©Titan Tool Inc. All rights reserved. 7

Le liquide introduit dans un pistolet

pulvérisateur sans air doit l’être à pression

extrêmement élevée. Les liquides à haute

pression, en provenance du pulvérisateur ou

d’une fuite quelconque, sont capables de

pénétrer la peau et d’injecter d’importantes

quantités de liquide toxique dans l’organisme.

Si elle n’est pas traitée promptement et avec

toute l’attention voulue, la lésion causée de la

sorte peut provoquer la nécrose des tissus ou

la gangrène et donner lieu à de sérieux

handicaps permanents, voire à l’amputation

du membre atteint. Une prudence extrême

s’impose donc lors de l’utilisation de matériel

de pulvérisation sans air. EN CAS

D’INJECTION, CONSULTEZ UN MEDECIN

IMMEDIATEMENT. NE TRAITEZ PAS LA

BLESSURE COMME S’IL S’AGISSAIT

D’UNE SIMPLE COUPURE!

REMARQUE A L’INTENTION DU MEDECIN:

Une injection pénétrant la peau constitue

une lésion traumatique grave qu’il est

important de traiter chirurgicalement

aussitôt que possible. Ne perdez pas de

temps à rechercher la toxicité de

l’injection. Il s’agit là d’un risque à

envisager en cas d’injection directe dans

le circuit sanguin de certains revêtements

exotiques. La consultation d’un chirurgien

plasticien ou d’un spécialiste de la

chirurgie reconstructive de la main peut

être conseillée.

