SPEX Genoseal 2060 User manual

Operating Manual

1

1300-87075-1A

2060 Genoseal™

Semi-automatic Heat Sealer for Microplates and Tube Racks

Operating Manual

2

1300-87075-1A

Contents

Before You Begin ...........................................................................................................................................3

Safety Considerations...................................................................................................................................3

Warning Symbols Used in Accordance With IEC 417...........................................................................................3

Introduction .....................................................................................................................................................5

Unpacking/Packing the Genoseal ............................................................................................................................5

Principle of Operation...................................................................................................................................5

Installation .......................................................................................................................................................6

Intended Use..................................................................................................................................................................6

Inventory ..........................................................................................................................................................6

Operating Environment ................................................................................................................................6

Connecting the Voltage Supply.................................................................................................................................6

Operation Procedure ....................................................................................................................................7

Optimization....................................................................................................................................................8

Temperature and Time Setting ..................................................................................................................................8

Sealing PCR Plates - No Skirt, Half Skirt..................................................................................................................8

User Interface .................................................................................................................................................9

Specifications of Genoseal ......................................................................................................................... 11

Troubleshooting ............................................................................................................................................ 11

Service and Repairs..................................................................................................................................... 12

Regulatory Information ............................................................................................................................... 12

CE Declaration of Conformity .................................................................................................................................. 12

Operating Manual

3

1300-87075-1A

Before You Begin

Read this instruction manual. Failure to follow the instructions, in this manual, may result in damage to the unit,

injury to operating personnel, and poor equipment performance.

Caution: All internal adjustments and maintenance must be performed by qualified service personnel.

Material in this manual is for informational purposes only. The contents and the product it describes are subject

to change without notice. Spex makes no representations or warranties with respect to this manual. In no event

shall Spex be held liable for any damages, direct or incidental, arising from or related to the use of this manual.

©2022 Spex, an Antylia Scientific company. All rights reserved.

Safety Considerations

It is Important that the Genoseal unit is installed and operated in such a way that all applicable health and safety

requirements are met. It is the user’s responsibility to ensure that all relevant health and safety regulations are

identified and complied with. Failure to do so may result in damage to the equipment and may result in personal

injury. In particular, the user should study the contents of this guide carefully before handling or operating this

equipment.

Under no circumstances will the supplier of this equipment be liable for any incidental, consequential or any

special damages of any kind whatsoever, including but not limited to lost profits arising from, or in any way

connected with the use of this equipment or this instruction manual.

Warning Symbols Used in Accordance With IEC 417

This symbol used alone indicates important operating instructions which reduce the risk of injury or

poor performance of the unit.

Caution: This symbol, in the context of a caution, indicates a potentially hazardous situation which,

if not avoided, could result in minor to moderate injury or damage to the equipment.

Warning: This symbol indicates potentially hazardous situations which, if not avoided, could result

in serious injury or death.

Warning: This symbol indicates situations where dangerous voltages exist and potential for

electrical shock is present.

Caution: Protective Conductor Terminal

Operating Manual

4

1300-87075-1A

Caution: Hot surface/hot area. This instrument is fitted with an internal heater with a maximum

temperature of 200 °C when in use.

This symbol indicates a need to use gloves during the indicated procedures. If performing

decontamination procedures, use chemically resistant gloves. Use insulated gloves for handling

samples and when using liquid nitrogen.

Caution: Keep hands clear during priming process to avoid risk of finger entanglement and

entrapment.

Before installing, using, or maintaining this product, please be sure to read this manual and product

warning labels carefully. Failure to follow these instructions may cause this product to malfunction,

which may result in injury or damage.

Main Switch Symbols

I = ON

0 = OFF

Below are important safety precautions that apply to this product:

Warning: Do not operate this instrument in an atmosphere containing explosive gases.

