spidocook CALDOLUX SCH 030 Instruction manual

OVEN FOR COOK & HOLD FOUR COOK

SCH 030

ENGLISH INSTRUCTION MANUAL AND

TECHNICAL DATAS

07-2018

2

I. INSTRUCTIONS FOR THE INSTALLER

II.

III.

1. DATA PLATE

2. CERTIFICATION

3. INSTALLATION - PRELIMINARY OPERATIONS

3.1 - CHECK OF HTE INSTALLATION LOCATION

3.2 - POSITIONING

3.3 - REMOVAL OF THE PROTECTIVE FILM

4. INSTALLATION - ELECTRICAL CONNECTION

5. REVERSAL OF THE DOOR

INSTRUCTIONS FOR THE USER

1. INSTRUCTION FOR THE OPERATOR

2. NOTES FOR THE USE

3. DIGITAL CONTROL PANEL

3.1 - PREMISES

3.2 - DESCRIPTION AND USE OF THE DIGITAL

3

3

3

3

3

3

3

4

4

5

5

5

6

6

CONTROL PANEL 6

4. MAINTENANCE - CLEANING OF THE APPLIANCE 7

4.1 - FIRST USE OF THE OVEN 7

4.2 - CAVITY CLEANING 7

4.3 - CLEANING OF THE EXTERNAL

PART OF THE OVEN 7

5. TURNING OFF IN CASE OF BREAKING 7

COOKING VARIABLES

1. TEMPERATURE

2. TIME

3. QUANTITY OF FOOD

4. USE OF TRAYS - WIRE GRIDS

IV. MAINTENANCE

1. ORDINARY MAINTENANCE

2. SPECIAL MAINTENANCE

3. MORE FREQUENT BREAKINGS

8

8

8

8

8

8

8

8

9

DIGITAL CONTROL PANEL 10

- TECHNICAL DATA - AT THE END OF THE MANUAL -

ENGLISH

Technical Data

Electrical diagrams

Drawings

See attached le “TECHNICAL

DATA”AT THE END OF THE

MANUAL

ENGLISH

I. INSTRUCTION FOR

THE INSTALLER

Dear Customer, we would like to thank you

and congratulate you on the purchase of one

of the SPIDOCOOK products. The instructions

and suggestions

that follow concern the phases

of a proper installation, as well as the use and

maintenance for your safety and for the best use of

the appliance.

1. DATA PLATE

2. CERTIFICATION

The“CE”brand you nd on the appliances included in

this instructions manual refers to the following directi-

ves:

ELECTRIC STATIC OVENS - SERIE XCH :

- Low Tension Directive DBT 73/23/CEE

e 93/68/CEE, according to rule EN60335-1: 2001

e according to rule EN60335-2-36: 2002

- Electromagnetic Compatibility Directive,

according to rule EN60555-3, EN55014 and

EN55104.

3. INSTALLATION – PRELIMINARY OPERATIONS

All the electrical connections and installations must be

done by qualied personnel according to actual laws.

3.1 CHECK OF THE INSTALLATION LOCATION

Before placing the appliance, please verify the

overall measurements and the exact position of the

electrical connections looking at the pictures on the

attached le“TECHNICAL DATA”.

3.2 POSITIONING

Place the appliance respecting the safety standards

in force that you nd here following described:

1. Place the appliance so that its back and sides

can be easily reached in order to make electrical

connections and provide the needed service.

2. The appliance is not suitable for built-in

installation and side by side positioning.

3. It is suggested to leave a distance of 10 cm.

between the back of the oven and the wall

behind the appliance.

All the models must be placed upon a support, for

example a metal table.

Do not ever install the appliance on the oor.

If the appliance is placed near walls, dividers, kitchen

cabinets, decorated edges, etc., it is recommended

that this be of non combustible material.

Otherwise,theymustbecoatedwith noncombustible

thermal insulating material and you must be very

respectful of the re prevention standards.

3.3. REMOVAL OF THE PROTECTIVE FILM

Carefully remove all the protective lm from the

external walls of the appliance. Pay attention not to

leave any rest of glue on the sides. If there should be

any residue, please remove it with an appropriate

solvent.

