STERO SG Building instructions

SG, SU-L, SU-H DISHWASHERS

SG

SU-L

SU-H

SERVICE and PARTS MANUAL

F45577 (1215)

TABLE OF CONTENTS

GENERAL .................................................................................................. 4

INTRODUCTION ....................................................................................... 4

MODELSCOVERED ................................................................................... 4

TOOLS ................................................................................................. 4

ELECTRICAL SPECIFICATIONS ....................................................................... 4

ENGINEERINGDATA .................................................................................. 5

INSTALLATION AND OPERATION CYCLES ............................................................ 5

PROGRAMMING MENUS .............................................................................. 6

REMOVAL AND REPLACEMENT OF PARTS ............................................................... 7

CONTROL PANEL SERVICE POSITION ................................................................ 7

LEFTANDRIGHTTRIMPANELS ...................................................................... 7

SWITCH MEMBRANE .................................................................................. 8

CONTROLPANELCOVER ............................................................................. 8

WATER LEVEL SENSORS ............................................................................. 9

CHEMICAL PUMPS - WELCO ......................................................................... 10

DRAINPUMP ......................................................................................... 10

FILLVALVE(1SOL) ................................................................................... 11

RINSEPUMP ......................................................................................... 11

RINSEPROBE(2QTM) ............................................................................... 12

WASH PIPE ASSEMBLY .............................................................................. 13

WASH PUMP/MOTOR (1MTR) ........................................................................ 14

BOOSTERHEATER(SU-H) ........................................................................... 15

BOOSTER THERMISTOR & HIGH LIMIT PROTECTION (SU-H) ....................................... 15

SUMP THERMISTOR & HIGH LIMIT PROTECTION ................................................... 16

AIRGAP .............................................................................................. 16

DOORSWITCH ....................................................................................... 17

SERVICEPROCEDURESANDADJUSTMENTS ........................................................... 18

REPLACEMENT CONTROL BOARD PROGRAMMING ................................................ 18

SERVICE PROGRAMMING (8934) .................................................................... 18

SOAP PROGRAMMING (7627) ........................................................................ 25

MANAGER PROGRAMMING (1001) ................................................................... 27

TESTING SANITIZER (BLEACH) CONCENTRATION (P.P.M.) ......................................... 29

BYPASS WASH/HEAT CYCLES FOR TROUBLESHOOTING .......................................... 30

10KOHMTHERMISTORTEST-BOOSTER(3QTM)&SUMP(1QTM) ................................. 30

PURGEBOOSTER/HOLDINGTANKFORSERVICE ................................................... 31

DOORADJUSTMENT ................................................................................. 31

SUMPHEATERTEST ................................................................................. 32

BOOSTERHEATERTEST ............................................................................ 32

100K OHM THERMISTOR TEST - RINSE PROBE (2QTM) ............................................. 33

ELECTRICAL OPERATION ................................................................................ 34

COMPONENT FUNCTION ............................................................................ 34

COMPONENTLAYOUT ............................................................................... 35

CONTROLBOARDLEDS ............................................................................. 37

CONTROLBOARDTESTPOINTS .................................................................... 38

CONTROL BOARD JUMPERS ........................................................................ 40

CONTROL BOARD WIRE CONNECTIONS ............................................................ 41

POWERSUPPLYBOARDLEDS&TESTPOINTS ..................................................... 42

SU-L&SGWIRINGDIAGRAM ........................................................................ 43

SU-H(3WIRE-1PH)WIRINGDIAGRAM .............................................................. 45

SU-L & SG SEQUENCE OF OPERATION ............................................................. 47

SU-H SEQUENCE OF OPERATION ................................................................... 49

CYCLETIMINGCHART ............................................................................... 52

TROUBLESHOOTING ..................................................................................... 53

SG, SU-L, SU-H DISHWASHERS

F45577 (1215) Page 2 of 59

TOGGLE DIAGNOSTICS .............................................................................. 53

ERRORCODES ...................................................................................... 53

TROUBLESHOOTING GUIDE WARE .................................................................. 55

TROUBLESHOOTING GUIDE MACHINE .............................................................. 56

SG, SU-L, SU-H DISHWASHERS

© COMPETITIVE 2015

Page 3 of 59 F45577 (1215)

PARTS CATALOG .................................................................................... 60

GENERAL

INTRODUCTION

This manual is applicable to the models on the cover

page. Procedures apply to all models unless specified

otherwise.

MODELS COVERED

The SU and SG Series dishwashers are fully

automatic, front-loading dishwashing machines.

SU-L 33 racks per hour

SU-H 31 racks per hour

SG 34 racks per hour

All SU and SG Series dishwashers shut down

automatically 4 hours after last use to conserve

energy.

SU-H dishwashers include Rinse Assurance to insure

proper hot water temperature during rinse.

MODEL DESCRIPTION

SU-L

SG

Fresh water rinse; low-temperature,

chemical-sanitizing models for use

with 6% or 8.40% sodium hypochlorite

solution (bleach) as the sanitizing

agent.

SU-H

Fresh water rinse with a built-in 70° F

rise booster heater. This allows an

incoming water temperature of 110° F.

TOOLS

Standard

• Standard set of hand tools.

• Metric set of hand tools.

• VOM with measuring micro amp current tester.

Any VOM with minimum of CAT III 600V, CE

certified. Sensitivity of at least 20,000 ohms per

volt can be used. In addition, meter leads must

also be a minimum of CAT III 600V.

• Temperature tester (thermocouple type).

• Field service grounding kit.

Special

• Precision Chlorine Test Paper Vial, for testing

sanitizer p.p.m.

• Cleaner used in removal of switch membrane.

• T25 Torx bit. Used in removal of door.

