Bracton Subzero SZSC1800 User manual

Product Manual

Bracton Sub Zero glycol chiller

PREFACE

The manufacturer reserves the right to modify the

product and the relative technical documentation

without any obligations in relation to third parties,

and does not accept liability for any errors or

inaccuracy in the contents of this manual. This

version of the operator's manual describes the

technical characteristics of the standard production

appliance as of the date when this publication is

approved for printing.

CONTENTS

1.0 General specifications

2.0 Installation

2.1 Positioning - General

2.2 Commissioning procedure

2.2.1 Flush

2.2.2 Fill the tank

2.3 Operations

2.4 Maintenance / Cleaning

3.0 Thermostat controller

3.1 Alarms

3.2 Wiring diagrams

4.0 Troubleshooting

5.0 Checklist

1.0 General specifications

Bracton Subzero glycol chillers have been designed

to chill and maintain a set temperature for beer and

associated dispense equipment.

Bracton manufactures two main types of

commercial glycol chillers, remote and self

contained. Remote glycol chillers are supplied

without the condensing unit and designed for large

scale draught beer systems. Self contained glycol

chillers are plug and play solution including the

condensing unit. No refrigerant plumbing is

required for Bracton Subzero self contained glycol

chillers.

Bracton glycol chillers have been designed to

operate in Australian conditions.

2.0 Installation

Installation should only be performed by a suitably

qualified technician. NOTE 1: Bracton Subzero

Remote Glycol Chillers are quality checked,

pressure tested and dispatched with a nitrogen

holding charge at between 600 - 800 kPa. NOTE 2:

Bracton Subzero Self Contained Glycol Chillers are

quality checked, pressure tested and charged with

R507 refrigerant prior to dispatch.

2.1 Positioning - General

The chiller must be placed on a level surface

capable of bearing the weight of the machine

complete with coolant. The appliance must not be

placed close to direct or indirect heat sources

(ovens, stoves, radiators, etc.). The electricity and

glycol manifold points should be close to the

cooler, and positioned so that the electric cable and

water hose do not create obstacles. Do not install

area where liquid can drip onto tank.

Remote chillers

The chosen position must in any case allow

satisfactory ventilation; in particular, there must be

a gap of at least 400mm around the top for pump

ventilation. Bracton Subzero Remote Glycol Chillers

are designed to be installed indoors, either in the

cool room or back of house. For best performance

install inside the cool room.

Self contained chillers

The chosen position must in any case allow

satisfactory ventilation; in particular, there must be

a gap of at least 400mm at top and on a minimum

two sides including the condenser. Bracton Subzero

Self Contained Glycol Chillers are designed to be

installed indoors, either in the cool room or back of

house. For best performance install outside of cool

room in a well ventilated area. If installed outdoors,

a weatherproof housing must be fitted.

Revision date: 30/06/2021 Bracton Industries | www.bracton.com | +61 2 9938 1800

Bracton Subzero

Self contained glycol

chiller

Bracton Subzero

Remote glycol chiller

Tank capacity

80 Litres

80 Litres

180 Litres

Dimensions

SZSC1800

67 x 64 x 153cm

SZSC2800

67 x 64 x 158cm

62 x 40 x 85 - 95cm

SPK2-11 Installed

72 x 59 x 125 - 127cm

SPK4-11 Installed

72 x 59 x 138 - 140cm

Dry weight

SZSC1800 = 90Kg

SZSC2800 = 105Kg

Approx 50Kg

Approx. 100Kg depending on

configuration

Operational

weight

SZSC1800 = 172Kg

SZSC2800= 187Kg

Approx 136Kg

Approx 285Kg

Electrical input

SZSC1800

1 Ø / 10A / 240v / 50Hz

SZSC2800

1 Ø / 15A / 240v / 50Hz

1 Ø / 10A / 240v /50Hz

1 Ø / 10A / 240v /50Hz

Thermostat

Carel PJ Easy

Pump(s)

