Steffes ThermElect Hydronic 9150 Instruction Manual

Popular Boiler manuals by other brands

REMEHA

REMEHA 24c user guide

Laars

Laars NTH Installation and operation instructions

STIEBEL ELTRON

STIEBEL ELTRON HSBC 300 cool Operation and installation manual

Baxi

Baxi Power HT Installation, operation and maintenance manual

REMEHA

REMEHA Gas 550 technical information

Truma

Truma BGF installation instructions

Beretta

Beretta NOVELLA user manual

Daikin

Daikin Altherma EHVH-C Technical data

Fröling

Fröling TI 350 operating instructions

Windhager

Windhager DuoWIN Assembly instructions

Smith Cast Iron Boilers

Smith Cast Iron Boilers GB300 Installation & operating manual

Viessmann

Viessmann VITOROND 200 Service instructions

Weil-McLain

Weil-McLain Series 4 User's information manual

DeDietrich

DeDietrich DTG 330 S user guide

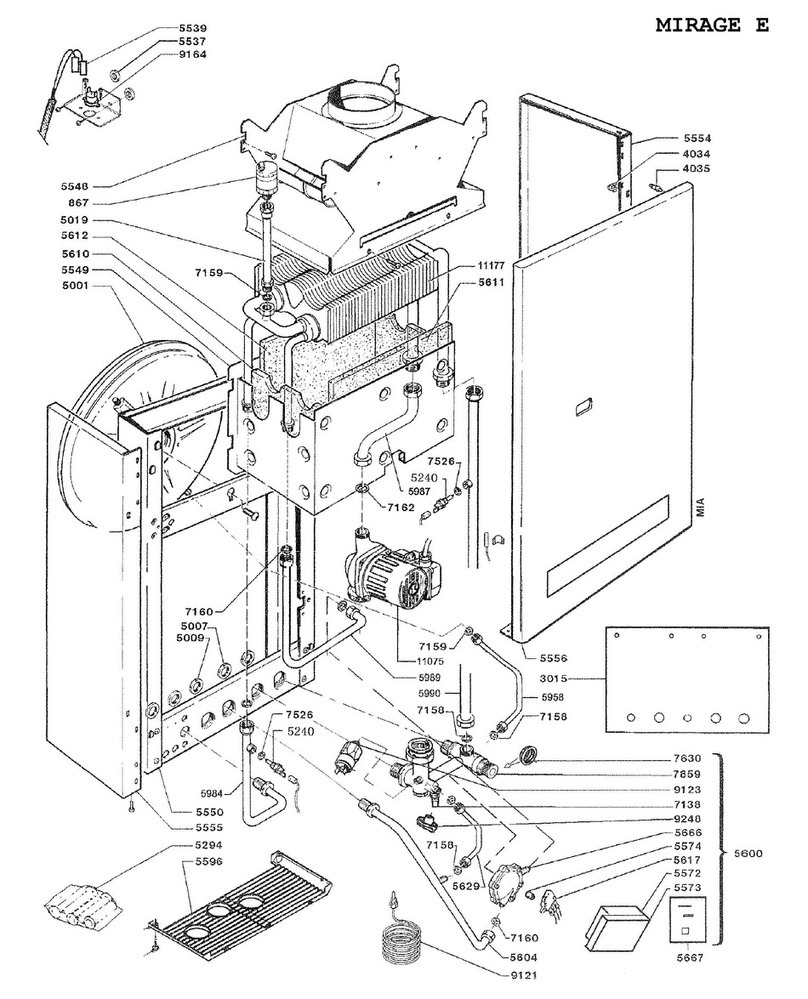

SANT ANDREA

SANT ANDREA MIRAGE E - SCHEMA manual

Comfee

Comfee D30-15EFG instruction manual

Worcester

Worcester Greenstar 4000 Installation and maintenance instructions

ACV

ACV EVO S 40 Installation, use and maintenance instructions