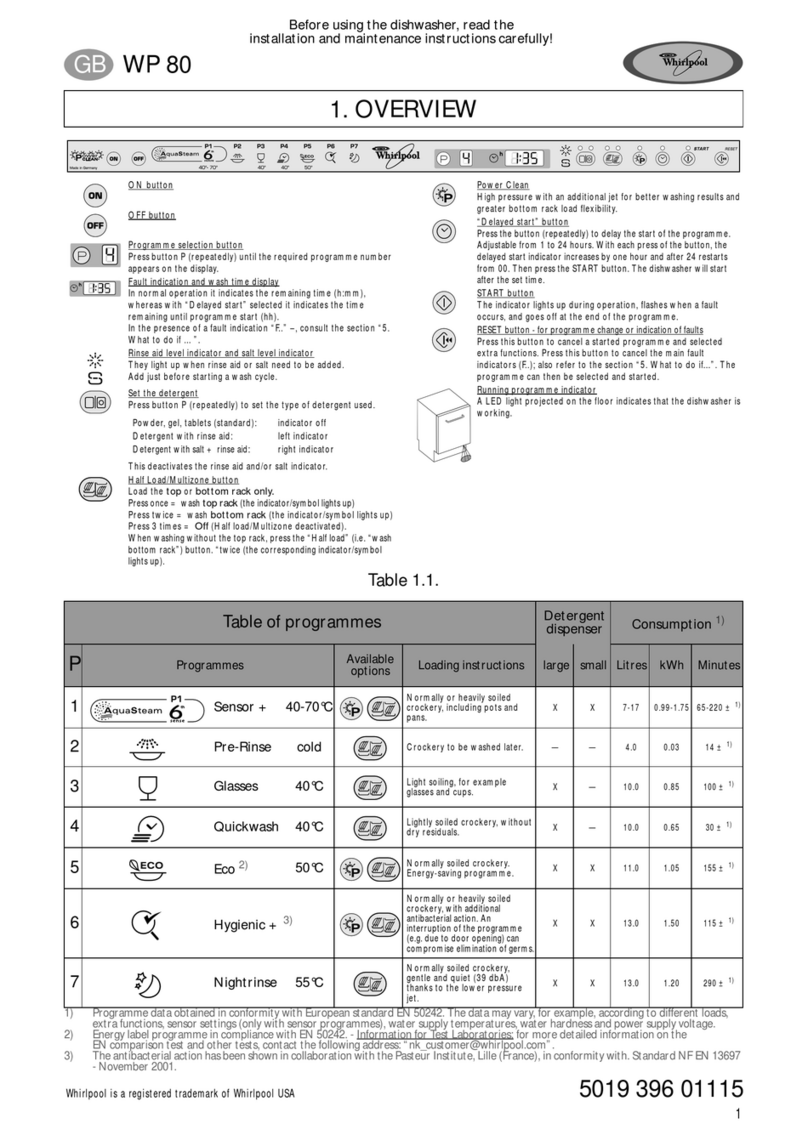

• Service Tool: Used in removal of Wash Pump Nut

and Wash Manifold Nut.

Fig. 1

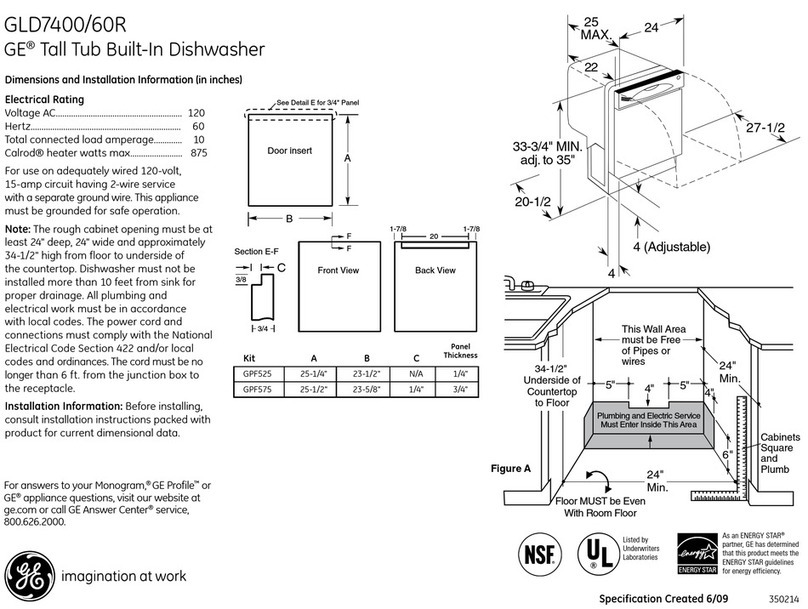

ELECTRICAL SPECIFICATIONS

NOTE: Always check incoming voltage to verify

service connection meets machine specification.

ELECTRICAL SPECIFICATIONS

Model Volts / Hertz / Phase Rated Amps

Minimum Supply

Circuit Conductor

Ampacity

Maximum Protective

Device Ampacity

SG 120/60/1 15.4 20 20

SU-L 120/60/1 13.4 20 20

SU-H

120/208-240(3W)/60/1 30.5 40 40

NOTE: This system requires three power wires that include a current carrying neutral. An additional

fourth wire must be provided for machine ground.

