.

• Inform persons in the working area that they must observe the regulations!

Danger when coupling multiple power sources!

Coupling multiple power sources in parallel or in series has to be carried out by

qualified personnel and in accordance with the manufacturer's guidelines. Before

bringing the power sources into service for arc welding operations, a test has to verify

that they cannot exceed the maximumallowed open circuit voltage.

• Connection of the machine may be carried out by qualified personnel only!

• When decommissioning individual power sources, all mains and welding current leads have

to be safely disconnected from the welding system as a whole. (Danger due to inverse

voltages!)

• Do not couple welding machines with pole reversing switch (PWS series) or machines for

AC welding, as a minor error in operation can cause the welding voltages to be combined.

WARNING!

Hazards due to improper usage!

Hazards may arise for persons, animals and material objects if the equipment is not

used correctly. No liability is accepted for any damages arising from improper usage!

• The equipment must only be used in line with proper usage and by trained or expert staff!

• Do not modify or convert the equipment improperly!

CAUTION!

Installation site!

The machine must not be operated in the open air and must only be set up and

operated on a suitable, stable and level base!

• The operator must ensure that the ground is non-slip and level, and provide sufficient

lighting for the place of work.

• Safe operation of the machine must be guaranteed at all times.

Equipment damage due to dirt accumulation!

Unusually high quantities of dust, acid, corrosive gases or substances may damage the

equipment.

• Avoid high volumes of smoke, vapour, oil vapour and grinding dust!

• Avoid ambient air containing salt (sea air)!

Non-permissible ambient conditions!

Insufficient ventilation results in a reduction in performance and equipment damage.

• Observe the ambient conditions!

• Keep the cooling air inlet and outlet clear!

• Observe the minimum distance of 0.5 m from obstacles!

3. Applications

Magnum THF 238 PRO is intended for tungsten electrode welding but also MMA welding. The device

is made for metal arc welding of low-alloy, high-alloy, carbon steels, aluminium and its alloys,

The manufacturer is not liable for damage caused by improper use of the device.

