SSI TC-20 User manual

Tube Cut-Off Machine

Operator’s Manual

90-2333RES REV A

CAUTION HIGH VOLTAGE

CAUTION - REFER TO MANUAL

EARTH GROUND

SAFETY SYMBOLS

i

TABLE OF CONTENTS

1INTRODUCTION ....................................................................................................1-1

1.1 Important Safety Notices.......................................................................................... 1-1

1.2 Description of the Model TC-20 Tube Cut-Off Machine......................................... 1-1

2INSTALLATION AND USE ....................................................................................2-2

3ROUTINE MAINTENANCE ....................................................................................3-3

3.1 Changing the Cutting Wheel.................................................................................... 3-3

3.2 Changing the Dressing Tool.................................................................................... 3-4

4SPARE PARTS ......................................................................................................4-1

4.1 Spare Parts for your TC-20 Tube Cut-Off Tool....................................................... 4-1

5VOLTAGE CONVERSION PROCEDURES...........................................................5-1

5.1 Convert from 115 VAC to 230 VAC.......................................................................... 5-1

5.2 Convert from 230 VAC to 115 VAC.......................................................................... 5-2

6GENERAL SAFETY RULES..................................................................................6-1

6.1 Work Area.................................................................................................................. 6-1

6.2 Electrical Safety........................................................................................................ 6-1

6.3 Personal Safety......................................................................................................... 6-1

6.4 Tool Use and Care .................................................................................................... 6-1

6.5 Service....................................................................................................................... 6-2

1-1

1 INTRODUCTION

This operator's manual contains information needed to install, operate, perform user

maintenance on, and service the Model TC-20 Tube Cut-Off Machine.

1.1 Important Safety Notices

To ensure safe and satisfactory operation of this equipment, it is essential

that the ground wire of the power cord is connected to a ground that

complies with all national, state, and local electrical codes.

Before using this equipment read the instructions carefully, paying

particular attention to potential hazards arising from its use.

Even with the power switch turned off there is still voltage on the input side of the

switch and therefore the equipment must be unplugged before lifting the front cover.

This equipment contains a safety interlock switch for the lid. Closure screws must be

fully tightened for equipment to operate.

WARNING: SAFETY GLASSES SHOULD ALWAYS BE WORN WHILE

MACHINE IS IN USE.

WARNING: DO NOT CUT TUBING NEAR ORGANIC VAPORS.

1.2 Description of the Model TC-20 Tube Cut-Off Machine

The Tube Cut-Off Machine has been designed for light or intermittent duty using a

high-speed, dry abrasive cut-off wheel housed in a protective cabinet. The motor

speed, wheel, and cutting arm are carefully matched and aligned to provide safe,

square cutting of 1/16, 1/8 and 1/4 inch (1.6, 3.2 and 6.4 mm) OD stainless steel

tubing with ID down to 0.008 inches (0.2 mm). The unique dressing tool deburrs by

shaving the OD and ID with hard tool-steel cutting edges. Properly maintained, the

TC-20 should provide years of trouble free operation.

2-2

2 INSTALLATION AND USE

1. Plug the Tube Cut-Off Machine into a properly grounded outlet. Be sure that the

line voltage matches the voltage rating on the left side of the unit.

2. For 115V operation use 93-5062: Fuse 5 amp SLO-BLO, 1 each

Install fuse opposite clip on fuse holder, insert fuse holder so 115V appears

through window in fuse door.

For 230V operation use 93-5062: Fuse 5 amp SLO-BLO, 2 each

Remove clip on fuse holder to install both fuses. Insert fuse holder so 230V

appears through window in fuse door.

3. Place the tubing to be cut into the vise-clamp on the end of the cutting arm and

tighten. Be certain the tubing is as straight as possible for best results.

4. Turn on the high-speed abrasive wheel and lower the arm to direct the tubing into

the slot. (Safety glasses should be worn while machine is in use.) Raise and lower

the arm several times to make certain the tube-end in the vise arm is square cut.