SG, SU-L, SU-H DISHWASHERS - GENERAL

F45577 (1215) Page 4 of 59

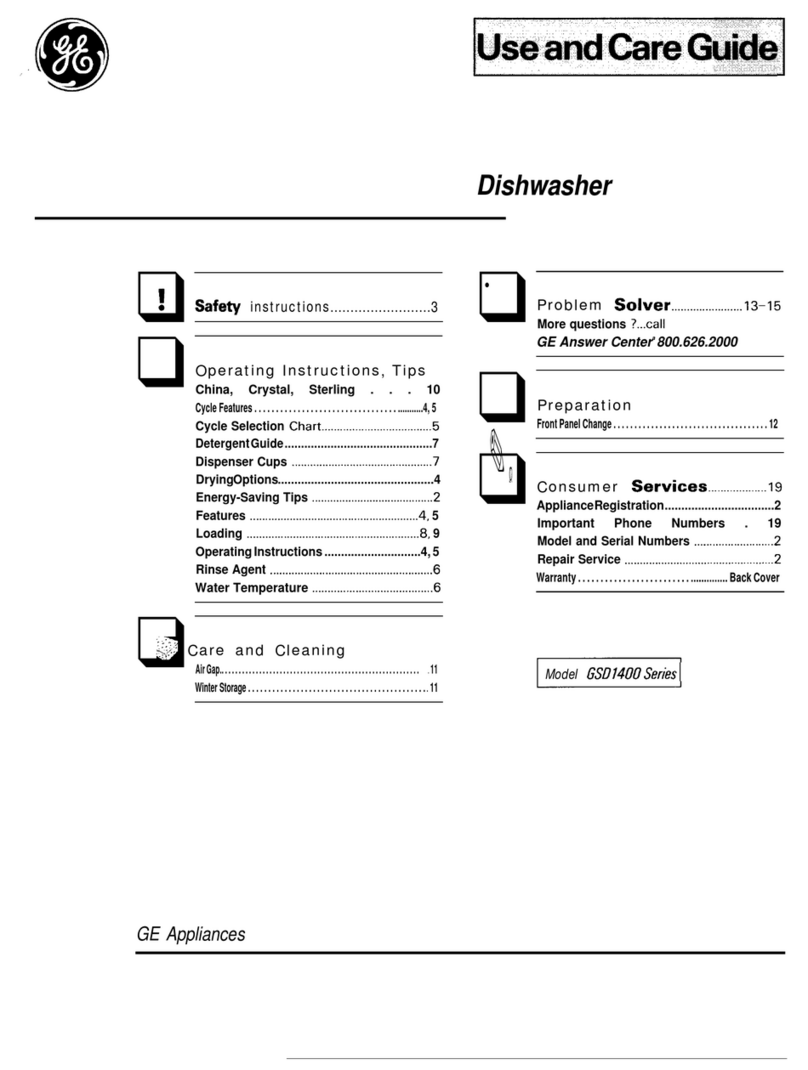

ENGINEERING DATA

3/4 HP pump motor, thermally protected internally, automatic reset.

Required water supply characteristics are as follows:

Model Temperature Flowing Pressure

SG

SU-L 120°F minimum 15 - 65 psi

SU-H 110°F minimum 15 - 65 psi

INSTALLATION AND OPERATION

CYCLES

INSTALLATION

Generally, all installations are made by the

dealer or others contracted by the dealer or

owner.

POWER-UP DIAGNOSTICS

When the Power Button is pressed, the control

board checks the probes and sensors to be

within operational range. Once the self-check is

passed, the machine automatically enters Fill/

Preheat Mode.

NOTE: If there is a detectable water level in the

sump prior to turning the machine on, the

dishwasher will perform a power drain.

PRIMING CHEMICAL PUMPS

Chemical pumps prime on Power Up or at the

start of a Wash Cycle if sensors do not detect

chemicals.

1. Initial prime attempt is 60 seconds.

A. If chemical not sensed "Add Chemical" will

display.

NOTE: The 60 second prime is in intervals of 6

seconds.

2. If not primed after 3 attempts, the "Add

Chemical" indicator will continue to display.

3. Priming is terminated.

4. Reset by cycling power.

5. Once chemical is sensed, pumps continue to

prime for 10 seconds to allow chemicals to reach

machine.

FILL/PREHEAT

Without Booster (SG & SU-L): The holding

tank will fill. The water is then moved through the

rinse arms to the sump. Process repeats until

the sump is at operational water level. Sump

heater maintains wash temperature.

With Booster (SU-H): The booster will fill and

heat to 140°F. The booster water is then moved

through the rinse arms to the sump. Process

repeats until the sump is at operational water

level. Sump heater maintains wash

temperature.

NOTE: If the door is opened during the Fill

cycle, the process is suspended. After door is

closed the process continues where it left off.

NOTE: During the Fill cycle, the detergent pump

is activated for the normal detergent cycle.

READY MODE

While a cycle is not in process, the SU and SG

Series will maintain in idle state. In this mode,

the heat will be maintained in both the sump and

booster. The sump temperature will be

displayed.

NORMAL OPERATION (WASH CYCLE)

After the fill cycle is completed, a wash cycle is

begun by pressing the WASH key.

On 120VAC cold machines, sump heater is de-

energized while wash motor is energized.

If the door is opened during the Wash cycle, the

process is suspended. After door is closed the

process continues where it left off.

During a cycle, both sump and booster heat are

controlled. Hot machines only.

During the wash portion of the cycle, the sump

temperature will be displayed. During the rinse,

the final rinse temperature will be displayed.

RINSE

SG, SU-L, SU-H DISHWASHERS - GENERAL

Page 5 of 59 F45577 (1215)

After the wash cycle ends, water is drained from

the sump to allow for the rinse water from the

holding tank (cold machines) or booster (hot

machines).

POWER-DOWN / DRAIN

When the POWER key is pressed, the unit will

enter a drain cycle. Booster or holding tank will

be purged, and sump will be drained. After the

completion of the drain cycle, power to the

controls is removed under software control. At

this point, the control is inoperable until the

POWER key is pressed.

PROGRAMMING MENUS

There are 3 Programming Menus that can be

accessed when the Menu/Down Arrow button is

selected. Each menu has parameters that can be

changed that affects the way the dishwasher

operates. Each menu is protected by a 4 digit access

code.

Use the arrow keys to change the ( -> ) to the desired

number and press enter to move to the next digit.

NOTE: The Manager Programming menu uses 1001

as the access code. Just select enter to move to the

next digit.

•MANAGER PROGRAMMING (1001)

•SOAP PROGRAMMING (7627)

•SERVICE PROGRAMMING (8934)

SG, SU-L, SU-H DISHWASHERS - GENERAL

F45577 (1215) Page 6 of 59

REMOVAL AND REPLACEMENT OF PARTS

CONTROL PANEL SERVICE

POSITION

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Certain components in this system are

subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is required

to prevent damage. The field service kit must be used

anytime the control board is handled.

1. Pull dishwasher out from underneath counter.

2. Open door and remove two screws using #3

Phillips screwdriver.

Fig. 2

3. Pull out control cover, then hinge up and back.

Fig. 3

4. Reverse procedure to install.

5. Check for proper operation.

LEFT AND RIGHT TRIM PANELS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Certain components in this system are

subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is required

to prevent damage. The field service kit must be used

anytime the control board is handled.

Control Panel Service Position

1. Open door and remove (2) screws.

Fig. 4

2. Slide control cover forward (Approximately 2-3").

Left and Right Trim Panel Removal

1. Remove left and right trim panel screws, using #3

Phillips screwdriver.

