Star Cool SCU-20 Service manual

Operating and service manual

Star Cool refrigeration unit Model SCU-20/40 and SCI-20/40

Version 810900C April 2015

24-hour hotline support

Our service department is available 24 hours a day, 7 days a week -

providing easy access to the answers You need.

For further troubleshooting help, go to our website URL: m.starcool.com

or simply scan the QR code with Your smartphone

Bjerndrupvej 47,

6360 Tinglev, Denmark

Phone: +45 73 64 34 00

Fax.: +45 73 64 35 69

www.starcool.com

Version 810900C April 2015 © Copyright 2015 Maersk Container Industry AS

Operating and service manual Version 810900C April 2015

1 of 194 pages

Operating and service manual

Preface

This version of the manual is dated April 2015, edited by Maersk Container Industry AS.

All rights reserved.

This user’s manual is valid for software version 0353 or newer versions.

The information herein is subject to change without notice and does not represent a commitment

on any part of Maersk Container Industry AS.

While the information herein is assumed to be accurate, Maersk Container Industry AS assumes

no responsibility for any errors or omissions that may appear in this documentation.

This manual is valid for:

Model SCI - 20/40 and SCU - 20/40

Release Date 10.04.2015

Part number 810200B and 810300B.

Warnings

Do not operate or maintain this refrigeration unit until you have familiarized

yourself completely with the equipment and operating of this unit by reading the

instruction in this manual.

Do not perform any welding on the unit before disconnecting the power plug.

Furthermore, disconnect the power meas module and main controller (and

modem if present).

Disconnect main power supply to unit before inspecting the interior of the

controller box.

The unit is charged with R134a and ester oil BSE 55. Do not use any other

refrigerant or oil.

Do not use contaminated refrigerant or oil.

Do not release R134a into the atmosphere. Use recovery equipment according to

present legislation.

During maintenance please observe that R134a is operating with high and low

temperatures in combination with high pressures, which may cause personal

injuries if not handled properly.

During recovery and maintenance of R134a unit personal protection equipment

has to be worn.

Do not trap any liquid refrigerant inside pipes during soldering work. This may

lead to explosion of pipe.

Please note that some unit models do not have Schräder valve installed for PSUC

and PDIS transmitter.

Operating and service manual

2 of 194 pages

Contents

Preface............................................................................................................................................................ 1

Warnings......................................................................................................................................................... 1

Legend ............................................................................................................................................................ 6

General description......................................................................................................................................... 8

Function description ....................................................................................................................................... 9

Start-up procedure..................................................................................................................................... 9

Climate Control Function ........................................................................................................................... 10

Temperature Control ................................................................................................................................ 10

Capacity Control and Limiter ..................................................................................................................... 10

Expansion Valve....................................................................................................................................... 11

Economizer Valve ..................................................................................................................................... 12

Dehumidication ...................................................................................................................................... 12

Condenser Fan......................................................................................................................................... 13

Evaporator Fan ........................................................................................................................................ 13

Defrost Function ...................................................................................................................................... 13

QUEST (optional)...................................................................................................................................... 15

Bulb mode (Overall Description)................................................................................................................. 15

Product Perspective.................................................................................................................................. 15

Product Functions..................................................................................................................................... 15

User Interface.......................................................................................................................................... 15

Communication to Data Logger .................................................................................................................. 16

Bulb mode (System Feature) ..................................................................................................................... 16

Setting.................................................................................................................................................... 16

Conguration........................................................................................................................................... 16

Limitations .............................................................................................................................................. 16

Alarms .................................................................................................................................................... 16

Defaulting ............................................................................................................................................... 16

Tests ...................................................................................................................................................... 16

Function test ........................................................................................................................................... 17

Full PTI ................................................................................................................................................... 18

Short PTI ................................................................................................................................................ 18

Data Log ................................................................................................................................................. 18

Alarm Action System (AAS) ....................................................................................................................... 20

Temperature control ................................................................................................................................. 20

Expansion valve control ............................................................................................................................ 20

Condenser fan control............................................................................................................................... 21

Dehumidication control ........................................................................................................................... 21

Defrost control......................................................................................................................................... 21

Electrical control ...................................................................................................................................... 21

Refrigeration system data............................................................................................................................. 22

Refrigerant charge, R134a......................................................................................................................... 22

General specication ................................................................................................................................ 23

Compressor – motor assembly................................................................................................................... 23

Frequency converter (FC).......................................................................................................................... 23

High Pressure cut – out switch................................................................................................................... 23

Fusible plug, receiver................................................................................................................................ 23

Economizer.............................................................................................................................................. 23

Evaporator coil......................................................................................................................................... 23

Condenser coil ......................................................................................................................................... 24

Evaporator fan ......................................................................................................................................... 24

Condenser fan ......................................................................................................................................... 24

3 of 194 pages

Operating and service manual

Water cooled condenser (optional) ............................................................................................................. 24

Defrosting ............................................................................................................................................... 24

Fresh air exchange ................................................................................................................................... 25

Refrigeration controls ............................................................................................................................... 25

Electrical data.......................................................................................................................................... 25

Circuit Breaker......................................................................................................................................... 25

Contactors .............................................................................................................................................. 25

Fuses...................................................................................................................................................... 25

Power plug .............................................................................................................................................. 25

Power Cable ............................................................................................................................................ 25

USDA socket requirements ........................................................................................................................ 26

Evaporator fan motor................................................................................................................................ 26

Condenser fan motor ................................................................................................................................ 26

Evaporator coil heaters ............................................................................................................................. 27

Temperature sensors, including USDA ........................................................................................................ 27

Pressure transmitters ............................................................................................................................... 27

Miscellaneous .......................................................................................................................................... 27

User Interface............................................................................................................................................... 27

Indicator lights......................................................................................................................................... 27

Display.................................................................................................................................................... 28

Key pad .................................................................................................................................................. 29

Menu overview.............................................................................................................................................. 30

General Page layout.................................................................................................................................. 30

Using the cursor....................................................................................................................................... 31

Changing a parameter value ...................................................................................................................... 31

Activating a function................................................................................................................................. 31

Air exchange page.................................................................................................................................... 31

Operation...................................................................................................................................................... 32

Menu Structure ........................................................................................................................................ 32

General Operation.................................................................................................................................... 33

Temperature Setting................................................................................................................................. 33

Wake-up Mode ................................................................................................................................. 33

Contrast adjustment of the display ............................................................................................................. 33

PTI or Function Test execution ........................................................................................................... 34

Info Menu Viewing ................................................................................................................................... 37

Operation Parameter Setting ............................................................................................................. 40

Programs: ............................................................................................................................................... 40

Multiple Temperature Set points program, MTS............................................................................................ 41