ENGLISH 3

R

ENGLISH

4. INSTALLATION – ELETTRICAL CONNECTION

4

a- The connection to the electrical power supply

system must be done according to the standard

in force.

b- Before connecting the appliance, make

yourself sure that the voltage and the frequency

correspond to those stated on the data plate of

the appliance.

c- The appliance must be placed so that the

connection plug to the network can be easily

reached.

d- Place an omni-polar switch between the

appliance and the network. The omni-polar

switch must have the following characteristics:

- must be easily reached after the installation;

- the contacts of the switch must have a minimum

opening distance of 3 mm;

- must have an appropriate input (for example,

magneto-thermal switch.

When the appliance is working the power supply

voltage must not diverge from the value of the

nominal voltage, written on the technical data

plate, by more than ± 10%.

b- The appliance must be connected to the ground

line of the network.

Moreover, the appliance must be included in

equipotential system whose eciency must be

properly checked according to the

current law. This connection must

be done between the dierent

appliances using the terminal

marked with the symbol:

The equipotential conductor must have

a minimum section of 10 mm2.

ENGLISH

5. REVERSAL OF THE DOOR

To meet the customers’ need, the appliance

is equipped with a reversible door. With this

characteristics, the user can choose, at any time, on

which direction he/she wants to open the door.

Needed equipment:

• Medium size screwdriver with Philips driver;

• Small size screwdriver with Slotted driver

Procedure:

1. Disconnect the appliance from the electrical power

supply and wait for the appliance to cool down.

2. Remove eventual trays containing food from the

cavity.

3. Lay the oven on the side so that the fulcrum of

the door is on the top (see following picture).

4. With the screwdriver with Philips driver, unscrew

anticlockwise both the screws that x the stirrup

(see following picture).

ENGLISH

5. Remove the door and lay it on a at surface.

6. With the screwdriver with Slotted driver remove

the cap and the bronze washer from the bottom

of the lid; after this proceed with the reversal of

the door (see following picture).

7. Turn the oven and lay it on the left side

8. Re-assemble the door inserting the hexagon

screws in the bronze kasher.

9. Assemble the stirrup on the bottom of the oven

paying attention to position properly the bronze

washer inside the hole you nd on the stirrup.

10. Fix the stirrup with the two proper screws.

11. Position the oven in the horizontal position and

plug the oven back to the net.

II. INSTRUCTIONS FOR

THE USER

WARNING!

The appliance cannot be cleaned with a jet of water.

Never wash the cavity with acids or aggressive

detergents. Use only water and soap.

The appliance is made for a specic professional use

and must be used by qualied personnel only.

1. INSTRUCTIONS FOR THE OPERATOR

2.

WARNING!

Carefully read this user manual before starting to

operate with the appliance as it gives you important

information regarding safety during installation, use

and maintenance of the appliance itself.

Keep the manual in a safe place where the dierent

operators that work with the appliance can easily

nd and read it.

For any eventual repair, please apply only to

authorized service centres. Always require original

SPIDOCOOK spare parts.

Failure to observe the above suggestions can

compromise safety of the appliance and the

guarantee cannot be recognized anymore.

NOTES FOR THE USE

Premise:

This appliance must be used only in the way in which

it was expressly intended. The ovens were designed

to cook food as here below described. Every other use

is to be considered improper.

The oven allows you to work on temperatures up to

120°C.

The appliance can be used to:

- cook all gastronomy preparations, fresh or

frozen;

- regenerate refrigerated or frozen food.

ENGLISH 5

R

ENGLISH

When placing the food in the cavity, leave at least 10

mm between the trays in order to allow the hot air

to circulate inside the cavity. Please, avoid to put

salt on the food when it is inside the cavity.

3. DIGITAL CONTROL PANEL

3.1

6

3.2

PREMISE

Caldolux is an appliance with two main functions:

- cooking (COOK), during which the food inside

the cavity is cooked;

- holding (HOLD), during which the food already

cooked is held at a constant temperature.

The main function of the electronic panel control

for HOLD is to regulate the temperature inside

the baking chamber by piloting the warming

up element and by modulating the power with a

circuit in TRIAC. The surrounding inside the baking

chamber is static therefore no fan is present.

