6 Operation................................................................................................ 19

6.1 User interface description........................................................................................................... 19

6.1.1 Overview of the user interface........................................................................................ 19

6.1.2 Buttons and indicators.................................................................................................... 20

6.1.3 Color codes of the status indicator LEDs........................................................................20

6.1.4 Operating modes............................................................................................................ 20

6.1.5 Booster function.............................................................................................................. 22

6.1.6 Last fill-time (item no. 7)..................................................................................................22

6.1.7 Pump input signal (item no. 8)........................................................................................ 22

6.1.8 Pump feedback signal (item no. 9)................................................................................. 22

6.1.9 Total degassing hours.....................................................................................................22

6.1.10 Weekend break...............................................................................................................23

6.1.11 Default degassing settings..............................................................................................23

6.1.12 User settings / menu items............................................................................................. 24

6.2 Start up the unit.......................................................................................................................... 24

6.3 Shut down the unit...................................................................................................................... 25

6.4 Navigate the display of the control panel....................................................................................25

6.5 Change a setting.........................................................................................................................25

6.6 Reset a warning or error............................................................................................................. 25

7 Description.............................................................................................. 26

7.1 Overview of the unit.................................................................................................................... 26

7.2 Overview of the PCB of the control panel...................................................................................27

7.2.1 BMS connector (NO-C-NC)............................................................................................ 28

7.2.2 Connector of the power cable......................................................................................... 28

7.3 Wiring diagram............................................................................................................................29

7.4 Working principle of the degassing process............................................................................... 30

7.5 CE and UK CA marking.............................................................................................................. 30

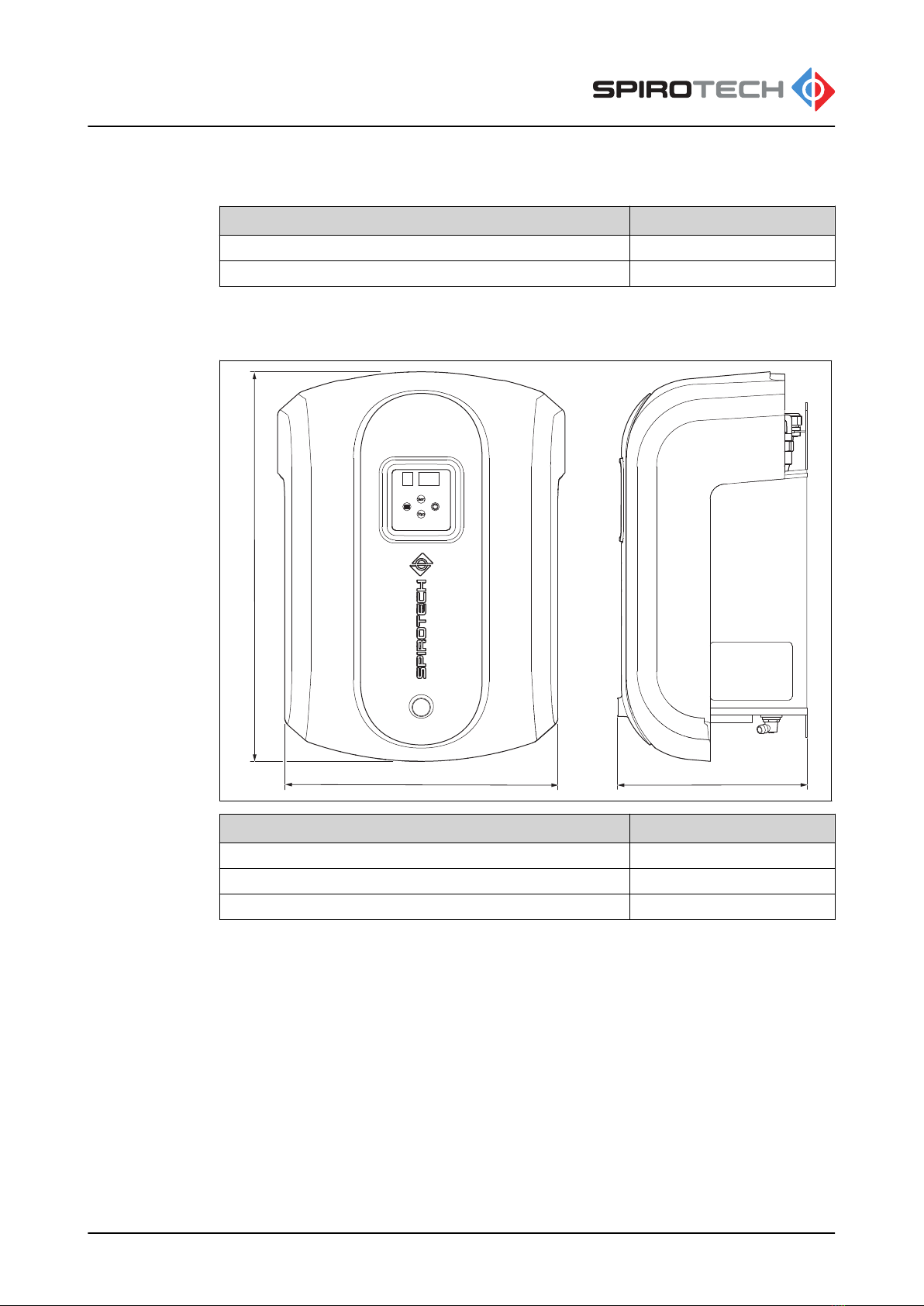

7.6 Identification of the unit...............................................................................................................31

7.6.1 Type plate....................................................................................................................... 31

7.6.2 Location of the type plate................................................................................................32

8 Access to parts....................................................................................... 33

8.1 Get access to the hydraulic parts and the PCB of the control panel.......................................... 33

8.2 Remove or install the cover........................................................................................................ 33

8.3 Get access to the hydraulic parts............................................................................................... 33

8.4 Get access to the PCB of the control panel................................................................................34

9 Maintenance........................................................................................... 35

9.1 Maintenance instructions............................................................................................................ 35

9.2 Maintenance schedule................................................................................................................35

Contents

474.358_00 - 28.04.2021