SPECTRACOOL G28 User manual

© 2014 Pentair Equipment Protection 89116684

Rev. A P/N 89116684

SPECTRACOOL™

Air Conditioner

G28 Model

INSTRUCTION MANUAL

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 2 -

TABLE OF CONTENTS

RECEIVING THE AIR CONDITIONER...............................................................................................................................................................................3

HANDLING AND TESTING THE AIR CONDITIONER ......................................................................................................................................................3

HOW TO READ MODEL NUMBERS.................................................................................................................................................................................3

TECHNICAL INFORMATION ............................................................................................................................................................................................4

Sequence of Operation..........................................................................................................................................................................................................................4

Heating..........................................................................................................................................................................................................................................4

Cooling..........................................................................................................................................................................................................................................4

Standard and Optional Component Operation .....................................................................................................................................................................................4

Thermostat ...................................................................................................................................................................................................................................4

Remote Access Control (optional) ...............................................................................................................................................................................................4

Head Pressure Control (optional)................................................................................................................................................................................................4

Contactor (460V Units only)..........................................................................................................................................................................................................4

Overload (460V Units only) ...........................................................................................................................................................................................................4

Phase Monitor ..............................................................................................................................................................................................................................5

460V to 230V Transformer............................................................................................................................................................................................................5

115V/230V to 10V Transformer (optional)....................................................................................................................................................................................5

115V/230V to 24V Transformer and Relay (optional)...................................................................................................................................................................5

Schematics and Wiring Diagrams for Thermostat Control .................................................................................................................................................................5

4000 BTU 1-Phase Schematic (actual unit options may vary)....................................................................................................................................................5

6000 BTU 1-Phase Schematic (actual unit options may vary)....................................................................................................................................................6

G28 Generic 3-Phase Schematic (actual unit options may vary) ...............................................................................................................................................6

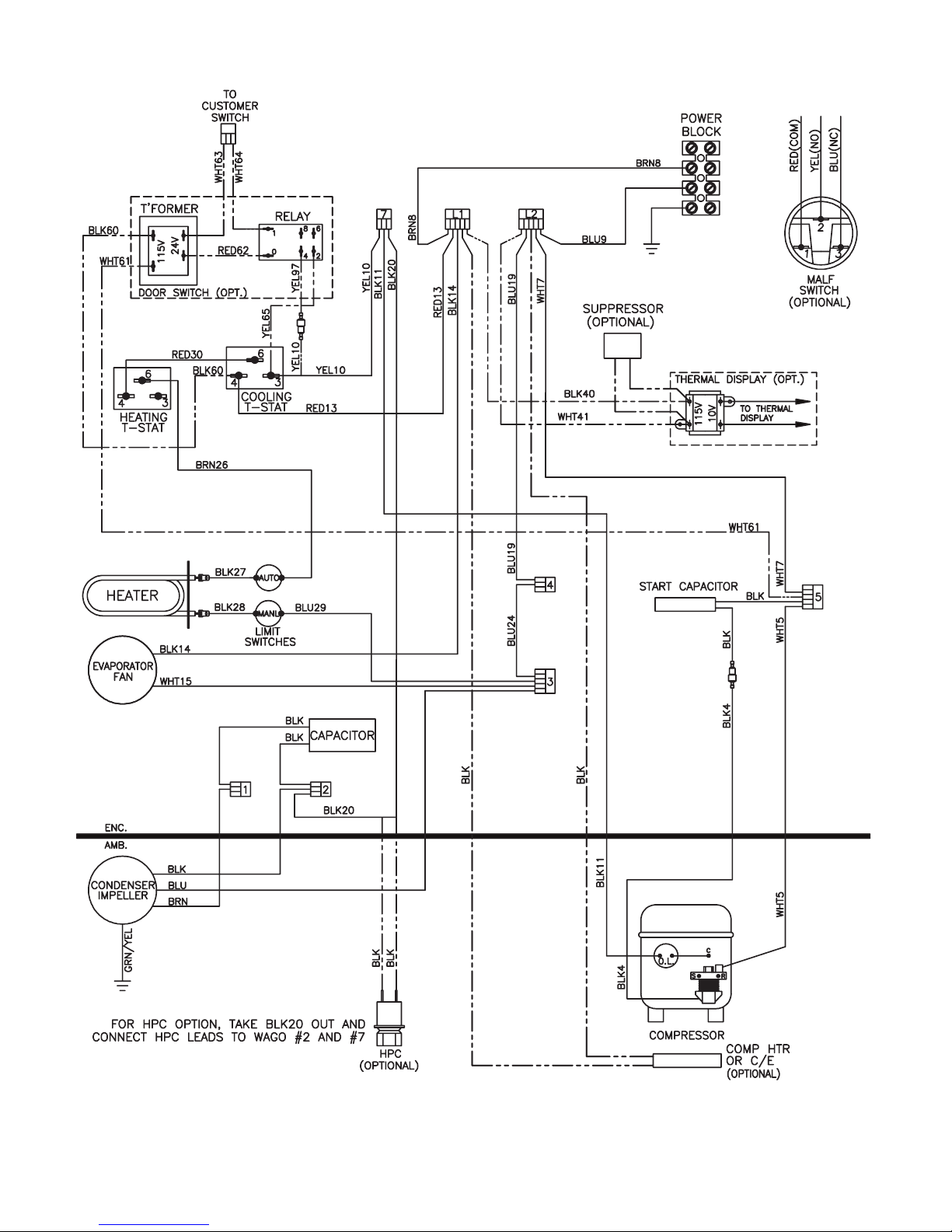

4000 BTU 1-Phase Wire Diagram (actual unit options may vary) ..............................................................................................................................................7