4. Welding machine description

4.1 Front view

1. Functions and parameters control panel

2. Gas outlet

3. Connection socket ( - )

4. Torch control connector

5. Connection socket ( + )

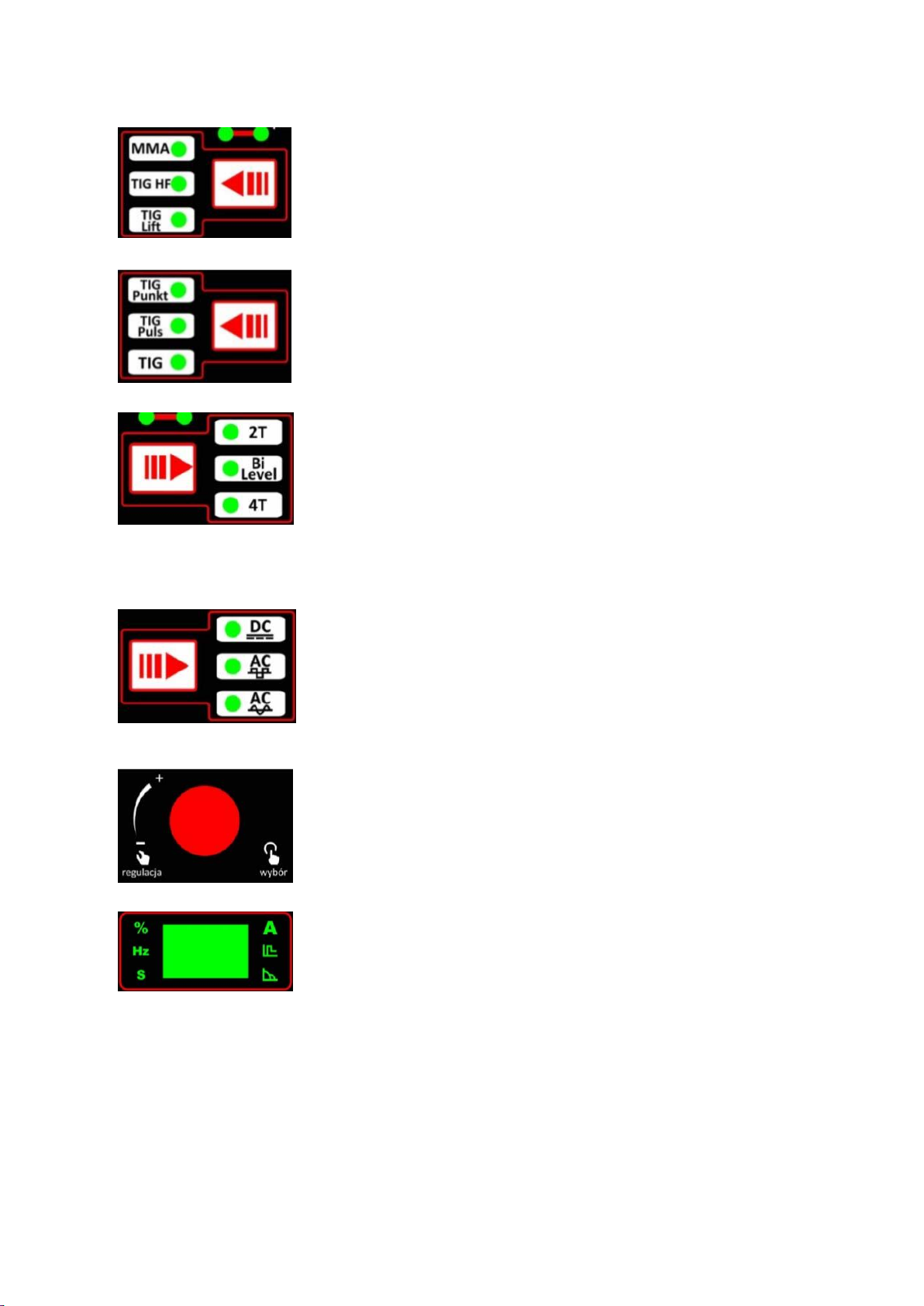

4.2 Control panel

4.2.1 Control panel description

Welding mode selection button. Select desired welding mode by

pressing the button.

MMA –stick welding mode

TIG HF –tungsten electrode welding with High Frequency arc ignition

TIG Lift –tungsten electrode welding with lift arc ignition

TIG welding features

TIG Punkt –spot welding mode

TIG Puls –pulse welding

TIG –welding without pulse

Torch control mode

2T –two stroke mode. To ignite the arc press the button and proceed

welding while holding the button. To stop the arc release the button

BiLevel –it allows to set two different values of a welding current and

switch between them during welding.

4T - four stroke mode. To start the arc press the button until arc is

ignited. At this point release the button and continue welding. To stop

the arc press and release the button

Current type selection

DC –welding with direct current

AC –welding with alternating current (flat waveform)

AC –welding with alternating current (sinus waveform)

Adjustment knob / button

Turning the knob left or right decreases or increases parameter value.

Pressing the knob confirms selection and jumps to next parameter.

Parameter display. Display shows actual value whereas corresponding

symbol lights up.

4.2.2 TIG welding parameters description

Gas bottle symbol –Adjustment of a shield gas supply before arc ignition

lp –Start amps. Start current lasts while welding pool creates than it ramps up to welding current.

tn –Current ramping time. Setting the time it takes for start current to reach welding current value.

lb –Base current when welding with pulse. Lower value of pulse amperage.

Is –Welding current. Upper value of pulse amperage when welding with pulse.

Puls bal. –Pulse balance. Adjustment of a base current (Ib) to welding current (Is) ratio. 50% setting

means that base current lasts for the same time as welding current.

Puls Hz –Adjustment of a TIG pulse frequency.

AC balans –Adjustment of a positive to negative polarization when welding with AC/DC current.

AC Hz –Alternating current frequency. Number of cycles per seconds.

to –Time it takes from welding current to decrease to end current.

