SprintRay Pro Wash/Dry User manual

Level surface away from light and heat.

A C

B

Pro Wash/Dry™

Quick Start Guide

Congratulations!

Your new Pro Wash/Dry system is the most technologically

advanced system for cleaning 3D printed parts. Thanks to

its patented mechanical jetting system and onboard

computer, you’ll be saving time, money, and resources.

But before you get started, please read through this guide

and make sure to follow all procedures outlined herein when

using Pro Wash/Dry.

Training and Support

Your Pro Wash/Dry comes with complimentary phone and

email support. If you have questions, please get in touch:

Version 3.3

Updated on 05/20/21

Visit

Call

Email

support.sprintray.com

800-914-8004

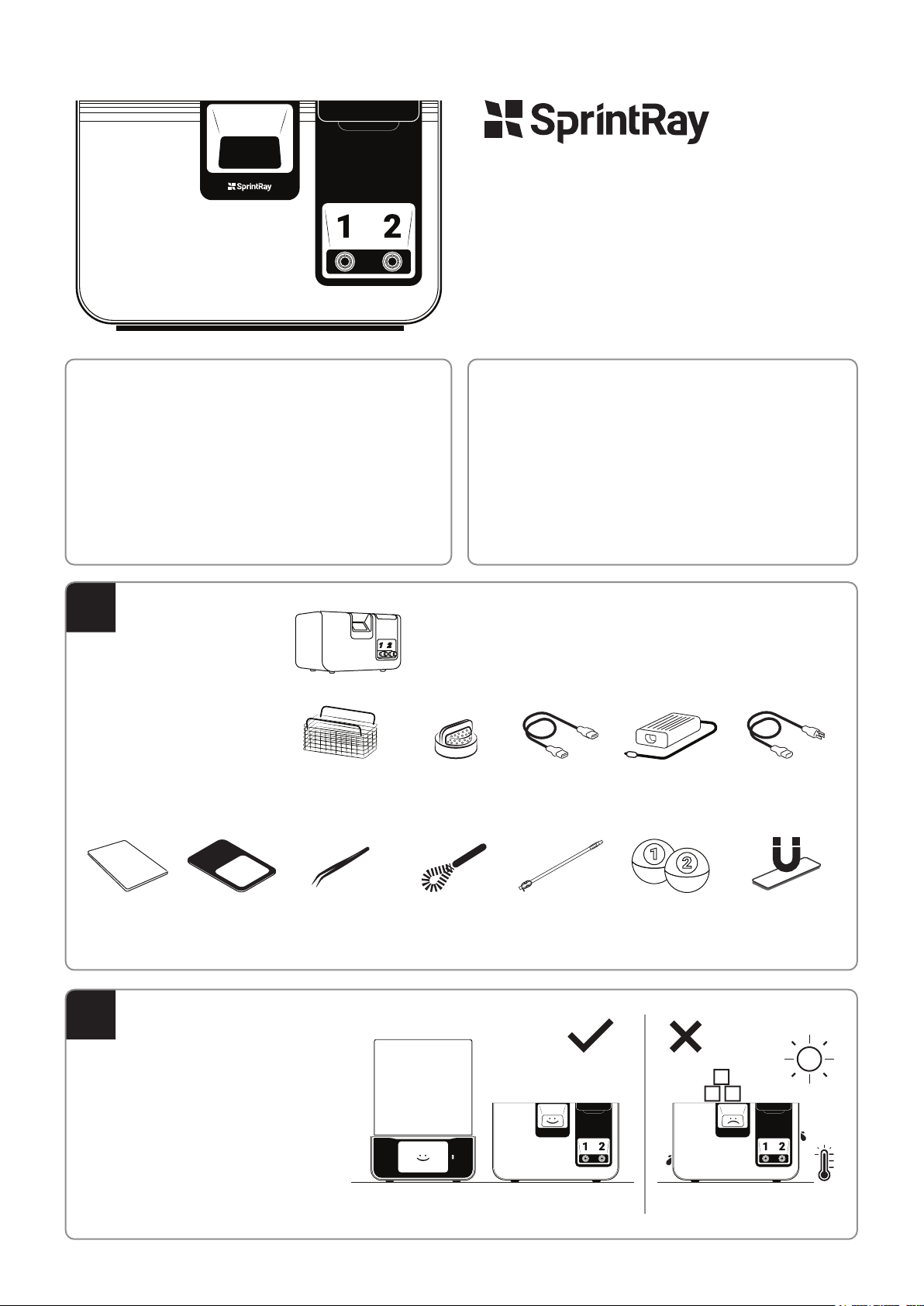

Pro Wash/Dry Unit

Drain Hose

Pre-installed

(See Section 7)