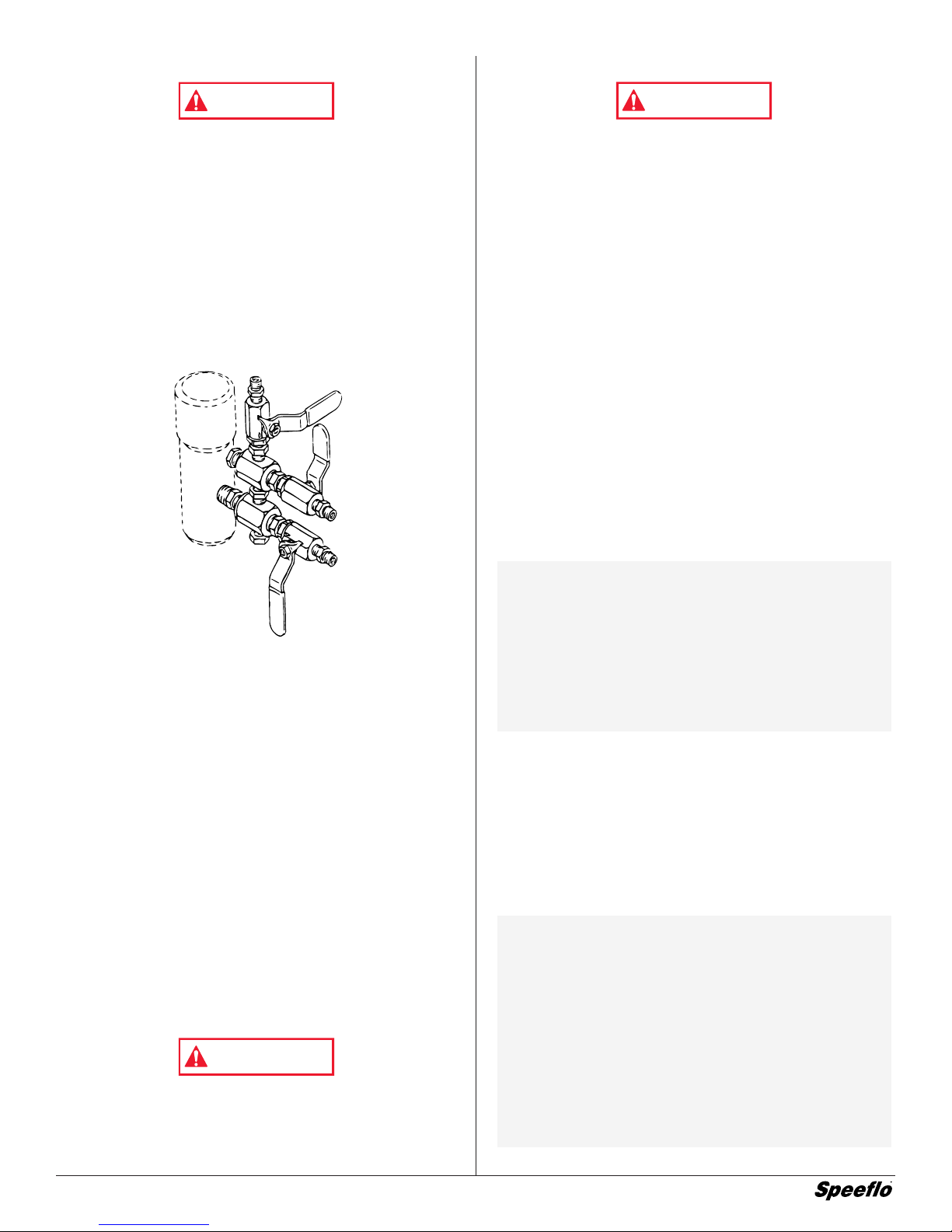

1. Maniez le pistolet avec soin. Maintenez-

vous à l’écart de la buse. N’en dirigez

JAMAIS la buse vers aucune partie de

votre corps ou vers aucune autre

personne. Ne laissez JAMAIS aucune

partie de votre corps entrer en contact

avec le flux de liquide s’échappant du

pistolet ou d’une fuite quelconque au

niveau du flexible. Verrouillez TOUJOURS

le levier de sûreté de la détente lorsque

vous n’êtes pas occupé à pulvériser.

Veillez à TOUJOURS utiliser un dispositif

de sûreté à la buse du pistolet.

2. N’essayez JAMAIS de refouler le flux de

liquide dans le pistolet au moyen de votre

doigt, de votre main ou d’un objet maintenu

contre la buse du pistolet. CET APPAREIL

N’EST PAS UN PISTOLET

PULVERISATEUR A AIR. N’utilisez aucune

pièce de matériel sans air avec une pompe

non équipée d’une soupape de surpression.

3. N’essayez JAMAIS d’enlever la buse, de

démonter ou de réparer l’appareil avant

d’avoir accompli la procédure suivante :

4. Avant de procéder au rinçage du

système, enlevez toujours la buse de

pulvérisation et réglez la pression au

niveau le plus faible possible.

5. Serrez bien tous les raccords du système

hydrodynamique avant chaque emploi. Ne

dépassez JAMAIS, avec cet appareil, une

pression de 3300 psi. Assurez-vous que

tous les flexibles accessoires, raccords,

articulations, etc. sont bien capables de

résister aux hautes pressions prévues. Ne

dépassez JAMAIS la capacité de pression

nominale d’aucun composant du système.

DANGER : Afin de réduire tout risque

d’électrocution, n’exposez pas à la pluie.

6. Des fuites risquent de se produire le long du

flexible de peinture sous l’effet de l’usure,

des torsions, des rudes traitements, etc.

auxquels il est éventuellement soumis. Les

injections de liquide dans la peau sont

possibles par la voie de telles fuites. Il est

donc important d’inspecter le flexible avant

chaque usage. N’essayez JAMAIS d’obturer

une fuite à l’aide de votre doigt ou de tout

autre membre de votre corps, de ruban

adhésif ou de tout autre moyen de fortune.

N’essayez pas non plus de réparer un

flexible de pulvérisation ; remplacez-le plutôt

par un nouveau flexible mis à la terre.

Veillez à n’utiliser que les flexibles munis de

dispositifs de sécurité à ressort.