Ik –End current. Adjustment of a current it takes to fill out the crater before arc goes off.

Gas bottle symbol 2 –Adjustment of a time when shield gas is provided after arc stops.

4.2.3 Bi-Level feature description

Bi-Level is active only when the pulse welding is off. This feature allows to switch between previously

provided welding current values ( Ib and Is ). It it mostly used when welding material with various

thickness or when there is a need to use two different amperage values without putting the arc off.

To use the feature first pulse welding must be put to off. Than using the torch control mode button select

Bi-Level. it is described with an rsymbol and a value from 2 to 10 seconds. It is the time you need to

press the button to terminate welding. After the feature is activated the welding current Ib and Is can be

provided.

To conduct welding hold the button on the torch handle until arc ignites. While you hold the button the

device keeps the base current ( Ib ). To switch between previously provided amperage values release

the button. Afterwards the device sets the second provided amperage which is welding current ( Is ). If

you want to switch back to the previous amperage value ( Ib ) you need to quickly press and release

the button. And again if you want to switch between the values you need to press and release the button.

To terminate the welding press and hold the button for the time previously selected ( r).

4.2.4 Spot welding (TIG Punkt)

Spot welding in the device gives you an option to make short welds in a given time gaps. Using this

feature there are fewer parameters to be set: pre gas, welding current ( Is ), pulse balance, post gas

and a time gap between the welds. To conduct welding you need to press the torch button and hold it.

Device will provide short amperage impulses in a given time gaps e.g. if you set the time gap for 5

seconds and start welding you need to hold the button constantly and the device will provide amperage

impulses every five seconds.