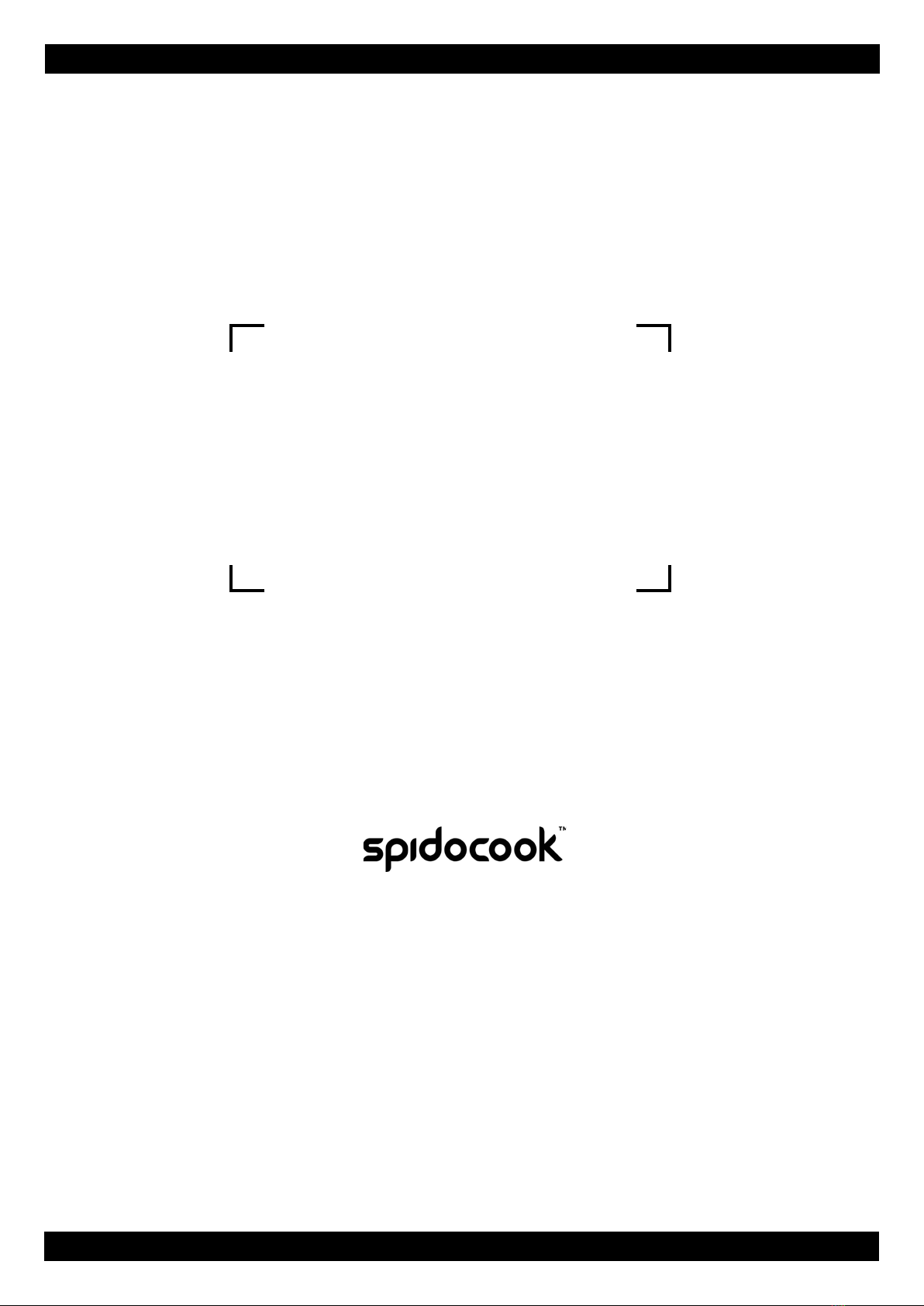

DESCRIPTION AND USE OF THE CONTROL PANEL

SEE THE IMAGE PAG10

Starting

The lighting and the extinction of the control are

made by pushing the button ON/OFF. When the

control is in state of OFF the relative LED (placed to

the right of the push-button) is lighted in order to

signal the presence of the grid voltage; when the

control comes lighted the LED is extinguished.

Cooking (COOK)

At the lighting, the electronic control goes

in the phase of baking (COOK) and the LED

“TEMPERATURE ROOM” is lighted: it is therefore

possible to set up the temperature in the baking

chamber by acting on the two push-buttons + and

–- (temperature range between 0 - 120 ºC). When

the display indicates a temperature equal to 000,

by pressing the button –- , you go directly to 120

ºC.

Once the temperature in the chamber is set up, you

ENGLISH

must decide between using the core probe or the

time in order to determine the duration of the baking.