7. Assurez-vous que le matériel sans air

utilisé et que l’objet à peindre sont

adéquatement mis à la terre, de façon à

éviter toute décharge d’électricité statique

ou toute étincelle susceptible de

provoquer un incendie ou une explosion.

ATTENTION : Tenez TOUJOURS le

pistolet contre un récipient en métal lors

du rinçage du système, après en avoir ôté

la buse. Ne vaporisez JAMAIS de

substances inflammables à proximité de

flammes nues, lampes témoin ni d’aucune

source d’allumage. Rangez à l’intérieur.

8. Le moteur électrique de cet appareil n’est

pas protégé contre les explosions. Il est

donc essentiel d’assurer une bonne

ventilation de la zone de travail et des

alentours de la pompe. Il est également

important de maintenir la pompe à une

distance minimale de 7,6 m de la zone de

pulvérisation. Certains matériaux

présentent, à défaut de suivre ces

consignes, un risque d’incendie ou

d’explosion. Suivez TOUJOURS les

précautions et avertissements du fabricant

de chaque solvant ou revêtement utilisé.

9. Portez TOUJOURS un masque et des

lunettes de protection lors de vos travaux de

pulvérisation. D’autres articles de protection

personnelle peuvent être nécessaires

suivant le type de produit pulvérisé et les

conditions d’aération. Demandez toujours

ses recommandations à votre fournisseur.

10. Maintenez toutes les tiges de rallonge à

distance des fils électriques.

11. N´altérez ou ne modifiez JAMAIS une

partie quelconque de cet appareil, ce qui

pourrait causer des défaillances.

12. Ne laissez JAMAIS le matériel sans

surveillance. Gardez-le hors de portée des

enfants et de toute personne

inexpérimentée quant à l’usage de

matériel sans air.