Warning: Only approved supplied power cord set must be used with this instrument. If it is required

to use an extension cord, the cord must be earthed. The Genoseal is supplied for direct connection

to normal 115 / 230 VAC, 50 / 60Hz supply, with a variation in supply that gives a voltage range of

108 VAC to 250 VAC. If you should require to clean the heater block, turn the power o and allow

the block to cool to ambient room temperature. You can now access the heater block and clean it.

The Genoseal is designed to be operated with a maximum sealing temperature of 200 °C.

The Genoseal should be switched on 5 minutes prior to use when plugged into 230 V and 6

minutes when plugged into 110 V. This is to enable the set temperature to be reached and to

stabilize. The Genoseal should only be used in a suitably ventilated area. The use of solvents on

the unit is not recommended. Certain components become hot during the correct operation of the

equipment. These components are marked with the hot surface symbol. Due care should be taken

to avoid personal injury. Spex accepts no responsibility for the misuse of this equipment.

Please ensure that heater block is at ambient temperature before cleaning and a senior operator carries out

the cleaning.

Operating Manual

5

1300-87075-1A

Introduction

The Genoseal heat sealer has been designed to seal most types of microplates. Our product utilizes various

heat seal films and foils to give either permanent or peelable seals for all common microplate material types

(polypropylene, polystyrene, polyethylene). Seal times and seal temperatures are fully adjustable on the product

via the control screen. The Genoseal has dual voltage capability, operating on both 110 and 230 VAC supplies

without the need for a power transformer.

Unpacking/Packing the Genoseal

When unpacking your Genoseal, visually inspect the unit for any damage which may have occurred during

shipping. Do not use the unit if there is any damage. Check that all components are present. Refer to the

packing list.

The unit is supplied in a re-usable crate and a transit bracket (if applicable) that must be retained in case the

unit requires servicing. The Genoseal is a precision instrument and requires the proper packaging for shipping.

Inadequate packaging can lead to damage. Ensure that all packing foam and ties are removed prior to powering

on the unit.

Use appropriate PPE and necessary tools available in the facility to remove the unit from the crate properly.

Pack in the same way the unit was originally shipped, with correct foam and crate. If any damage was caused or

the original crate that the Genoseal came in is lost, please contact support.