SPK 2-11

Single pump option only

SPK 2-11

SPK 2-15

SPK 4-11

Single or dual pump

Cooling

Capacity

SZSC1800

@32C - 10 SST = 2kW

SZSC2800

@32C - 10 SST = 3kW

1.8 - 2.7kW

1.8 - 16kW

Refrigerant

R507

R22, R134a, R404a

Refrigerant

connections

Suction line = ⅝”

Liquid line =⅜”

Suction line = ⅝”

Liquid line =⅜”

1.8 - 10kW

Suction line = ⅞”

Liquid line =⅜”

>10 - 16kW

Suction line = 1 ⅜”

Liquid line = ½”

Revision date: 30/06/2021 Bracton Industries | www.bracton.com | +61 2 9938 1800

2.2 Commissioning procedure

Inspect for damage, if any damage evident contact

bracton service centre for advice.

Remote systems

Install in accordance with Australia and New

Zealand Refrigerant handling code of practice

2007, Part 1 — Self-contained low charge systems.

NOTE: Units are delivered with a holding charge of

600-800 kPa of nitrogen. Pressure test remote

systems if no holding charge, report back to

manufacturer prior to installing. No warranty will be

available if this step is missed.

Brazing

All copper connections must brazed with flowing

dry nitrogen within through the system to prevent

oxidation build up.

Charging

System is to be charged in accordance with AS/NZS

1677.2:1998 Section 6.1: Charging and discharging

refrigerant

Test and tag

On completion of installation test and tag in

accordance with AS/NZS 3760:2010

Insulating

All outlet points and lines are to be appropriately

insulated to prevent condensation formation. For

more information contact the Manufacturer.

2.2.1 Flush

Flush the system with fresh potable water, ensure

no debris is in tank or water/glycol lines.