Cleaning

Brush

(See Section 8)

Basket

Pre-installed

(See Section 6)

Hydrometers

Pre-installed

(See Section 4)

Power CableUSB Cable

(See Section 12)

Wash Filter

(See Section 9)

Metal

Tweezers

(See Section 9)

Power Adaptor

Magnet Sticker

For Platform

(See Section 10)

Pro 55

Adaptor

(See Section 11)

Onboarding

Card

In the Box

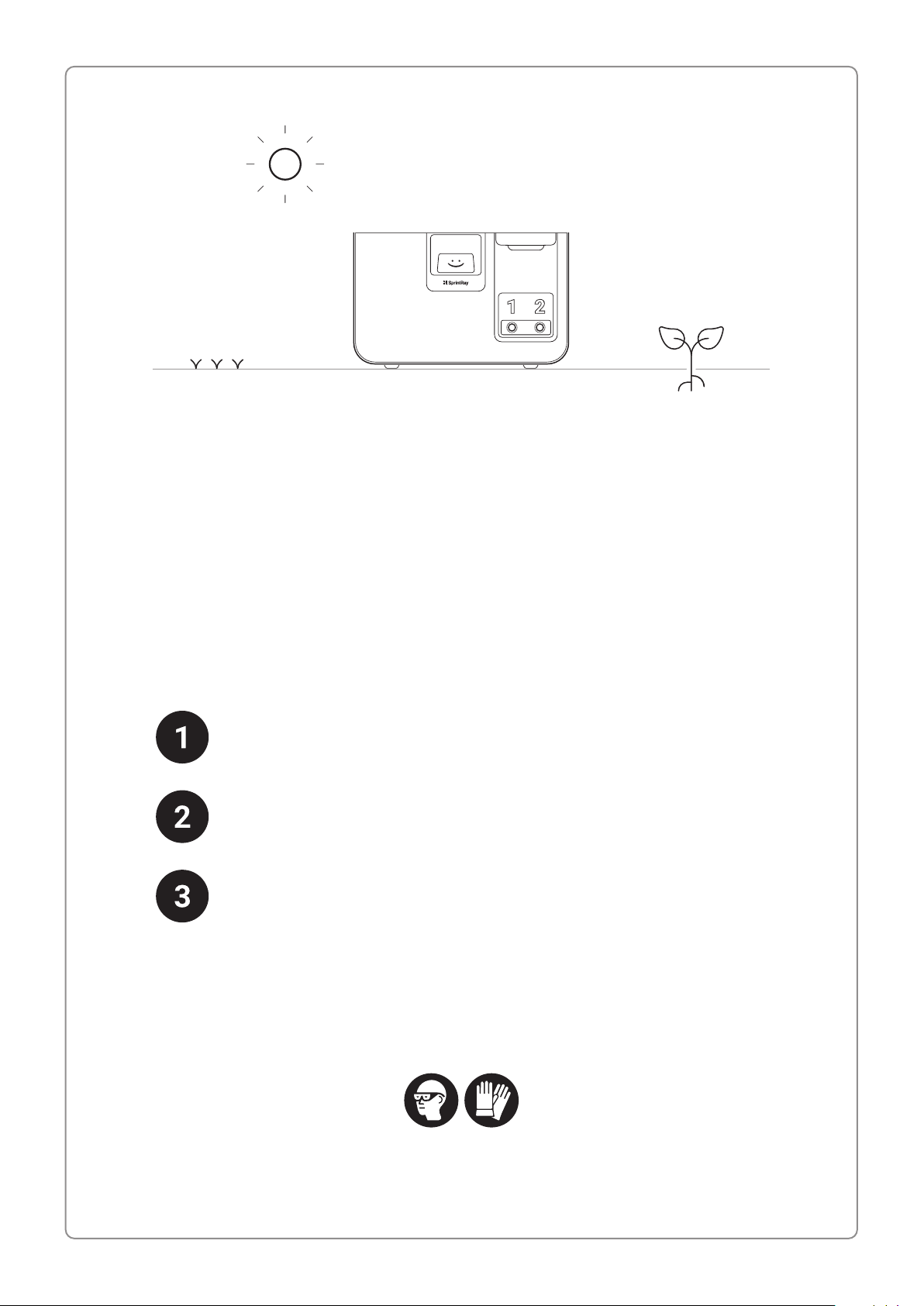

Place your Pro Wash/Dry in a well-ventilated

area on a flat, level surface. Keep it away from

extreme temperatures, windows, bright light

sources, and direct sunlight.

Never set anything on top of Pro Wash/Dry.

Pro Wash/Dry comes out of the

box with most parts pre-installed.

The hydrometers are pre-calibrated

for each chamber to float when it’s

time to refresh solvent.

Where to Set Up

Hello!

1

2

MAX

Plug in Your Pro Wash/Dry

The Basics

Use the provided power cable and power adaptor

to plug your Pro Wash/Dry into a surge protector

or uninterrupted power supply.

If you need to perform a hard reset or disconnect

your Pro Wash/Dry from its power source, simply

unplug and then plug in the power cable.