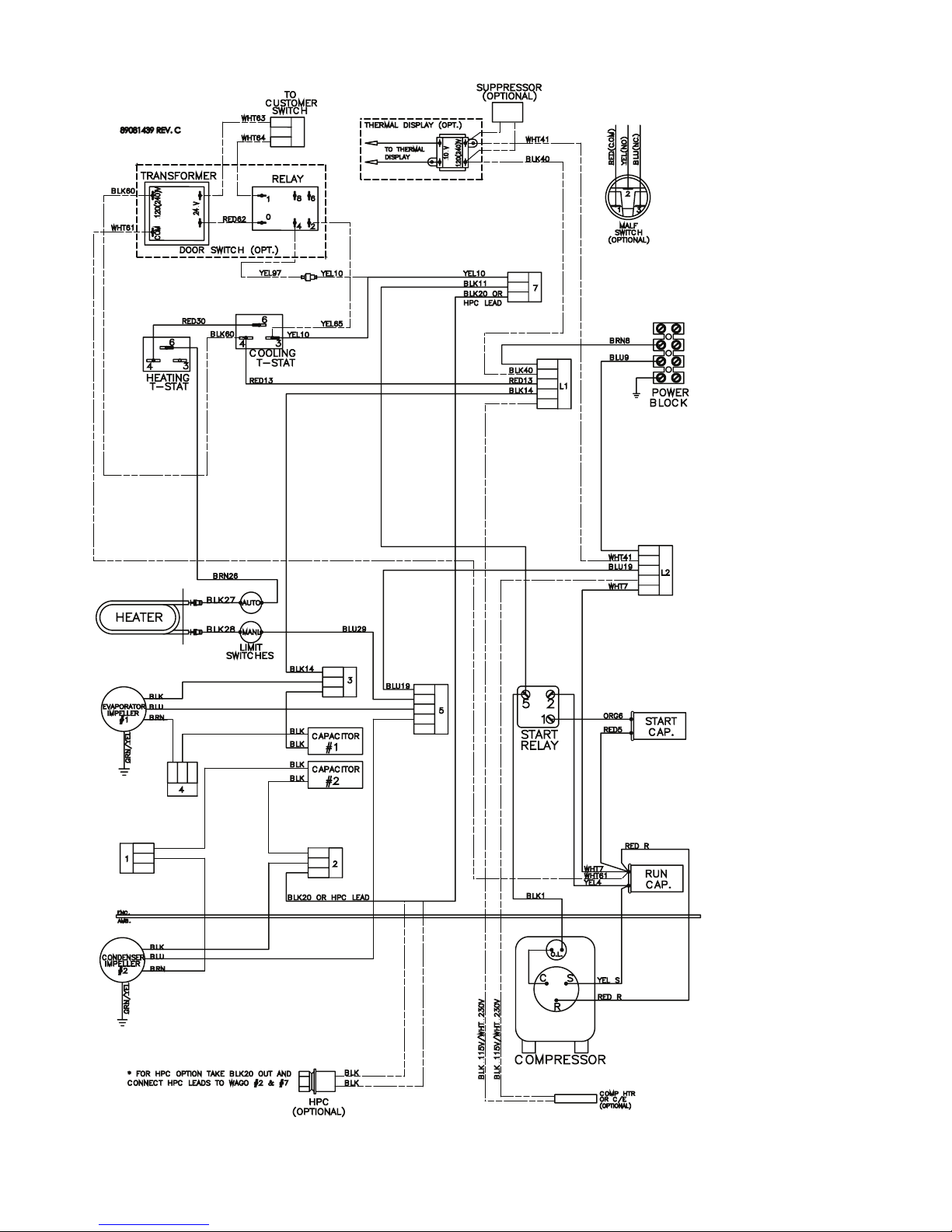

6000 BTU 1-Phase Wire Diagram (actual unit options may vary) ..............................................................................................................................................8

G28 Generic 3-Phase Wire Diagram (actual unit options may vary)..........................................................................................................................................9

