the goods, must pay attention to whether the dealer is less loaded or missing equipment parts, if quality problems or other errors,

you should refer to The following "right item" content for processing

II. Claims

1. Transportation damages

If your equipment or parts that are damaged during shipping, you must be accountable to the transportation sector demand

compensation.

2. Quality problems or defects

If the box inspection equipment or parts found to have quality problems or missing parts, and confirmed that the device

does not exceed the Company within one year of starting date of manufacture, the following measures should be taken

immediately: If you are ordering in the dealer should immediately made to the dealer and request correction or supplement, if it

is in the Company's direct order, and should be immediately made to the Company by the company responsible for amendment

or padded.

III. Equipment layout

Equipment must be placed in a dry, ventilated and relatively clean place, and pay attention to the host, the outlet with walls

or other obstructions between the distance shall not be less than 200 mm.

Power switch should be placed as close as possible in a place away from the device, and requires strict implementation of

safety electrical grounding specifications, see the chapter "Power Supply Requirements."

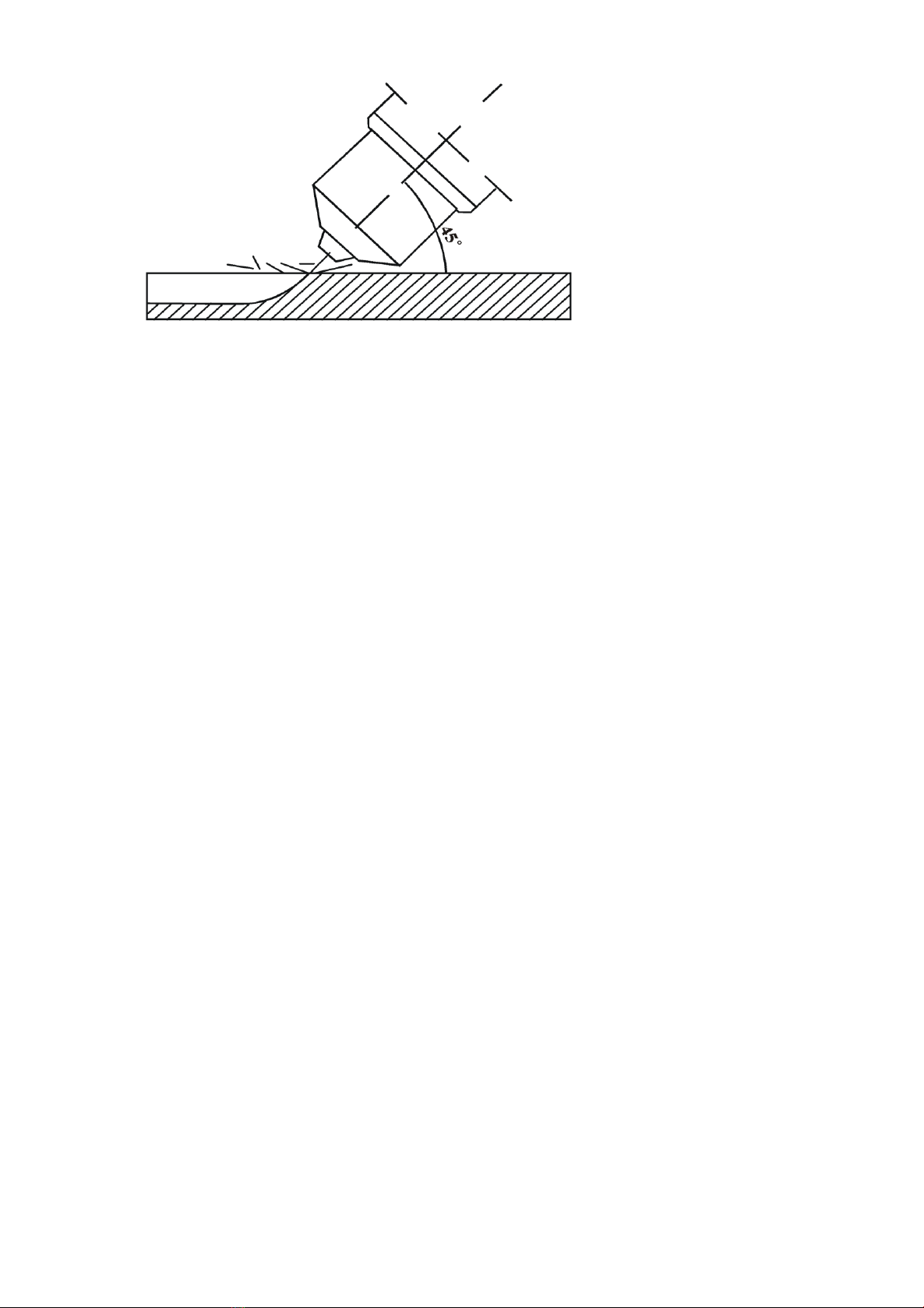

IV. Torch cable routing

Torch leads (especially machine torch) to pay attention to just try to avoid cutting sparks and hot metal cut to prevent scorch

lead, causing an accident. V. Air source requirements and connected

Whether you use the pipeline gas plant, air compressor pump gas or nitrogen, shall be the middle of the series with a gas-

water separator before the air supply hose and power on the back of the gas pressure reducer output connector.

WARNING! Input gas pressure must not exceed 1.0MPa, otherwise, the system will not be able to withstand and danger!

VI. Gas supply hose

1. Air source

If you are using compressed air (whether or pipeline pump compressed air), we must ensure that its output gas drying, oil-

free and clean, if you can not meet this requirement, the input device must be installed before the filtration and purification

devices. And asked to enter the host at 0.8MPa ~ 1.2MPa pressure range between otherwise, does not work. The rear panel of