Turn off the cutting wheel.

5. Discard the short piece that has been cut off, turn the tube around in the vise and

square-cut the other end. Measure carefully before cutting.* The tube in the vise is

now ready for deburring. The piece not held by the vise arm usually will not be

square or suitable for deburring, unless it is also firmly captured during the cutting

operation.

6. Deburr by inserting the tube into the appropriate size dressing tool on the opposite

end of the cutting arm and turning the knurled nut clockwise. Always turn the

dressing tool in the same direction, like a pencil sharpener. Light pressure and

several revolutions are sufficient in most cases to remove burrs from the OD and

ID of the tubing. Results will improve with practice.

*Scale on lid is for reference only.

3-3

3 ROUTINE MAINTENANCE

Figure 1. Cutting Wheel and Arbor

3.1 Changing the Cutting Wheel

Eventually, both cutting wheel and dressing tools will have to be replaced. A cutting

wheel must be replaced when it wears down below the cutting slot. Occasionally, a

wheel may also break or clog with fine steel particles .To change the cutting wheel,

follow the instructions below.

1. Unplug the power cord, and then remove the two thumbscrews on the front

cover. Do not attempt to bypass the open cover safety switch. Doing so

could allow the cutting wheel to start unexpectedly.

Do not adjust arbor (behind cutting wheel). Two setscrews hold it

in correct alignment to the cover slot.

2. Hold the arbor (A) on the motor side of the cutting wheel (see Figure 1) and

turn the knurled nut (B) counterclockwise to remove.

3. Remove the cutting wheel carefully from hub using your fingertips to hold the

edge of the wheel.

4. Insert the new cutting wheel, carefully into place and keeping the cardboard

washers on each side.

3-4

5. Replace the knurled nut while holding the arbor on the motor side. The knurled

nut should be tightened to its original finger-light position.