Cold Treatment program, CT ..................................................................................................................... 42

Alarms ................................................................................................................................................... 43

Service Function Setting/Viewing ....................................................................................................... 44

Manual operations:................................................................................................................................... 45

Datalog view: .......................................................................................................................................... 46

Time adjust: ............................................................................................................................................ 47

Run time counters:................................................................................................................................... 47

Conguration:.......................................................................................................................................... 48

Serial Numbers ........................................................................................................................................ 49

°C and °F Temperature Scale Showing, Alternately ................................................................................ 50

Viewing graph of Supply and Return Temperature ................................................................................ 50

Manual Defrost Initiation ..................................................................................................................... 50

Water-cooling Activation/Deactivation ................................................................................................ 51

Emergency Operation ................................................................................................................................... 51

FC defective ............................................................................................................................................ 51

Controller defective .................................................................................................................................. 51

Operating and service manual

4 of 194 pages

External interfaces ....................................................................................................................................... 52

General requirements ............................................................................................................................... 52

List of terms used for external interfaces .................................................................................................... 52

Functions overview................................................................................................................................... 53

Location of valves ......................................................................................................................................... 54

Location of motors, temperature sensors, humidity sensor and air exchange potentiometer ...................... 55

Location of pressure transmitters, high pressure switch and oil outlet port ................................................ 56

General trouble shooting .............................................................................................................................. 56

Trouble shooting for Star Cool main controller ............................................................................................. 57

Detailed alarm description............................................................................................................................ 57

Alarm list ................................................................................................................................................ 58

Events ........................................................................................................................................................... 61

Temperature Sensor Alarms (AL 1XX)......................................................................................................... 63

Pressure transmitter Alarms (AL 2XX) ....................................................................................................... 73

Other Sensor Alarms (AL 3XX) ................................................................................................................... 76

Power Alarms (AL 4XX) ............................................................................................................................. 80

Frequency Converter (FC) Alarms (AL 5XX) ................................................................................................. 90

Operation Alarms (AL 6XX)...................................................................................................................... 105

Communication Alarms (AL 7XX).............................................................................................................. 119

Test Alarms (AL 8XX).............................................................................................................................. 123

Controller Alarms (AL 9XX)...................................................................................................................... 138

Calibration of air exchange sensor.............................................................................................................. 163

Sensor calibration using StarView .............................................................................................................. 163

Replacing of unit ......................................................................................................................................... 164

Replacement Evaporator motor and fan...................................................................................................... 165

Replacement Condenser motor and fan ...................................................................................................... 165

Replacement of evaporator......................................................................................................................... 166

Replacement of heating elements............................................................................................................... 167

Replacement of FC ...................................................................................................................................... 168

Replacement of compressor........................................................................................................................ 169

Replacement of compressor valve plate / cylinder head gasket ................................................................. 170

Service and maintenance ............................................................................................................................ 171

Evacuation of refrigerant......................................................................................................................... 171

Compressor pump down, operation .......................................................................................................... 172

Compressor pump down, replaced............................................................................................................ 172

Pump down of unit.................................................................................................................................. 173

Pressure Test......................................................................................................................................... 173

Charging of refrigerant ........................................................................................................................... 174

Charging of an empty unit....................................................................................................................... 174

Charging of unit low on charge................................................................................................................. 174

Leakage detection .................................................................................................................................. 175

Fan motors (in not using plug) ................................................................................................................. 175

5 of 194 pages

Operating and service manual

Drying lter........................................................................................................................................... 176

Replacing of drying lter ......................................................................................................................... 176

Compressor........................................................................................................................................... 176

Check of oil level .................................................................................................................................... 176

Charging of oil ....................................................................................................................................... 177

Draining of oil from compressor ............................................................................................................... 177

Soldering .............................................................................................................................................. 178

Welding................................................................................................................................................. 178

Tables ......................................................................................................................................................... 178

Datalog description ................................................................................................................................ 178

Temperature Sensor [°C] - Resistance Table.............................................................................................. 180

Temperature Sensor [°F] - Resistance Table .............................................................................................. 181

Air exchange Sensor table Voltage - m3/h for 35 CMH ................................................................................ 182

Voltage – Pressure Table, Low pressure transmitter (NSK) .......................................................................... 182

Air exchange Sensor table Voltage - m3/h for 75 CMH ................................................................................ 183

Voltage – Pressure Table, Low pressure transmitter (AKS) .......................................................................... 183

Voltage – Pressure Table, High pressure transmitter (NSK) ......................................................................... 184

Voltage – Pressure Table, High pressure transmitter (AKS) ......................................................................... 185

Temperature Sensor - Voltage Table ......................................................................................................... 186

Pressure/Temperature table for R134a ..................................................................................................... 187

Tightening torques ................................................................................................................................. 188

Controller Unit Illustration ......................................................................................................................... 189

Star Cool Unit, installation dimensions ....................................................................................................... 190

P & I diagram .............................................................................................................................................. 191

Overall Wiring Schematic............................................................................................................................ 192

Overall wiring schematics (optional) .......................................................................................................... 193

