The heating system must be designed in

such a way that hot water can circulate all the

time through at least some of the radiators.

Antifreeze fluids – because of their unsuitable

properties, we do not recommend to use

them. They have a reduced ability to transfer

heat, have large volumetric expansion, age

and damage rubber components. If under

concrete circumstances there is no other

option how to reliable prevent.

Before final installation, the heating system

distribution piping must be flushed several

times with pressurised water. In old, already

used system, the flushing must be done in

opposite direction to the hot water circulation.

In new systems, all radiators must be cleaned

from conservation material. And rinsed with

warm water under pressure.

We recommend installing a sludge trap

upstream of the boiler (i.e. on hot water

return pipe). The sludge trap design should

allow emptying in regular intervals, without

the need to drain a lot of hot water. The

sludge trap may be combined with a filter;

however, a filter alone will not provide an

adequate protection.

Please note

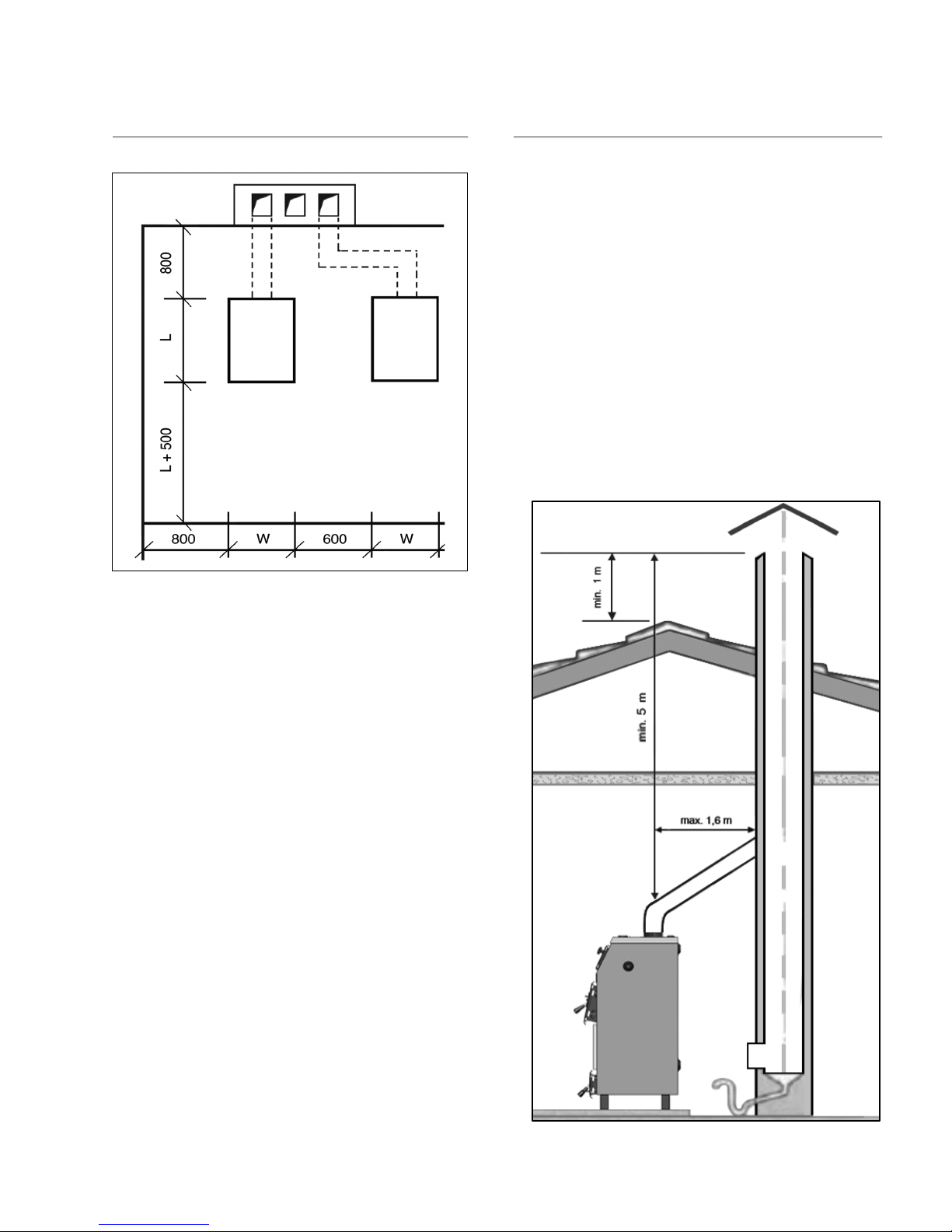

•System must be connected to open

expansion tank for safety reasons.

•Any valve must not be connected to safety

input and safety output lines.

•For increasing safety of the system, by-

pass line must be installed on the line

between input and output of circulation

pumps, as shown in diagrams.

•By-Pass line's valve must be kept closed

as the boiler is working normally.

•By-Pass line's valve can be used in

electricity problems and must be opened if

there is a risk of overheating in system

water caused by an electricity cut or

problem.