6. Before closing the cover, brush or vacuum dust from inside the case.

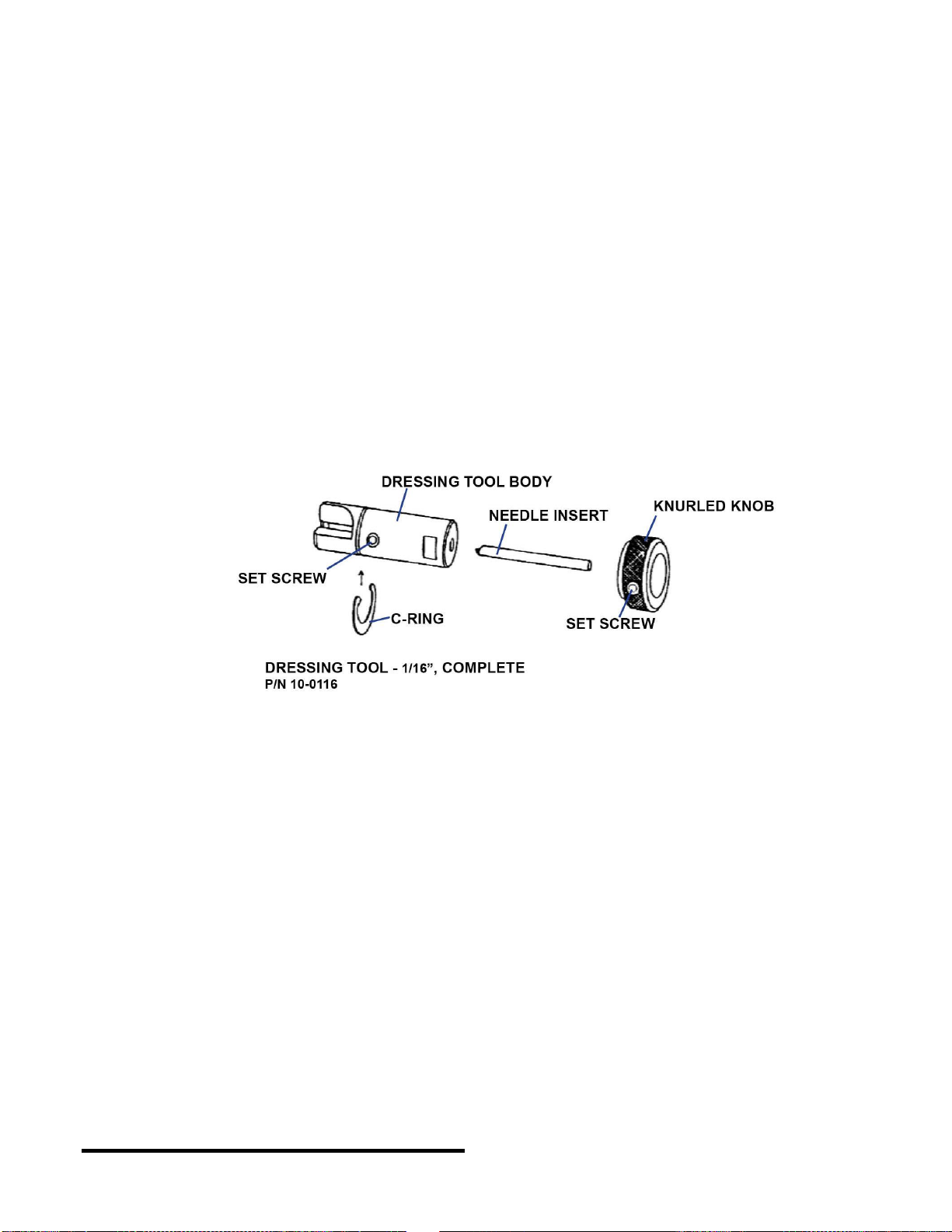

3.2 Changing the Dressing Tool

A dressing tool should be replaced when it gets dull and pushes rather than shaves

burrs. The needle insert (see Figure 2) that deburrs the ID will break or wear out

more frequently than the body that deburrs the OD. To replace the dressing tool:

1. Remove the dressing tool from the vise arm by opening the C-ring. The needle

insert is held inside the tool body by a set screw.

2. Note the position of the needle Insert cutting tip before loosening the set

screw. Remove and replace the needle to the same position. Normally the

back of the insert will be flush with the back of the tool body.