Operating and service manual

6 of 194 pages

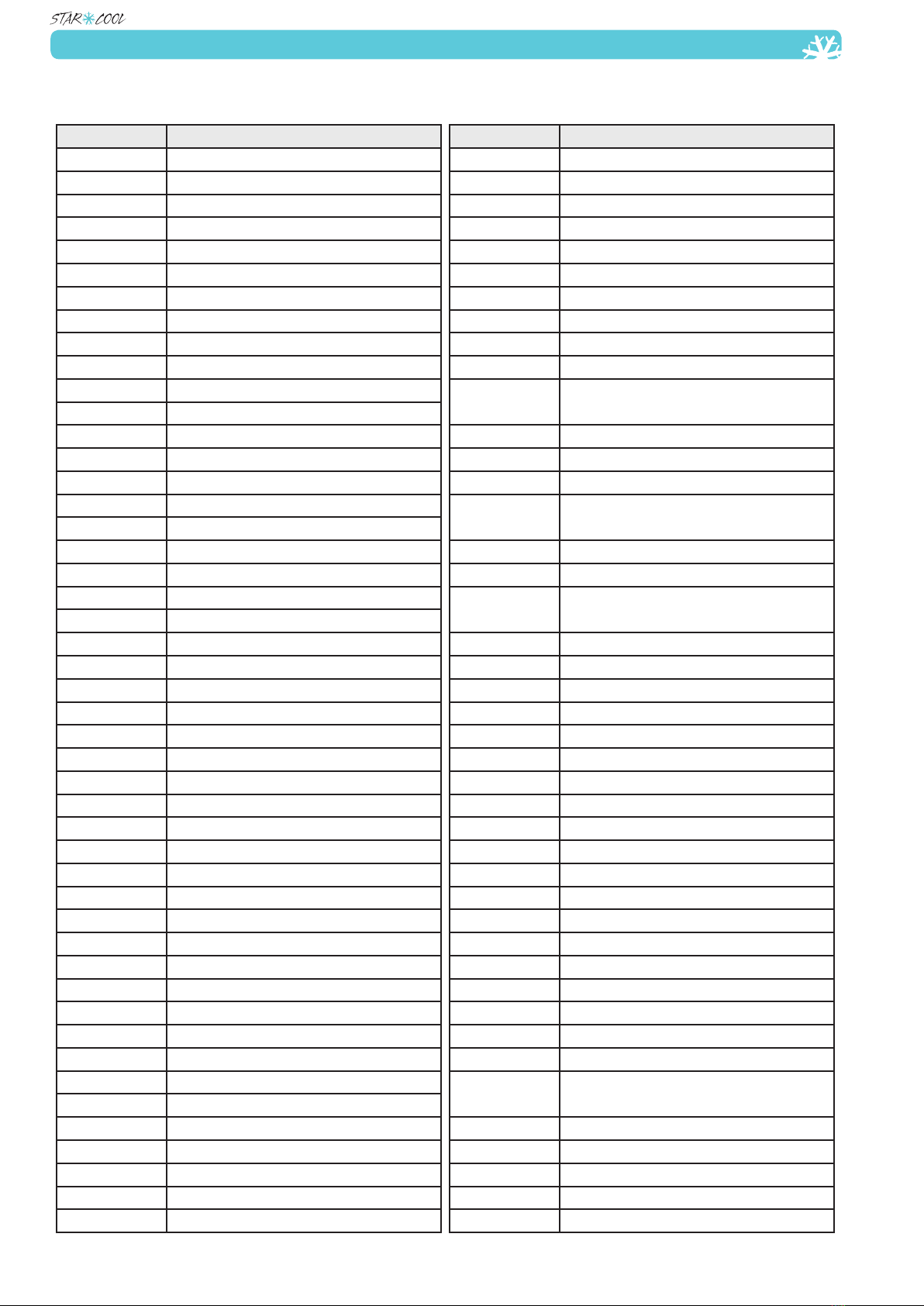

Legend

Short name Name Short name Name

AirEx Air Exchange Pdis Discharge Pressure

AirEx mo Air exchange motor Pfc Power used by Frequency Converter

Alarm Alarm PhDir Phase Direction

AKS Danfoss pressure transmitter Psuc Suction Pressure

Bat Battery Ptot Power Total

CalAex Calibration value AirEx PTI Pre Trip Inspection

CalUs1 Calibration USDA sensor 1 PTI Short Pre Trip Inspection Short

CalUs2 Calibration USDA sensor 2 Pwr Power

CalUs3 Calibration USDA sensor 3 RH Relative Humidity

CalCar Calibration Cargo sensor RHset Relative Humidity Set point

CapAct Actual capacity RMM Remote Monitoring Modem

(power line communication)

CapReq Requested capacity

Com Communication SHTV Superheat Expansion Valve

ComQ Communication Quality FC Shp High pressure switch

Cpr Compressor SHReq Superheat Requested

CT Cold Treatment T0 Calculated Evaporator

Temperature

FC Frequency Converter

Fcpr Compressor Frequency Tact Actual Temperature

FcprAct Compressor Frequency actual Tamb Ambient Temperature

FcprReq Compressor Frequency requested TC Calculated condenser

Temperature

Flower Compressor Frequency min.

Fpower Power supply Frequency converter Tcargo Cargo Temperature

Fref Compressor Frequency requested Tevap Evaporator Temperature

Fupper Compressor Frequency max. Tfc Frequency converter Temperature

Gear Gear Tint Tinternal (controller board)

Gnd Ground Tret Return Air Temperature

Hevap Evaporator Heater Tset Temperature Setpoint

I1 Current Phase 1 Tsuc Suction Temperature

I2 Current Phase 2 Tsup Supply Air Temperature Average

I3 Current Phase 3 Tsup1 Supply Air Temperature 1

Idc Current in DC Frequency Converter Tsup2 Supply Air Temperature 2

Ifc Current in AC Compressor Motor Tusda1 USDA 1 Temperature

IceMas Theoretical Ice mass in Evaporator Tusda2 USDA 2 Temperature

LED Light Emitting Diode Tusda3 USDA 3 Temperature

MaxInt Max. internal temp. controller U12 Voltage Phase 1-2

Mcpr Compressor Motor U13 Voltage Phase 1-3

McOH Condenser Motor Over Heat U23 Voltage Phase 2-3

Mcond Condenser Motor U/f Voltage/frequency ratio

Mevap Evaporator Motor Ubat Battery voltage

Mevap1 Evaporator Motor 1 Udc DC voltage in Frequency Converter

Mevap2 Evaporator Motor 2 Umean Mean Voltage =

(U1-2+U1-3+U2-3)/3

Mevap1OH Evaporator Motor 1 overheat

Mevap2OH Evaporator Motor 2 overheat Umotor Mean Voltage Compressor Motor

MTS Multi Temperature Settings Veco Economizer Valve

NSK SAGInoMIYA pressure transmitter Vexp Expansion Valve

OprMod Operation Mode Vhg Hot gas Valve

PCB Printed Circuit Board Warn Warning

7 of 194 pages

Operating and service manual

Prex Description

FFrequency

HHeater

I Current

MMotor

PPressure

QPower

RH Relative humidity

S Switch / contact / key

SH Super heat

TTemperature

T0 Saturated suction temperature

UVoltage

VValve

Contraction Full name

Amb Ambient

Bat Battery

Cond Condenser

Cpr Compressor

Dis Discharge

Eco Economizer

Evap Evaporator

Fc Frequency converter

Motor Compressor motor

Pwr Power

Ret Return

Suc Suction

Sup Supply

Sufx Specication

Act Actual

In Input

OH Overheat

Out Output

Req Requested

Set Setpoint

Operating and service manual

8 of 194 pages

General description

The units, models SCU-40 and SCI-40 are electric powered picture frames, cooling

and heating units operating on refrigerant R134a.

The unit is designed to maintain cargo temperatures in a range from –30°C (-22°F) to +30°C

(86°F). The unit is designed to operate in ambient temperatures from –30°C (-22°F) to +50°C

(122°F). The outer front frame is constructed of marine grade aluminium, 5000 and 6000 series,

designed to serve adequately as the container end wall.

The rear bulkhead is made of food-approved material. The unit is designed to operate with satis-

faction under sea going and environmental conditions as specied below:

• Salt – laden air, sea spray and high humidity.