Using the core probe , the phase of baking (COOK)

ends when the temperature measured by the core

probe reaches the set up value. Using the time, you

have to set up the wanted duration of the baking in

hours and minutes.

The two functions are mutually exclusive: if the core

probe is used you cannot set up the time and, vice

versa, setting up the time, the core probe cannot be

set up.

By pressing the SELECT button, the LED “ CHAMBER

TEMPERATURE “ goes out and the LED “ CORE

TEMPERATURE“ switches on. The display, in this case,

points out the temperature established for the core

probe. To change the core temperature you have

to act on the buttons + and –- (temperature range

between 0 - 120 ºC).

When the display indicates a temperature equal to

000, by pressing the button –- , you go directly to

120 ºC.

By pressing the SELECT button, the LED “ CORE

TEMPERATURE “ goes out and the LED “ TIME

“ switches on: the display, in this case, shows the

established time.

To establish the time of functioning it is sucient

to act on both buttons + and –- (you have the

possibility to establish the time between 0 hour.01

minutes - 9 hours.59 minutes).

Maintenance (HOLD)

After setting the baking chamber temperature and

the core temperature or the time, by pressing the

SELECT button, the control enters in the maintenance

phase(HOLD) and the LED“ CHAMBER TEMPERATURE

“ related to this phase switches on.

To x the temperature inside the baking chamber,

you have to act on the buttons + and –- (the possible

temperature range is between 0 - 120 ºC). When

the display points out a temperature equal to 000,

by pressing the button - on the display, you pass

directly to 120 ºC.

In this phase of maintenance (HOLD) it is possible

to establish the temperature only inside the baking

chamber, this condition remains unchanged for an

innite time, except a manual extinction of the user

ENGLISH

4.

by using the button STAR / STOP.

After setting the parameters of functioning, you

make the cycle go on by using the START/STOP

button. When the control is in a t state of STARTING

(DEPARTURE), the related LED switches on (put to the

left of the button).

During the functioning of the baking phase (COOK),

they are alternately shown, with a space of 4 “, the

temperature read inside the baking chamber and the

temperature read by the core probe or the remaining

time to end baking (count down), according to the

parameter selected in the positioning phase.

By pressing the SELECT button during this phase, the

established parameters can be shown and can be

possibly changed (the baking chamber temperature

and the core temperature/ time). After 15 “ during

which you press no button to modify, the electronic

control turns to the normal visualization (temperature

read in the chamber and temperature read in heart /

count down ).

During the functioning of the maintenance

phase(HOLD), the temperature read in the baking

chamber is shown.

Cycle Interruption

It is possible to interrupt the baking cycle by pressing

the button START / STOP, at any time. When the

baking cycle is interrupted with the button START

/ STOP, all the established parameters (baking

chamber temperature, core temperature or time) is

put at zero.

MAINTENANCE – OVEN’S CLEANING

WARNING!

All maintenance operations must be done only by

qualied personnel.

Before starting any maintenance operation, you

need to disconnect the appliance from the electrical

power supply and wait for the appliance to cool

down.

4.1

4.2

FIRST USE

Before using the appliance for the rst time it is necessary

to clean up the metal baking chamber with hot water and

soap and then rinse it. Never wash the baking chamber

with acids or aggressive detergents.

it is necessary then to heat the equipment emptied

for about 30 minutes

at approximately 100 ºC, in order to eliminate

eventual smells caused from the thermal isolation.

BAKING CHAMBER CLEANING

It is necessary to clean up the inside of the baking

chamber with suitable products at the end of every

cooking cycle.

In order to clean the appliance it is requested to

follow the following indications:

- To help cleaning, remove the lateral

grids, taking them out from the oven;

- Switch on the oven;

- Set the temperature at about 80°C for about 10

minutes;

- Let the appliance cool down and clean with a

cloth.

Do not use for the cleaning of the steel acids,

aggressive products or products containing chlorine

(sodium hypochlorite, hydrochloric acid etc.), not

even if diluted.

4.3 OVEN EXTERNAL CLEANING

Never use a jet of water in pressure to clean the

external part of the oven. Use wet clothes.

5. TURNING OFF IN CASE OF BREAKDOWN

In case of a breakdown, please :

- deactivate the appliance;

- disconnect the electrical power supply

automatic circuit breaker placed upstream from

the appliance;

- consult a technical assistance center with

trained sta.