2.2.2 Fill the tank

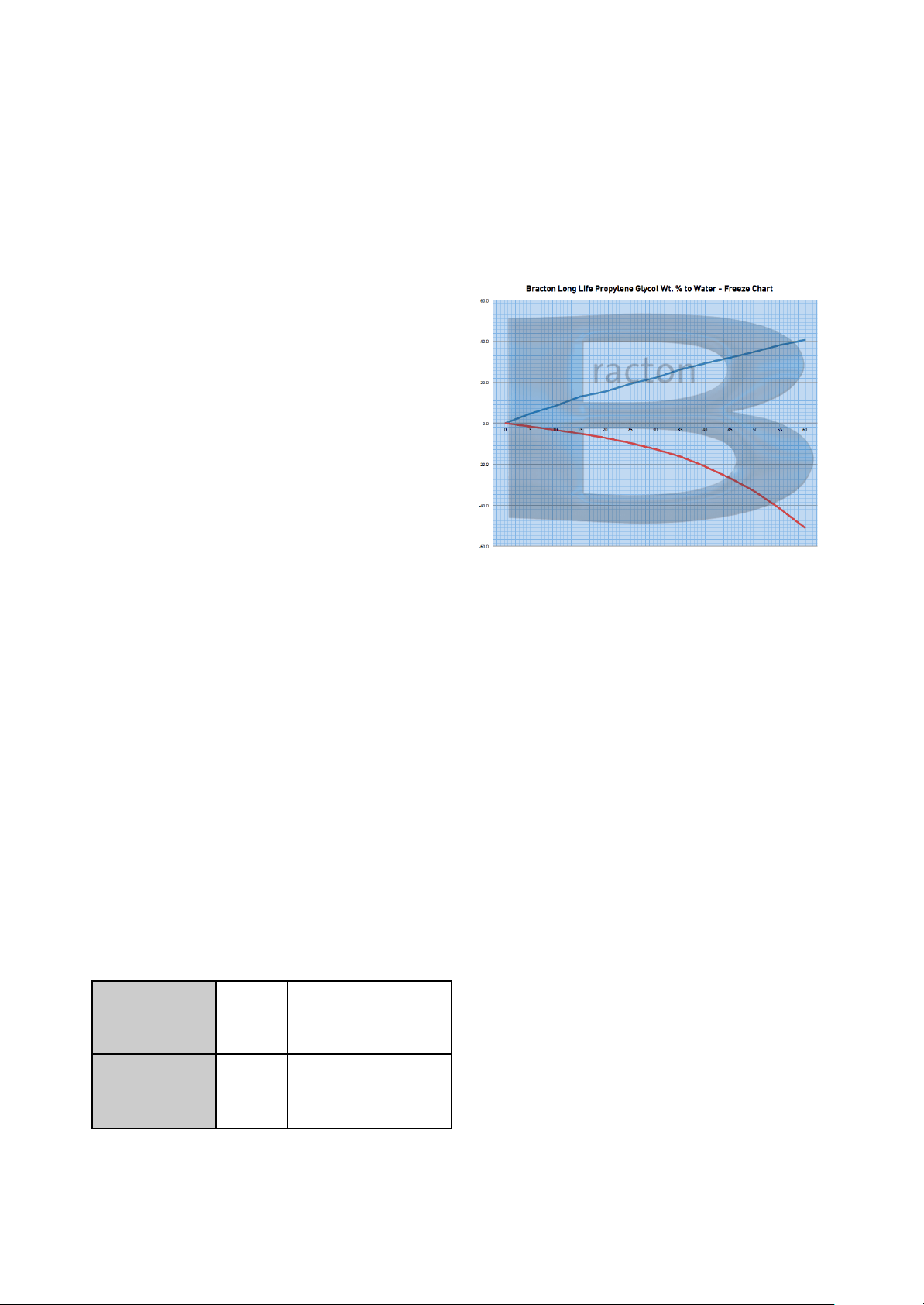

Remove the cover and fill the tank with a 30%

mixture of propylene glycol to 70% distilled water.

Standard propylene glycol may be used, however

for the ultimate protection consider using Bracton

Long Life Propylene Glycol to protect the

reticulation system for up to five times longer than

standard glycol.

NOTE: ethylene glycol is toxic and

under NO circumstances should be used.

Remote

Glycol Chiller

Tank

size

80 Lt

Propylene glycol 24L

Distilled water 56L

Self Contained

Glycol Chiller

Tank

size

180 L

Propylene glycol 54L

Distilled water 126L

Note 1: one litre of propylene glycol = 1.09 Kg,

therefore 24Lt of propylene glycol = 26.6Kg

Note 2: calculation above to include charging

python water lines and fonts.

To verify concentration of glycol / water mixture,

place a couple of drops of the mixture onto a

refractometer sight and view the concentration

reading, which should be approximately 21 bx.

2.3 Operations

Safety Do not allow anyone to operate the machine

unless suitably trained. Keep the machine in good

working order and do not allow any modifications

to it unless these have been authorised by the

manufacturer.

Electrical Safety Always disconnect the machine

from the electricity supply before doing any work

on it, to prevent damage and health hazards.

General use The use of the chiller for any purposes

other than those for which it was designed is not

recommended. Likewise, its use in any way other

than that indicated in this manual is forbidden.

This machine is not intended to be used by people

(including children) with reduced physical or

sensory capacities, or with a lack of experience and

knowledge, unless under supervision and with the

instructions of someone responsible for their

safety.

For the purposes of your safety, and in accordance

with the current legislation, any repair operations

on the machine must be carried out by the Service

Centre or approved contractor.

Revision date: 30/06/2021 Bracton Industries | www.bracton.com | +61 2 9938 1800

●Do not tamper with the internal

components; if they do not work well,

contact the Service Centre or approved

contractor

●Do not place any objects on the chiller

●Do not place the chiller on top of any other

object.

●Do not use liquids other than those

indicated.

●If you believe the chiller to be damaged,

contact the Service Centre or approved

contractor.