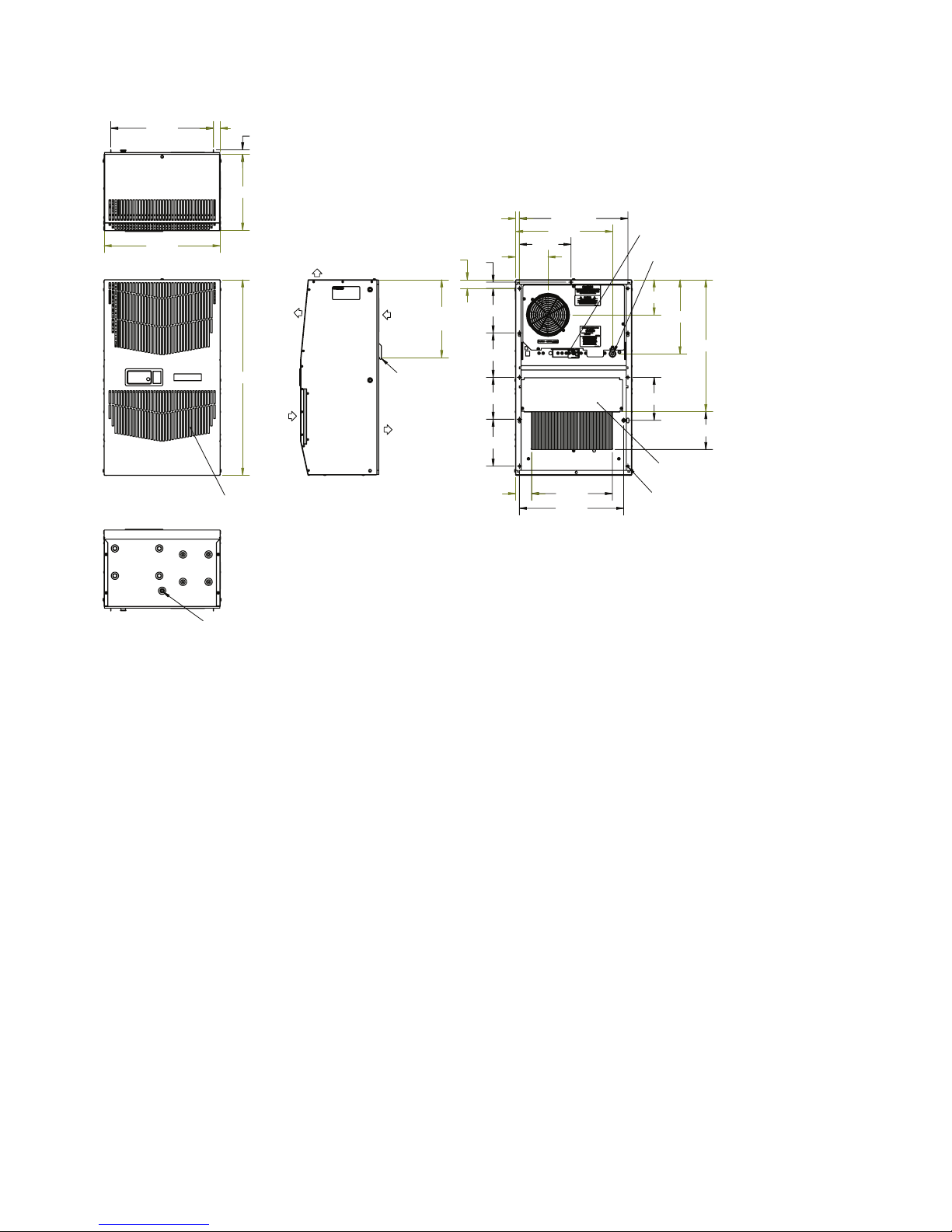

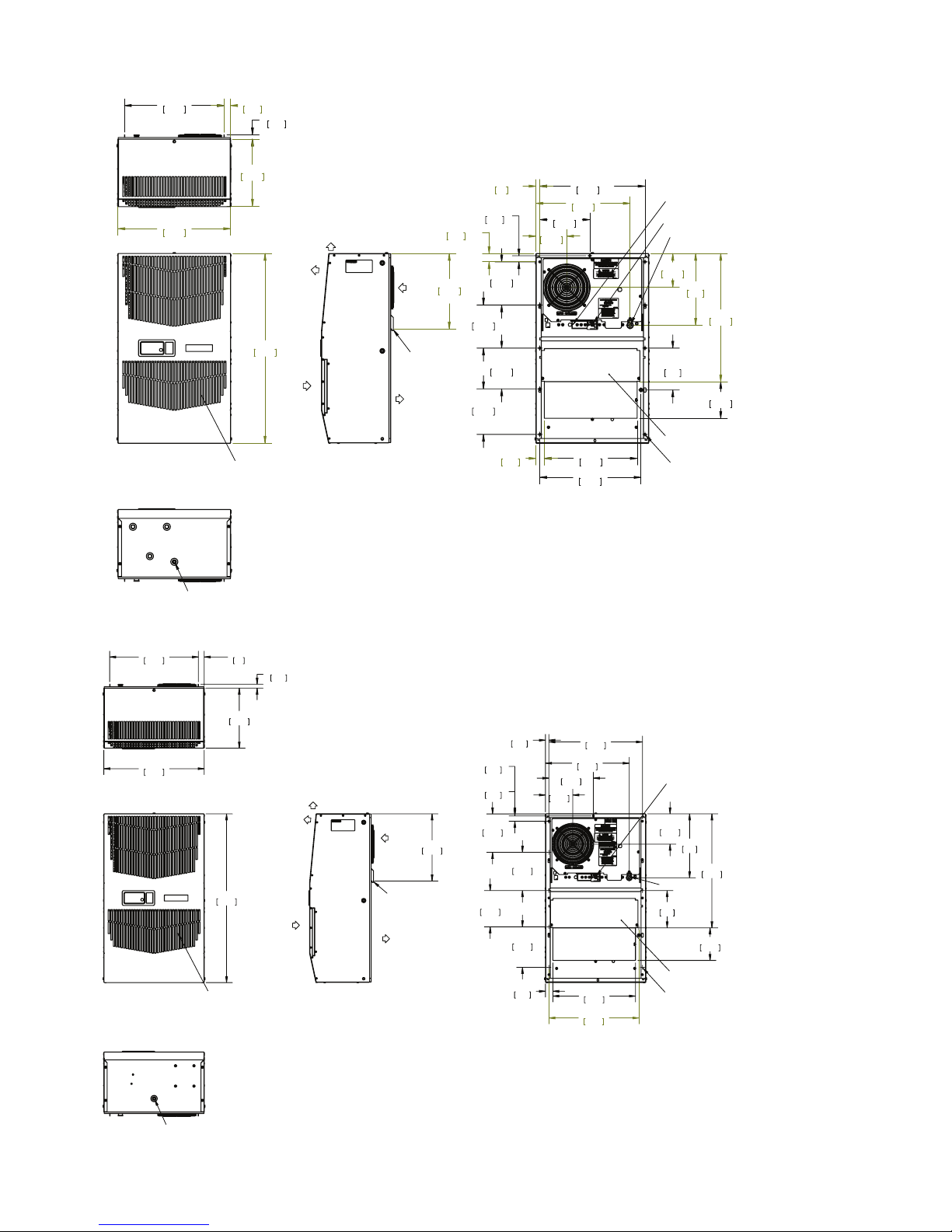

DIMENSIONAL DRAWINGS...........................................................................................................................................................................................10

4000 BTU 115V With Thermostats ......................................................................................................................................................................................................10

6000 and 4000 BTU 230V With Thermostats ......................................................................................................................................................................................11

G28 Generic 460V With Thermostats..................................................................................................................................................................................................11

INSTALLATION INSTRUCTIONS....................................................................................................................................................................................12

REMOTE ACCESS CONTROL (optional)........................................................................................................................................................................13

INTRODUCTION ...................................................................................................................................................................................................................................13

ENERGIZING THE CONTROLLER........................................................................................................................................................................................................13

CONTROL STATUS INDICATION..........................................................................................................................................................................................................13

DISPLAYING AND CHANGING PROGRAM VARIABLES ......................................................................................................................................................................14

OPERATING PARAMETERS.................................................................................................................................................................................................................14

ALARM PARAMETERS.........................................................................................................................................................................................................................14

DISPLAYING TEMPERATURE SENSOR #2 .........................................................................................................................................................................................14

COMPRESSOR RESTART TIME DELAY ...............................................................................................................................................................................................14

ALARM OUTPUT CONTACT .................................................................................................................................................................................................................14

ALARM INPUT CONNECTION .............................................................................................................................................................................................................15

ALARM CONDITION DISPLAY..............................................................................................................................................................................................................15

AIR CONDITIONER UNIT COMMUNICATION FEATURES...................................................................................................................................................................15

USB COMMUNICATION..............................................................................................................................................................................................................15

ETHERNET COMMUNICATION ..................................................................................................................................................................................................15

USING THE PC INTERFACE TOOL.......................................................................................................................................................................................................16

USB COMMUNICATION MODE...................................................................................................................................................................................................16

ETHERNET COMMUNICATION MODE .......................................................................................................................................................................................17

Remote Access Control Pin-out ...................................................................................................................................................................................18

