INSTALLATION INSTRUCTIONS

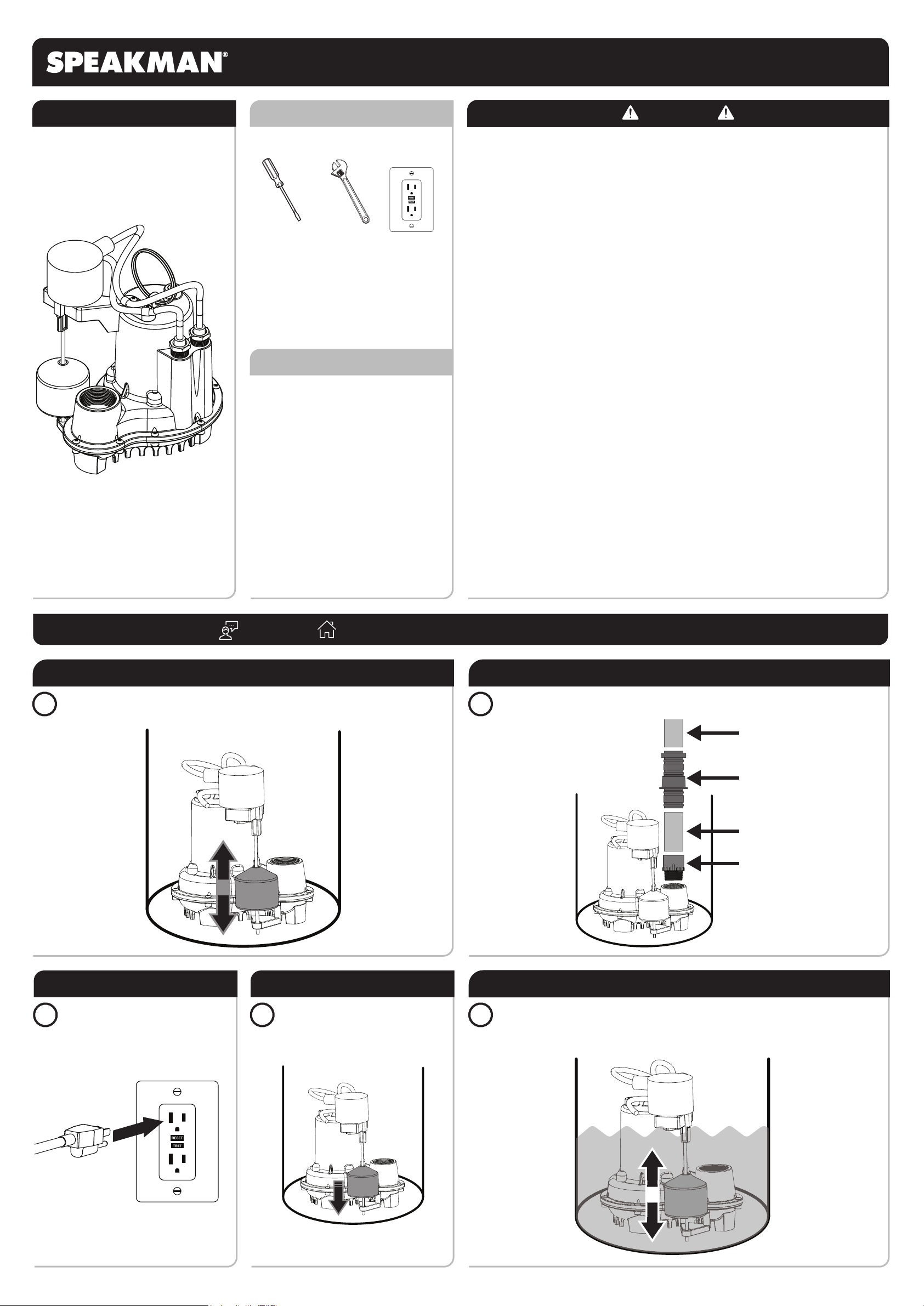

SP-8012

½ HP Sump Pump

92-SP-8012-01

TOOLS & SUPPLIES NEEDED

IMPORTANT

RISK OF ELECTRIC SHOCK The pump is supplied with a grounding conductor and

grounding-type attachment plug. To reduce the risk of electric shock, install only on a circuit

