Spitwater HP30275P Installation and operation manual

This manual suits for next models

3

Other Spitwater Pressure Washer manuals

Spitwater

Spitwater G120 User manual

Spitwater

Spitwater SHW89 Operating instructions

Spitwater

Spitwater SLD19 Operating instructions

Spitwater

Spitwater SCWA61 Operating instructions

Spitwater

Spitwater SLD25 Operating instructions

Spitwater

Spitwater SCW85 Operating instructions

Spitwater

Spitwater SCWA68 Operating instructions

Spitwater

Spitwater SCWA60 Operating instructions

Spitwater

Spitwater HP25400DE Installation and operation manual

Spitwater

Spitwater SLD24 Operating instructions

Spitwater

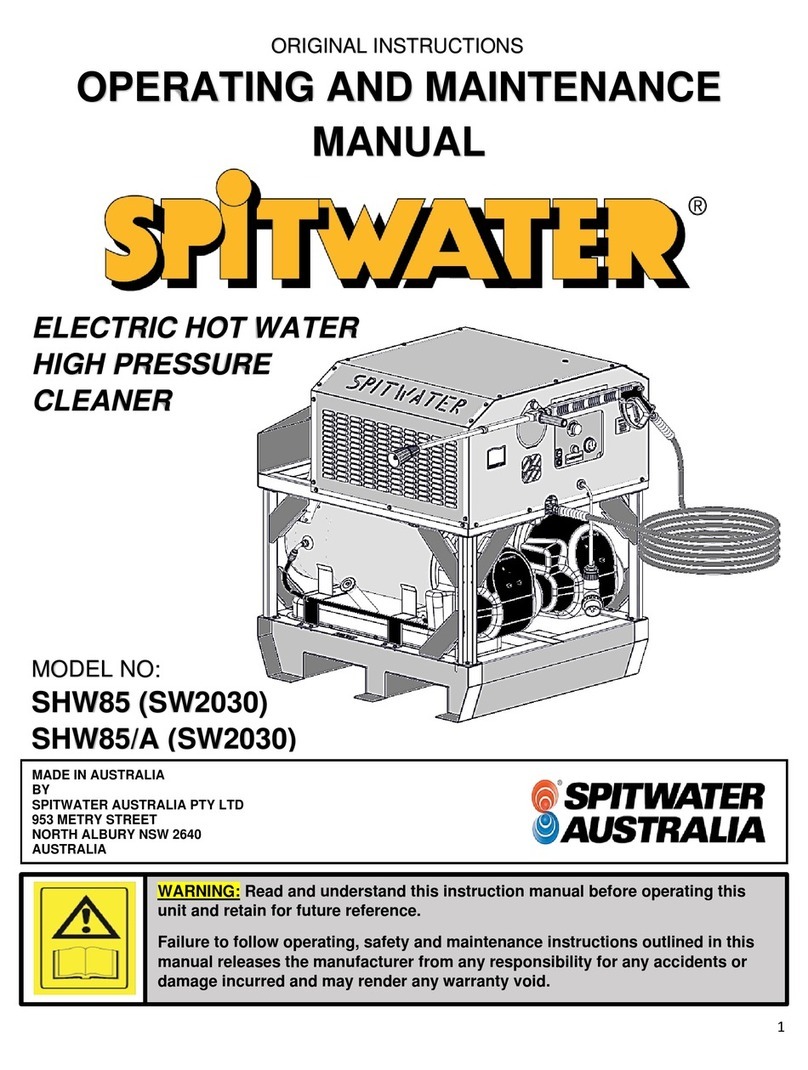

Spitwater SHW85 Operating instructions

Spitwater

Spitwater 8-140P Operating instructions

Spitwater

Spitwater SHW69 Operating instructions

Spitwater