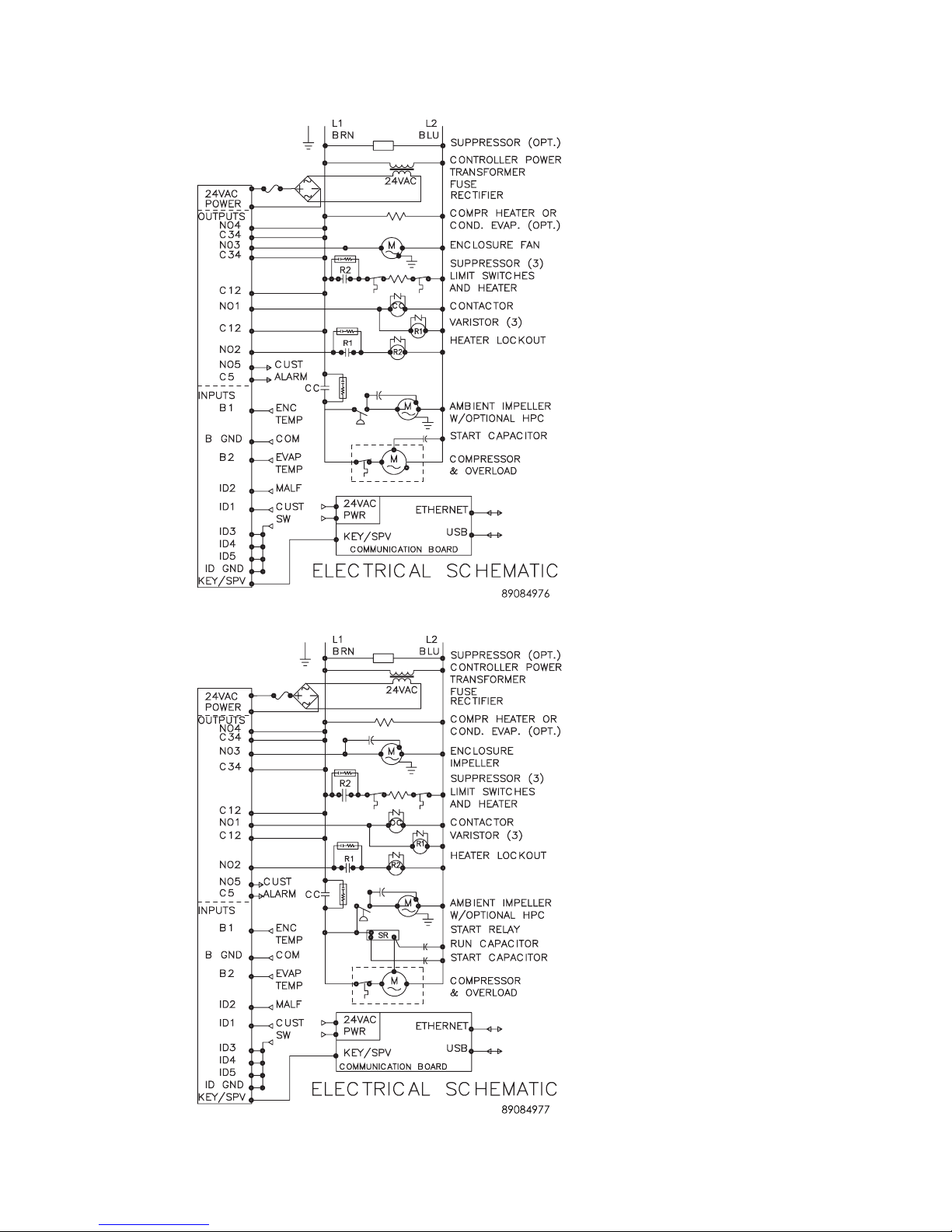

Schematics and Wiring Diagrams for Remote Access Control .........................................................................................................................................................19

4000 BTU 1-Phase Schematic (actual unit options may vary)..................................................................................................................................................19

6000 BTU 1-Phase Schematic (actual unit options may vary)..................................................................................................................................................19

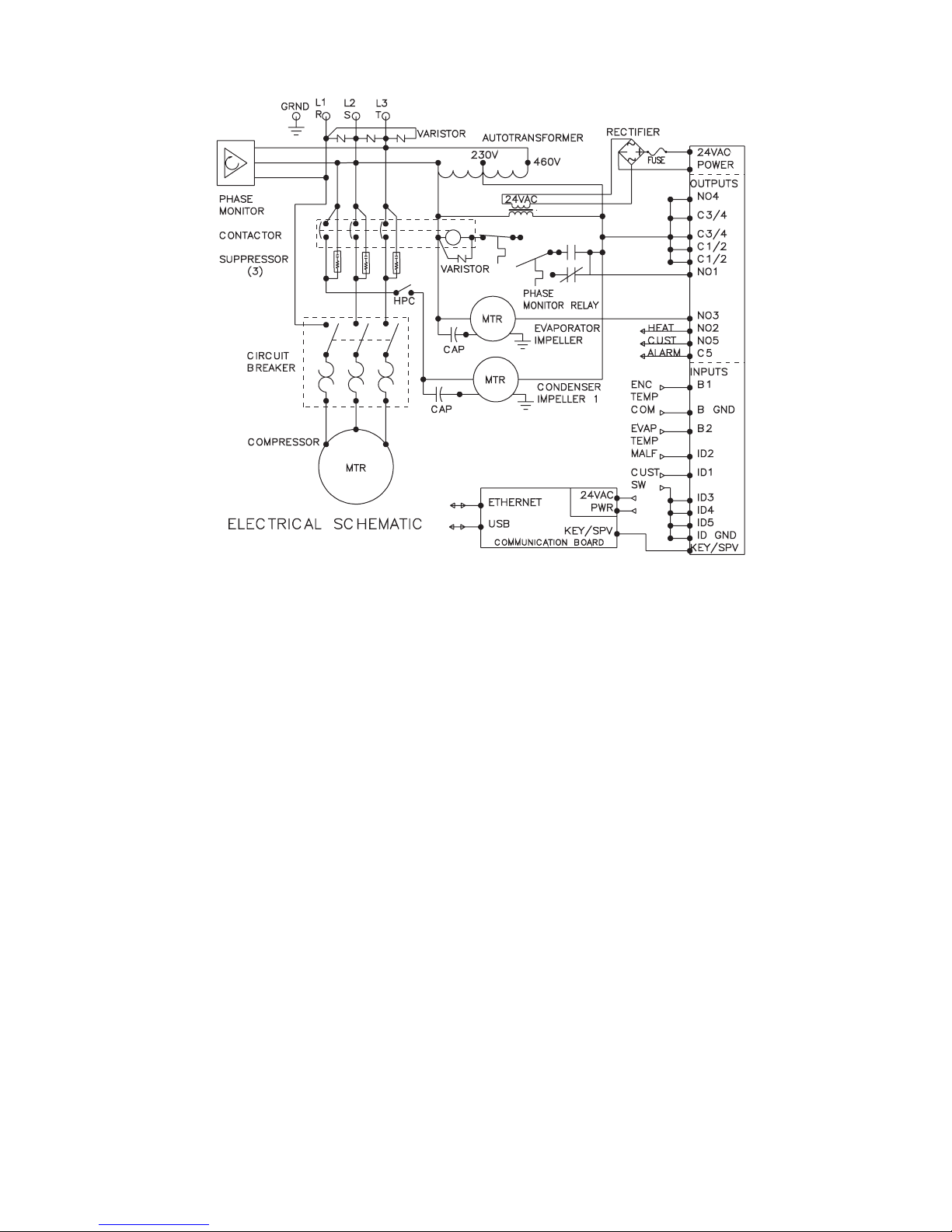

G28 Generic 3-Phase Schematic (actual unit options may vary) .............................................................................................................................................20

4000 BTU 1-Phase Wire Diagram for Remote Access Control (actual unit options may vary)...............................................................................................21

6000 BTU 1-Phase Wire Diagram for Remote Access Control (actual unit options may vary)...............................................................................................22

G28 Generic 3-Phase Wire Diagram for Remote Access Control (actual unit options may vary)...........................................................................................23

DIMENSIONAL DRAWINGS...........................................................................................................................................................................................24

4000 BTU 115V With Remote Access Control.....................................................................................................................................................................................24

4000 and 6000 BTU 230V With Remote Access Control.....................................................................................................................................................................24

INSTALLATION INSTRUCTIONS WITH REMOTE ACCESS CONTROL..........................................................................................................................25

MAINTENANCE .............................................................................................................................................................................................................26

Compressor .........................................................................................................................................................................................................................................26

Inlet Air Filter.......................................................................................................................................................................................................................................26

How To Remove, Clean or Install a New Inlet Air Filter.....................................................................................................................................................................26

Condenser and Evaporator Air Movers ..............................................................................................................................................................................................27

Refrigerant Loss..................................................................................................................................................................................................................................27

Refrigerant Properties Chart (R 407c)................................................................................................................................................................................................28

Refrigerant Properties Chart (R 134a)................................................................................................................................................................................................28

Functional Data....................................................................................................................................................................................................................................29

4000/6000 BTU Unit Characteristics...................................................................................................................................................................................................30

SERVICE DATA ...............................................................................................................................................................................................................31

Components List .................................................................................................................................................................................................................................31

TROUBLE SHOOTING....................................................................................................................................................................................................32

Basic Air Conditioning Trouble Shooting Check List - Thermostat Version .....................................................................................................................................32

Symptoms and Possible Causes - Thermostat Version.....................................................................................................................................................................33

Basic Air Conditioning Trouble Shooting Check List - Remote Access Control Version..................................................................................................................34

Symptoms and Possible Causes - Remote Access Control Version .................................................................................................................................................36

WARRANTY....................................................................................................................................................................................................................38

RETURN AND REPAIR POLICY ...........................................................................................................................................................................................................38

LIMITATION OF LIABILITY ...................................................................................................................................................................................................................39

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection

89116684 - 3 -

RECEIVING THE AIR CONDITIONER

Inspect the air conditioner. Check for concealed damage that may have occurred during shipment. Look for dents,

scratches, loose assemblies, evidence of oil, etc. Damage evident upon receipt should be noted on the freight bill.