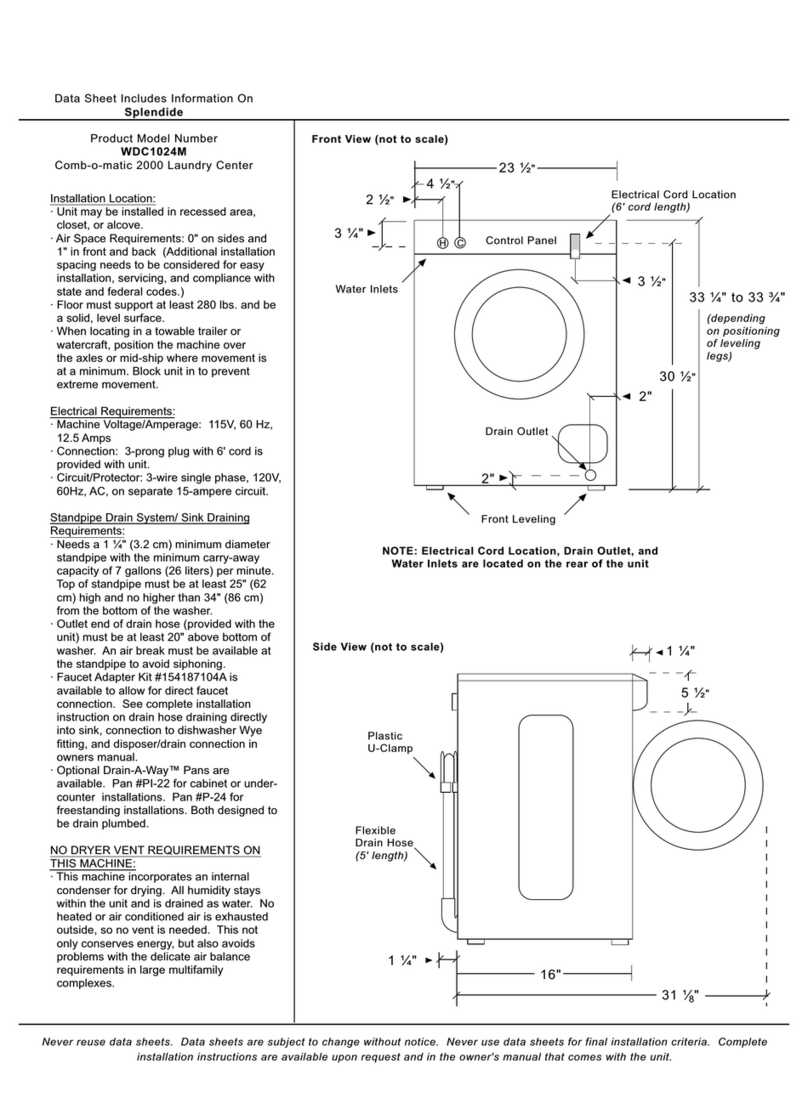

Principle of Operation

The unsealed plate is placed on the shuttle which extends from the front

of the sealer, allowing full access for the user to the system. The drawer

unit is manually pushed into the unit. The plate sealing operation will vary

based on user settings and set sealing time. (See user inface section for

operation.) The drawer and the plate returns to its original start position

once the sealing process is complete.

The sealer operates as a stand-alone, manual unit. Each sheet of sealing

film is sucient for sealing one plate to cover the entire plate surface with

a fixed length of 125 mm, allowing peelable or automation compatible

applications. See Figure 1.

The sealing films are either aluminum or clear laminates and are able to produce permanent, pierceable or

peelable seals with polypropylene, polystyrene, polythene or COC plates.

To keep the size and weight to a minimum, the unit is fully electronic and all parameters, such as temperature

and time, are fully adjustable to ensure a perfect, even seal with dierent plates and film formats.

User safety has been carefully considered during the design process to eliminate risk of contact with hot

surfaces or the internal mechanism during operation.

Figure 1. 384-Well Sealed Plate

Operating Manual

6

1300-87075-1A

Installation

The unit should be installed on a sturdy bench to avoid any vibration during operation. When locating the unit,

there should be enough space allowed for the drawer to move out without obstruction.

Intended Use

The Genoseal is intended to be used for the heat sealing of microplates or tubes during experimentation,

storage, or transportation. This device is not intended to be used as a medical device.

Caution: Use appropriate lifting and carrying equipment available in the facility during unit movement

from one place to another. Always use any necessary PPE during unit movement.

Inventory

Note: All of the items listed below are available as spare components from Spex.

DESCRIPTION PART NUMBER

Plate Adapter for PCR 384-Well Format 2060-PA-384

Skirtless Plate Adapter 2060-PA-96

Heat Sealing Film 2061

Plate Weight for Recessed Plates* 2060-WT-RC

Plate Weight for Standard and Rimless Plates* 2060-WT-STD

Plate Locators* 2060-PL

* Accessories supplied with the Genoseal

Operating Environment

The Genoseal should be operated in an environment with a temperature range of 10 °C to 30 °C and a non-

condensing relative humidity range of 10% to 80%.

The unit should be kept out of drafts and air currents, as they will have an adverse eect upon the temperature

stability of the sealing plate area. If the sealing plate area is subjected to drafts or air currents, quality or process

time may be aected.

The unit should be placed on a secure and stable surface with a minimum of 100 mm (4-inch) clearance on all

sides.

Connecting the Power Supply

The Genoseal utilizes a standard IEC inlet, which is fused and switched. Plug the IEC Lead in the inlet and switch

the Rocker I.O. Switch to the On position ( | ). The display screen should illuminate.

Note: The system is self-regulated to sense voltage dierences between 100 / 250 VAC.