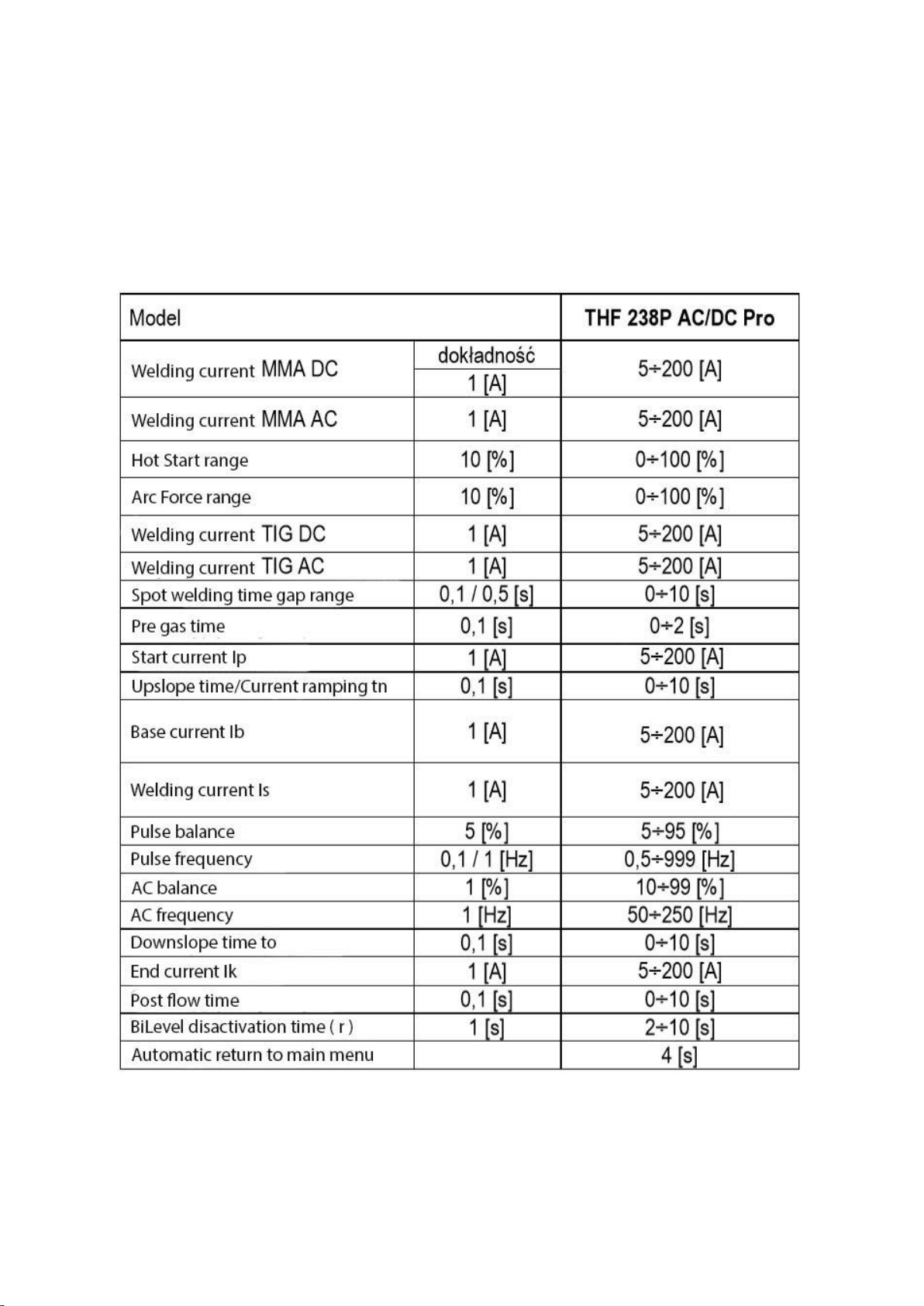

5. Technical specification

6. Connecting power supply precautions

WARNING! Before any operations carried out on the device pull the plug out of the power

socket.

1. Make sure that the device is not connected to the electricity

2. Check if the ground wire has a clamp or screw clamp

3. Connect the ground clamp to the socket on the front panel with proper polarization.

4. Insert the torch plug into the socket on the panel and tighten it.

7. Cleaning and maintaining the device

The protection class of this device is IP21S. Do not use the device in the rain, nor expose it to

extensive moisture.

WARNING!

Device based on electronic components. Metal grinding and cutting close to the welder

may cause contamination of the inside of the device, thus causing its damage.

The damage mentioned above is not covered by the warranty. If you need to work in such

an environment, please clean device before use by blowing the inside of the welding

machine with compressed air.

To prolong the life and reliable operation of the device, several rules must be observed:

1. The device should be placed in a well-ventilated room where there is free air circulation.

2. Do not place the device on a wet surface.

3. Use a wire diameter and spool weight according to the table.

4. Check the technical condition of the device and welding cables.

5. Remove any flammable materials from the welding area.

6. Use suitable protective clothing for welding: gloves, apron, safety boots and welding helmet

8. Transporting and storage

Always store the devices in a dry, ventilated place, out of reach of children and

bystanders. Protect the device against vibrations and shocks during transport.

9. Recycling

The packaging and device materials are suitable for recycling use. Disposal of the packaging and

device must be done in accordance with local regulations. The packaging materials should be

protected against children as they are potential source of danger.

10. Warranty

The manufacturer of the device provides full warranty service for the power supply unit within 24

months from the day device was purchased. An individual warranty card is issued for each device.

Warranty is valid only if all conditions listed in the instructions manual were fulfilled. If the device

was used inappropriate or against instructions the warranty becomes invalid. Service centre does

not cover the postage cost for sending the device for repairs or sending it back after repairs.

Spaw S.C. –Service Centre

ul. Kosiarzy 3

30-731 Krakow

Poland

phone: +48 123 480 722

repair request form - www.spawsc.pl - service tab.

Table of contents

Other Spaw Welding System manuals

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric Mobiflex 200-M Operator's manual

ESAB

ESAB Caddy Tig 2200iw instruction manual

Kemppi

Kemppi Evo 150, 150VRD operating manual

King Ultrasonic CO

King Ultrasonic CO KWL3215 user manual

AUTO ARC

AUTO ARC BENCHMARK owner's manual

Lincoln Electric

Lincoln Electric CWT WOC-2 Operator's manual