2.4 Maintenance / Cleaning

Electrical Safety Always disconnect the machine

from the electricity supply before doing any work

on it, to prevent damage and health hazards.

Authorised Technical Service Only technical staff

who are skilled refrigeration technicians, or with

expertise in cooling systems, may carry out work on

the machine. All wiring and plumbing components

must comply with national and local legal

requirements (when replacing components, use

only genuine parts certified by Bracton).

Coolant mixture The coolant mixture should

checked quarterly to ensure concentration ratio of

propylene glycol to distilled water is appropriate.

ie. Reading of 21 brix on the refractometer,

indicating a 30:70 propylene glycol: distilled water.

Refer to section 2.2.2 for more information.

3.0 Thermostat controller

Bracton programs thermostats prior to dispatch

with the following settings.

Parameter

Setting

st

set point

- 2.5oC (minus)

rd

temperature

differential

1.5 oC

AH

high temperature

alarm

8.0 oC

AL

low temperature

alarm

- 8.0 oC (minus)

For more information visit www.carel.com

3.1 Alarms

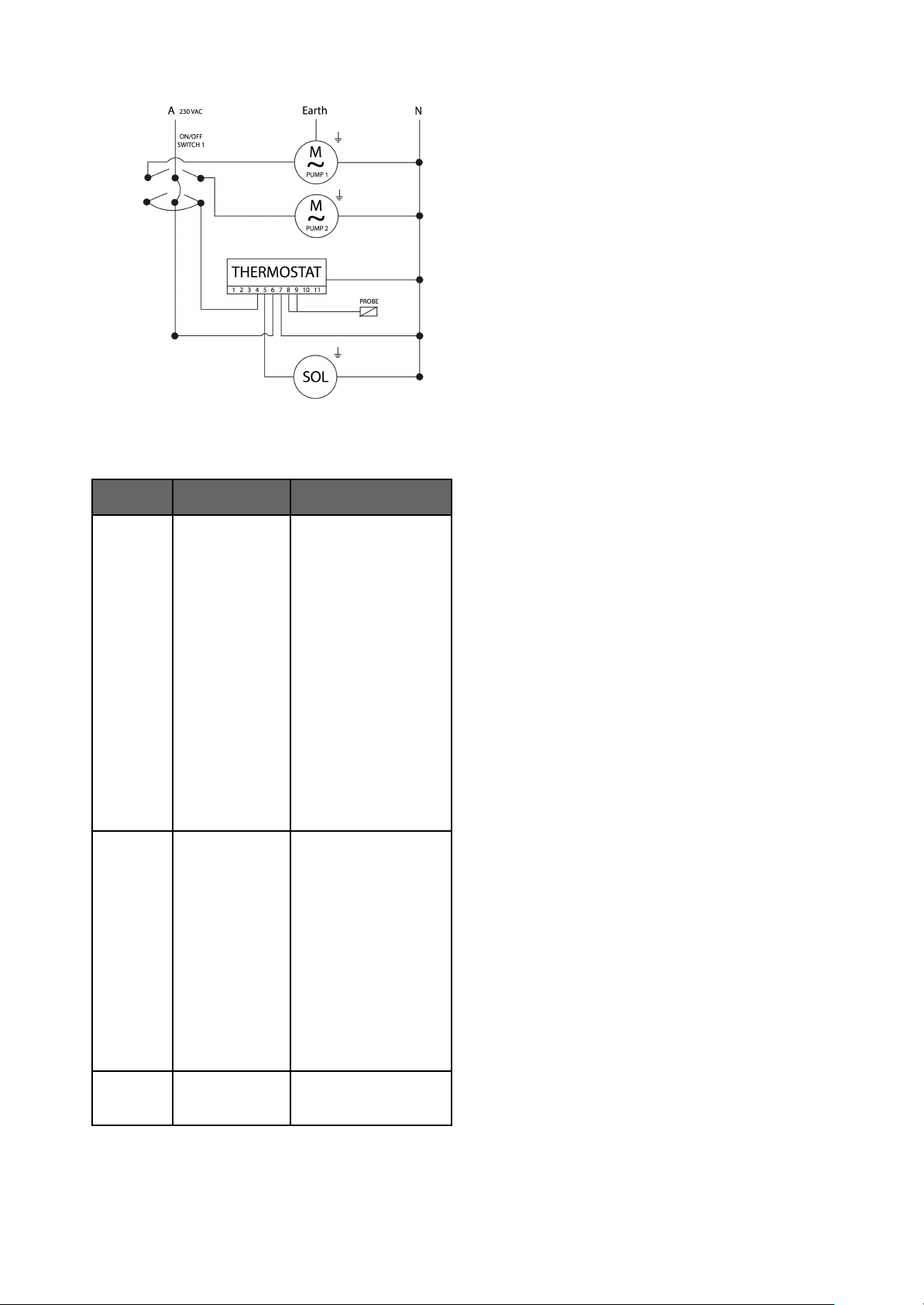

3.2 Wiring diagrams

Subzero self contained glycol chiller

Subzero remote glycol chillers

Revision date: 30/06/2021 Bracton Industries | www.bracton.com | +61 2 9938 1800

4.0 Troubleshooting

Problem

Cause

Solution

Warm

beer

Glycol mixture

too weak

Glycol heat

exchanger

Glycol pump

failure

Tank on

defrost

Capacity

exceeded

Other

Increase glycol

concentration

Check thermostat

parameters and

probe

Replace pump

Change thermostat

parameters

Reduce load on

tank.

Contact bracton

service centre

No beer

flow

No beer gas /

air

compressor

failure

Keg handle up

Frozen beer

lines from

glycol mixture

to cold

Check gas board,

replace gas, check

air compressor.

Push keg handle

down

Check set

temperature/

thermostat, check