•The pipe used in by-pass line must be at

least in the diameter of plumbing systems

pipe.

•UPS (Power Supply Units) can be used for

preventing electricity problems.

•Any problems (malfunctions) caused by

boiler clogging with dirt from the heating

system and/or malfunctions induced by

clogging, are not covered by the boiler

warranty.

•The filter as well as the sludge trap must be

checked and cleaned regularly.

Heating water requirements

Heating water requirements are specified in

EN Standards. When the sum of

concentrations of calcium and magnesium in

the water exceeds 1,8 mmol/L, additional

non - chemical treatments preventing lime

deposition must be considered (e.g. Magnetic

or electrostatic field treatment).

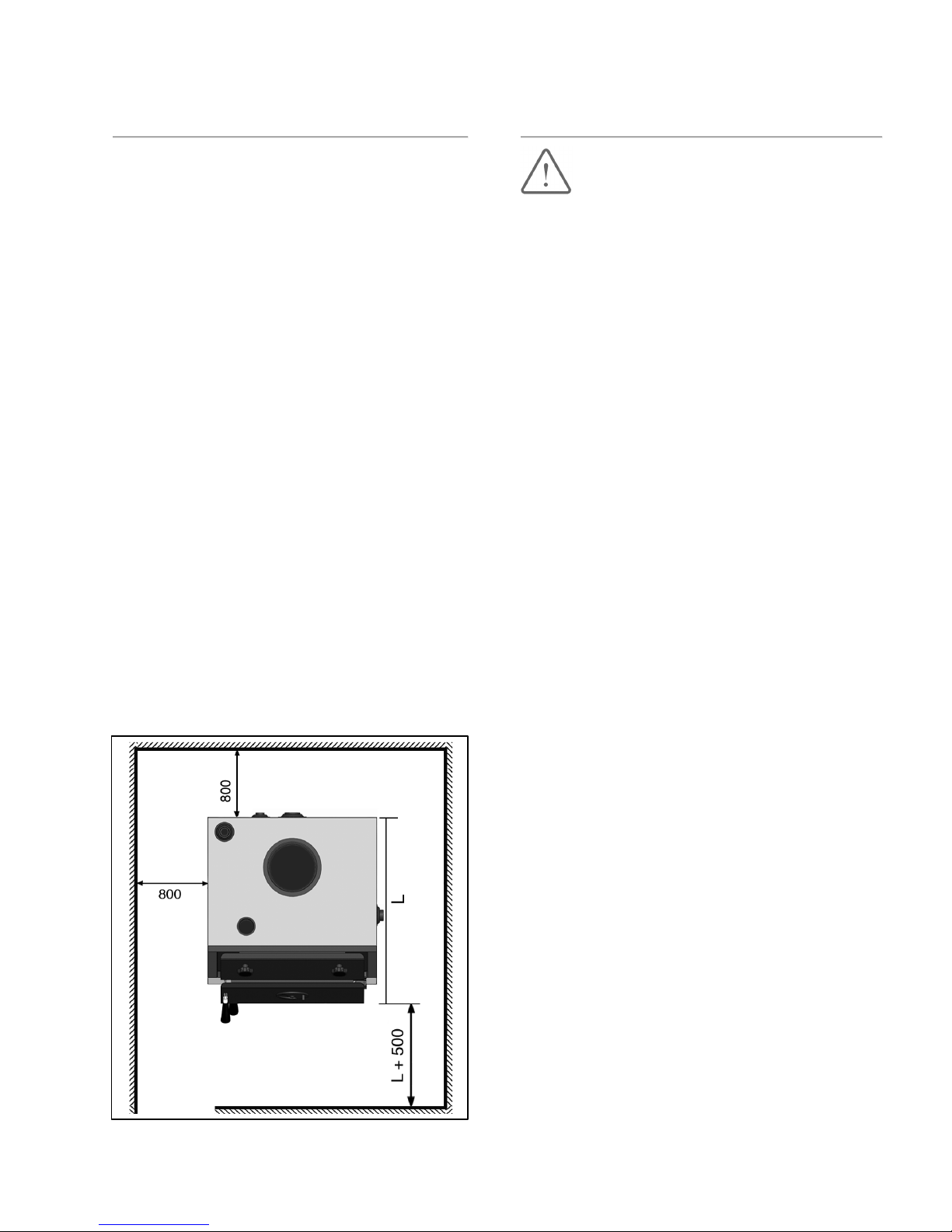

Boiler location

ARTA boilers can be located both on non-

habitable premises (e.g. in boiler room, cellar,

corridor…) and in habitable rooms. The room

in which the boiler is located must have a

permanent supply of air necessary for the

combustion process. The air must be free of

halogen hydrocarbons and corrosive vapours,

and must not be excessively humid and dusty.

The room must be protected against frost, with

ambient temperature within the range +5 °C

to +35 °C and relative humidity not exceeding

% 80.

To comply with fire regulations, the boiler must

be installed:

•On floor constructed of non-flammable

material.