Operating Manual

7

1300-87075-1A

Operation Procedure

Plate Locators and Adapters

Plate locators are used specifically on skirted plates, it

allows for the plate skirt to sit around the corresponding

locator and support the underneath of the plate. To

ensure the correct plate locator is used, check the

dierence in the bottom of the well distance to the

plate skirt base, if there is a dierence, the center of

the plate can flex when pressed. This means a suitable

plate locator needs to be used to take up the dierence.

Poorly supported wells will result in an uneven seal

across the plate surface.

However, if you are using an unskirted plate where the edge of the plate skirt is the same level as the bottom

surface of the plate, you will have to use a plate adapter. They support each cell individually and ensure that the

seal is even. They are designed to support most plate types.

How to Begin the Sealing Process

The Genoseal seals microplates by the following method:

1. First set the temperature and sealing time of the unit.

2. Next, select the correct plate locator for the plate you want to seal.

3. Place the unsealed microplate on the top shuttle plate.

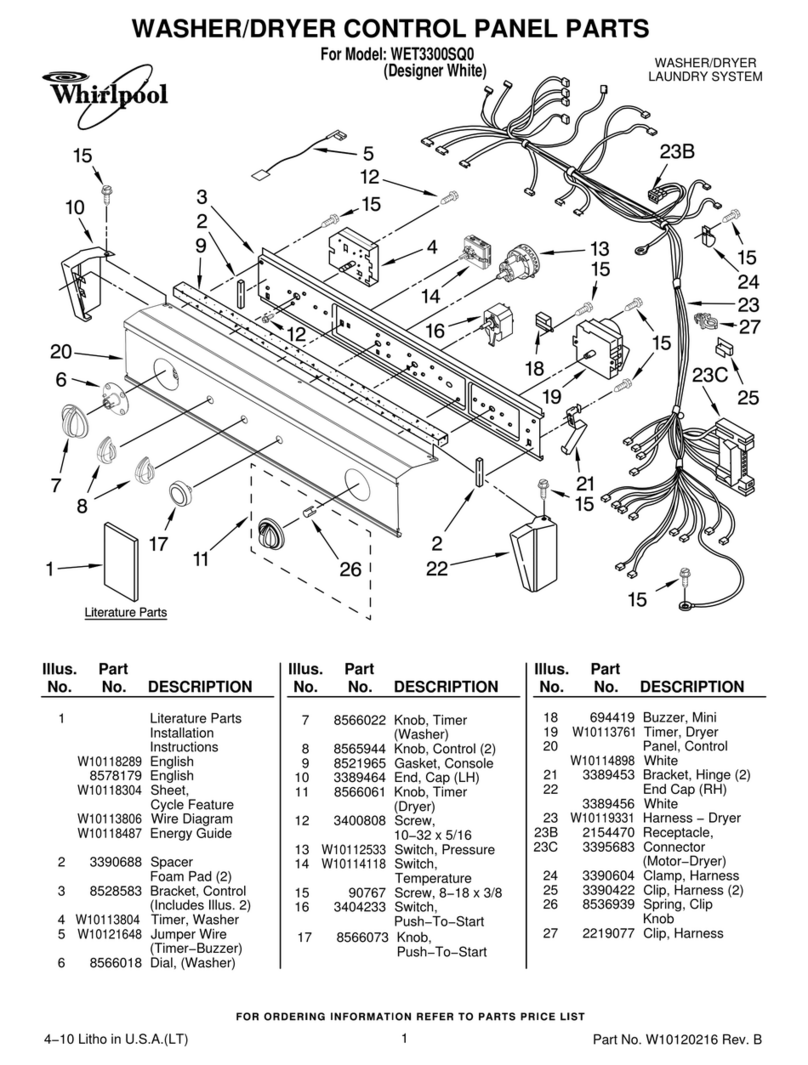

4. Place the pre-cut length of film/foil on the microplate and place the foil

brass weight on top of the foil on the microplate. Ensure that the foil is

centrally placed on the microplate.