probe, solenoid.

Noisy

pump

Pump ware

Check fan seal or

replace pump

5.0 Checklist - Remote

❏Evacuate, charge with nitrogen to 600 -

800kPa and leak check all refrigeration

components.

❏Liquid line and glycol solenoid installed in

the correct flow direction.

❏TX valve refrigerant matches unit.

❏TX valve sensing bulb is secured tightly and

in correct position, TX valve capillary not

rubbing on anything.

❏Taped TX bulb.

❏Turn on unit, check thermostat operates

and solenoid energise.

❏Glycol probe in correct position and suction

line probe checked for sensor tightness.

Confirm operation of glycol probe, check

for temp change.

❏Check pump(s) operate.

❏Remove rubber grommet from pump neck

❏Check wiring to ensure no internal

insulation is exposed.

❏Branding and Serial number correctly

positioned.

❏Supply leveling legs

❏Tank area clean.

❏Supply manual.

❏Lid and body insulation is installed and the

unit is fully sealed.

❏Check glycol return tube is fitted.

Assembly technician: _________________

Date: ________________

Revision date: 30/06/2021 Bracton Industries | www.bracton.com | +61 2 9938 1800

This manual suits for next models

1

Table of contents

Popular Chiller manuals by other brands

Parker Hiross

Parker Hiross Hyperchill-Plus ICEP002 user manual

S&A

S&A CWFL-3000BT user manual

Techfrost

Techfrost E Series user manual

Trane

Trane CGAH Series Installation operation & maintenance

Sinclair

Sinclair SCV-EB Series Service manual

Trane

Trane Arctic Manhattan Gen II Installation, operation and maintenance

Daikin

Daikin EWLD120MBYNN Operation manual

Baltimore Aircoil Company

Baltimore Aircoil Company ICE CHILLER TSU-M Series Operating and maintenance instructions

Electrolux

Electrolux EAT1AX operating instructions

A2B Accorroni

A2B Accorroni RPE Series manual

AIREDALE

AIREDALE LogiCool InRak Technical manual

AERMEC

AERMEC NRL FC 800 installation manual