Damage should be brought to the attention of the delivering carrier -- NOT to Pentair Equipment Protection --

within 15 days of delivery. Save the carton and packing material and request an inspection. Then file a claim with

the delivering carrier.

Pentair Equipment Protection cannot accept responsibility for freight damages; however, we will assist you in any

way possible.

HANDLING AND TESTING THE AIR CONDITIONER

If the air conditioner has been in a horizontal position, be certain it is placed in an upright, vertical or mounting

position for a minimum of five (5) minutes before operating.

Do not attempt to operate the air conditioner while it is horizontal

or on its side, back or front. The refrigeration compressor is filled

with lubricating oil. This will cause permanent damage to the air

conditioner and also voids the warranty.

CAUTION

TEST FOR FUNCTIONALITY BEFORE MOUNTING THE AIR CONDITIONER TO THE ENCLOSURE.

Refer to the nameplate for proper electrical current requirements, and then wire the unit to a properly grounded

power supply using copper conductors only. Power supply wiring should be restrained after field installation to

ensure no contact with internal fan. Minimum circuit ampacity should be at least 125% of the amperage shown on

the unit nameplate. No other equipment should be connected to this circuit to prevent overloading

Immediately after applying power, the evaporator blower (enclosure air) should start running. Operate the

air conditioner with the compressor running for five (5) to ten (10) minutes. You will need to set the cooling

thermostat or controller setpoint below the ambient temperature to operate the compressor.

Condenser air temperatures should be warmer than normal room temperatures within a few minutes after the

condenser impellers start.

See Sequence of Operation on page 4 for specifics on how the unit operates when powered up.

HOW TO READ MODEL NUMBERS

G28 06 4 6 G150

12345

1. Identifies the type/family of air conditioner and the approximate height (i.e. G28 = Global family

about 28 inch high).

2. This is the air conditioner’s listed capacity in BTU/Hr. at rated conditions. (i.e. 06=6,000 BTU/Hr. at

131/131 F)

3. 1 = 115 Volt, 2 = 230 Volt, 4 = 460 Volt.

4. 6 = 50/60 Hz or 60 Hz only.

5. Unique set of numbers for each air conditioner which identifies the accessories on a model.

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 4 -

TECHNICAL INFORMATION

SEQUENCE OF OPERATION

The air conditioner comes standard with two internally mounted thermostats or remote access control. There

are two modes of operation; heating and cooling. During heating and cooling modes the evaporator fan will be

running.

HEATING

When the enclosure temperature is below the heating thermostat setpoint, power is applied to the

heaters. When the enclosure temperature is 10 degrees above the setpoint the heater is powered off.

COOLING

When the enclosure temperature is above the cooling thermostat setpoint, power is applied through the

thermostat. The compressor is then energized either directly or through a contactor if unit requires one.

The condenser impellers will start immediately if the unit is not equipped with an optional head pressure

control switch. If the unit is equipped with an optional head pressure control switch, the condenser

impellers will start once the refrigerant pressure reaches the setting of the switch. Component specific

information is listed below.

Operating the air conditioner below the minimum ambient temperature or above the maximum ambient

temperatures indicated on the nameplate voids all warranties. DO NOT set the enclosure thermostat to a

temperature lower than 70 F. Doing so can increase the likelihood of frost buildup on the evaporator coil.

The moisture that the enclosure air can contain is limited. If moisture flows from the drain tube

continuously this can only mean that ambient air is entering the enclosure. Be aware that frequent

opening of the enclosure’s door admits humid air that the air conditioner must then dehumidify.

STANDARD AND OPTIONAL COMPONENT OPERATION

THERMOSTAT

The standard G28 air conditioner uses our standard 10-1061-16 thermostat. The thermostat setpoint

equals the temperature that the air conditioner turns off. The thermostat has a 10 F differential from

setpoint until it calls for cooling or heating. An example of operation is shown below.

FOR COOLING (75100 F RANGE):

• Thermostat setpoint = 80 F

• Cooling turns on at 90 F

• Cooling turns off at 80 F

FOR HEATING (5565 F RANGE):

• Thermostat setpoint = 55 F

• Heating turns on at 55 F

• Heating turns off at 65 F

NOTE: For testing purposes only, the thermostat stop screw may be removed (on units so

equipped) to allow settings below 70 F. After testing, replace the stop screw and verify that

the thermostat cannot be set below 70 F. Extended operation below 70 F can cause coil freeze

ups resulting in reduced load and/or unit damage.

REMOTE ACCESS CONTROL (OPTIONAL)

See REMOTE ACCESS CONTROL (optional) on page 13

HEAD PRESSURE CONTROL (OPTIONAL)

Unit is set at the factory, no adjustment necessary.

At a saturated condenser temperature of 85 F (95 psig), the condenser fans will power off. At a saturated

condenser temperature of 118 F (165 psig), the condenser fans will power on.

CONTACTOR (460V UNITS ONLY)

The contactor on this model uses a 230V coil.

OVERLOAD (460V UNITS ONLY)

Set overload reset setting to automatic “A” and trip point dial to 1.6A.

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection

89116684 - 5 -

PHASE MONITOR

This product is equipped with Phase/Voltage Protection. Please verify correct phasing and voltage before

operating. Note the fans may still operate if phasing is incorrect, but the compressor will not, so the unit

will not cool. Illuminated light on Phase Monitor indicates phase is correct.

If the light is not illuminated, disconnect power from the unit and swap any two power leads at the

terminal block. This should correct the phasing. The light should now illuminate when power is reapplied.

460V TO 230V TRANSFORMER

The 230V from this transformer powers the fans, contactor and optional transformers. 460V is only used

to run the compressor.

115V/230V TO 10V TRANSFORMER (OPTIONAL)

This transformer powers the thermal display on thermostat controlled units only.

115V/230V TO 24V TRANSFORMER AND RELAY (OPTIONAL)

The transformer and relay are used to operate the condenser blower and compressor by using a customer

supplied, remote mounted door switch. This is not a safety door switch, but rather, only helps to reduce

condensation at the evaporator coil if the door is opened. The unit will remain electrified when the door

switch is operated with the evaporator fan continuing to operate, and potentially, if temperatures are low

enough, the heater may continue to operate on outdoor models.