Note: Some sealing material may curl when heated and the foil brass weight

will be required to keep the seal flat before sealing and to prevent the plate

from sticking to the heater block. Two types of foil weights are supplied with

each Genoseal; one for normal plates (

Figure 2

), and one for plates with high

rims and recessed wells (

Figure 3

).

5. The sealing process is started by pressing “seal” on the software. Once

pressed, begin by placing the correct plate locator, plate and plate weight

as demonstrated on the display. Thirdly, start pushing the drawer fully

into the unit, following the instructions on the display. Once the drawer is

pushed in it will automatically latch and the screen will display a sealing

message. You may now release your grip on the drawer handle. The

sealing process will finish itself based on the parameters entered.

6. When the seal has finished, the drawer will automatically open, presenting the plate for removal.

Note: Care MUST be taken when removing the foil loading tool, IT WILL BE HOT. Always hold it by the

specified tab as shown in Figures 2 and 3.

Plate Weight Tab

Figure 2. Normal plate weight

Figure 3. Recessed Plate Weight

Plate Weight Tab

Shuttle Plate Locator Plate

Operating Manual

8

1300-87075-1A

Optimization

The Genoseal has been designed to reliably seal plates of dierent heights and dierent plastics, using a variety

of films, to give a seal with varying properties. These components will require dierent sealing conditions.

The quality and strength of the seal created between the sealing film will vary with dierent conditions. In

general, increasing either the sealing temperature or duration of seal, gives a stronger, more complete seal.

However, over-sealing on a regular basis is not recommended, as applying more heat can cause excessive

damage to the plate being sealed. This, in turn, would reduce the number of times a particular plate can be

resealed. Therefore, a balance has to be achieved, giving an acceptable seal with the minimal plate damage or

distortion.

Another optimization factor to be taken into account is the surface area of the plate. A plate with thin raised rims

around each well will have a reduced surface area, compared to a plate with wide raised rims. This would mean

that less heat is needed to seal the thin rim plate in comparison to the wide rim.

The pressure that the heater plate exerts during sealing is pre-set and cannot be adjusted. Plates that do not

have any raised rims are not usually suitable for heat-sealing.

Temperature and Time Setting

The following table gives a guideline as to the sealing temperature and time for dierent materials.

PLATE MATERIAL TEMPERATURE SETTING (ºC) TIME SETTING (SECONDS)

Polystyrene 145 to 165 2 to 5

Polypropylene 150 to 175 2 to 5

Polyethylene 150 to 170 2 to 5

Sealing PCR Plates - No Skirt, Half Skirt

An adapter will be required to seal plates which have well bottoms protruding past the plate skirt as well as

plates with no skirt. This is available from Spex.

Operating Manual

9

1300-87075-1A

User Interface

Plug in the system to turn the power on. Once the system is turned

on, the Spex logo is displayed. The home screen appears as shown

to the left. If the system is in ECO mode, it will prompt you to wake it.

This screen will show upon power up. It will instruct you to close the

drawer to home the system and enable the unit to be ready to seal,

simply push the drawer in.

The screen will then show the sealing time, heater set temperature

and heater actual temperature along with the active status of the

heater block, cooling or heating depending on the temperature.

This is the main sealing screen. Here, you will see the main button to

press “seal” and begin the sealing process. Once you press this, you

will be prompted on how to complete the sealing procedure. Firstly,

place the correct plate adapter onto the shuttle, followed by the

plate and plate weight.

This screen will show once you press the seal button, it will prompt

you to ensure that the sealing plate is ready to be sealed, including

the correct plate support, the corresponding plate, the correct foil,

and finally the corresponding plate weight. Once all of these have

been checked, you can manually push the drawer in to begin the

sealing process. Once this is complete, the automated spring will

return the drawer back out.