Fig. 5

2. Remove left and right trim panels.

3. Close unit door.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

Page 7 of 59 F45577 (1215)

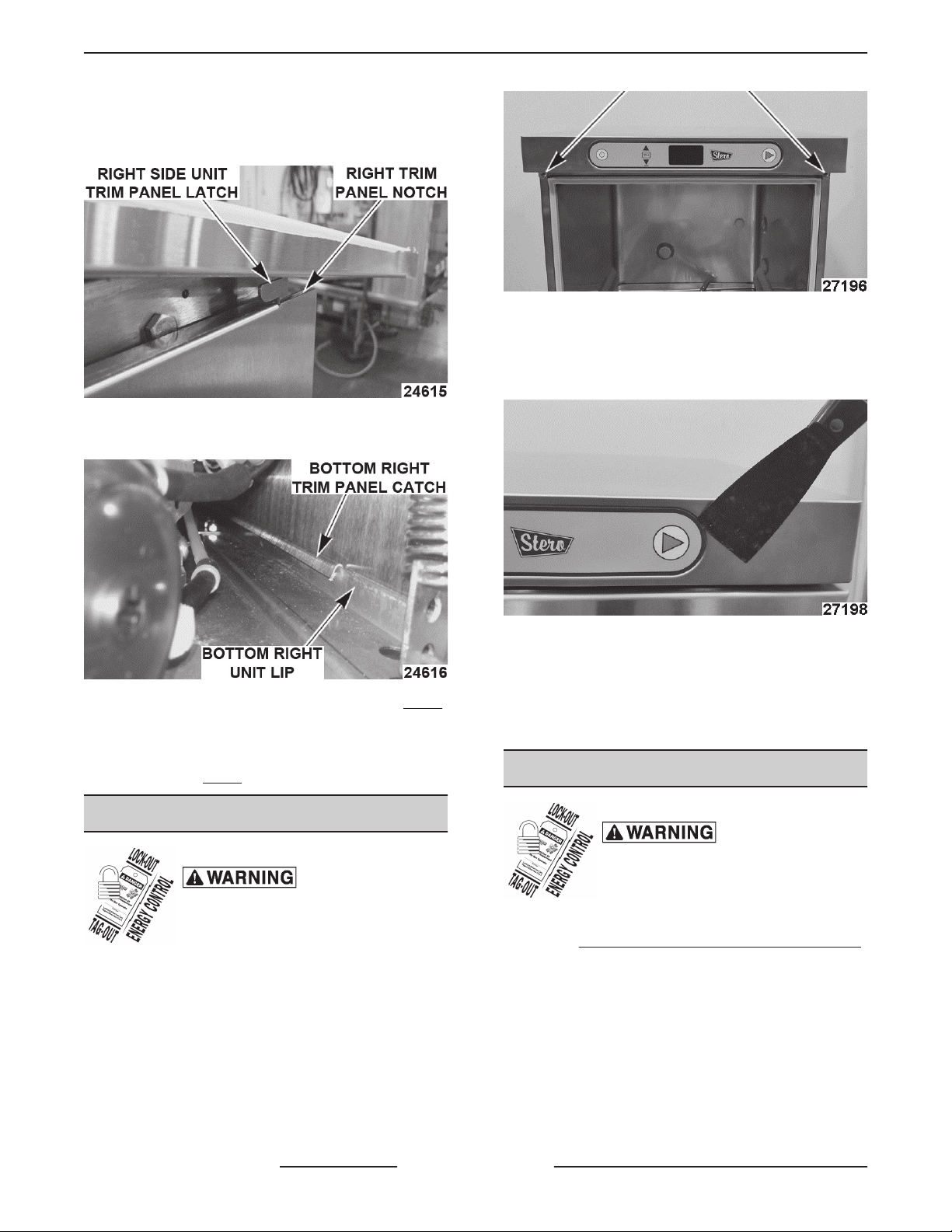

Left and Right Trim Panel Installation

1. Insert right trim panel notch into right side unit

trim panel latch.

2. Verify bottom right trim panel catch is fastened to

the bottom right lip of the unit.

3. Insert and tighten right trim panel screw. (Fig. 5)

4. Repeat steps 1 - 3 for left trim panel installation.

5. Slide control cover back in place and tighten with

(2) screws. (Fig. 4)

SWITCH MEMBRANE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Open door and remove screws, using #3 Phillips

screwdriver.

Fig. 8

2. Pull out control cover and disconnect switch

membrane ribbon cable from connector.

3. Pry up switch membrane.

Fig. 9

4. Reverse procedure to install.

NOTE: Before installing replacement membrane, use

cleaner to remove old adhesive and allow to dry.

5. Check for proper operation.

CONTROL PANEL COVER

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Pull dishwasher out from underneath counter,

when CONTROL PANEL SERVICE POSITION

is not possible or entire cover needs replaced.

2. Open door and remove two screws, using #3

Phillips screwdriver.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

F45577 (1215) Page 8 of 59

Fig. 10

3. Slide control cover forward and disconnect

switch membrane ribbon cable from connector.

4. Loosen nut, washer and center bearing washer

from both sides. (Do NOT remove hardware)

Fig. 11

5. Remove control cover.

6. Reverse procedure to install.

NOTE: Center bearing washer must be centered in

hole to allow rotation.

Fig. 12

7. Check for proper operation.

WATER LEVEL SENSORS

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove CONTROL PANEL COVER.

2. Remove LEFT AND RIGHT TRIM PANELS

(Booster/Holding Tank) or LEFT AND RIGHT

TRIM PANELS (Sump tank).

3. Drain sump or Booster/Holding tank below air

trap (1, Fig. 13) inlet.

NOTE: Not draining sump or booster / holding tank

may cause a leak.

Fig. 13

4. Disconnect water level cable from sensor and

tube clamp.

5. Push plastic tabs (using screwdriver or pliers) to

remove.

NOTE: Do NOT over squeeze pinch clamps on

bottom of sensors.

Fig. 14

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

Page 9 of 59 F45577 (1215)

6. Reverse procedure to install.

A. Verify there is no water in air trap.

B. Verify there is no water, kinks or holes in

pressure sensor tubing.

C. Verify tubing clamp is properly installed.

7. Check for proper operation.

CHEMICAL PUMPS - WELCO

If chemical pump label is no longer visible, replace

label to identify pump for future servicing.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Fig. 15

NUMBER DESCRIPTION

1Chemical Pump Motor

2Detergent Chemical Pump

3Rinse Aid Chemical Pump

4Chemical Sensor

5Sanitizing Chemical Pump (SU-L & SG

only)

1. Remove front trim panel.

2. Remove clamps and tube and pull from sensor.

3. Remove snap cover.

4. Remove tube from chemical sensor [5].

5. Replace with new chemical sensor [5].

6. Replace snap cover.

7. Replace hose to tube and sensor. Secure with

clamps.

NOTE: Do NOT use zip ties.

NOTE: Do NOT over squeeze clamp. Over squeezing

causes leaks.

Replacing Chemical Pump

1. Twist pump Counter Clock Wise and slide off

shaft.