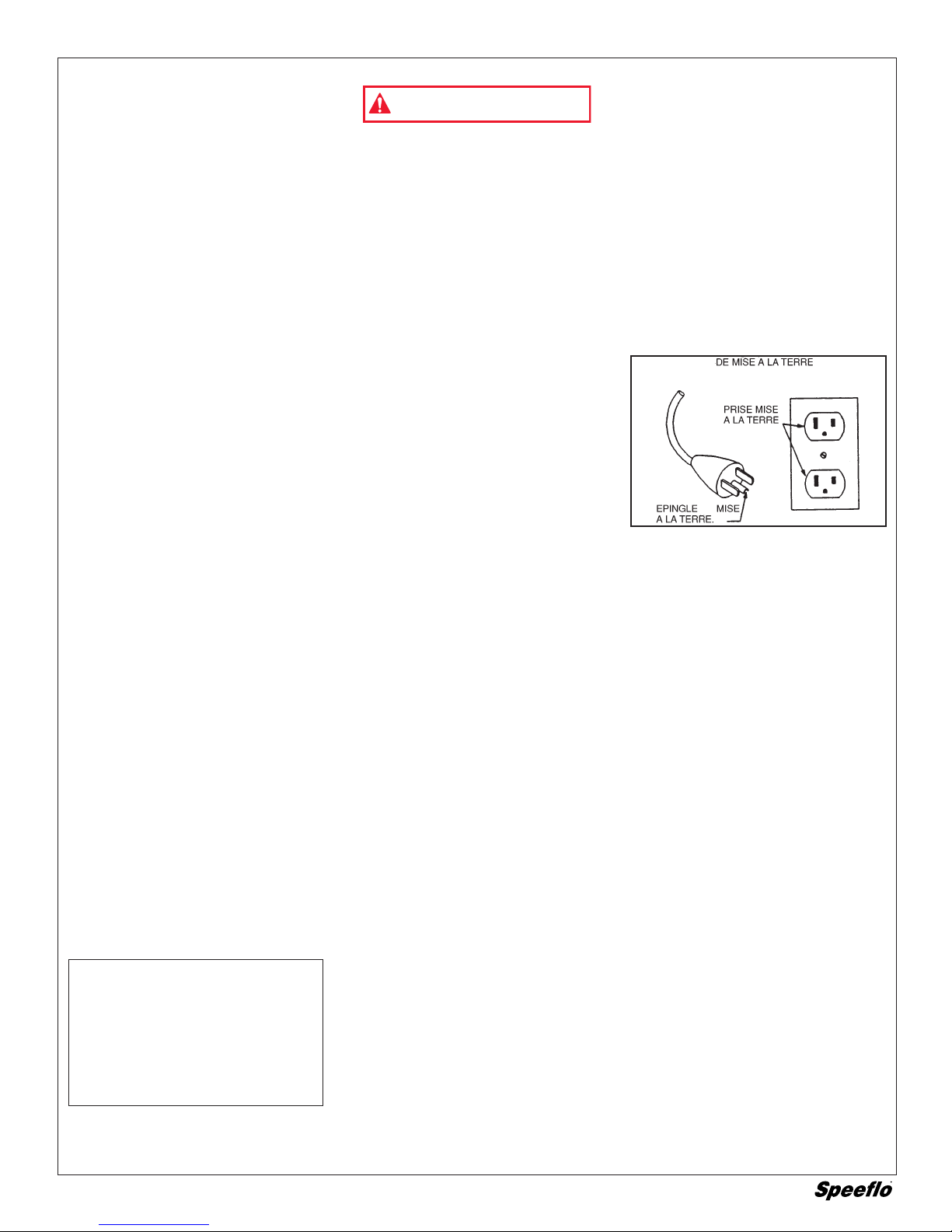

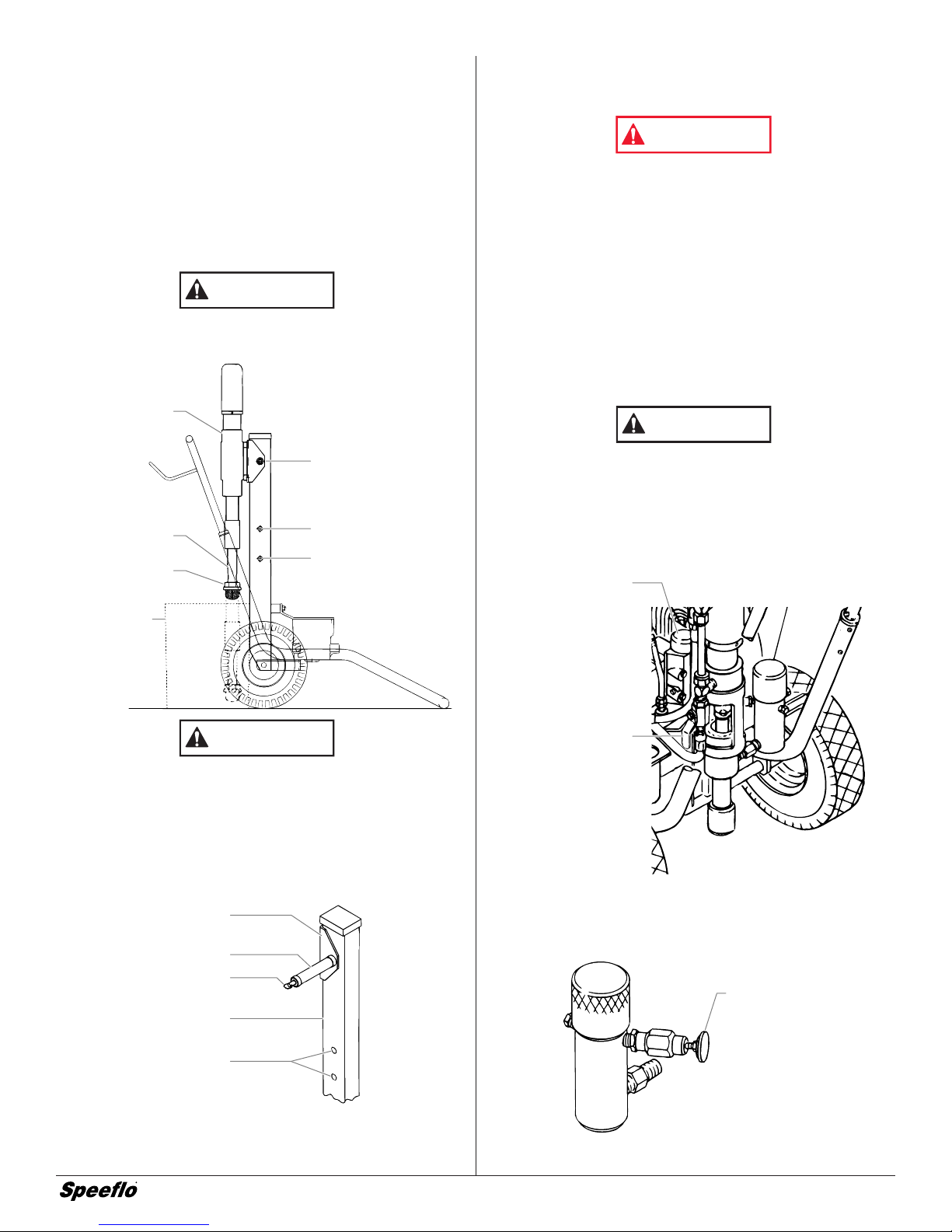

INSTRUCTIONS DE MISE A LA TERRE : Ce

produit doit être mis à la terre. Dans

l’hypothèse d’un court-circuit électrique, la

mise à la terre réduit le risque de chocs

électriques en assurant un fil de fuite pour le

courant électrique. Ce produit est pourvu d’un

cordon possédant un fil de terre avec fiche

appropriée de mise à la terre. La fiche doit

être branchée sur une prise qui est posée et

mise à la terre adéquatement conformément

à tous les codes et règlements locaux.

DANGER: La pose inappropriée de la

fiche de terre peut provoquer un risque

de chocs électriques.

Si le cordon ou la fiche doit être réparé ou

remplacé, ne raccordez pas le fil de terre à

l’une ou l’autre borne à lame plate. Le fil

possédant une isolation dont la surface

extérieure est verte (avec ou sans rayures

jaunes) est le fil de terre. Consultez un

électricien ou un technicien de service

compétent si vous ne comprenez pas

parfaitement les instructions de mise à la terre

ou si vous ne pouvez affirmer avec certitude

que le produit est dûment mis à la terre. Ne

modifiez pas la fiche fournie ; si elle ne rentre

pas dans la prise, faites poser la prise

appropriée par un électricien compétent.

•Ce produit est destiné à être utilisé sur

un circuit à tension nominale de 120

volts et a une fiche de terre qui

ressemble à la fiche illustrée ci-après.

•S’assurer que le produit est branché sur

une prise ayant la même configuration

que la fiche. Aucun adaptateur ne doit

être utilisé avec ce produit.