Close drawer to

home system

Place plate foil

and foil weight

onto shuttle and

close drawer

Operating Manual

10

1300-87075-1A

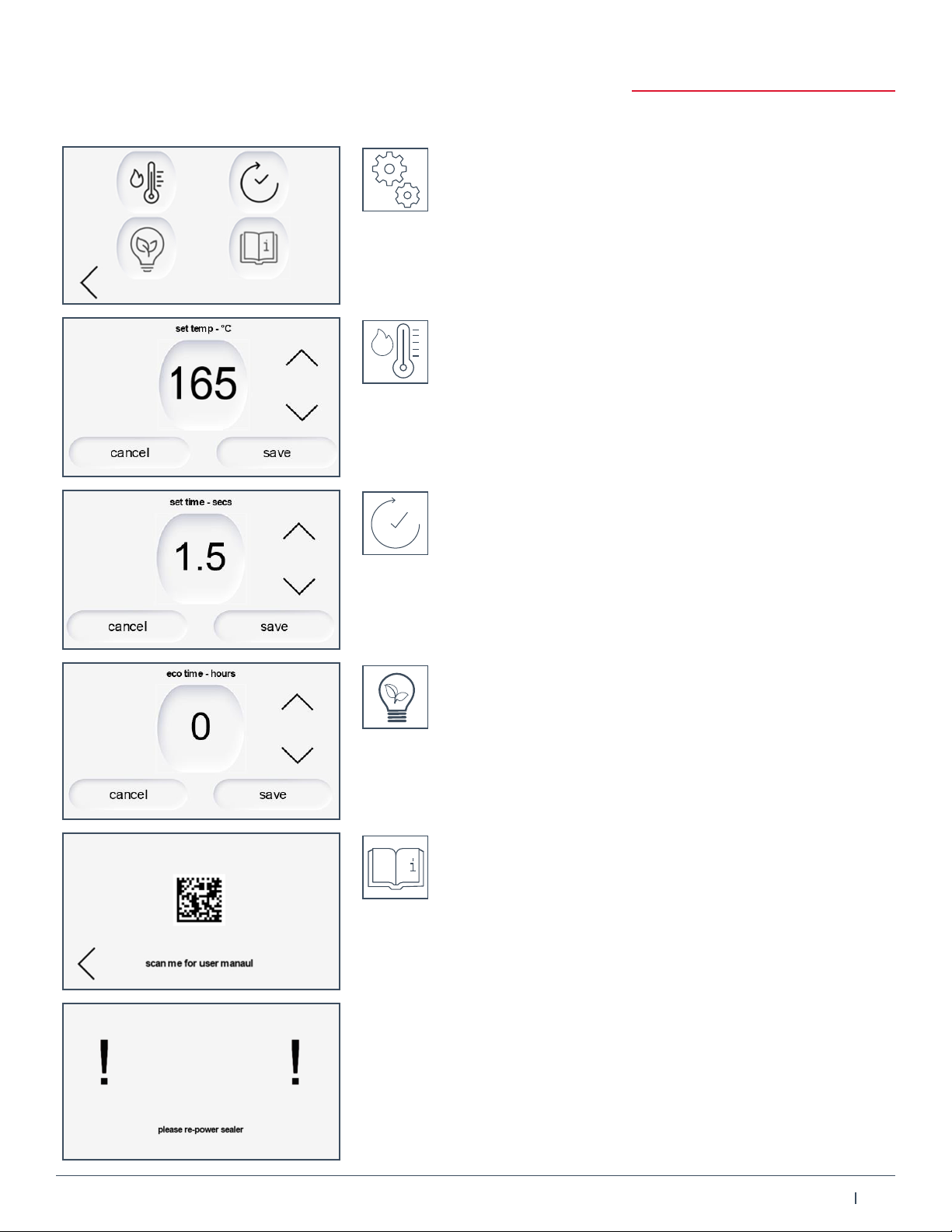

This screen will allow you to select the settings that

control the sealing time, temperature, ECO time and

scan a copy of the user manual through the QR code

displayed. After clicking settings, you will be shown this

screen, simply click the o

To adjust the set temperature of the heater block and

control the temperature that the Genoseal seals at, click

the first option showing a thermometer. Here you can

adjust the temperature up or down with the arrows on

the right side of the display. Once satisfied with the set

temperature, press “save”.