2. Reverse procedure to install.

DRAIN PUMP

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove front trim panel and LEFT AND RIGHT

TRIM PANELS.

2. Remove electrical connections noting their

location.

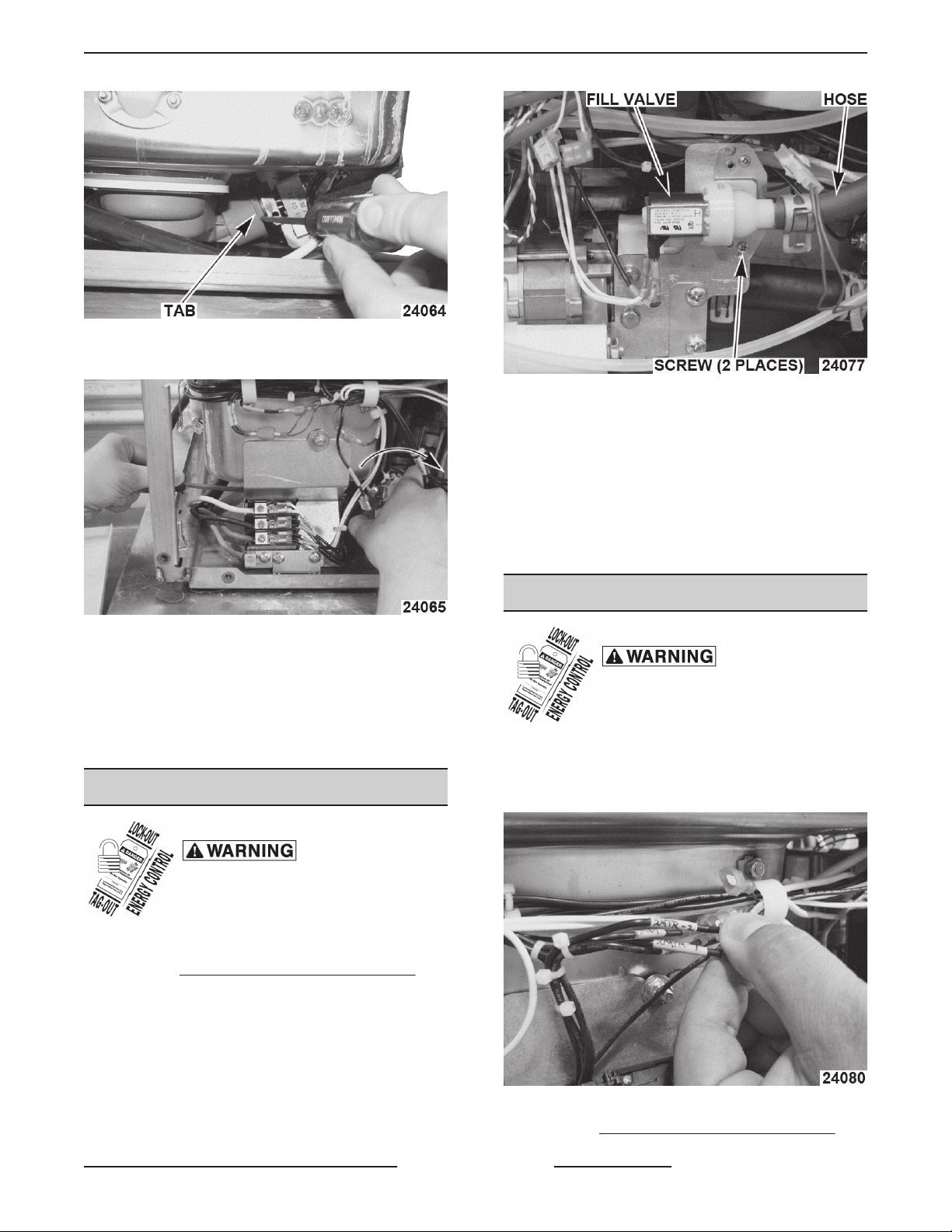

Fig. 16

3. From left side using a long flathead screwdriver,

GENTLY open tab securing drain pump.

NOTE: Tab is easily broken. Do not need to replace

broken tab.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

F45577 (1215) Page 10 of 59

Fig. 17

4. Twist drain pump clockwise (CW) to remove.

Fig. 18

5. Reverse procedure to install.

NOTE: If tab on wash manifold is broken during drain

pump replacement, DO NOT replace wash manifold.

Drain pump can still be mounted securely without tab.

6. Check for proper operation.

FILL VALVE (1SOL)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Shut off water supply.

2. Remove LEFT AND RIGHT TRIM PANELS.

3. Disconnect and drain water hose.

Fig. 19

4. Disconnect electrical connections from valve.

5. Remove mounting bracket screws.

6. Remove fill valve from bracket.

7. Disconnect and drain braided water line.

8. Reverse procedure to install.

9. Check for proper operation.

RINSE PUMP

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove front trim panel.

2. Disconnect rinse motor connections, 2MTR-1,

2MTR-2 and Ground.

Fig. 20

3. Remove LEFT AND RIGHT TRIM PANELS.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

Page 11 of 59 F45577 (1215)

4. Remove fill valve (1SOL) from rinse pump.

NOTE: Leave electrical connections and hoses

connected to fill valve. Fill valve will be transferred to

replacement rinse pump.

Fig. 21

5. Disconnect inlet and outlet hoses from rinse

pump.

6. Remove 2 nuts securing rinse pump to base of

unit.

Fig. 22

7. Slide mounting bracket out from underneath clip

on base of unit, and remove rinse pump.

8. Transfer mounting bracket and fill valve to

replacement rinse pump.

9. Reverse procedure to install.

10. Check for proper operation.

RINSE PROBE (2QTM)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove LEFT AND RIGHT TRIM PANELS.

2. Disconnect 2QTM at harness.

Fig. 23

3. Remove rinse probe from rinse tee.

Fig. 24

4. Reverse procedure to install.

NOTE: Use tape or thread compound to help seal

threads.

5. Check for proper operation.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

F45577 (1215) Page 12 of 59

WASH PIPE ASSEMBLY

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove rinse pump and chemical pump bracket.