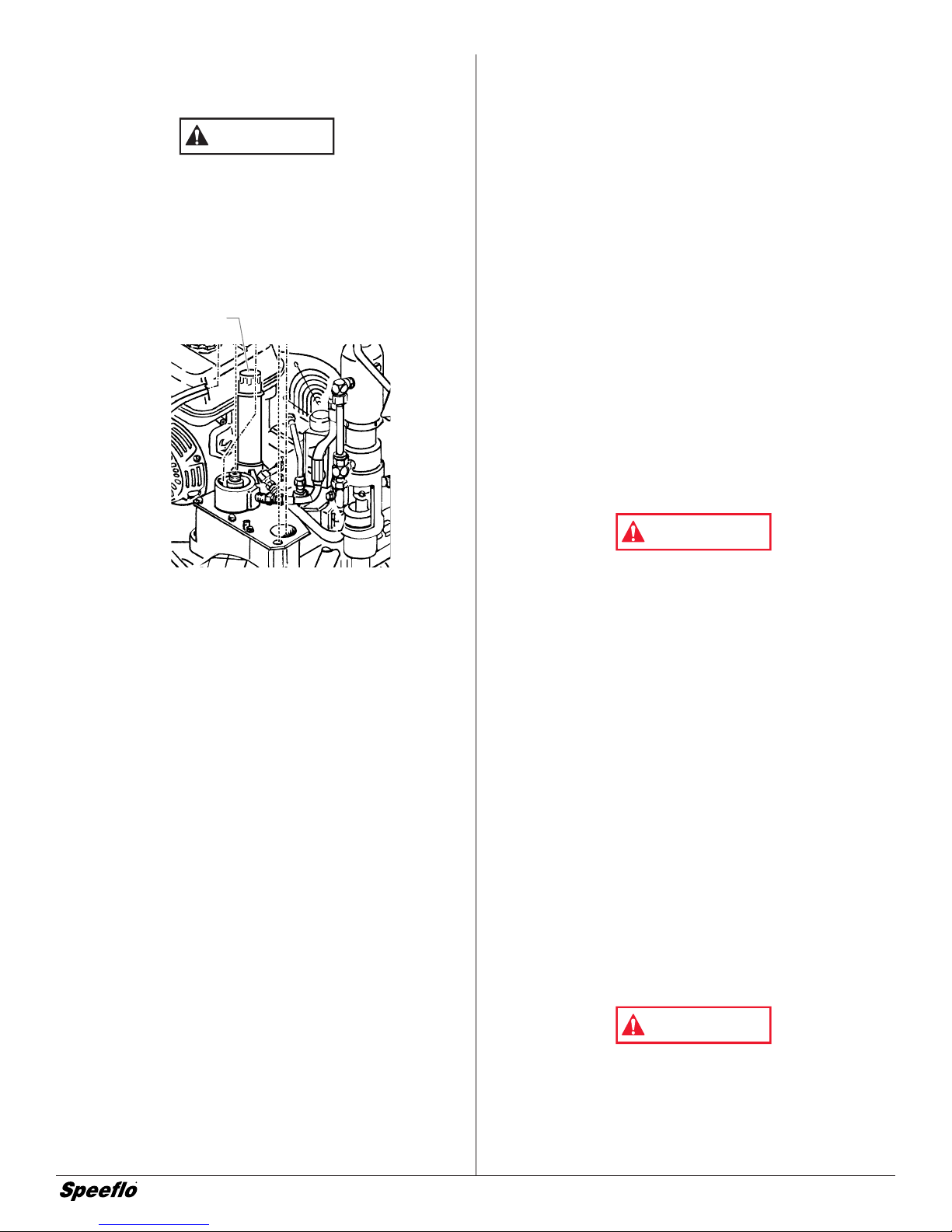

CORDONS DE RALLONGE - Utilisez

uniquement un cordon de rallonge à trois fils

pourvu d’une fiche de mise à la terre à trois

lames, et une prise à trois fentes qui

acceptera la fiche de la pompe. Assurez-

vous que votre cordon de rallonge est en

bon état. Lorsque vous utilisez un cordon de

rallonge, veillez à en utiliser un

suffisamment puissant pour transporter le

courant que consommera cette pompe.

Pour les longueurs Utilisez une

de moins de rallongede calibre

15,2 m 14 AWG

30,4 m 12 AWG

45,7 m 10 AWG

Un cordon sous-calibré provoquera une chute

de tension secteur ayant pour conséquences

une perte de puissance et une surchauffe. En

cas de doute, utilisez le calibre immédiatement

plus puissant. Plus le numéro de calibre est

bas, plus le cordon est puissant.

