Status Instruments SEM1401 User manual

SECTION CONTENTS PAGE NO.

1.0 DESCRIPTION 1

2.0 SPECIFICATION 1

3.0 INSTALLATION 2-3

4.0 ALARM TRIP SET UP 3-4

5.0 OPERATION 4

6.0 MECHANICAL 5

Status Instruments Ltd, Green Lane Business Park, Tewkesbury, Glos. GL20 8DE

Tel: +44 (0)1684 296818 Fax: +44 (0)1684 293746

52-214-2410-01 Issue: Web 1401

SEM1401

INDEX

Loop Powered Trip Amplifier

The SEM1401 is a single trip amplifier.

Type Two wire (4 to 20) mA, 50 mA max.

Protection Reverse connection protected

Loop Drop 5 V max.

Alarm HIGH or LOW level, switch selected, side entry

Contact Single relay changeover with N/O / N/C contacts available

Rating Resistive Load 2 A @ 250 VAC/125 VDC max. Power 150 W (Inductive Loads)

Indication Alarm LED on module front face

Set point (0 to 100) % multi turn potentiometer, access on module front face

(Repeatability ± 0.2 %)

Hysteresis (0.1 to 5) % Single turn trim pot on module front face

Delay 0.5 second fixed delay

Failure Mode On loss of signal:- HIGH level No alarm condition; LOW level alarm

condition (i.e. Alarm operates as if signal has fallen to -25 % or 0 mA)

Minimum Current 3.5 mA

Isolation 3000 VAC rms between contacts and input 1000 VAC rms between contacts

Ambient (0 to 50) ºC; (10 to 95) % RH non condensing

Connection Captive clamp screws

Cable Size 4 mm² solid/2.5 mm² stranded

Case Material Grey Polyamide

Case Flammability To UL94-V0 VDE 0304 PT3 level 111A

Dimensions (60 x 60 x 21) mm (67.5 mm above rail)

Mounting Snap on “Top Hat” (DIN EN 50022-35)

Max Vibration 12 G (10 to 55) Hz at double amplitude 2 mm

Shock Res. 12 G

Compliant With EN50081-1, EN50082-1

Weight 100 grams

Page 1

WARNING! Hazardous voltages may be present on the terminals - the equipment must

be installed by suitability qualified personnel and mounted in an enclosure

providing protection to at least IP20.

WARNING! If not installed and used in accordance with these instructions, protection

against hazards may be impaired.

IMPORTANT NOTE it may be preferred to set the user adjustment on the bench prior to

installation. Please read Section 3.0 before installation.

This trip must be housed within a suitable enclosure that will provide protection from the external

environment, to ensure that the stated temperature and humidity operating ranges are maintained. As

SEM1401 contains a high quality relay, care must be taken to ensure the trip is not subjected to strong

shock or vibration, as this may result in momentary opening of the relay contacts. The SEM1401 must not

be located near a strong magnetic field, such as a transformer, solenoid or electric motor.

The SEM1401 case is designed to snap fit onto a standard “Top Hat” DIN rail. To remove from DIN rail, apply

pressure at the bottom face of the back upwards towards the rail to release the spring clip and tip away

from the top. The trip may be mounted in any orientation and stacked side by side along the rail.

Connections to the trip are made via screw terminals, with wire protector plates provided inside each

terminal. To maintain CE compliance twisted pair (screened) cables are recommended for signal connections.

It is also good practice to ensure that all (4 to 20) mA loops are grounded at a single point. Before

installation ensure the (4 to 20) mA loop has enough voltage available to drive the trip. Refer to the above

specification for the loop voltage drop. The change over contacts provided by the SEM1401 are capable of

switching 250 VAC 125 VDC @ 2 A resistive load, 150 W inductive load. Internal Varistors are connected

across the contacts to protect against over voltage. It is advised that a external R/C snubber network is

used when switching inductive AC loads (see Figure 1). When switching DC inductive loads, a diode

connected in parallel with the inductor must be used to protect the contacts from the energy stored in

the inductor (See Figure 2).