Spitwater SCW82/G Operating instructions

Spitwater

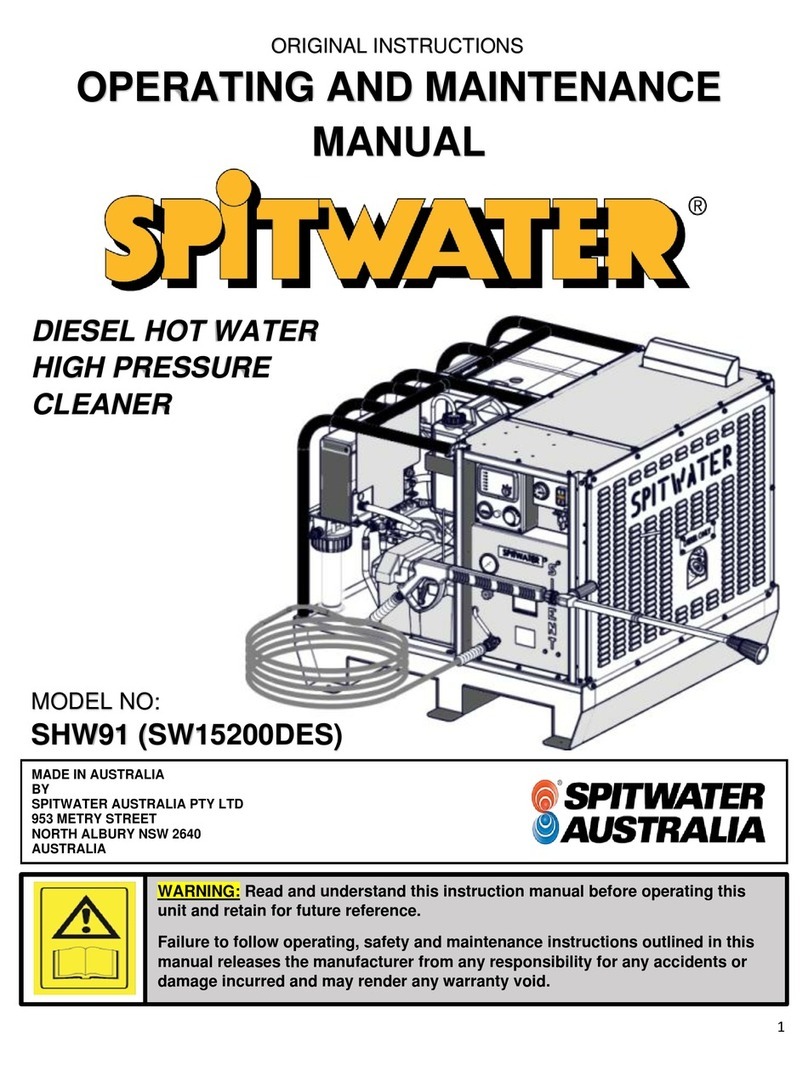

Spitwater SHW91 Operating instructions

Spitwater

Spitwater SCW69 Operating instructions

Spitwater

Spitwater HP201 Operating instructions

Spitwater

Spitwater SCW70/TS Operating instructions

Spitwater

Spitwater SHW87 Operating instructions

Spitwater

Spitwater SLD10 Operating instructions

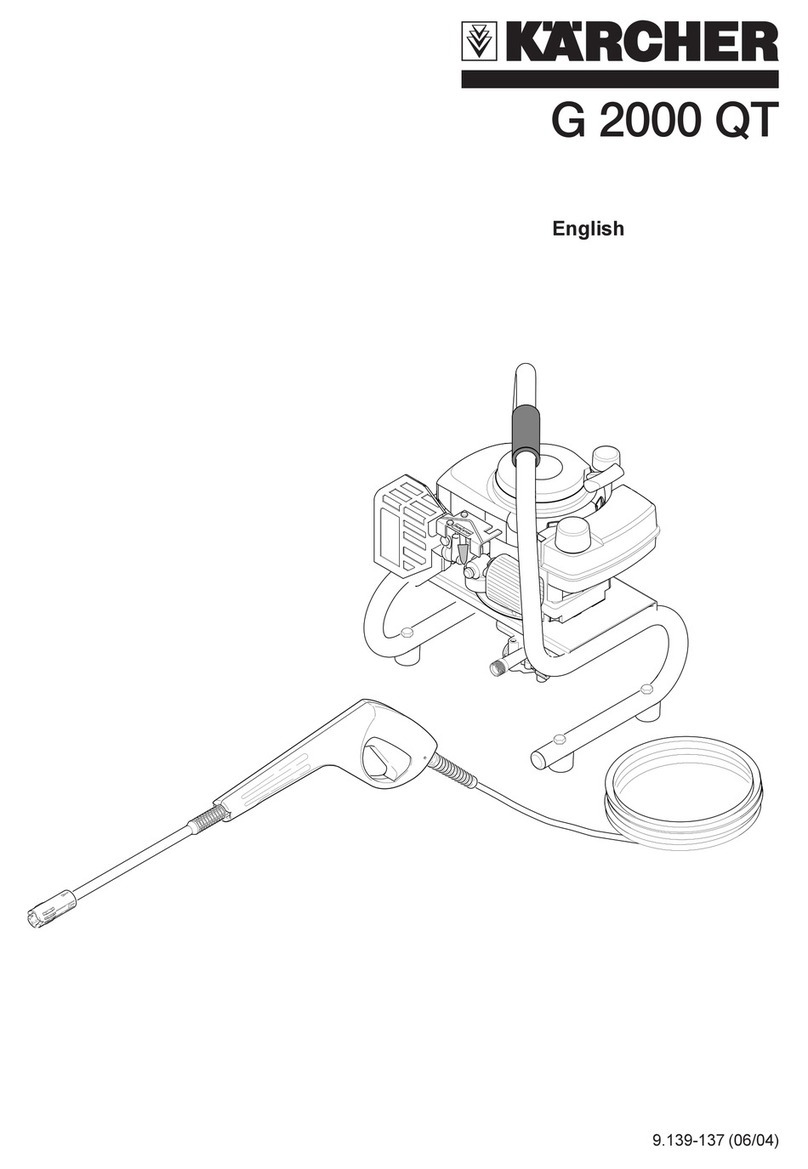