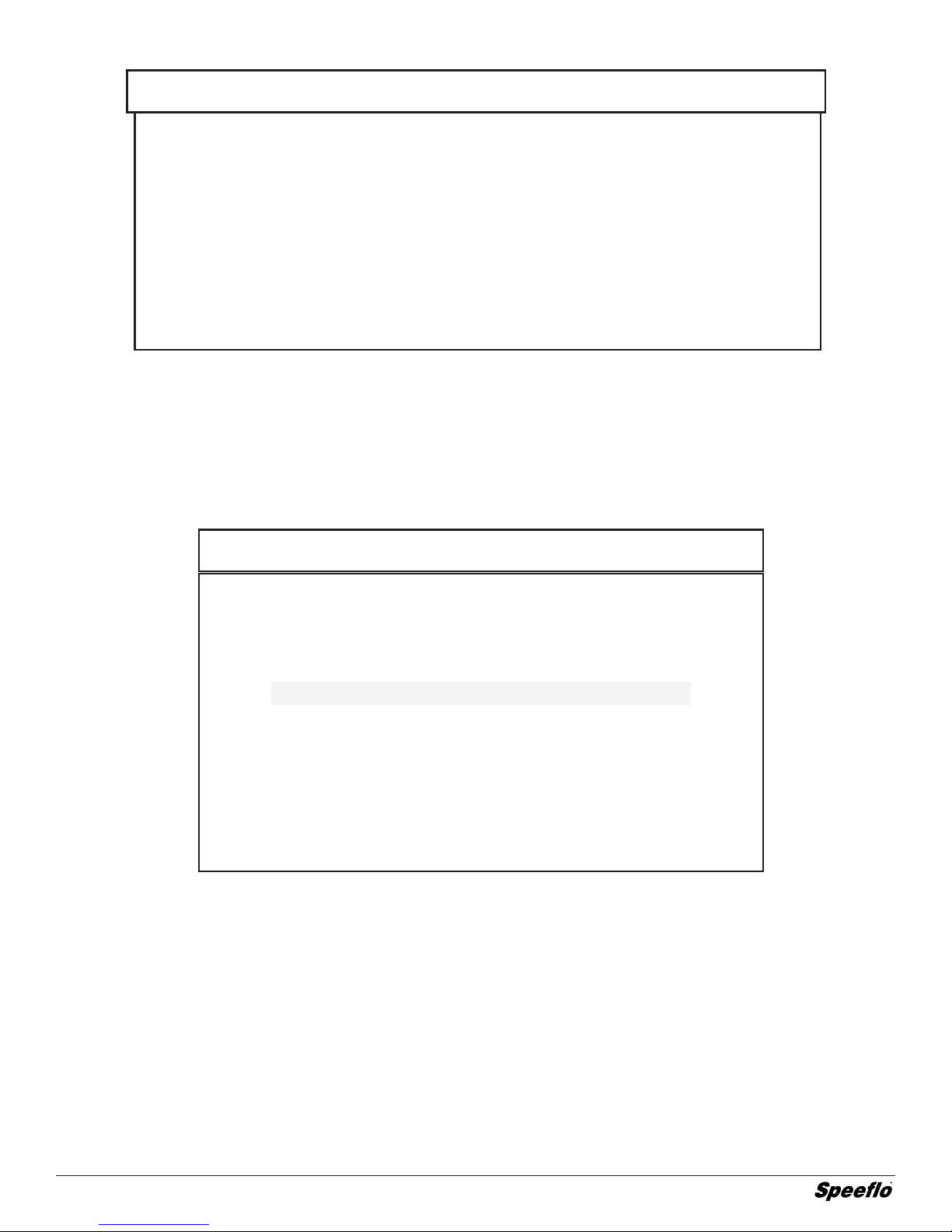

PROCEDURE DE DELESTAGE

DE PRESSION

A. Verrouillez la sûreté de la détente.

B. Arrêtez la pompe et débranchez le

cordon électrique.

C. Délestez la pression dans tout le

système et appuyez sur la détente

du pistolet.