Installation overvoltage Category 2 (as per BS EN61010-1)

If this equipment is to be used in environments with overvoltage Category 3, transient suppressors

should be installed on wiring carrying greater than 50 VAC or 75 VDC.

Any power supply to the equipment greater than 50 VAC or 75 VDC must be protected by a suitable

fuse and a switch or circuit breaker which should be near the equipment.

The equipment contains no user serviceable parts.

Page 2

1.0 DESCRIPTION 3.0 INSTALLATION

2.0 SPECIFICATIONS

2.1 INPUT

2.2 OUTPUT

2.3 GENERAL SPECIFICATION

3.1 MECHANICAL

3.2 ELECTRICAL

NOTE: Latching relays are used in this product in conjunction with an advanced relay drive circuit. During

commissioning, on initial power up, or after switch settings have been modified, one trip operation must

be completed in order to synchronise the latching relay(s). Once this cycle has been completed the unit

will function correctly during normal operation cycles. On power down the trip contacts will rest as for a

-25 % (0 mA) process value and take this state indefinitely until power up. The initial power up cycle will

only be required again if the unit switch settings are changed, or the unit is removed from the installation

and is subjected to shocks greater that 12 G, i.e. during transit.

This section deals with the trip setup. Three adjustments are available to the user:

High/Low alarm selection switch located on the side of the trip.

Set point adjustment -15 turn front panel potentiometer provides (0 to 100) % set point range.

Hysteresis adjustment - single turn potentiometer located on front panel provides (0.1 to 5) % set

point hysteresis. Hysteresis is provided to stop relay chatter at the trip point, the amount of

hysteresis required will be dependent on the process signal noise.

Page 3 Page 4

(4 to 20) mA (4 to 20) mA

RC

SNUBBER LOAD

LOAD

AC DC

IN

TRIP

HYS

SEM1401

OUT

CN/C N/O

IN

TRIP

HYS

SEM1401

OUT

CN/C N/O

Figure 1 Figure 2

(4 to 20) mA

IN N/C

N/O

C

H

LOUT

-

+

4.0 ALARM TRIP SETUP

A red LED indicates alarm state ON.

With care, the SEM1401 trip set point may be set up in the process but the task is greatly simplified by

replacing the process signal with a adjustable (4 to 20) mA current source, to simulate the (4 to 20) mA

process signal.

The set up process is as follows:

1. First decide on the type of trip required, “High” for alarm ON state above set point, or “Low” for

alarm ON state below set point. Set the High/Low alarm selection switch on the side of the

enclosure to the desired setting, by inserting a 3 mm blade screw driver into the hole and apply

one press against the switch plunger. This will toggle the switch between the the two alarm settings

being :

High alarm state - plunger out (flush with the enclosure inside face)

Low alarm state - plunger in (depressed below inside face)

2. Using a 3 mm screw driver, turn the Hysteresis control full anti-clockwise to set the hysteresis

to 0.1 %

3. Set the process current to the desired trip alarm setting, then using a 3 mm screw driver adjust the

set point until the alarm changes state. Clockwise to increase, anticlockwise to decrease. Adjust

the set point backwards and forwards until it is positioned at the point at which the alarm LED has

just come on.

4. Set the hysteresis control to the desired value, as a guide fully clockwise sets 5 %, mid position

2.5 %.

5. Now raise and lower the process input signal about the trip setting and ensure the alarm trips at set

point and trips off at set point plus (minus) hysteresis. If required fine adjust settings.

6. Now fully operate the system, it may be found necessary to adjust the hysteresis setting during

operation depending upon the fluctuation or noise present on the process signal.

Once setup and operating satisfactorily the trip amplifier requires no further user adjustments.