SCHEMATICS AND WIRING DIAGRAMS FOR THERMOSTAT CONTROL

4000 BTU 1PHASE SCHEMATIC (ACTUAL UNIT OPTIONS MAY VARY)

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 6 -

6000 BTU 1PHASE SCHEMATIC (ACTUAL UNIT OPTIONS MAY VARY)

G28 GENERIC 3PHASE SCHEMATIC (ACTUAL UNIT OPTIONS MAY VARY)

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection

89116684 - 7 -

4000 BTU 1PHASE WIRE DIAGRAM (ACTUAL UNIT OPTIONS MAY VARY)

89077284

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 8 -

6000 BTU 1PHASE WIRE DIAGRAM (ACTUAL UNIT OPTIONS MAY VARY)

89081439

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection

89116684 - 9 -

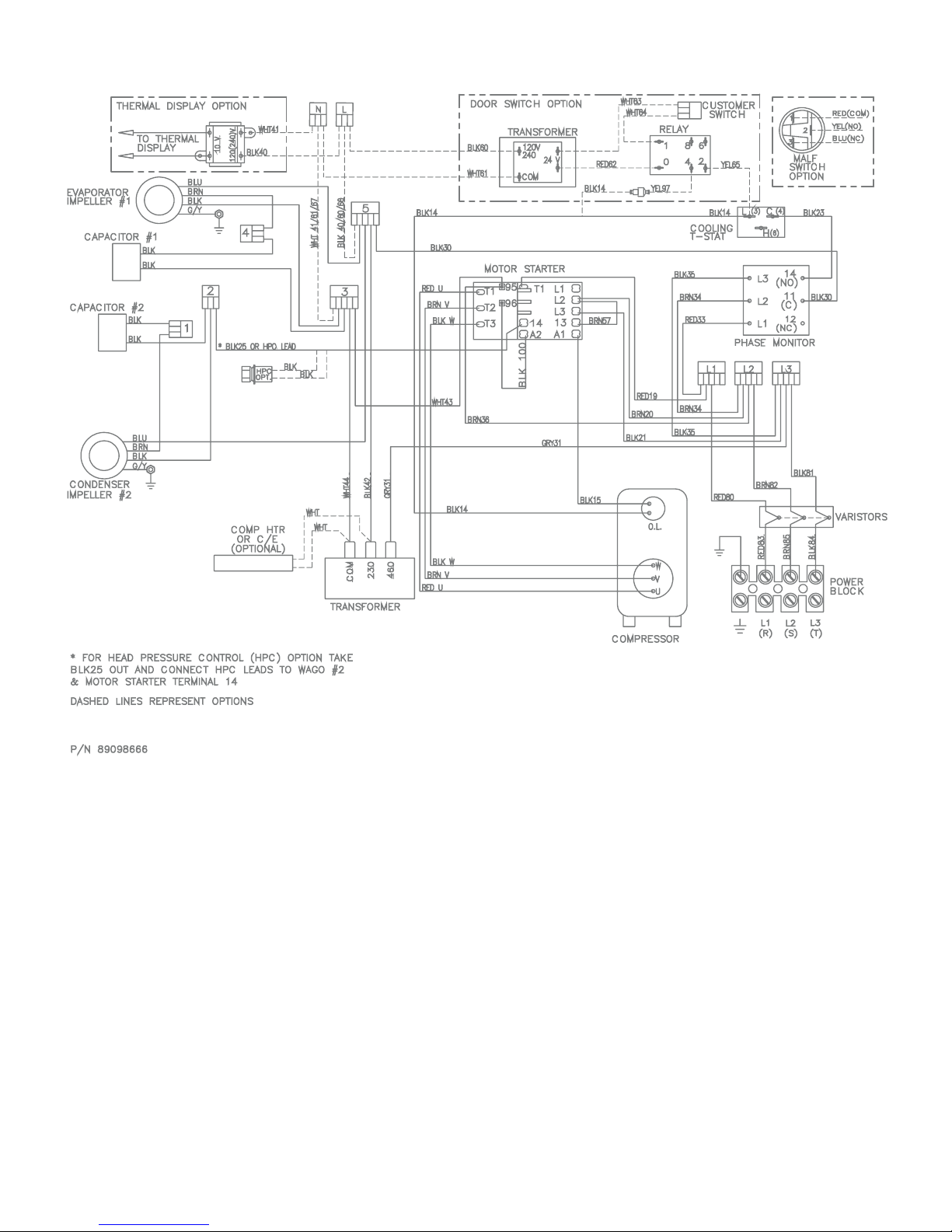

G28 GENERIC 3PHASE WIRE DIAGRAM (ACTUAL UNIT OPTIONS MAY VARY)

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 10 -

DIMENSIONAL DRAWINGS

4000 BTU 115V WITH THERMOSTATS

&/($1$%/(5(86$%/(

$/80,180,1/(7),/7(5

%(+,1'5(029$%/(3$1(/

&22/

$,5287

(1&/2685(

$,5,1

$0%,(17

$,5,1

:$50

$,5287

5(029$%/(

+$1*,1*

7$%6

81&

02817,1*+2/(6

&22/,1*+($7,1*

7+(50267$76

32:(5,1/(7

237,21$/$&&(663$1(/

21/<)2581,76:,7++($7(5

$&&(66+2/(72

2''5$,1678%

127(

$33529(727<3(5

02817,1**$6.(76833/,('1276+2:1

89076942

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection

89116684 - 11 -

6000 AND 4000 BTU 230V WITH THERMOSTATS

&/($1$%/(5(86$%/(

$/80,180,1/(7),/7(5

%(+,1'5(029$%/(3$1(/

&22/

$,5287

(1&/2685(

$,5,1

$0%,(17

$,5,1

:$50

$,5287

5(029$%/(

+$1*,1*

7$%6

81&

02817,1*+2/(6

32:(5,1/(7

&22/,1*7+(50267$7

+($77+(50267$7

237,21$/

237,21$/$&&(663$1(/

21/<)2581,76:,7++($7(5

$&&(66+2/(72

>@2''5$,1678%

127(

$33529(727<3(5

02817,1**$6.(76833/,('1276+2:1

88026303

G28 GENERIC 460V WITH THERMOSTATS

28.59

726.2

CLEANABLE, REUSABLE

ALUMINUM INLET FILTER

BEHIND REMOVABLE PANEL.

15.05

382.2 .65

(2)

16.6

17.01

432.1

.98

25

10.18

258.6

11.38

288.9

COOL

AIR OUT

ENCLOSURE

AIR IN

AMBIENT

AIR IN

WARM

AIR OUT

REMOVABLE

HANGING

TABS

15.26

387.6

14.00

355.6

5.52

140.2

1.26

31.9

5.13

130.2 10.83

275

19.32

490.7

.57

14.5 15.87

403.1

14.20

360.6

7.55

191.8

4.64

117.7

1.26

32.1

.91

23.2

6.30

160

6.87

(2)

174.5

6.13

155.7

6.50

(2)

165.1

6.50

(2)

165.1

1/4-20 UNC (11)

MOUNTING HOLES

POWER INLET

COOLING THERMOSTAT

OPTIONAL ACCESS PANEL

(ONLY FOR UNITS WITH HEATER)

ACCESS HOLE TO

.375 [9.5] O.D. DRAIN STUB

NOTE:

APPROVE TO TYPE 3R/4/12.

