3.4 Installing the Header and Jamb Assembly

3.4.1 LIFT header and jamb assembly and POSITION into opening.

3.4.2 Temporarily SECURE frame in place as necessary to prevent header and jamb assembly

from falling,

3.4.3 SHIM beneath jamb(s) as necessary to level header and maintain required height from

highest point of finished floor.

3.4.4 INSPECT one jamb for plumb in vertical and horizontal planes. IF required, SHIM

back of jamb.

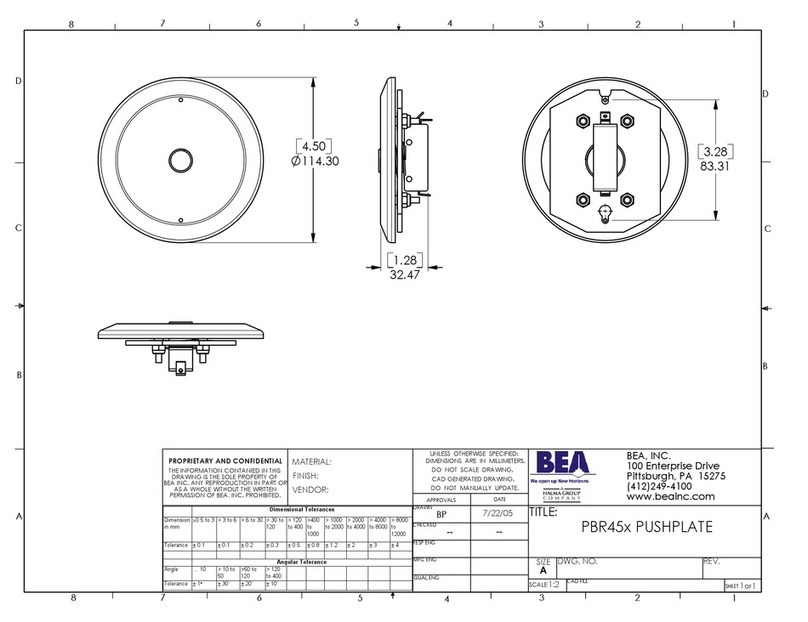

3.4.5 Refer to Figure 2, and, using the previously drilled jamb holes as a guide, DRILL holes

in rough opening for the following fasteners as required:

• IF rough opening is concrete, DRILL W dia. hole for concrete screw, and

ENSURE screw will be embedded VA" minimum.

• IF rough opening is steel, DRILL #14 SMS (Note 18 GA steel minimum).

• IF rough opening is wood, DRILL for #14 wood screw, and ENSURE screw will

be embedded 1 Vi" minimum.

.>

Figure 2. Installing the Header and Jamb Assembly

— ^

(D

-—^^

— U d-J

1 1 . SI

3.4.6 INSTALL, but do not tighten, fasteners securing one jamb to opening, and ENSURE

jamb remains plumb.

3.4.7 INSPECT opposite jamb for plumb in vertical and horizontal planes. IF required, SHIM

back of jamb.

3.4.8 Using the previously drilled jamb holes as a guide, DRILL holes in rough opening.

3.4.9 INSTALL, but do not tighten, fasteners securing jamb to opening, and ENSURE jamb

remains plumb.

3.4.10 Starting at the top of jamb and moving downward, SHIM jambs as necessary to ensure

jambs remain level and plumb, and TIGHTEN fasteners securing jambs to opening.

3.4.11 INSTALL and TIGHTEN fasteners securing header to opening, and ENSURE header

remains level.

©2011, THR STANLEY WORKS. ALL RIGHTS RESERVED.

204068

Rev. B, 2/26/11

5 of 15