5.0 OPERATION

Smart In Head Temperature Transmitters

DIN Rail Mounted Temperature Transmitters

Panel & Field Temperature Indicators

Temperature Probes

Trip Amplifiers

Signal Conditioners

And many other products

For further information on all products:

Status Instruments Ltd, Green Lane Business Park, Tewkesbury, Glos. GL20 8DE

Tel: +44 (0)1684 296818 Fax: +44 (0)1684 293746

ALSO AVAILABLE:

Hi/Lo

Switch

Select

SEM1401

HYS

TRIP

IN

CN/C N/O

SERIAL NO.

OUT: RELAY 2 A @ 250 VAC

IN: 2 WIRE (4 to 20) mA

www.status.co.uk OUT

LO

HI

Figure 3

60.0 mm 21.0 mm

60.0 mm

6.0 MECHANICAL DETAIL

Page 5 Page 6

Popular Network Hardware manuals by other brands

8e6 Technologies

8e6 Technologies Enterprise Filter Authentication R3000 quick start guide

ADC

ADC PG-FLEXPLUS PMU-712 manual

ZyXEL Communications

ZyXEL Communications X6004 Specifications

RFID

RFID HF-3600E-RS232 product manual

Ruckus Wireless

Ruckus Wireless ZoneFlex 7731 802.11n Getting started guide

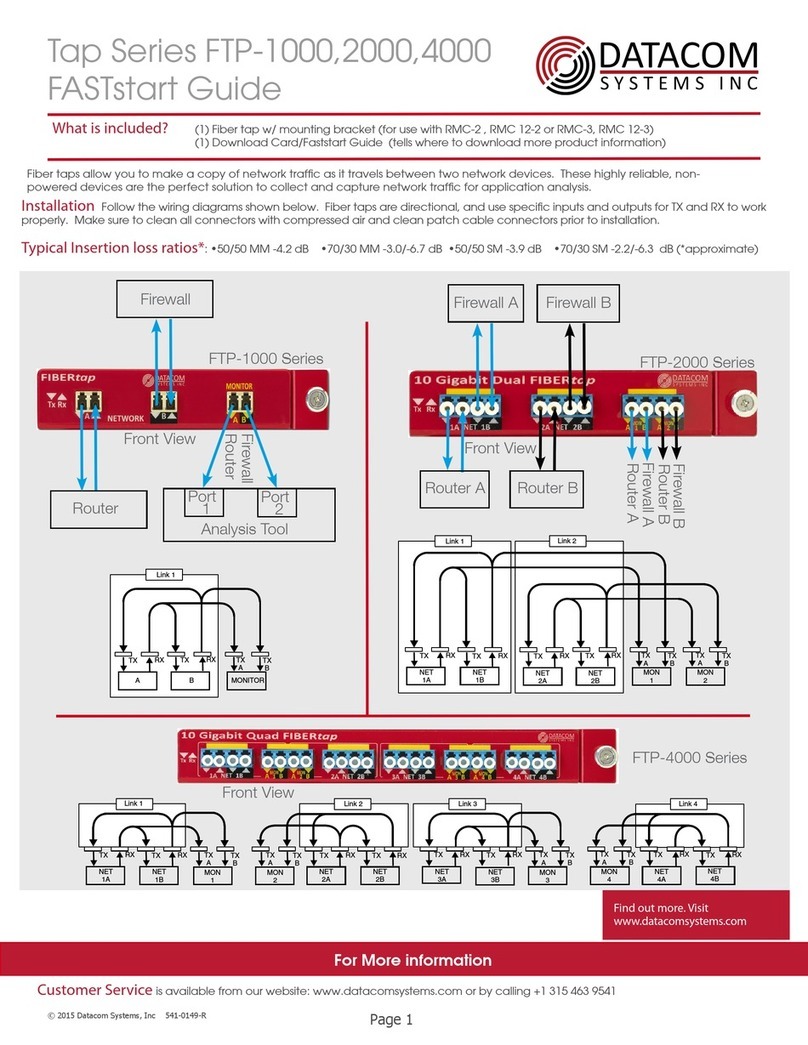

Datacom Systems

Datacom Systems Tap Series Fast start guide