2. Remove WASH PUMP/MOTOR (1MTR).

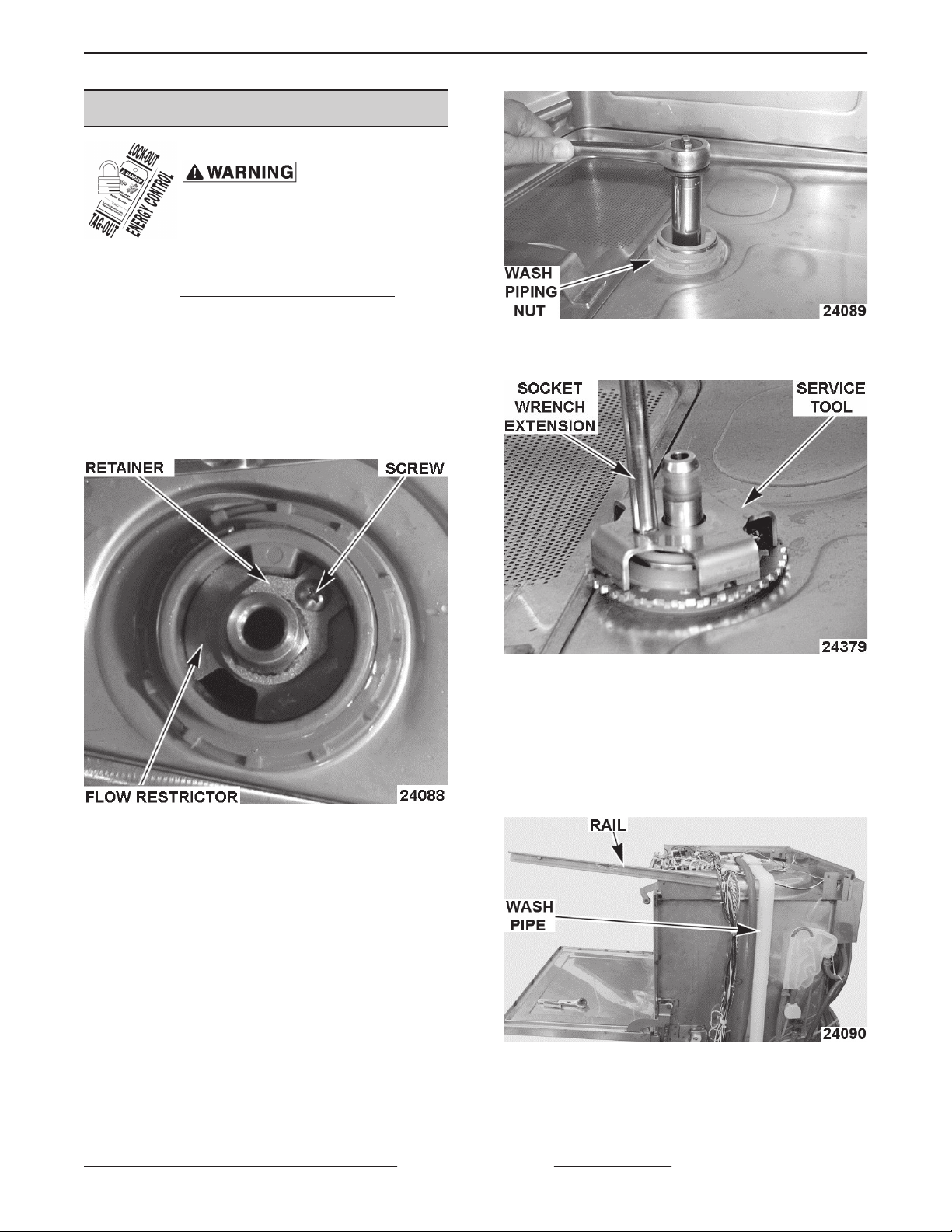

3. Remove upper and lower wash and rinse arms.

4. Remove screw and retainer (top and bottom).

NOTE: Be careful to not drop screw or retainer into

wash pipe.

NOTE: Ensure retainer is off by removing wash

pipe.

Fig. 25

NOTE: Ensure retainer is off before removing

wash pipe.

5. Remove spindle using 13/16" deep well socket.

6. Remove flow restrictor (lower manifold only).

Fig. 26

7. Remove wash piping nut using service tool.

Fig. 27

8. Disconnect any wiring that impedes wash pipe

assembly removal.

9. Remove CONTROL PANEL COVER.

10. Remove rear nut of rail.

11. Loosen front nut and rotate rail.

Fig. 28

12. Disconnect and note location of all electrical

connections to wash pipe assembly as

necessary.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

Page 13 of 59 F45577 (1215)

13. Remove wash pipe assembly.

NOTE: If any tubes or wiring are routed between

wash pipe and rinse hose, disconnect rinse hose at

rinse tee to free tubes/wiring.

14. Transfer rinse hosing to replacement wash pipe.

15. Replace wash pipe O-rings.

16. Reverse procedure to install.

17. Check for proper operation.

WASH PUMP/MOTOR (1MTR)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove front and right trim panels.

2. PURGE BOOSTER/HOLDING TANK FOR

SERVICE

3. Remove RINSE PUMP with fill valve (1SOL)

attached for a path to remove wash pump/motor

assembly.

NOTE: Stainless steel fill valve intake hose can

remain connected, but slack will need to be fed

through back of machine to clear assembly out of the

way.

Fig. 29

4. Remove any chemical tubing blocking removal

through the right side.

5. Disconnect pump manifold hose.

Fig. 30

6. Remove locator nut and rubber motor mount.

Fig. 31

7. From front of machine, unhook drain hose to

pump manifold and disconnect 1MTR

connections.

Fig. 32

8. Remove DRAIN PUMP.

9. Open door and remove strainers.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

F45577 (1215) Page 14 of 59

10. Using service tool, remove pump nut.

NOTE: ⅜" drive extension can be used to turn service

tool.

Fig. 33

11. If clearance is necessary to remove wash pump/

motor, move chemical pump mounting bracket

assembly.

Fig. 34

12. Remove wash pump and motor assembly.

13. Reverse procedure to install.

NOTE: Transfer motor mount with locator nut just

started on threads onto replacement wash pump/

motor assembly.

NOTE: Once wash pump and motor are positioned

under dishwasher with motor mount slid into place,

tighten pump nut inside sump one thread for stability.

Once hose and electrical connections have been

made, tighten pump nut.

14. Check for proper operation.

BOOSTER HEATER (SU-H)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove front trim and right side panel.

2. PURGE BOOSTER/HOLDING TANK FOR

SERVICE.

3. Disconnect booster heater wires from contactor.

4. Remove mounting screws.

Fig. 35

NOTE: Proper position with element wires on bottom.