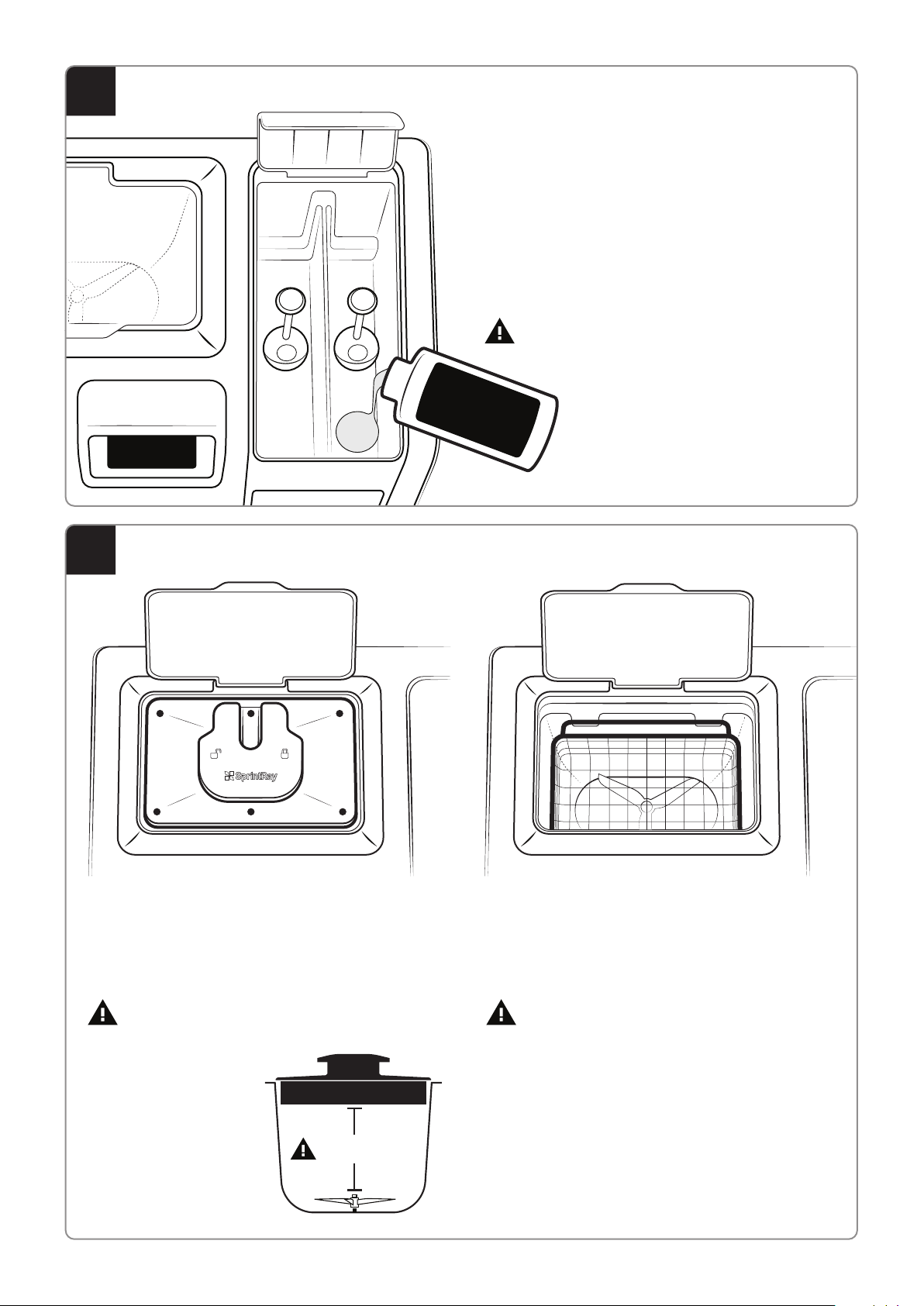

Wash Chamber

This chamber is where the washing and drying is performed.

There are two wash methods: direct platform and basket wash.

Solvent will automatically pump in and out of these reservoirs.

Never pour solvent directly into this chamber. It

should only ever be poured into the reservoirs.

Failure to replace IPA when hydrometer

floats will void warranty.

Reservoir

The reservoir consists of two chambers, each capable

of holding 2 liters. Pour solvent directly into the

reservoir chambers.

Chamber 1 performs the bulk wash.

The solvent in this chamber will need to be refreshed

more frequently.

Chamber 2 performs the fine wash.

The solvent in this chamber can be recycled into

Chamber 1 if desired.