protected by ground-fault circuit-interrupter. Always disconnect the pump from the power

source before handling or making adjustments. Always wear rubber boots when servicing in

wet areas. Make sure the pump power source is a separately fused, grounded 3-wire type

receptacle of 15-amp capacity. DO NOT REMOVE GROUND PRONG OR PLUG. DO NOT

USE AN EXTENSION CORD. Check to make sure installation is in accordance with the

National Electric Code and all applicable local codes. Installation and servicing are to be

conducted by qualified personnel.

• DO NOT pump flammable liquids.

• DO NOT use around explosive materials.

• DO NOT handle unit with wet hands or while standing in water.

• DO NOT lift the pump by the power cord.

• DO NOT handle or carry the pump by the power cord. Use the handle, or rope.

• DO NOT connect to any voltage other than that listed on the nameplate.

• DO NOT use in water over 104˚F (40˚C).

• DO NOT modify the pump in any way.

• DO NOT expose pump or discharge to freezing temperatures.

• DO NOT use this product to pump salt water or brine. Use with salt water or brine will void

the warranty. Pump water only.

The sump pit must be a minimum of 12” diameter x 10” depth for Vertical switch models usage.

• Do keep the pump inlet screen clear.

The pump MUST be placed on a solid foundation, such as a brick, stone, or other flat

heavy surface. Do not place the pump directly on the ground in sandy or rocky surfaces.

Earth, sand, or gravel that enters the pump would damage the impeller of the sump and

cause flooding. Sand or mud-choked pumps can be back-flushed clean.

• Extended usage of the pump in a partially submerged or non-submerged situation may

cause the pump to overheat due to lack of heat dissipation from the water. If this occurs, the

pump will shut itself off until the motor cools to its normal temperature. Repeated overheating

may cause damage to the pump.

WARNING

Adjustable

Wrench

Flat Tip

Screwdriver

Dedicated

120V, 60 Hz

15A GFCI

SHOCK HAZARD:

Turn OFF electrical power at Fuse Box or

Circuit Breaker before performing any work!

SAFETY TIPS:

Be sure to read and understand all instructions

before beginning installation.

Inspect all connections after installation.

Be sure to wear proper eye protection.

800-537-2107 www.speakman.com

NEED HELP?

For additional assistance or service please contact:

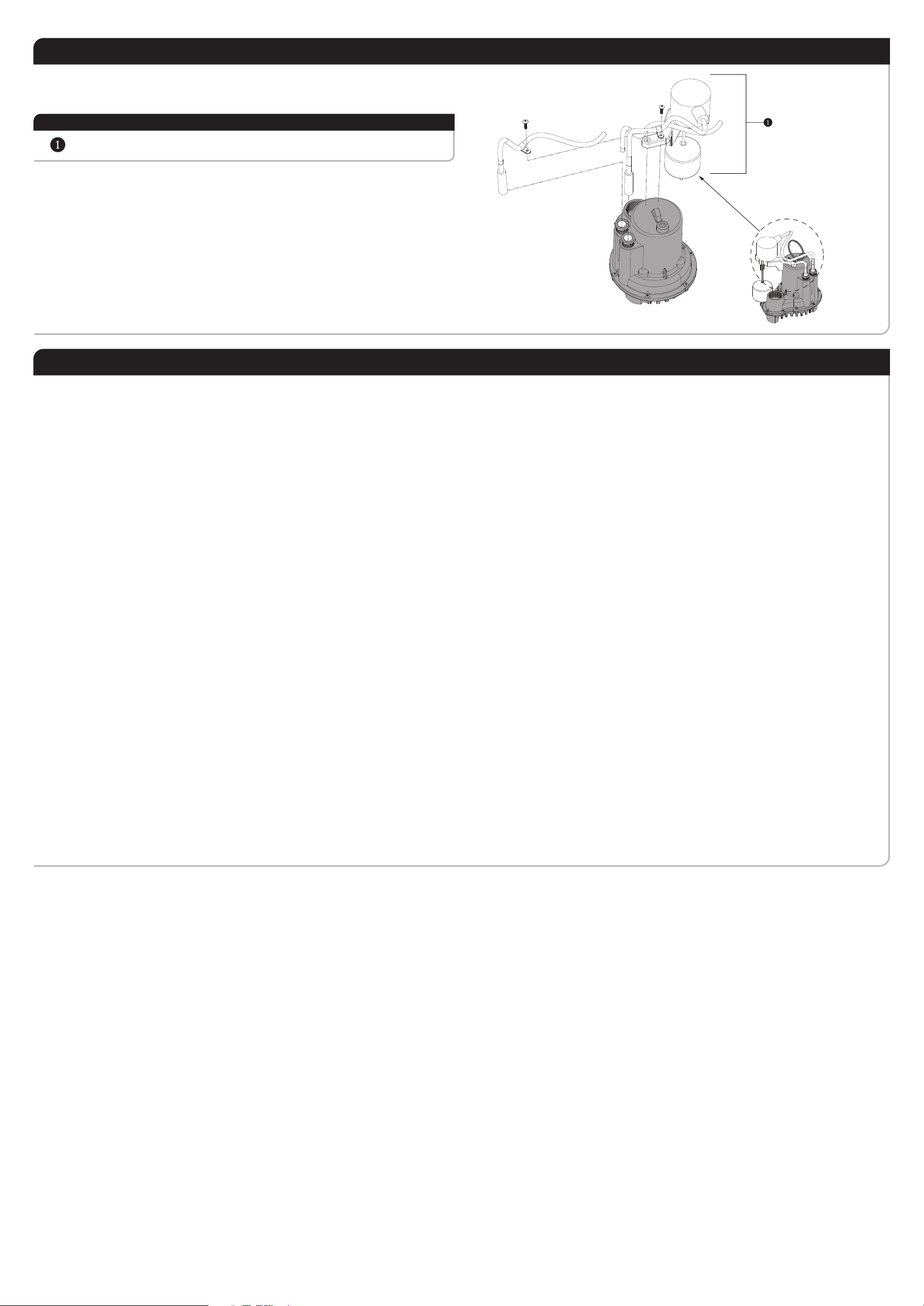

1

POSITION PUMP

Position your Pump in the sump and be sure that the Float Switch moves freely without touching

the wall of the sump or other obstructions. Be sure the incoming water does not interfere with

Float Switch. Ensure the Pump is sitting on a hard surface.