5. Remove booster heater.

6. Reverse procedure to install.

7. Check for proper operation.

BOOSTER THERMISTOR & HIGH

LIMIT PROTECTION (SU-H)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

NOTE: Before replacing the High Limit, push reset

button on face of both high limit protectors. Verify that

this does not fix issue before proceeding.

Surface-Mount Thermistor

1. Remove front, left, and right trim panels.

2. Remove mounting nut and disconnect wires at

connector.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

Page 15 of 59 F45577 (1215)

NOTE: When installing thermistor, verify there is

thermal paste on the side of the thermistor that is

mounted to the booster. Mount tightly to booster

surface and in same position as from the factory.

Thermal paste can be purchased at local store.

Fig. 36

3. Reverse procedure to install.

4. Check for proper operation.

High Limit Protectors

1. Remove front, left, and right trim panels.

2. Remove 2 screws and position FILL VALVE

(1SOL) out of the way.

3. Remove mounting bracket for 3TAS / 4TAS high

limit protectors.

Fig. 37

4. Remove high limit protector.

5. Reverse procedure to install.

6. Check for proper operation.

SUMP THERMISTOR & HIGH LIMIT

PROTECTION

NOTE: Before replacing the High Limit, push reset

button on face of both high limit protectors. Verify that

this does not fix issue before proceeding.

1. Drain the sump.

2. Remove LEFT SIDE PANEL.

3. For Surface Mounted Thermistor, remove

mounting nut and disconnect lead wires at

connector.

NOTE: When installing thermistor, mount tightly to

booster surface and in same position as from the

factory.

4. For High Limit Protectors, remove electrical

connections at high limits [1] and heater element.

Fig. 38

5. Remove sump heater mounting nuts [2].

6. Remove high limit protector mounting bracket.

7. Remove high limit protector.

8. Reverse procedure to install.

9. Check for proper operation.

AIR GAP

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

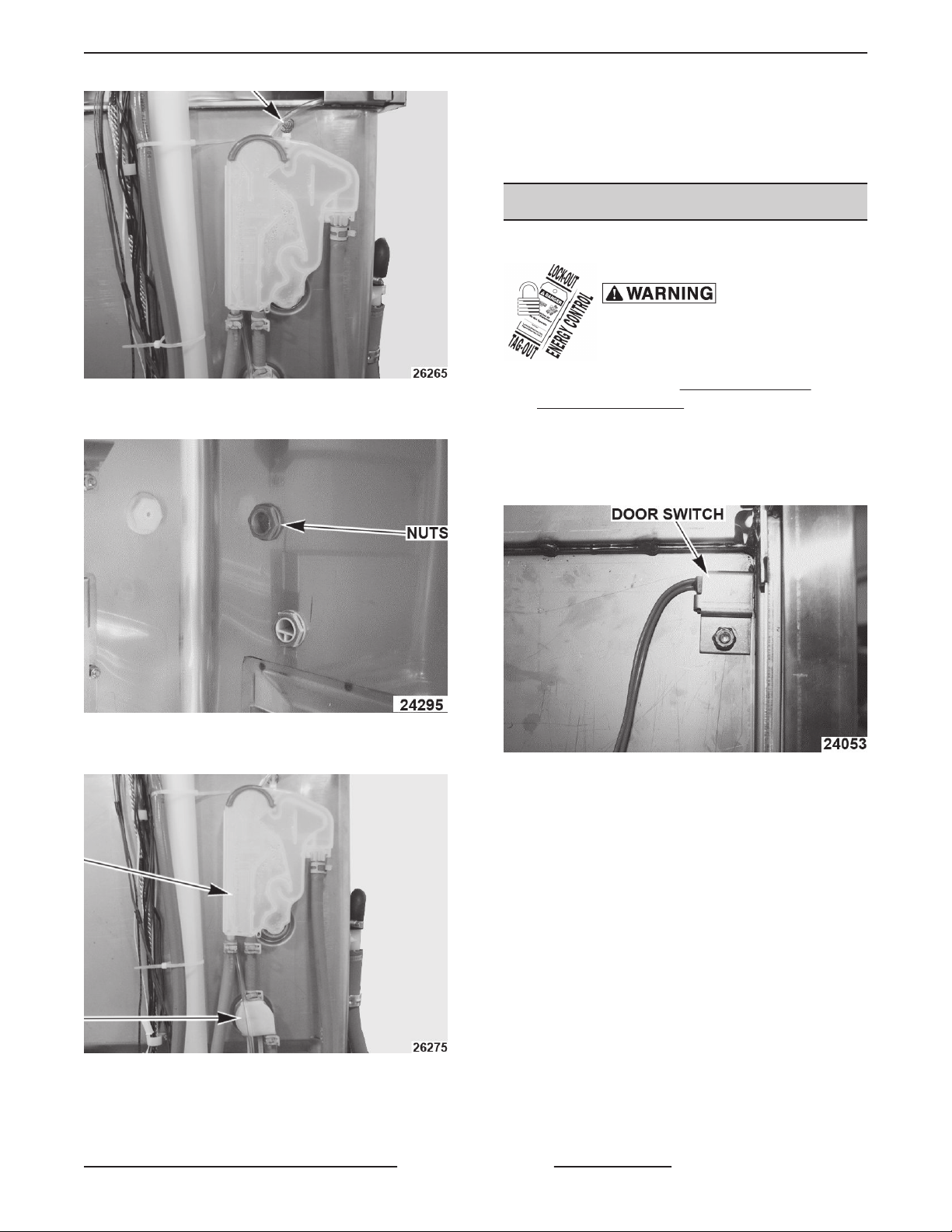

1. Remove right side panel.

2. Remove air gap mounting screw.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

F45577 (1215) Page 16 of 59

Fig. 39

3. Remove nuts from inside washer.

Fig. 40

4. Remove air gap.

Fig. 41

5. Disconnect hoses.

6. Reverse procedure to install.

NOTE: Make sure gasket is installed between inside

wall of tank and air gap. Replace gaskets as

necessary.

7. Check for proper operation.

DOOR SWITCH

NOTE: Door magnet is part of door.

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Place dishwasher in CONTROL PANEL

SERVICE POSITION.

2. Remove left side panel.

3. Disconnect door switch from control board (J10).

4. Remove screw securing door switch.

Fig. 42

NOTE: Door switch magnet is located inside the door

and is not serviceable.