3. Tighten the set screw and replace the dressing tool and C-ring.

Figure 2. Dressing Tool Assembly

4-1

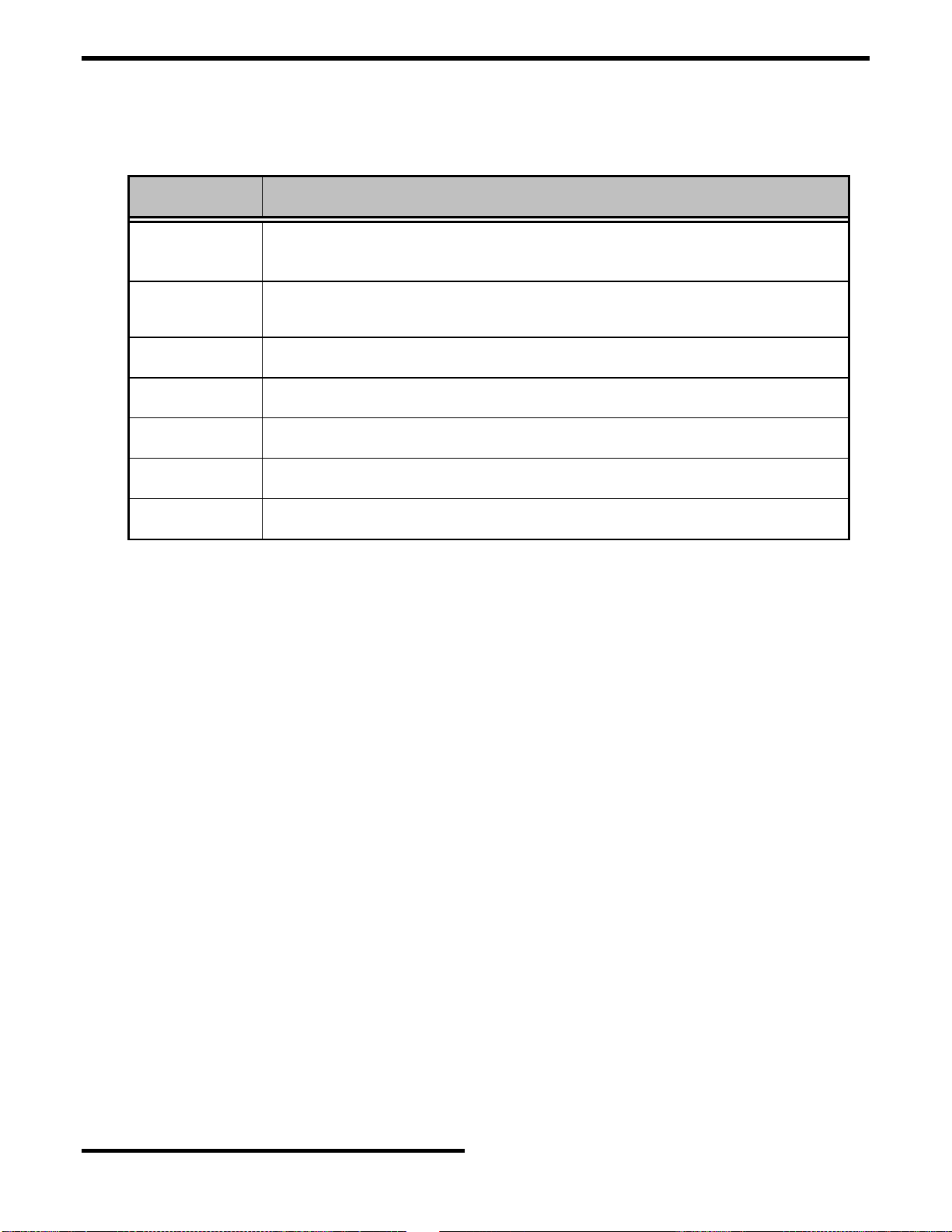

4 SPARE PARTS

4.1 Spare Parts for your TC-20 Tube Cut-Off Tool

P/N

Description

100124

Replacement Cutting Wheel, pack of 3

100116

1/16” Dressing Tool

101016

Replacement Needle Insert for 1/16” Dressing Tool

100118

1/8” Dressing Tool

101018

Replacement Needle Insert for 1/8” Dressing Tool

935062

Fuse, 5 Amp, Slo-Blo (115V)