You can also adjust the sealing time by pressing the

stopwatch icon on the settings screen. Press it and adjust

it using the arrows on the right side of the display. Once

satisfied with the set sealing time, press “save”. If you

want to keep the time unchanged, press “cancel”.

To access the eco-mode timer, press the icon that shows

the flower in a light bulb icon from the settings screen.

This will enable you to set a time limitfor how long the

unit is not in use before automatically turning o the

heaters and going into eco-mode. Use this screen similar

to how you set the temperature and time.

This will show you the QR code which is scannable with

any QR code scannable smart phones or QR scanners

for a desktop view. It will load a PDF in your default PDF

viewer.

If the unit encounters an error at any stage, it will display an error

screen prompting you to power cycle the machine or reset it. (Error

screens may vary.)

Operating Manual

11

1300-87075-1A

Specifications of 2060 Genoseal

Power Supply 115 / 230 VAC, 50 / 60 Hz

Power Consumption 600 watts nominal

Fuse Rating 5 amp anti-surge (T5AH 250 V)

Internal Heaters 4 x 100 watts (sealing plate)

Minimum Plate Height 9 mm

Maximum Plate Height 54 mm

Maximum Sealing Temperature 200 °C

Protection IP20

Cycle Time (approx.) 10 to 12 seconds (based on a 2 second seal)

Dimensions (depth x width x height) 12.13 in x 8.1 in x 15.3 in (308 mm x 205 mm x 389 mm)

Unit Weight 19.8 lb (9 kg)