ENGLISH 7

R

ENGLISH

III. COOKING VARIABLES

Warning:

a- Before baking, heat empty the appliance on

a temperature higher of about 30°C from the

necessary baking temperature, in order to obtain

the maximum uniformity of baking.

b- A higher temperatures than standard requested

for the product leads to a not uniform baking.

c- Avoid to touch the products put on the pan.

1. TEMPERATURE

The exact setting of the temperature guarantees the

a proper cooking of the food from the inside and the

outside. A lower temperature than the proper one

dries the food rather than cook it.

A higher temperature than the proper one burns the

surface and the inside remains uncooked ( sometimes

this is desired, especially for meat cooking).

2. TIME

3.

This variable depends a lot on the quantity of food

put in the oven. A bigger quantity of food needs a

longer cooking time and vice versa.

Shorter times than the proper ones do not allow the

complete cooking of the food.

Longer times than the proper ones cause the burning

of the food surface.

FOOD QUANTITY

The quantity of food aects the cooking time.

A bigger quantity of food needs a longer cooking

time and vice versa.

4. USE OF PANS AND GRIDS

It is recommended to use :

- Stainless steel pans : rst courses, meat, sh and

potatoes.

- Grids: meat to be browned like steaks, hot dogs,

sausage, frozen bread and frozen pizza.

8ENGLISH

IV. MAINNANCE

1.

2.

ORDINARY MAINTENANCE

All the maintenance operations must be done only by

qualied sta.

Before starting any maintenance operation, you have

to disconnected the appliance from the electric power

supply and wait for the appliance to cool down.

The appliance must be regularly controlled at least

once a year. A specialized technician has to control

the complete machine.

SPECIAL MAINTENANCE

All the maintenance operations must be done only by

qualied sta.

Before starting any maintenance operation, you

should disconnect the appliance from the electric

power supply and wait for the appliance to cool

down.

- The parts that need special maintenance can

be reached by removing the front control panel

and the back of the oven.

ENGLISH

ENGLISH

3. MORE FREQUENT BREAKINGS

R

ENGLISH 9

BREAKDOWN CAUSE SOLUTION

The oven is completely turned o

The tension of the electrical system is

missing Restore the tension

Intervention of one of the fuses of the

power board Replacement of the fuse

The connection to the electric system

not made in the correct way

Control the connection of the

appliance to the electric system

The oven does not warm up well

even if the temperature and the

time were established and the key

STARTING /

STOP was pressed

Safety thermostat intervention

the thermostat of safety has an

automatic rearmament:

You must wait for some minutes so

that the temperature of the oven goes

down and the thermostat reequips

Damaged resistance Contact a specialized technician for

reparation

Damaged electronic control Contact a specialized technician for

reparation

On the temperature display you can

read S01

The wires that connect the temperature

(chamber) probe are not connected to

the power board

Control the connection

Damaged chamber probe Contact a specialized technician for

reparation

Damaged electronic control Contact a specialized technician for

reparation

On the temperature display you can

read S02

The wires that connect the core

temperature probe are not connected to

the power board

Control the connection

Damaged core temperature probe Contact a specialized technician for

reparation

Damaged electronic control Contact a specialized technician for

reparation

Even with the door closed water

goes out across the gasket

Damaged door gasket Contact a specialized technician for

reparation

Damaged magnetic closing system

Screw on magnets in clockwise sense

per hour by paying attention not to

damage them

LED indicating the chamber

temperature during the baking

Digital Display

LED indicating the

chamber temperature during

the maintenance

LED indicating

the time Button to select the

modality

Button and LED for

START/STOP

Button and LED for

switching on

10 ENGLISH

DIGITAL CONTROL PANEL

LED indicating the product’s

core temperature

ENGLISH

Button to reduce the

established data

Button to increase the

established data

R

ENGLISH

NOTES:

ENGLISH 11

ENGLISH

ELECTRICAL POWER

FREQUENCY

POWER SUPPLY CABLE TYPE

POWER SUPPLY CABLE EXTERNAL

Ø VOLTAGE / CABLE SECTION

MAX FOOD LOAD

NOISE LEVEL

TECHNICAL DATA

kW 0,76

50 Hz

H07RNF 10 ÷ 16 mm

230 V~ 3G x 1,5 mm2

Kg 15

<70 db (A)

SCH 030

07-2018

TECHNICAL DATA

Spazio etichetta

-*"%

Table of contents