1.

MOUNTING GASKET SUPPLIED (NOT SHOWN).

2.

89059479

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 12 -

INSTALLATION INSTRUCTIONS

1. Inspect the air conditioner and verify correct functionality before mounting the air conditioner. See

HANDLING AND TESTING THE AIR CONDITIONER on page 3.

2. Using the mounting gasket kit provided with the unit, install gaskets to the air conditioner, see

Figure 1.

3. Mount air conditioner on enclosure taking care not to damage the mounting gasket. The

mounting gasket is the seal between the air conditioner and the enclosure. Avoid dragging the air

conditioner on the enclosure with the mounting gasket attached as this could cause rips or tears

in the gasket and risk losing the water tight seal.

4. Allow unit to remain upright for a minimum of five (5) minutes before starting. CAUTION! Air

conditioner must be in upright position during operation.

5. Refer to the nameplate for electrical requirements. Wire the unit to a properly grounded power

supply. For 3 phase units, once power is applied, verify that phase monitor light is illuminated

which indicates correct electrical phasing. Electrical circuit should be fused with slow blow or

HACR circuit breaker.

6. Some air conditioners require a remote mounted thermostat. Wire the thermostat outputs to the

appropriate terminals on the 24 VAC terminal strip by noting the locations on the correct wiring

diagram.

7. Set thermostat for required cabinet temperature. Refer to Sequence of Operation on page 4 for

thermostat adjustment and operation.

28100013

89059115

Surface Mount Partial Recess Mount

Figure 1

Cut-out Drawing

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection

89116684 - 13 -

REMOTE ACCESS CONTROL (OPTIONAL)

INTRODUCTION

The Remote Access Control is a parametric controller for the complete management of air conditioners. All

settings are pre-programmed at the factory. Cooling/heating set-points, cooling/heating differential and high /low

temperature alarm set-points can be adjusted by the user. Alarms are outputted through a relay contact and also

can be accessed through an Ethernet connection utilizing SNMP, EtherNet/IP and Modbus TCP. A USB connection

is also provided and can be used to interface with the controller utilizing Modbus RTU.

ENERGIZING THE CONTROLLER

The controller is wired and programmed at the factory to be energized when power is supplied to the air

conditioner.

CONTROL STATUS INDICATION

The display has numerous symbols that indicate if the controller is heating, cooling, alarming, if the compressor

is enabled, and if the ambient fan is enabled. The 3 alpha-numeric characters further describe alarms and show

the cabinet temperature by default.

SYMBOL COLOR ICON ON ICON FLASHING

1AMBER Compressor On Start-up Request

2,3,4 AMBER Not Used Not Used

AAMBER Compressor On Not Used

BAMBER Evaporator Fan On Start-up Request

CAMBER Not Used Not Used

DAMBER Not Used Not Used

EAMBER Heater Active Not Used

FRED Alarm Active Not Used

GAMBER Controller Active Not Used

HAMBER Not Used Not Used

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 14 -

DISPLAYING AND CHANGING PROGRAM VARIABLES

Access: To view and/or change parameters, press and hold the Prg and Sel buttons for greater than 5 seconds.

Press the up or down arrow buttons until “22” is displayed, then press Sel button. When “S-P” is displayed, press

Sel.

Navigation: Press up or down arrows to display sub-menus then press Sel to select the desired sub-menu. In the

sub-menu, use up or down arrows to display parameters for viewing or changing and press Sel. Use Prg button to

back out of menu levels as desired.

Adjust: Use the up or down arrows to change the parameter value then push Sel to save that setting. If Sel is not

pressed, the change to the value will not be saved. Navigate to and change other parameters as desired. When

finished, push Prg to back out of the sub-menus to the main menu.

NOTE: The display will revert to normal temperature display mode if no buttons are pressed

for 60 seconds.

OPERATING PARAMETERS

Parameter Default Value Range Description

r01 80 F 72 F to 120 F Cooling set-point

r02 7 F -Cooling differential

A04 50 F* 32 F to 60 F Heating set-point*

A05 7 F* -Heating differential*

Cooling turns on at r01 + r02, and off at r01

Heating turns on at A04, and off at A04 + A05

*Functional only on units with heater option

ALARM PARAMETERS

Parameter Default Value Description

P16 125 F High Temperature Alarm

P19 40 F Low Temperature Alarm

DISPLAYING TEMPERATURE SENSOR #2

Sensor number 2, the air outlet or condenser coil sensor, can be viewed at any time by pressing the up or down

arrow button on the front panel of the controller display. The display will revert to displaying temperature sensor

number 1 (the AC inlet temperature) after 60 seconds. Both sensors can also be read through the Ethernet and

USB connections.

COMPRESSOR RESTART TIME DELAY

A factory set 6 minute (360 second) restart delay exists to reduce residual back pressure before allowing the

compressor to restart. The compressor will stay off for the entire restart duration after the compressor is

disabled. A flashing “1” on the controller display will indicate the unit is in a compressor restart delay while

calling for cooling.

ALARM OUTPUT CONTACT

The Remote Access Control has a normally open dry contact alarm output with a resistive load rating of 250 VAC

at 3 amps. Two yellow 18 AWG wires located at the back of the air conditioner provide a connection to this output.

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection

89116684 - 15 -

ALARM INPUT CONNECTION

The Remote Access Control can accept a dry contact/switch input via the two 18 AWG white wires located at the

back of the air conditioner. This input is associated with the controller display alarm mnemonic TP (door open

and/or smoke detected). [To use this feature, remove the splice connector connecting the two white wires and

connect customer supplied enclosure door switch in its place.]

ALARM CONDITION DISPLAY

There are seven possible non-latching alarm conditions detectable by the controller and are indicated on the

controller display. All alarms can also be accessed through the Ethernet and USB connections.

Alarm Mnemonic Description Cause Result Alarm Relay

TP General Alarm Door open and/or

smoke detected Unit turns off for

duration of alarm Relay Contacts Close

LA High Pressure

Warning MALF high pressure

switch opens No effect on function N/A

E1 Air Inlet Temperature

Sensor Alarm Sensor Failure Unit turns off for

duration of alarm Relay Contacts Close

E2 Air Outlet Temperature

Sensor Alarm Sensor Failure Unit turns off for

duration of alarm Relay Contacts Close

Ht High Temperature

Alarm

Default = 125 F

Cabinet over

temperature

Alarm clears at default

setting -2 F

No effect on function Relay Contacts Close

Lt Low Temperature

Alarm

Default = 40 F

Cabinet under

temperature

Alarm clears at default

setting +27 F

No effect on function Relay Contacts Close

A1 Frost Alarm Evaporator coil frozen

Alarm clears at 59 F

Compressor and

Evaporator fan off for

duration of alarm Relay Contacts Close

AIR CONDITIONER UNIT COMMUNICATION FEATURES

Air conditioner units equipped with communication capabilities provide SNMP, EtherNet/IP and Modbus TCP

protocols through Ethernet and Modbus RTU protocol via USB. Hoffman®Cooling has a PC Interface Tool

available for download that can utilize either mode to communicate with the air conditioner unit.