Popular Pressure Washer manuals by other brands

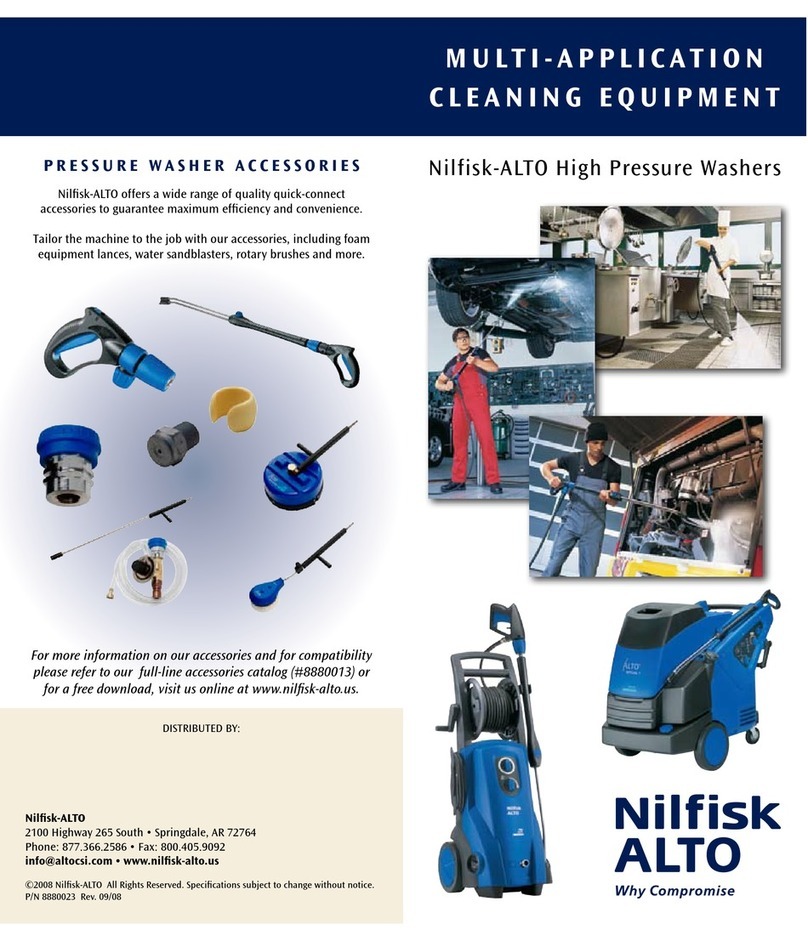

Nilfisk-ALTO

Nilfisk-ALTO POSEIDON 2-19 X Specifications

Greencut

Greencut JET-3200 instruction manual

Generac Portable Products

Generac Portable Products 2500PSI owner's manual

EUROM

EUROM 135428 instruction manual

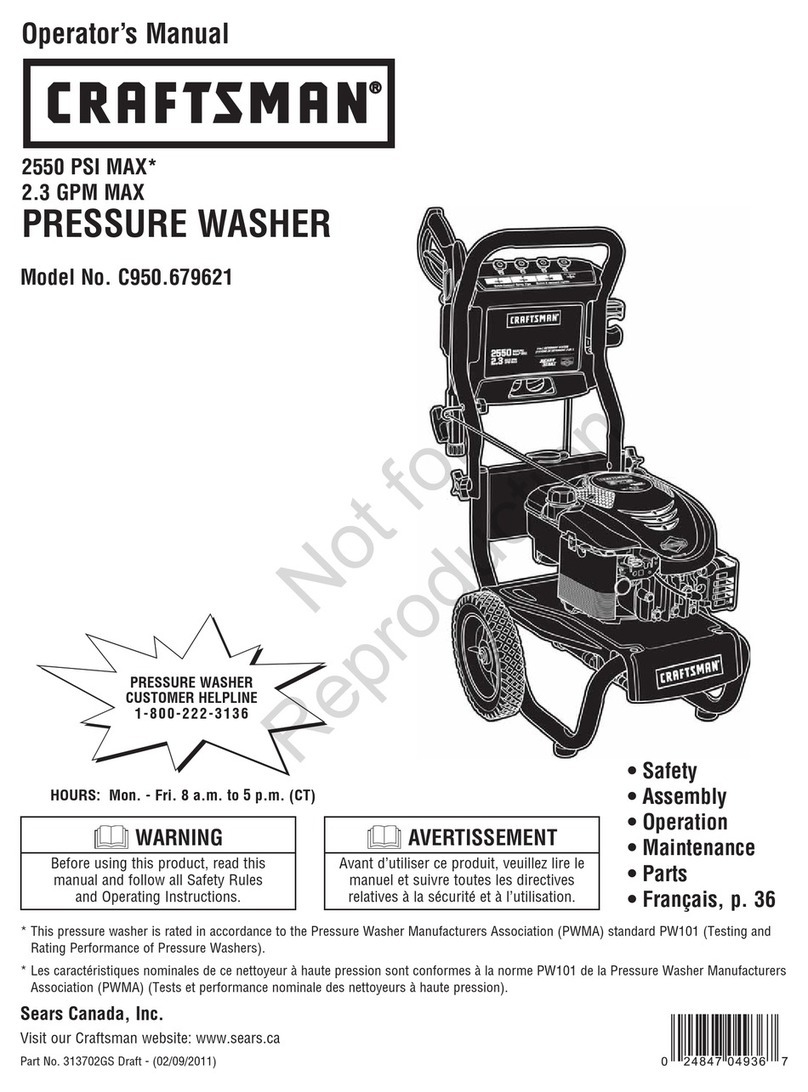

Craftsman

Craftsman C950.679621 Operator's manual

SNOWJOE

SNOWJOE SUNJOE SPX 3200 Operator's manual