D. Reverrouillez la sûreté de la détente.

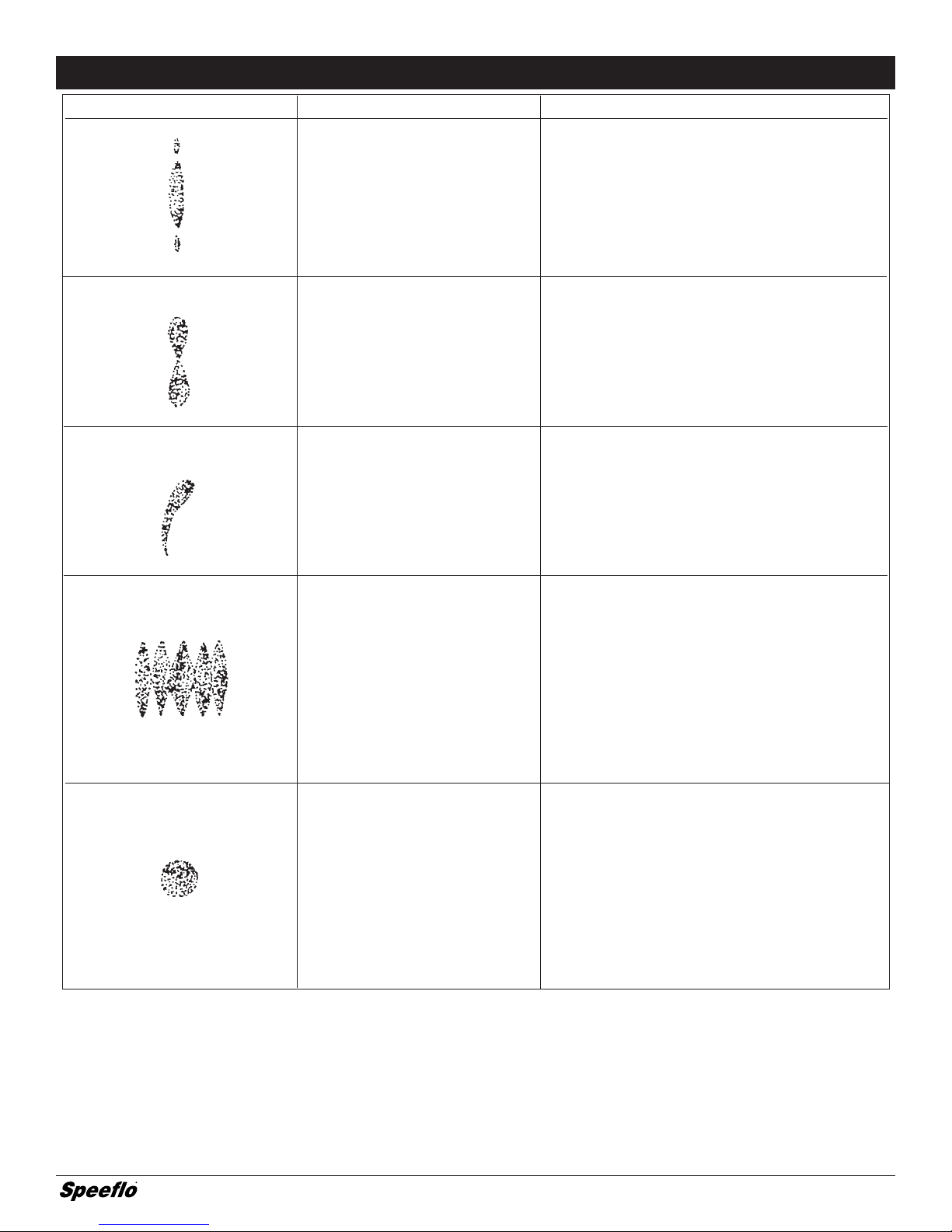

NE PAS UTILISER LE MATERIEL AVANT D’AVOIR LU CETTE SECTION

LES PULVERISATEURS A HAUTE PRESSION PEUVENT PROVOQUER

DE SERIEUSES LESIONS

Pression de travail maximale: 3300 psi — 228 bar