• Rolling: Amplitude of 30° each side, period of 13 seconds.

• Pitching: Amplitude of 6° each side, period of 8 seconds.

• Permanent list: 15° on each side.

• Shock: 2g horizontal and 5g vertical.

• Vibrations: Of the types encountered on ships, trucks and rail.

The unit consists of the following modules.

• Frame module

• Condenser / compressor module

• Evaporator module

• Evaporator fan module

The cooling system of the unit is equipped with a two – stage compressor, electrically driven

through a FC.

The cooling system is also equipped with an economizer, which performs the task of sub-cooling

the liquid from receiver to evaporator, thereby increasing the cooling capacity of the cooling unit.

The evaporator and economizer are controlled by electronic expansion valves.

The equipment is designed to operate on a nominal 410/450 V AC, 3 phase, 50/60 Hz, primary

power source, according to ISO 1496-2.

An integrated dual winding transformer supplies the control circuit voltage. One winding for 24 V

AC (for RMM modem supply) and another for 26 V AC converted to DC-Voltage in the controller (for

controller and contactor supply). The output voltage is dependent on supply voltage. An automatic

system, power supply sensing and correction, is provided to ensure the correct direction of rota-

tion for the fan motors. This is done regardless of the incoming phase sequence from the primary

power supply, provided that all fan motors are wired correctly.

An optional water-cooled condenser is mounted in series with the air-cooled condenser. This

water-cooled condenser allows operation of unit below deck, where no air ventilation is possible,

provided that water connections are present.

The unit is controlled by an electronic controller manufactured by Lodam Electronics, controlling

the supply temperature probe in chilled mode (temperature setting above or equal to –5°C

(23°F)) and the return temperature in the frozen mode (temperature setting below –5°C (23°F)).

Controller accuracy is ±0.25°C (±0.45°F). The unit can operate the evaporator fans in low speed

and high speed. From the controller display, Normal or Economy mode can be selected under

operation menu. In economy mode the fans always run on low speed. In normal mode the fan

speed can run in high or low speed depending on running conditions.

The air from the unit is delivered to the bottom of the container, with return air through the top of

the evaporator coil section (bottom air delivery).

The unit is equipped with a de-humidication function controlled by the electronic controller of the

unit. The humidity setpoint can be set in the range from 95 – 65% (or 50 % with closed

ventilation) RH. The unit can control to the lowest level. The de-humidication function is active as

long as the temperature control is in set point range. The unit is equipped with heating elements,

mounted under the evaporator coil, for the de-humidication. The de-humidication system is also

active in economy mode.

9 of 194 pages

Operating and service manual

The unit is equipped with a dual system for defrosting. There is installed a hot gas valve, in the

refrigeration system, for hot gas defrosting of the evaporator coil. Furthermore the heating

elements, mounted under the evaporator coil, are energized during defrost. This dual system for

defrosting ensures a fast defrost sequence and thereby only a very small input of heat to the

container. This results in very small temperature variations for the transported cargo, after a

defrost sequence. The dual system for defrost also ensures an even distribution of heat to the

evaporator coil. The result of this is that there is no building up of ice in corners or other places of

the evaporator coil. The two defrost systems, hot gas and heating elements, are independent. This

ensures a defrost sequence to be carried out, any time. A demand defrost system is integrated in

the software ensuring that the evaporator coil will not ice up.

The unit is equipped with a datalogger incorporated in the controller.

The logging interval is in predened intervals, 15, 30, 60, 120 or 240 minutes. The logging of the

USDA–sensors (3 pieces) and Cargo-sensor is done with an interval of one hour according to USDA

requirements. With a logging interval of one hour, there is storage capacity for 365 days of tem-

perature loggings.

Datalogger accuracy is ±0.25°C (±0.45°F).

The data–log can be retrieved with a PC–system Starview and Psion Logman, via high-speed serial

communication port.

The controller has a battery back–up system for the datalogger, which after power down the unit

continues logging in battery mode for 120 times. For CIM6 the battery is rechargeable and for

CIM5 the battery is not rechargeable.

The controller is optimized for communication with Remote Monitoring Equipment, according to

ISO standard 10368. Events + Alarms and Data Log can be retrieved by various download tools

such as Refcon, Logman, StarView etc. and can be viewed by same.

Function description

Start-up procedure

The start-up procedure has 5 modes:

1. Initialize: Self check controller.

2. Stabilize: The evaporator fan operates at high speed to ensure that temperature sensors are at

current temperature.

3. Crank case heating: If Tamb is lower than 2°C (36°F) heat is applied until Tfc is above 12°C

(54°F).

4. Ramp up

5. Terminate: Switching to normal temperature and valve regulation.

Operating and service manual

10 of 194 pages

Climate Control Function

Temperature Control

This function incorporates the container temperature controller.

The function has 2 modes: Chill and Frozen.

• Chill

If Tset more than (>) -5°C (23°F) the chill mode is activated.

If Standard Tact = Tsup if cooling need, and Tact = Tret if heating is needed.

If QUEST is activated, see QUEST

• Frozen

If Tset is less than or equal to (≤) -5°C (23°F) the frozen mode is activated and Tact = Tret.

The value the Tset limit is dependent on software version.

This function has four modes: Pull down, Pull up, Cool, and Heat.

Pull Down / Pull Up mode:

In Pull Up and Pull Down mode no in-range alarm is given. Upon start-up, defrost or another mode

deactivating temperature control (e.g. manual, set-point alternation, PTI) the temperature

control is set to Pull Down or Pull Up mode depending on Tact being above or below Tset. As long

as temperature is not within Tset ± ranges, the function remains in CoolPullDown or HeatPullUp

mode. If temperature is within range, the green “IN-RANGE” indicator light starts ashing. When

the temperature has been within Tset ± 1,5°C ranges for 30 min. the green “IN-RANGE” indicator

light is constant on.

Cool / Heat mode:

Temperature is within Tset +/- ranges and the green “IN-RANGE” indicator light is constant on.

If temperature is in out-of-range condition for more than 2 hours, the IN-RANGE indicator lights

start ashing. After 4 hours out-of-range condition, an in-range alarm is set. On the basis of Tact

and Tset the function calculates the requested capacity (CapReq) value by means of a Micro

controller. CapReq is the desired chilling / heating capacity. CapReq value can range from –100%

to +100%. –100% being maximum cooling and +100% being maximum heating.

Capacity Control and Limiter

On the basis of requested capacity this function determines operation mode and actions of the

individual system components (compressor, valves, heating elements) and ensures that

compressor minimum off time is observed. This function has 5 gears (modes). On the basis of

requested capacity, the gear is determined. Compressor frequency is directly dependent upon

current mode. Evaporator heater, on the other hand, is gear independent. There is overlap over

the modes to maintain slow mode shifting.