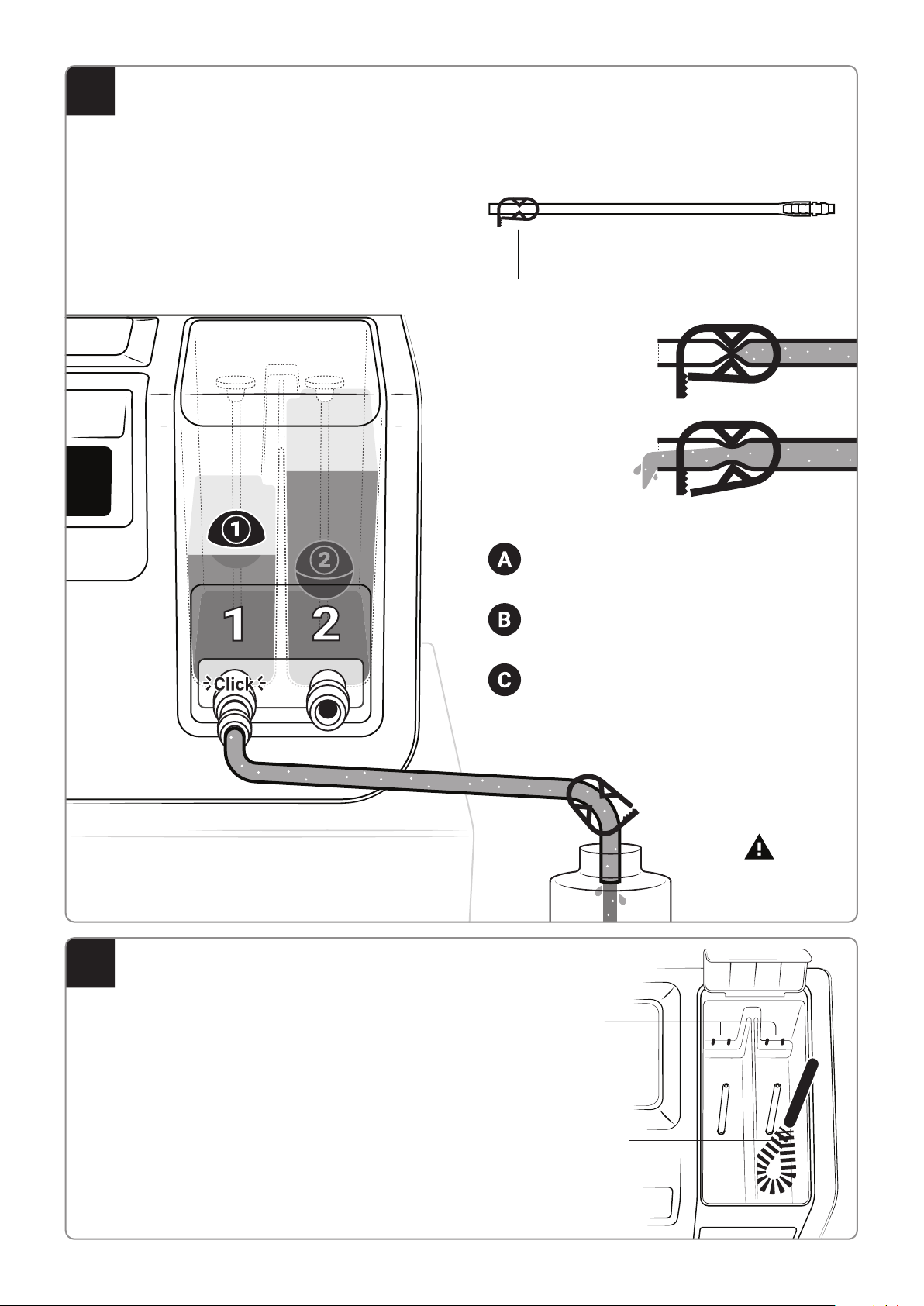

Quick Connect Ports

Each chamber has a quick connect port. When a hydrometer

floats to the top of the solvent, use the provided drain hose

(attached to the back of the machine) to drain the chamber as

shown in section 7.

Hydrometers

Hydrometers measure the resin saturation levels in each

chamber. When solvent becomes fully saturated, it will no longer

effectively clean 3D printed parts. Each hydrometer is specially

calibrated to float when the solvent has become saturated; when

this happens, it’s time to drain and refresh with clean solvent.

Submerged Hydrometer = Solvent Okay

When a hydrometer is submerged, it is acceptable for

use and will properly clean your printed parts.

Floating Hydrometer = Refresh Solvent

When a hydrometer floats, the solvent has become

saturated with resin and will no longer effectively clean

parts. Drain and replace with fresh solvent to continue.

USB Port

For Updates

Power Port

Drain Hose

Touchscreen

3

4

MAX

MIN 500 mL

12

MAX 4”

Minimum Required

Per Chamber

500 mL2 Liters

Recommended

Per Chamber

Isopropyl

Alcohol 91%

Recommended

How to Add Solvent to Pro Wash/Dry

How to Use Pro Wash/Dry

Wash with Print Platform

Pro Wash/Dry is designed with SprintRay Pro in mind.

Remove the basket and place the Pro95 print platform or

Pro55 print platform with adaptor (see Section 11) to wash

both parts and platform simultaneously.

Wash with Basket

To use the basket, place models inside, close the lid, and

select your preferred wash cycle from the touchscreen.

The system will not start washing until the lid is closed.

Recommended for:

- Models Taller than 4”

- Hollow/Shell Models

Recommended for:

- Models shorter than 4”

- Solid Models

- Models for Aligners

- Surgical Guides

- Night Guards

- Dentures

- Crowns

Do not stack models on top of each other or

crowd them together, as this can greatly

reduce wash efficiency.

When washing with the print platform,

remove the basket from the wash chamber.

Open the reservoir lid and add at least 500mL of the solvent

of your choice to each chamber. IPA 91% is recommended.

IPA 99% and ethanol can be used, but the chamber level

sensors may not be fully functional until after a few wash

cycles have been run.

If you haven’t added a sufficient volume of solvent, the

onboard computer will detect this and notify you.

Always ensure that the lid of the reservoir is closed in order

to preserve the life of your solvent to prevent evaporation.

Hydrometers may float when solvent is

refreshed, but will sink after a few minutes.

5

6

MAX

Unlocked

MAX

Unlocked

Solvent will flow

through the hose.