5. Reverse procedure to install.

NOTE: Add small amount of Permagum between

sensor and bracket.

NOTE: Verify sensor is not lose and rattling.

6. Check for proper operation.

7. Check for rattles.

SG, SU-L, SU-H DISHWASHERS - REMOVAL AND REPLACEMENT OF PARTS

Page 17 of 59 F45577 (1215)

SERVICE PROCEDURES AND ADJUSTMENTS

REPLACEMENT CONTROL BOARD

PROGRAMMING

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

Certain components in this system are

subject to damage by electrostatic discharge during

field repairs. A field service grounding kit is required

to prevent damage. The field service kit must be used

anytime the control board is handled.

NOTE: The replacement control board comes

programmed as an SG, SU-L, and SU-H or other OEM

machines must be reprogrammed to Stero.

Prior to removing board from machine, check and note

the settings of programmable variables as outlined

under SERVICE PROGRAMMING (8934) when

possible. When unable to access SERVICE

PROGRAMMING, check with establishment manager

to determine customer control settings. If control

settings cannot be determined, program according to

machine type SG, SU-L, and SU-H.

1. Press MENU button on keypad.

NOTE: Menu can also be accessed by shorting J27

(SVC) pins on control board. See CONTROL PANEL

SERVICE POSITION.

2. Enter SERVICE MENU.

3. Enter Service code 8934.

4. Select Edit Parameters, then Models.

5. Pick model based on data plate on door.

6. Select Exit Menu.

7. Shut down and cycle power to the dishwasher.

(Reboot)

8. Once power is reapplied turn machine on and re-

enter service programming to verify replacement

board is still set for the appropriate model.

9. Program replacement board to customer's

specifications using SERVICE PROGRAMMING

(8934).

10. Check for proper operation.

SERVICE PROGRAMMING (8934)

Service Programming

•EDIT PARAMETERS

•VIEW ERROR LOG

•VIEW STATS

•TOGGLE DIAGNOSTICS

•PRIME PUMPS

•IMMEDIATE SHUTDOWN

•SHOW SOFTWARE REVISION

•RESET PARAMETERS

•EXIT MENU

1. Press MENU button on keypad.

2. Enter SERVICE MENU.

3. Enter Service code 8934.

EDIT PARAMETERS

Parameter

Name

Cold Units

(Stero Cold SU-L)

(Glass Washer:

Stero Cold SG)

Hot Units

(Stero Hot SU-H) Description Possible Values Default Values

Model Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

Select

programming

for appropriate

model of

dishwasher.

Stero Hot SU-H

Stero Cold SU-L

Stero Cold SG

LXeH Base Hot

SG, SU-L, SU-H DISHWASHERS - SERVICE PROCEDURES AND ADJUSTMENTS

F45577 (1215) Page 18 of 59

EDIT PARAMETERS

Parameter

Name

Cold Units

(Stero Cold SU-L)

(Glass Washer:

Stero Cold SG)

Hot Units

(Stero Hot SU-H) Description Possible Values Default Values

Booster

Temp Set

Pt.

N/A Stero Hot SU-H

Booster

temperature

set point.

FSP -12 to FSP +12 FSP 0

Sump

Temp Set

PT.

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

Sump

temperature

set point.

120-170°F/49-77°C

130°F / 54°C

(Stero SU-L &

SG)

165°F / 77°C

(Stero SU-H units

only)

Detergent

Pump

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H Detergent

pump option. Disabled / Enabled Enabled

Detergent

Flow Rate

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

Detergent flow

rate measured

in mL per cycle.

OFF through 20.0 mL 7.9 mL

Rinse Aid

Pump

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

Rinse Aid

pump

operation.

Disabled / Enabled Enabled

Rinse Aid

Flow Rate

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

Rinse aid flow

rate measured

in mL per cycle.

OFF through 8.8 mL 1.8 mL

Sanitizer

Flow Rate

Stero Cold SU-L

Stero Cold SG N/A

Sanitizer flow

rate measured

in mL per cycle.

Off to 100 mL 60 mL

Detergent

PWM Freq

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

DO NOT

ADJUST.

Contact Stero

technical

support.

5000-50,000 (by

1000's) 10,000

Rinse Aid

PWM Freq

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

DO NOT

ADJUST.

Contact Stero

technical

support.

5000-50,000 (by

1000's) 10,000

Sanitizer

PWM Freq

Stero Cold SU-L

Stero Cold SG N/A

DO NOT

ADJUST.

Contact Stero

technical

support.

5000-50,000 (by

1000's) 10,000

Detergent

Threshold

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

Sets maximum

allowable

chemical

sense reading

(mV) for

detergent.

0-4000 (by 100's) 1100

SG, SU-L, SU-H DISHWASHERS - SERVICE PROCEDURES AND ADJUSTMENTS

Page 19 of 59 F45577 (1215)

EDIT PARAMETERS

Parameter

Name

Cold Units

(Stero Cold SU-L)

(Glass Washer:

Stero Cold SG)

Hot Units

(Stero Hot SU-H) Description Possible Values Default Values

Rinse Aid

Threshold

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

Sets maximum

allowable

chemical

sense reading

(mV) for rinse

aid.

0-4000 (by 100's) 2500

Sanitizer

Threshold

Stero Cold SU-L

Stero Cold SG N/A

Sets maximum

allowable

chemical

sense reading

(mV) for

sanitizer.

500-4000 (by 100's) 1100

Rinse

Assurance N/A Stero Hot SU-H

Lengthens

wash time, if

necessary, to

allow booster

to heat

incoming

110°F water to

180°F. Time

may vary.

Disabled / Enabled Enabled

Soft Start

Period

Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

Reduces

voltage and

current to wash

pump at

beginning of

wash cycle for

5-6 seconds.

Lower is not

softer and

higher is not

harder. If

unsure how to

adjust, call

Stero technical

support.

1.67 ms

2.09 ms

2.50 ms

2.92 ms

3.34 ms

3.75 ms

4.17 ms

4.59 ms

5.00 ms

5.42 ms

5.84 ms

6.26 ms

6.67 ms

4.17 ms

Exit Menu Stero Cold SU-L

Stero Cold SG Stero Hot SU-H

Exits

Parameter

Menu.

SG, SU-L, SU-H DISHWASHERS - SERVICE PROCEDURES AND ADJUSTMENTS

F45577 (1215) Page 20 of 59

This manual suits for next models

2

Table of contents

Other STERO Dishwasher manuals