935062

Fuses, Slo-Blo (230V), 2 each

5-1

5 VOLTAGE CONVERSION PROCEDURES

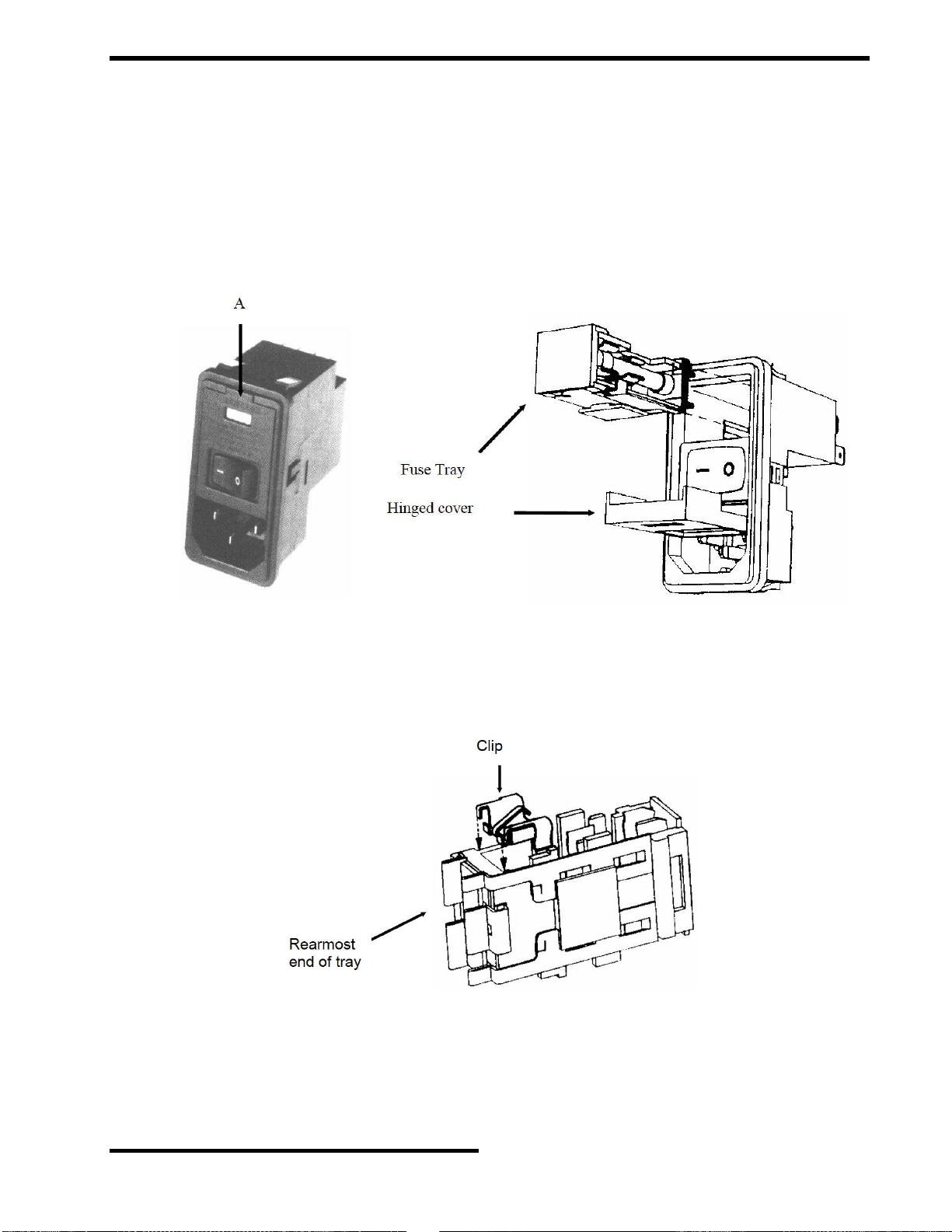

5.1 Convert from 115 VAC to 230 VAC

1. Remove the power cord from the power entry module (see Figure 3)

located in the rear of the unit.

2. Using a small, flat-blade screwdriver, carefully pry out the power entry

module cover at point A, Figure 3. The hinged cover will swing down as

shown in Figure 4.

Figure 3 Figure 4

3. Using a small, flat-blade screwdriver, carefully pry out at the top of the fuse

tray and carefully remove the fuse tray as illustrated in Figure 4.

Figure 5. Fuse Tray.

4. Holding the fuse tray in the exact orientation shown in Figure 5, observe

the small clip shown in Figure 5. Grasp at the two sides of the clip gently

remove from the tray assembly as shown in Figure 5.

5-2

5. Place one fuse into the compartment where the clip was removed in step 4.

The fuse ratings must be as shown on the back of the unit cabinet. The

European 20 mm long fuses must be placed fully to the rearmost end of

the tray (closest to the metal tabs extending from the tray), or contact will

not be made and the unit will not operate. Both fuses must be present to

complete the circuit.

6. With the two proper fuses in the tray, orient the tray with the two fuses at

the sides and the 230V marking at the top, as shown in Figure 4, and insert

it with the metal tabs first into the top of the power entry module until it is

firmly seated in place. It may be necessary to squeeze the two fuses at the

rear to permit them to enter the power module housing. Close the power

entry module cover by pressing at the top center until it snaps into place.

Insert a suitable 230V power cord.