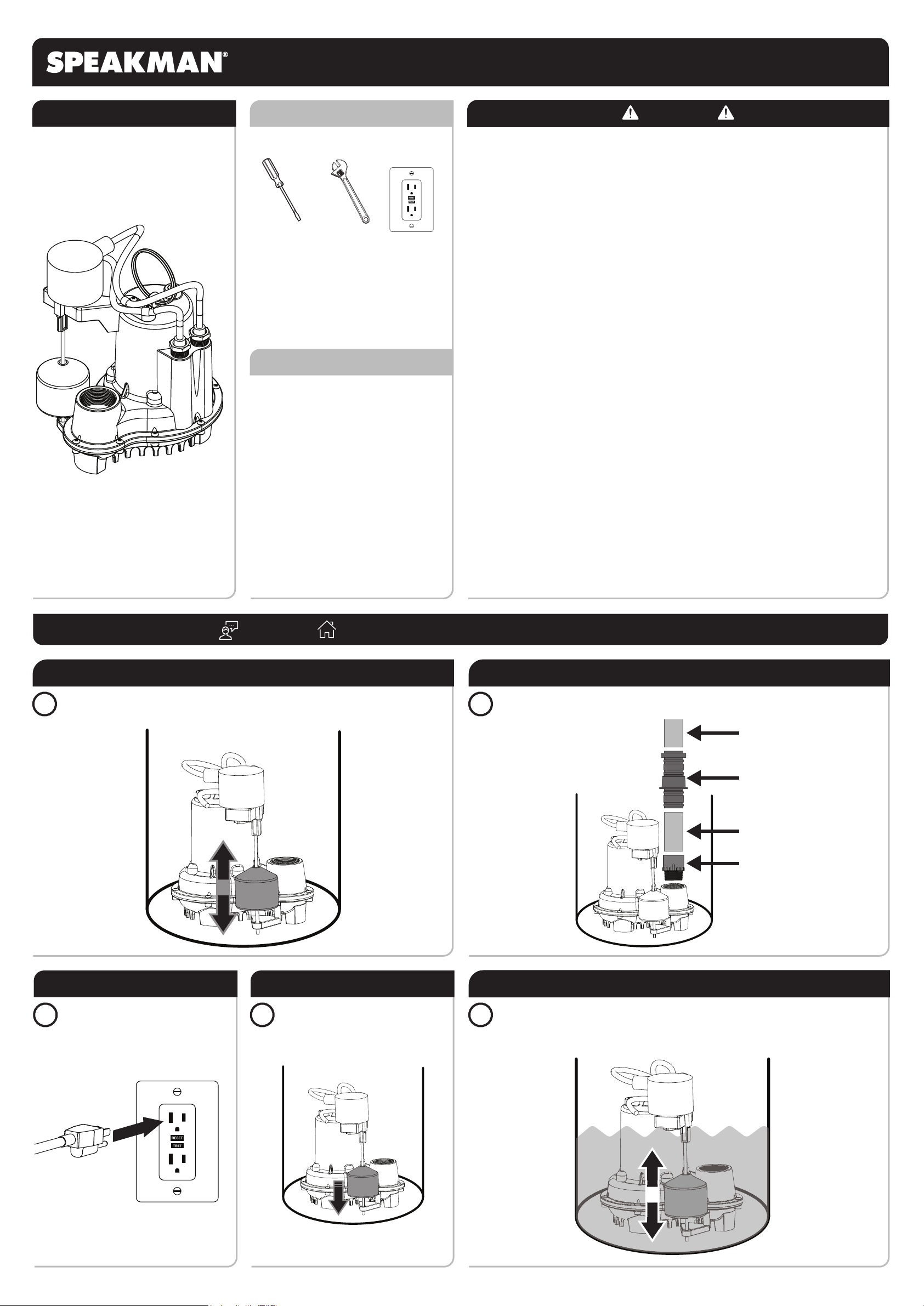

2

INSTALL DISCHARGE LINE

Install a 1-1/2” Male Pipe Adapter, 1-1/2” Discharge Pipe, and Check Valve in accordance to

code.

1-1/2” Male Pipe Adapter

1-1/2” Discharge Pipe

Check Valve

To Discharge Location

3

PLUG IN

Plug Power Cord into a properly

grounded GFCI outlet. A dedicated AC

circuit of 120v 15A is required.

Verify that the Power Cord routing does not

interfere with the Float Switch.

4

VERIFY FLOAT SWITCH POSITION

With the Pump plugged in and the sump

dry, the Pump should not activate. If

needed, adjust Float Level by

repositioning the rubber bushing on the

bottom of the Float Rod.

Verify that the Power Cord routing does not

interfere with the Float Switch.

5

TEST FOR PROPER OPERATION

Once installation is complete, check the functionality by filling the sump with water using a bucket

or hose. The unit should activate, pump the water from the sump, and turn off once the water

level reaches the set point of the float. If needed, adjust Float Level by repositioning the rubber

bushing on the bottom of the Float Rod.