Gear Function

Off Everything is turned off.

Start up If cooling is required, the FC is starting at default frequency before shifting to

correct cooling mode.

PWM On/Off regulation of compressor.

CoolEco Maximum cooling capacity with use of economizer.

Heat Only the heaters are used.

Defrost Heaters are always used and hot gas valve is used if ambient temperature is

above 5˚C (41˚F).

The capacity of the unit is controlled between maximum cooling capacity (-100% capacity) and

maximum heating capacity (+100% capacity). This is done by regulation of the compressor speed

by means of the FC or on/off regulation. In maximum capacity (+100% capacity) the unit uses the

heating elements, by means of pulse width modulation, to control the capacity.

11 of 194 pages

Operating and service manual

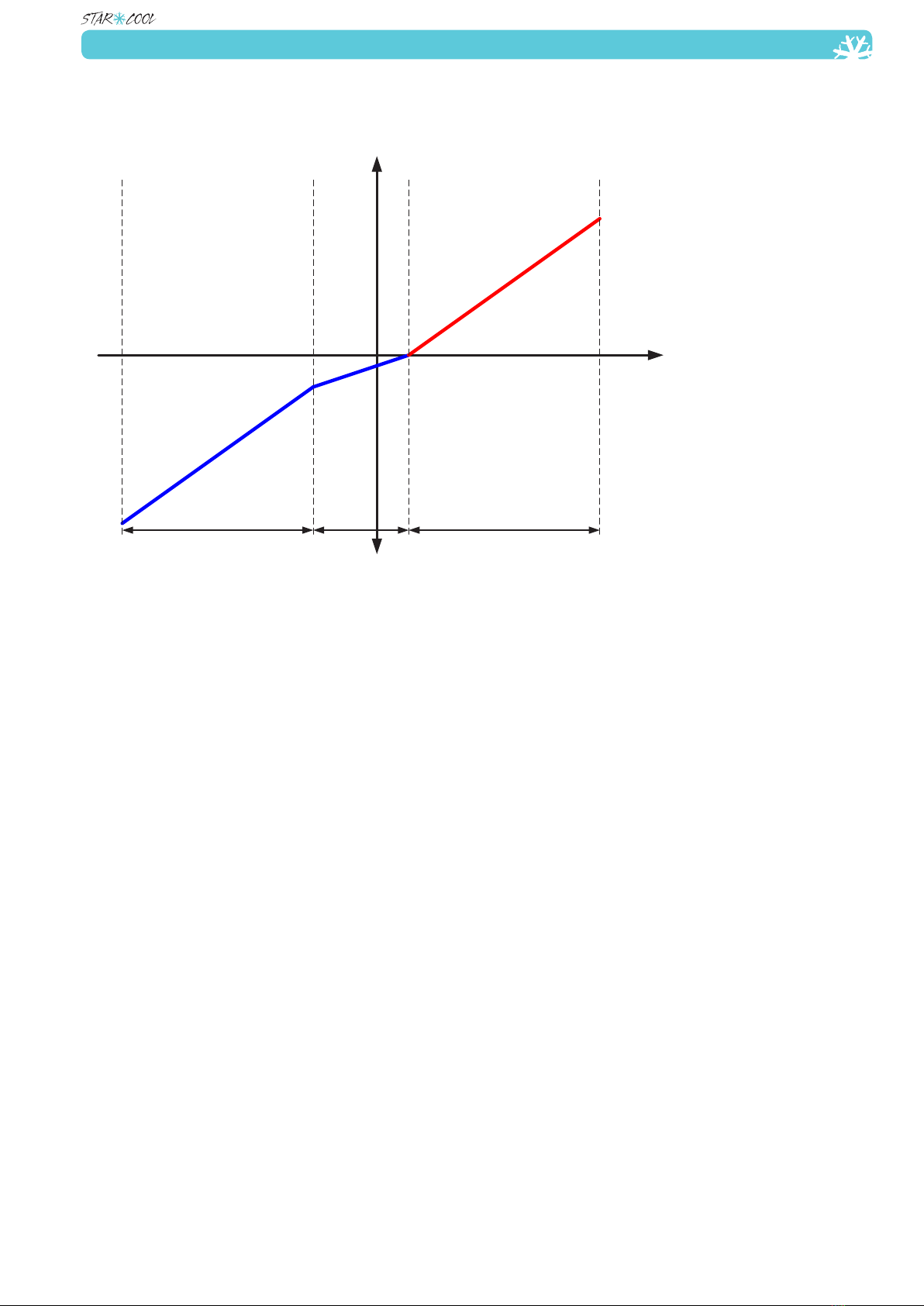

Below gure indicates the ranges for the capacity and compressor speed (frequency).

Heating %

Cooling %

Capacity %

-20 10-100 100

Cool eco Cool PWM Heat

-100%

cooling

100%

heating

System Capacity

-20% +10%

The limiter function secures that the controller operates with valid settings to protect the unit in

order to maintain the conditions for the cargo. To maintain the set point temperature, capacity

control constantly monitors and adjusts the capacity. The limiter acts as a brake to the capacity

change requests from capacity control and thereby controlling how fast the capacity can change,

so that safe operation of the unit constantly is ensured.

The limiter monitors the following parameters from the unit and generates a limiter factor for

each:

• IFC, to limit the maximum current draw from the FC.

• TFC, to limit the maximum internal FC temperature.

• Tc, to limit the maximum condenser pressure (and temperature).

• T0, to ensure a minimum evaporator pressure.

The largest of the factors is used as the active limiter. If the limiter factor is higher than the

requested capacity change, the capacity is actually reduced instead of increased. If for example

the ambient temperature is very high, the requested capacity may increase the FC temperature

over its limits and so the limiter will reduce the capacity until a safe and stable operation condition

for the FC has been reached.

Expansion Valve

This function ensures optimum evaporator superheat (SH) and calculates the percentage of

opening (SHVod) and controls the valve. This function is active during compressor operation. Valve

is closed during compressor turn off.

Expansion valve function includes the following sub-functions:

• MSS (Minimum Stable Superheat search).

• Superheat control.

• MOP (Maximum Operating Pressure).

MSS

This function searches for minimum stable superheat within the ranges SHmin and SHmax. With a

stable T0, SHset is reduced and with an unstable T0, SHset is raised.

SHact: = Tsuc – T0

Superheating

Operating and service manual

12 of 194 pages

Function output is the expansion valve opening rate (Vexp). At start-up the opening rate is 0%.