Locked

Solvent will not flow

through the hose.

How to Drain Solvent from Pro Wash/Dry

Pro Wash/Dry comes out of the box with the drain hose clipped to

the back. Gently pull to remove.

Locate the metal tip. This is the quick-connect inlet that mates to

the quick-connect ports on the front of each chamber. The outlet

has a plastic lock at the end.

To drain a chamber, press the inlet tip into the quick connect port

until it firmly clicks into place. When connected, solvent will begin

to run through the hose. To disconnect the drain hose, press the

outer ring of the quick connect port toward Pro Wash/Dry.

We recommend cleaning the wash chambers periodically, depending

on your usage.

To clean the chambers, remove the rubber caps from the tops of the

hydrometer rods, then remove the hydrometers. Use the provided

brush, a paper towel, and a solvent to remove all resin buildup and

residue from the walls and floor.

Make sure to clean the level sensor leads as well. If these sensors

become covered with resin, Pro Wash/Dry won't be able to detect

solvent levels.

The hydrometers are pre-calibrated for their reservoirs.

Return hydrometer 1 to chamber 1 and hydrometer 2 to chamber 2.

To drain a chamber, ensure the outlet clamp is in

the ‘locked’ position. Press the metal tip into the

quick connect port until it clicks into place.

Point the outlet of the hose into a disposable

container, then unlock the outlet clamp to open

the flow.

After draining, clean any residue left inside the

chamber using the provided brush and a paper

towel. Once clean, add fresh solvent. Repeat for

chamber 2 if necessary.

Liquid Stopper

The drain hose has a lock to prevent accidental drainage.

Quick Connect Metal Tip

The metal tip of the inlet port is designed to connect to

the quick connect ports on the front of Pro Wash/Dry.

Dispose of used wash

solvent responsibly.

Clean Sensors

Clean all resin and

residue buildup from

the level sensors.

Clean All Surfaces

Thoroughly scrub and

clean the walls and

floor of the chambers.

How to Clean the Wash Chamber and Reservoirs

7

8

How to Install Magnet on Print Platforms

How to Update Pro Wash/Dry

Pro Wash/Dry uses magnets to detect when a print platform is

present so that it can run the optimal cleaning program. To enable

this functionality, a magnet must be installed along the side of your

print platform.

To install, thoroughly clean and dry the right side of your print

platform, then adhere the magnet as indicated in the diagram below.

How to Clean the Wash Chamber Filter

Pro Wash/Dry has a mesh filter that prevents resin debris

from reaching the sensitive plumbing. This filter should be

regularly cleaned. If it cannot be sufficiently cleaned, the

filter should be replaced.

Remove

Clean the area around the filter

to ensure no debris falls into the

plumbing when it is removed.

Turn counter-clockwise by hand

to release the filter.

Clean

Flush the filter with solvent

to remove resin debris.

Use provided tweezers to

remove any additional

debris from the mesh.

Install

Replace the filter and turn

clockwise to hand tighten.

SprintRay will periodically update Pro Wash/Dry to improve

system functionality and add new wash profiles.

Visit sprintray.com/software to check for updates and to

view update instructions,

1/4 inch

1/2 inch

Center

Magnet

Pro 95

Print Platform

Place magnet on the right side.

Pro 55

Print Platform

Place magnet on the right side.

Locate Filter

Find the filter near the

wash propeller.

USB Port

For Updates

How to Use Pro55 Adaptor

If using a Pro55 with Pro Wash/Dry, place the

included adaptor atop the wash chamber so that

the opening is on the right. Place the Pro55 print

platform and start the wash process as normal. Label

Center

Magnet

Right Side

Right Side

10

9

12

11

Cleaner parts, less waste.

SprintRay Pro Wash/Dry uses patented technology to improve the

efficiency of the washing and drying processes. It’s better for your

pocketbook and better for the environment. Nice choice.

Here are three easy tips to help you go the extra environmental

mile with your used isopropyl alcohol (IPA):

For additional information, visit support.sprintray.com

Never flush IPA down the drain

Keep all IPA packaging for storing used IPA

Set up IPA recycling with a materials disposal company

Always wear gloves and proper eye protection.