the gas mains pressure reducer must correspond with the standard machine, the pressure is too high or too low can not reach the

normal ideal cutting results.

2. Nitrogen source

When you use nitrogen as the carrier gas, plasma, be sure to pay attention to 99.995% purity must meet in order to use, in

addition, requires the same input pressure range between 0.7MPa ~ 1.0MPa, otherwise, the same does not work.

3. Oxygen source

When you use this equipment to cut mild steel, you can special order using oxygen as carrier gas plasma models, in order

to improve cutting efficiency, but please pay particular attention to is the combustion of oxygen around the inflammable and

explosive materials or gases may exist , to prevent accidents. Note: Although the use of oxygen as carrier gas plasma to improve

the cutting efficiency of low carbon steel, but the electrode life is reduced.

4. The additional gas filter

When the input compressed air contains moisture or oil-sharing, host power alone inside the gas filters can not filter net, it

is recommended to increase the external gas water filter. If a single-stage filter net can not be used three filters in series and one

by one, in order to ensure that the input air dry and clean.

VII. Power supply requirement

1. Line switch

Each device should supply power line into the line to install a separate air switch, so in case of emergency can quickly cut

off the power, and note that this switch off power to the device as close as possible, the electrical switch parameter value

according to Table a standard input AC current value plus 20% to reliable operation. (Suggested the use of open space

Specifications: 60A)

2. Power line

Please follow the table a standard AC input current value plus 30%, select the appropriate power line, the supply line switch

to prevent power supply voltage drop is too large, affecting the normal cutting. (Suggested the cable specifications: 32 square×

3 pcs) VIII. Grounding requirement

To ensure personal safety, reduce RF interference, must be strictly connected safety ground wire.

Plug the power back panel screws marked with the earth symbol between the earth and in accordance with the requirements

of electrical safety, reliable connections and minimize contact resistance, to maximize security. (Suggested the use of cable

specifications: 25 square)

(Note: For longer cutting ground cable must select 25 square )

IX. Power connection