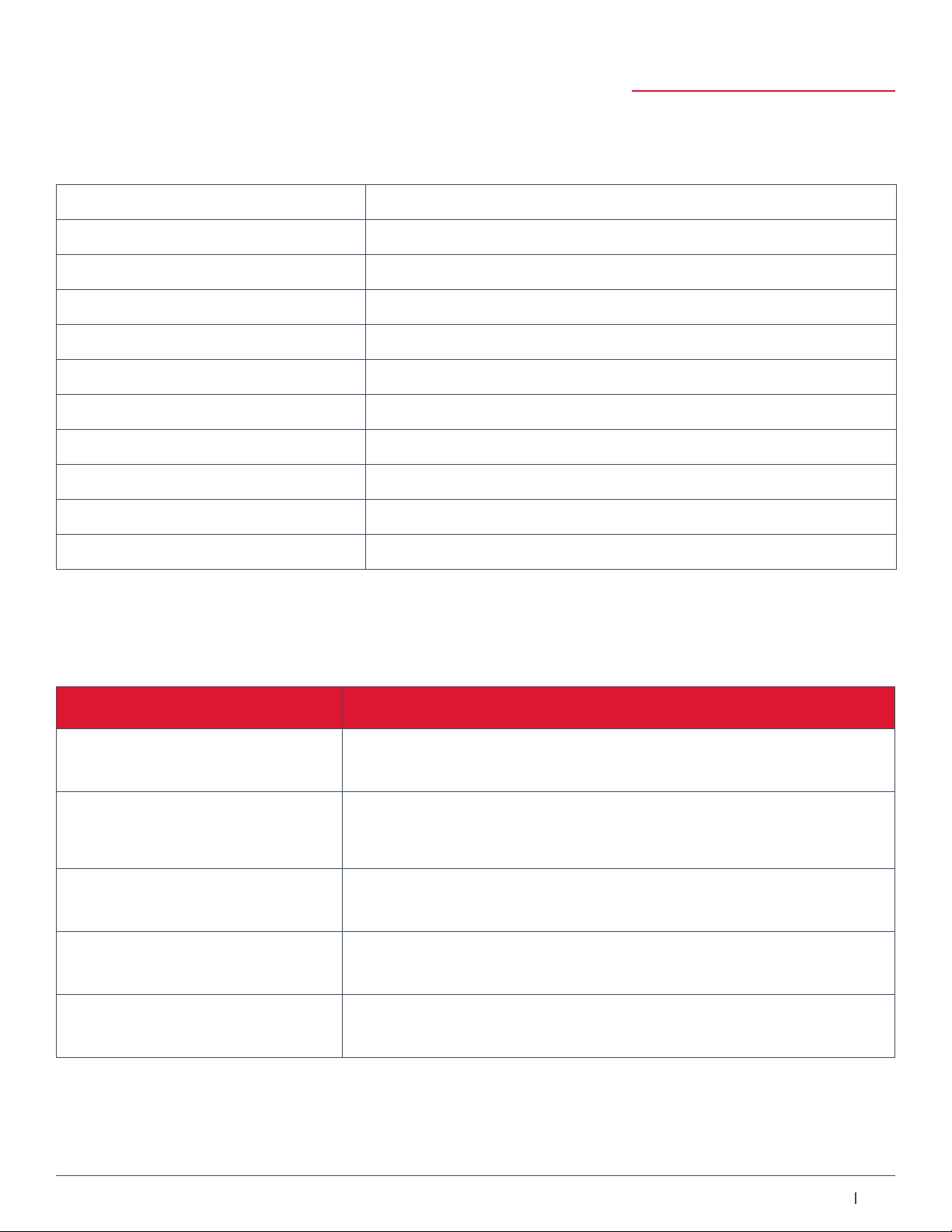

Troubleshooting

If the problem with the Genoseal unit persists after the below actions have been carried out, contact Spex for

further investigation.

PROBLEM ACTION

Genoseal will not power up after

switching on Check fuse

Foil will not seal properly on a

microplate

1. Check seal temperature and time and reset if necessary

2. Ensure the correct height of plate locators are being used

“Error up switch” is displayed on the

screen after a seal is run

Ensure the correct plate locator/combination is being used and restart

the machine

Poor plate seal in middle of plate Check if plate supports are required. If required, contact Spex

The unit fails to respond to

commands Restart the machine

If the problem with the Genoseal persists after the above actions have been carried out, contact Spex for futher

investigation.

spexsampleprep.com

Phone: +1.732.549.7144

spexsales@antylia.com

4819M

Connect with us

Operating Manual

Service and Repairs

For all requirements for service and repairs please contact: Spex at +1.732.549.7144.

Note: For any spare components, please refer to the inventory list and contact Spex for pricing information.

Regulatory Information

CE Declaration of Conformity

As detailed under the European Machinery Directive 89/392/EEC (amended by 91/368/EEC) and under the

UK legislation. The supply of Machinery (Safety) Regulations 1992 (SI 1992/3073). As detailed under The

Electromagnetic Compatibility Directive 89/336/EEC (amended by 91/263/EEC and 92/31/EEC and the UK

legislation, the Electromagnetic Compatibility Regulations 1992. As detailed under The European Low Voltage

Directive 73/23/EEC (amended by 93/68/EEC) and the UK legislation, The Electrical Equipment (Safety)

Regulations 1994.

The Declaration of Conformity is provided for the following equipment:

2060 Genoseal

Serial Number: To be included

Transposed Harmonized Standards

BSEN 12100-1 Safety machines: concepts

General: principles for design; basic terminology and methodology

BSEN 12100-2 Safety of machines: basic concepts, general principles for design; technical principles BSEN 61010

Safety requirements for electrical Equipment for measurement, control and laboratory use BSEN 60204 safety of

Machinery; electrical equipment of machines (section 19).

BSEN 50081-2 Electromagnetic Compatibility; generic emission standard, industrial environment.

BSEN 61000-6-2 Electromagnetic compatibility (EMC) Generic standard, immunity for industrial environments.

Other Standards: BS5378 safety signs and colors.

Table of contents

Other SPEX Washer Dryer manuals