The electronic expansion valve is an on/off valve controlled on the basis of opening rate with a

constant cycle time.

MOP function

The MOP function prevents the suction pressure from getting too high.

Economizer Valve

This function ensures optimum sub cooling of liquid to the evaporator and cooling of the FC.

In addition, the cooling capacity is increased, COP is enhanced and compressed gas temperature

is reduced.

Function output is the economizer valve opening rate (Veco).

The economizer control has two modes:

• Superheat control

• FC cooler.

Superheat control

Valve opening rate control is based on calculations.

FC cooler

This function is active during compressor operation.

Dehumidication

The dehumidication function dehumidies air in the container by means of a heater. This function

can only be activated if the temperature control function is active.

Dehumidication is achieved by decreasing evaporator surface temperature. This is done through

activation of the heater and letting the temperature control increase cooling capacity resulting in

an evaporator temperature descending.

This function has 3 modes:

Off

Active

Override

Dehumidication: Off

The dehumidication function is in the OFF position.

Dehumidication: Active

The heater (Hevap) is activated when RH is more than (>) RHSet and deactivated when RH is less

than (<) RHSet – 3 [%]

The humidity set point can be set in the range 50% to 95% relative humidity. The range 50% to

64% is only possible with no fresh air - evap. ventilation in low speed. The range 65% - 95% is

possible to run with fresh air - evap. ventilation in high speed.

Dehumidication: Override

Accessing override mode if:

- Cooling demand exceeds 80% capacity.

- Large demand for heating.

- PTI

- A fatal alarm is active.

- When operating without FC.

- Manual operation is active.

- Defrosting

Other comments

The dehumidication icon is shown in the display even if override is active.

The heat icon follows the current state of the heater.

13 of 194 pages

Operating and service manual

Condenser Fan

Condenser fan control will reduce condenser pressure through condenser ventilation. The

condenser pressure control also monitors the compressor outlet pressure in case of water-cooling.

This function is activated when control is being in the automatic mode.

Condenser pressure control has two primary modes:

Air-cooled

Water-cooled

Air-cooled

In the air-cooled mode ventilation takes place in the following way:

Depending on the compressor outlet pressure, the fan is Off or runs in 2 different speeds: High

and Low.

The fan runs in 4 modes: Off, low-speed, high-speed and a cycle shifting between high and

low-speed in two minutes intervals.

If Tamb is more than (>) 48°C (118°F) or the compressor outlet pressure remains constantly high,

the condenser fan constantly runs at high speed.

Water-cooled

If the condenser fan is constantly on for more than 1 hour, an alarm will be given.

The fan runs in 4 modes: Off, low-speed, high-speed and a cycles shifting between high and

low-speed in two minutes intervals.

Evaporator Fan

The evaporator fan function ensures correct fan speed (high or low). The function is active in the

automatic mode.

This function has 2 modes:

Normal

Economy

Normal

Low speed in the frozen mode or if the following three conditions are set

• Tset is more than or equal to (>) 0°C (32°F)

• No fresh air exchange

• Dehumidication is turned off or humidity set point below 65%

Otherwise high speed

Economy

The fans run at a constant low speed. Exception: Tret > Tsup + 8°C (14°F) then high speed, until

Tret > Tsup + 3°C (5°F) is reached

Economy mode is switched on by the operator.

Defrost Function

Defrost function ensures regular evaporator defrosting. The function is active in automatic mode.

The defrost function has 4 modes:

Wait

Initialize

Execute

Terminate

Operating and service manual

14 of 194 pages

Wait

In the wait mode the time is refreshed for the next defrost provided that the following conditions

are satised:

• Compressor is running

• T0 is less than (<) T0min.

Wait mode termination can be due to:

• Calculated ice amount in the evaporator is above critical level (Demand defrost)

• Defrosting action initiated manually (Manual defrost initiation)

Initialize

Wait until condenser temperature is above 50°C (122°F), however no more than 300 sec.

Execute

In this mode the actual evaporator defrosting takes place:

A Defrost start event is made in the trip log. Cooling system termination results in compressor

initiation, only ramp up mode is executed. Evaporator fan is stopped. Evaporator heating elements

are turned on. Compressor runs at a constant frequency at 83% of full speed. Expansion valve

control is deactivated. Hot gas valve is used to heat the evaporator from the inside with the hot

gas from the compressor.

Evaporator defrosting terminates when evaporator temperature, Tevap, is above defrost

termination temperature for 2 min. or upon elapse of max. defrost time. A defrost stop event is

made in the data log with the current interval and Tevap temperature.

Terminate

Terminate mode is dividable into two parts:

• Evaporator re freezing preventing remaining water drops on evaporator from blowing into

container upon evaporator fan initiation.

• Termination ensuring low evaporator fan speed to prevent shock boiling and to ensure that the

temperature controller takes over in a controlled way. After termination, the unit continues

normal operation again with the same setpoint temperature as before defrost start.

General information

If the Tevap sensor is not OK, adaptive defrosting uses a reduced defrost interval compared to

normal calculated defrost intervals. Set-point alteration leads to a new calculated defrost interval,

and defrost starts when the defrost criteria is reached. With manual defrost initiation the current

defrost interval is set to default defrost interval.

Manual defrost termination

Upon manual defrost termination, termination state is entered. No adaptive adjustment takes

place when defrosting is manually initiated.

Regarding user interface

Defrost icon is displayed during defrost function execution.

Other comments

If service mode or PTI mode is selected during a defrost, the defrost mode is terminated and the

time for the next defrosting is set to the preset value as if a normal defrost end had occurred.

If the unit is shut off for some reason during a defrost and the power disappears for less than (<)

12 hours, the unit will start and try to nish the defrost again when the power returns. If the unit

is shut off for more than 12 hours, the active defrost is terminated and the defrost function enters

the wait state.

15 of 194 pages

Operating and service manual

QUEST (optional)

QUEST is a program based on a xed protocol designed to reduce the energy consumption of the

unit, when operating in the interval -1°C to +30°C (30°F to 86°F). This energy saving is mainly

obtained by regulating the compressors on/off time and the evaporator fan speed.

Please note that when Tsup is in the range -1°C to +15°C (30°F to 59°F) its value can vary -2°C -

+1°C (28 °F to 34°F) from setpoint.

Please note that when Tsup is in the range +15°C to +30°C (30°F to 86°F) its value can vary -4°C

- +1°C (25°F to 34°F) from setpoint.