5.2 Convert from 230 VAC to 115 VAC

1. Remove the power cord from the power entry module (see Figure 3)

located in the rear of the unit.

2. Using a small, flat-blade screwdriver, carefully pry out the power entry

module cover at point A, Figure 3. The hinged cover will swing down as

shown in Figure 4.

3. Using a small, flat-blade screwdriver, carefully pry out at the top of the fuse

tray and carefully remove the tray as illustrated in Figure 4.

4. Observe the shorting clip in Figure 5 and remove the fuse present in the

fuse tray where the shorting clip will go by gently lifting it up at the rearmost

end of the tray (where the metal tab extends) and removing the fuse from

its retaining clip.

5. Observe the shorting clip placement as shown in Figure 5. Place a shorting

clip by hand onto the tray as follows. The tray must be oriented as drawn

(the marking PRSR will be at the top of the fuse tray front). The clip must

be oriented as shown with the “finger” at the center pointing toward the

front of the tray. Do not bend this finger or the required connections will not

be made. Grasping the clip only at the sides, slide it down into place on the

tray. The base of the clip will insert into the cavity in the tray when it is

placed in the correct position. Place one fuse into the compartment in the

side of the fuse tray opposite the side with the clip. The fuse rating must be

as shown on the back of the unit cabinet. A 20 mm long European fuse

must be placed fully to the rearmost end of the tray (closest to the metal

tabs extending from the tray) or contact will not be made and the unit will

not operate. Both the clip and the fuse must be present in their proper

places or the unit will not operate. With the clip and proper fuse in the tray,

orient the tray with the fuse at the side and the 115V marking at the top, as

shown in Figure 4, and insert it with the metal tabs first into the top of the

power entry module until it is firmly seated in place. It may be necessary to

squeeze the fuse at the rear to permit it to enter the power module

housing. (If the clip and fuse are on the incorrect sides of the tray, it will not

be possible to place the tray into the power entry module). Close the power

entry module cover by pressing at the top center until it snaps into place.

Insert a suitable 115V power cord.

6-1

6 GENERAL SAFETY RULES

WARNING! Read and understand all instructions. Failure to follow all

instructions listed below may result in electric shock, fire and/or serious

personal injury.

6.1 Work Area

• Keep your work area clean and well lit. Cluttered benched and dark areas

invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control of the tool.

6.2 Electrical Safety

• Do not abuse the cord. Never use the cord to carry the tool. Keep cord away

from heat, oil, sharp edges, or moving parts. Replace damaged cords

immediately. Damaged cords may create a fire.

6.3 Personal Safety

• Stay alert, watch what you are dong and use common sense when

operating a power tool. Do not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention while operating may result

in serious personal injury.

• Dress properly. Do not were loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from moving parts. Loose clothing, jewelry, or

long hair can be caught in moving parts.

• Avoid accidental starting. Be sure switch is in the off position before inserting

the AC power cord.

• Do not overreach. Keep proper footing and balance at all times. Proper footing

and balance enables better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

6.4 Tool Use and Care

• Operate this tool on a stable surface. Holding the unit by hand or against the

body is unstable and may lead to loss of control.

• Do not force tool. Use the correct tool for your application. The correct tool will

do the job better and safer at the rate for which it was designed.

• Do not use tool if switch does not turn it on or off. A tool that cannot be

controlled with the switch is dangerous and must be repaired.

6-2

• Store idle tool out of reach of children and other untrained persons. Tools

are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tool clean.

• Check for misalignment or binding of moving parts, breakage of parts, and

any other condition that may affect the tools operation. If damaged, have the

tool serviced before using.

• Use only accessories that are recommended by the manufacturer.

6.5 Service

• Tools service must be performed only by qualified repair personnel.

Service or maintenance performed by unqualified personnel may result in risk of

injury.

• When servicing a tool, use only identical replacement parts. Follow the

instructions of this manual. Use of unauthorized parts or failure to follow

instructions may create a risk of shock or injury.

Table of contents