USB COMMUNICATION

This communication mode allows direct connection of a PC to the air conditioner unit. The protocol

supported is Modbus RTU. Use the PC Interface Tool to communicate with the air conditioner unit. A

MINI-b USB connection is provided.

ETHERNET COMMUNICATION

This communication mode allows remote connection to the air conditioner unit using SNMP, EtherNet/IP

and Modbus TCP protocols. Customers using their own software can download a MIB file for SNMP, EDS

file or EtherNet_IP Object file for EtherNet/IP and Coil_Register file for Modbus TCP.

Note: ACU has a default IP Address of 192.168.1.2

Both Ethernet and USB communication modes allow the ability to:

• Read ACU inlet and outlet air temperatures

• Read and change Cooling Set-point and Cooling Differential

• Read and change Heating Set-point, Heating Differential

• Read and change High and Low Temperature Alarm Settings

• Read and change Gateway IP Address, Device IP Address, Subnet Mask, Trap IP Address and Community

• Read and change Unit Identification

• Read and change the state of IP addressing (static or dynamic)

• Read current Alarm Status

SOFTWARE AND CONFIGURATION FILE DOWNLOADS

The PC Interface Tool, MIB file, EDS file, EtherNet_IP Object file and Coil_Register file can be downloaded

from www.hoffmanonline.com.

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 16 -

USING THE PC INTERFACE TOOL

The PC Interface Tool gives the user the ability to communicate with the air conditioner unit to read/write

parameters using either Ethernet or USB connections.

USB COMMUNICATION MODE

NOTE: Before connecting unit to the PC, make note of the comm ports present. After the unit

is connected to the PC, a new comm port will be added to the list. Use this new comm port.

• From Tools menu select Use Ethernet

• When Use Ethernet is unchecked, then Comm Port menu is enabled, Device IP and Community boxes are not

shown, and USB communication can be used

• To set the comm port, choose Comm Port from the Tools menu and then select the comm port from the combo box

VIEWING AIR CONDITIONER UNIT VALUES

To view Air Conditioner Unit values

• Select the ACU Values tab

• Select the Enable Comm button (the PC Interface will now be communicating with unit)

• To stop communication select the Disable Comm button

CHANGING AIR CONDITIONER UNIT VALUES

To change ACU Values

• Select the Settings tab

• Select the value to change

• Make the change to the value

• Select the Change Setting button

• Change can be verified in ACU Values tab

VIEWING AND CHANGING ETHERNET INFORMATION

To view and change Ethernet Information

• Select Ethernet Info tab

To view Ethernet Information

• Click Read Ethernet Info button

To change to dynamically assigning IP Address Mode

• Check Use DHCP Server checkbox

• Enter Trap IP Address and Community

• Click Load Ethernet Info button

To change to statically assigning IP Address Mode

• Uncheck Use DHCP Server checkbox

• Enter Device IP Address, Subnet Mask, Gateway IP Address, Trap IP Address and Community

• Click Load Ethernet Info button

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection

89116684 - 17 -

ETHERNET COMMUNICATION MODE

• From Tools menu select Use Ethernet

• When Use Ethernet is checked, Comm Port selection is disabled, Device IP and Community boxes are shown and

Ethernet communication can be used.

• Enter unit’s IP Address and Community string in Device IP and Community boxes at the bottom of the PC Interface

Tool.

Each unit has two community strings. One is a Read/Write community string (defaulted to

‘private’) that can be changed by the customer (must be 4 to 8 characters long). The other is a

Read-Only community string (‘public’) and cannot be changed.

VIEWING AIR CONDITIONER UNIT VALUES

To view Air Conditioner Unit values

• Select the ACU Values tab

• Select the Enable Comm button (the PC Interface will now be communicating with unit)

• To stop communication select the Disable Comm button

CHANGING AIR CONDITIONER UNIT VALUES

To change ACU Values

• Select the Settings tab

• Select the value to change

• Make the change to the value

• Select the Change Setting button

• Change can be verified in ACU Values tab

VIEWING AND CHANGING ETHERNET INFORMATION

To view and change Ethernet Information

• Select Ethernet Info tab

To view Ethernet Information

• Click Read Ethernet Info button

To change to dynamically assigning IP Address Mode

• Check Use DHCP Server checkbox

• Enter Trap IP Address and Community

• Click Load Ethernet Info button

To change to statically assigning IP Address Mode

• Uncheck Use DHCP Server checkbox

• Enter Device IP Address, Subnet Mask, Gateway IP Address, Trap IP Address and Community

• Click Load Ethernet Info button

ALARM LOG ACCESSIBLE WITH SNMP

• Using custom software with the provided MIB file gives the ability to view a log of the last 25 alarms

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 18 -

REMOTE ACCESS CONTROL PINOUT

FUNCTION NAME PIN # WIRE #

U1 OUTPUTS

COOL No1 1ORG78

C1/2 2BLK

HEAT No2 7BRN76

C1/2 3BLK

ENCL MI No3 8BLK77

C3/4 4BLK

NA No4 (na) 9BLK

C3/4 10 BLK

ALARM RELAY OUTPUT No5 12 YEL39

C5 6YEL38

NA x 5 NA

NA x11 NA

U2 INPUTS

ALARM INPUT

CONNECTION ID1 8WHT63

MALFUNCTION NC SWITCH ID2 1BLU88

NA ID3 (na) 9BLU

NA ID4 (na) 2BLU

NA ID5 (na) 10 BLU

DIGITAL INPUT GROUND ID GND 3BLU

NA Y (na) 4NA

NA GND (na) 5NA

T1, EVAP IN THERMISTOR B1 13 RED

T2, EVAP OUT THERMISTOR B2 12 RED

T1, T2 GND GND 6WHT

NA B3 11 NA

CONTROLLER POWER G 7 BLK40

CONTROLLER POWER G0 14 WHT41

U3 DATA

POWER 1RED

GROUND 2BLACK

DIRECTION 3GREEN

DATA 4WHITE

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection

89116684 - 19 -

SCHEMATICS AND WIRING DIAGRAMS FOR REMOTE ACCESS CONTROL

4000 BTU 1PHASE SCHEMATIC (ACTUAL UNIT OPTIONS MAY VARY)

6000 BTU 1PHASE SCHEMATIC (ACTUAL UNIT OPTIONS MAY VARY)

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

© 2014 Pentair Equipment Protection 89116684

- 20 -

G28 GENERIC 3PHASE SCHEMATIC (ACTUAL UNIT OPTIONS MAY VARY)

Distributed by:

McLean Parts

317-257-6811

5736 N. Michigan Road

Indianapolis, IN 46228

www.mcleanparts.com

Other manuals for G28

1

Table of contents

Other SPECTRACOOL Air Conditioner manuals