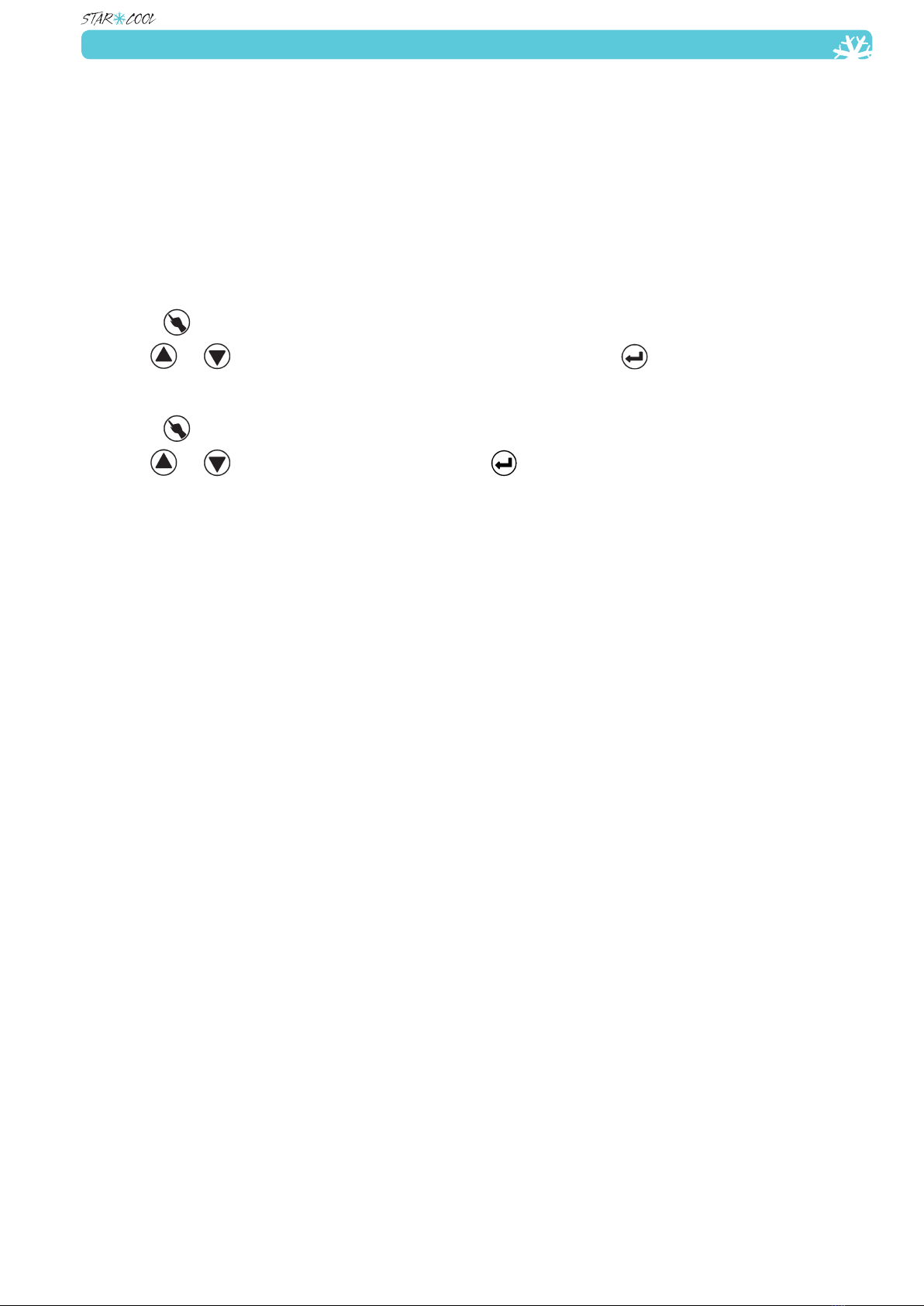

To deactivate QUEST:

1. Press

2. Use or to select O03 anything except QUEST and press

To activate QUEST:

1. Press

2. Use or to select O03 QUEST and press

If O03 does not contain QUEST, QUEST is not installed.

Star Cool is responsible for the QUEST function operating within the parameters and the run-

ning pattern dened by the protocol. Star Cool is however not liable for any consequent damages

caused by the QUEST functionality.

Bulb mode (Overall Description)

Product Perspective

This is a new functionality and will be incooperated in the already existing software for CIM 6.

Product Functions

The major functionality in bulb mode is:

1. Bulb mode selection:

a. MevapL.

b. MevapH

c. MevapL for 1 hour then MevapH for 1hour etc.

2. This in connection with the possibility to control dehumidication and termination temperature

of defrosts.

User Interface

Bulb mode setting: Hi or Lo or Alt

Relative humidity: xx%

Defrost Termination: xx °C

Temperature setting: xx °C

Fresh air setting: xxx M3/h

Temperature, Fresh air setting, Relative humidity and Defrost termination must be a part of the

user interface setup under Bulb Mode. Fresh air “setting” will be done by actually adjusting the

manual air vent to the desired amount of fresh air and hereafter accept the settings in the pro-

gram.

Operating and service manual

16 of 194 pages

Communication to Data Logger

In the datalog the following will be recorded as an event:

1. Bulb mode ON

2. Bulb mode OFF

The Bulb setup parameters will be logged as parameters to the event (RHset, Ventilation, Defrost

termination criteria, Type of Bulb Mode (either Hi, Low or Alt )).

Bulb mode (System Feature)

Setting

1. Temperature setting. From -1°C to +30°C, only chilled mode. Default 10°C.

2. RH setting. From 50% to 95%. Default 95%.

3. Fresh air setting (ventilation). From 0m3/h to 225m3/h. Default 0m3/h.

4. Defrost termination. From +4°C to +25°C. Default to 15 degree Celsius.

5. Bulp Mode selection:

a. MevapL. = BulbLo

b. MevapH = BulbHi

c. BulbAlt = MevapL for 1 hour then MevapH for 1 hour etc. (Always starting with low speed,

also after defrost or power on)

Conguration

Bulb Mode is selectable under Programs.

Limitations

Bulb Mode is only available under normal SC operation mode. Temperature control and control of

relative humidity must be as under normal operation mode conditions except from the control of

the Mevap. Mevap will be controlled according to the selection of the mode as described above.

Bulb Mode is NOT active in frozen mode, QUEST1, QUEST2 and CA/AV+. If Bulb Mode compromise

the temperature control, standard control will be active to correct temperature deviation. Default

on demand will be opened for this feature, however the possibility for opening other prex must

be available in the future.

Alarms

No additional alarms are related to this functionality.

Defaulting

Bulb Mode off after:

1. PTI pass or fail

2. Manual deactivation of program

Tests

The unit has 2 (3) test functions:

• Function test.

• PTI (Pre-Trip Inspection) test.

• PTI short (optional)

The PTI test is a function test followed by a capacity test where the requested temperature must

be reached within the time limit.

At test initiation an event is generated in the log.

17 of 194 pages

Operating and service manual

During function and PTI test the normal alarm system remains active. If an alarm is triggered

during test operation, it appears in the display and will be written in the log as it is the case

during normal operation. In case of a fatal alarm during testing the test is terminated and the unit

remains off.

Function or PTI sub-test failure causes an alarm ”PTI FAILURE” to be generated.

In case of Function or PTI sub-test pass an event, ”Test status” is displayed.

For more information, please see event list.

Clear the alarm list before starting a test. If there should be any active alarms in the alarm list

when a function or a PTI test is started, the test will always fail even if all the individual test steps

PASS without failures.

PTI menu has a primary status and a status for each sub-test with own indexes. Only the primary

status for a PTI test is memorized when supply voltage is removed. When PTI is initiated a Trip

start is set in the data log.

Function test

Function test is a unit component test. (Non destructive). Test is based on a GO/NO GO procedure.

All tests must be executed without failure one by one for the function test result to be PASS.

Note: The tests can also be performed individually.

Note: If there is too much liquid in the compressor house before compressor test (part of the

function test) the compressor test will fail because of high intermediate pressure. This liquid needs

to be evaporized. Let the unit run under normal conditions for 10 min, and activate PTI or function

test as usual after this.

Function test includes the following items:

1. PTI – init

2. Controller test

3. Power check

4. Evaporator fan (Mevap)

5. Condenser fan (Mcond)

6. Heating element (Hevap)

7. Compressor/FC/valve test (Vexpansion, Vhotgas and Veconomizer) - test descriptions as

follows:

Compressor/valve test (Vexp, Vhg, Vecon)

No Test description (steps) Passing conditions

80 Compressor

High pressure switch test

Pump down test

Max. duration 5 min

Reached within max. 5 min.

20 Bar < Pdis < 24 Bar

If error: AL250

Reached within max. 5 min.

Tc - T0 > 20°C

If error: AL845

81 Valve leak

All valves, reed valves included

Max. duration 5 min

T0diff < |25|°C

If error: AL840

83 Vexp

Testing capacity

Max. duration 5 min

When Pdis ≥ 5 Bar:

Max. change in Pdis ± 0.75

When Pdis < 5 Bar:

Max. change in Pdis ± 0.3

When Tret ≥ -15°C:

Min. change in T0 + 20 °K

When Tret < -15°C:

Min. change in T0 + 10 °K

If error: AL842

Operating and service manual

18 of 194 pages

84 Vhg (hot gas valve)

Testing capacity

Max. duration 5 min

When Pdis ≥ 5 Bar:

Max. change in Pdis ± 0.75

When Pdis < 5 Bar:

Max. change in Pdis ± 0.3

When Tret ≥ -15°C:

Min. change in T0 + 20 °K

When Tret < -15°C:

Min. change in T0 + 10 °K

If error: AL844

9. Test completion / status

NOTE: At ambient temperature above 40°C (104°F) and below –20°C (-4°F) the unit has

to be running in normal operating mode at setpoint of 0°C (32°F) for of 10 minutes with

compressor running before executing a function test or PTI test. The reason for this is

to ensure correct function of unit during PTI test or function test.

PTI Test:

The purpose of the PTI test is to verify the presence of cooling performance. The test is based

on a GO/NO GO procedure. All tests must be executed without failure one by one for the PTI test

results to be PASS. PTI test includes the following test items:

Full PTI

Full PTI includes the following test items:

1. Function test (see Function test)

2. 5°C (41°F) test + 5°C (41°F) hold test 45min. O2/CO2 sensor calibration if installed

3. 0°C (32°F) run test

4. -18°C (-0.4°F) run test

5. Defrosting

6. Test completion / status

Short PTI

Short PTI includes the following test items:

1. Function test (see Function test)

2. 5°C (41°F) test + 5°C (41°F) hold test 45min. O2/CO2 sensor calibration if installed

3. 0°C (32°F) run test

4. Defrosting

5. Test completion / status

CA PTI

CA PTI includes the following test items:

1. Function test (see Function test)

2. 13°C (55°F) run test

3. 5°C (41°F) run test + 5°C (41°F) hold test 45min. O2/CO2 sensor calibration if installed

4. 0°C (32°F) run test

5. Defrosting

6. Test completion / status

Data Log

The controller has a data log to record operation of the unit. The data log includes 4 items:

• Data.

• Extended data.

• Alarms.

• Event data.

19 of 194 pages

Operating and service manual

The logged data in the data log can be seen:

• On the display menu L01, the viewable temperatures are listed.

• On the display menu L03, the logged temperatures can be viewed graphically.

• Retrieved via the program RefCon and the RMM modem and the power line.

• Retrieved via a program, LogMan, on a PSION pda using the retriever socket.

• Retrieved via the StarView program using the retriever socket.

When an alarm is activated it triggers a complete log, however max. one per 15 min. The

datalogger can hold approximately 10.000 logs or more than 1 year of loggings with default

logging interval of one log per hour.

The following tables show retrievables with Starview and Psion Logman software:

File Download Info

F1 Signature

Header

F2 Container ID

F3 Controller ID

F4 Controller Software

F5 Retriever Software

F6 Extraction date

F7 Comments

Data log

D1 DT Date

Stamp

D2 Time

D3 Log Type [Event, Data, Log]

D4 Event ID

Events + Alarms

D5 Param. 1

D6 Param. 2

D7 Param. 3

D8 Param. 4

D9 Param. 5

D10 Tsup Supply Air Temperature [°C]

Short Log

D11 Tret Return Air Temperature [°C]

D12 Tusda1 USDA 1 Temperature [°C]

D13 Tusda2 USDA 2 Temperature [°C]

D14 Tusda3 USDA 3 Temperature [°C]

D15 Tcargo Cargo Temperature [°C]

D16 Tset Temperature Set Point [°C]

D17 Humidity Relative Humidity [%]

D18 AirEx Air Exchange [m3/h]

D19 Psuc Suction Pressure [BarE]

Extended Log Type 1

D20 Pdis Discharge Pressure [BarE]

D21 Fpower Net frequency [Hz]

D22 Upower Highest power voltage of U1, U2, U3

D23 I1 Current, Ph. 1 [A]

D24 I2 Current, Ph. 2 [A]

D25 I3 Current, Ph. 3 [A]

D26 Ifc FC current [A]

D27 Fcpr Compressor Frequency [Hz]

D28 Heater Heating element [%]

D29 Mevap Evaporator motor status

D30 Mcond Condenser motor status

D31 Tfc Frequency module Temperature [°C]

D32 Tamb Ambient Temperature [°C]

This manual suits for next models

3

Table of contents