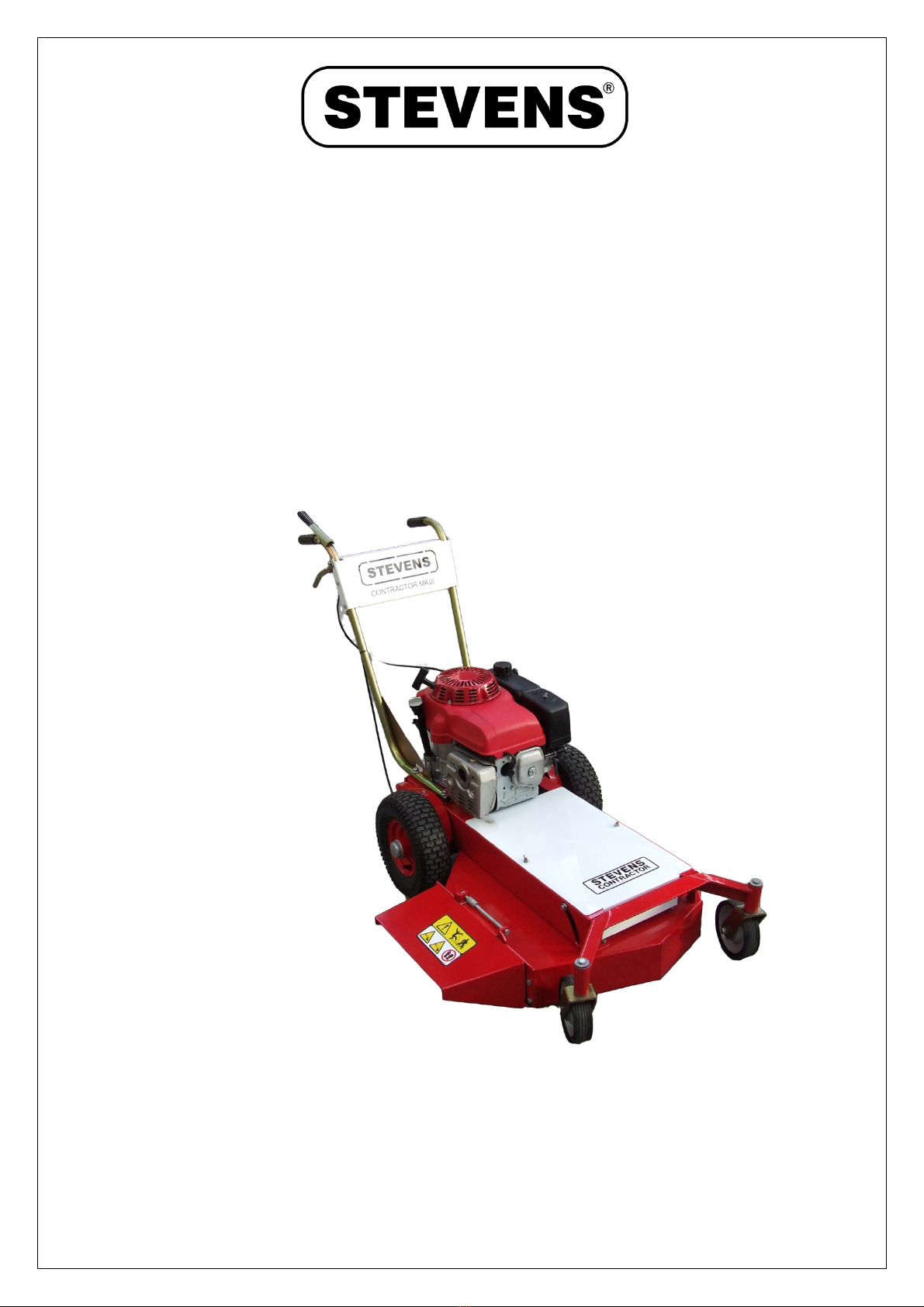

Stevens CONTRACTOR MKIII Maintenance and service guide

CONTRACTOR MKIII

OWNER’S MANUAL

Safety, Operating and Maintenance Instructions

Please read and save these instructions.

For safety, read all safety and operating

instructions prior to operating the machine. Effective date Sept 2013

2

Manufacturer’s Warranty

The Manufacturer is Stevens Products Ltd, hereinafter referred to as the ‘Manufacturer’.

The user/owner is the original purchaser, hereinafter referred to as the ‘User’.

The Manufacturer’s obligation under this warranty is limited to correcting without charge at its

factory or by one of its authorised dealers, with the Manufacturer’s approval, any parts thereof,

within 12 (twelve) months from the date of purchase by the original User, and which upon

examination shall disclose to the Manufacturer’s satisfaction to have been originally defective.

Correction of such defect by repair to, or supplying of replacements of defective parts, shall

constitute fulfilment of all obligations to the original User. The Manufacturer shall not be liable for

loss, damage, or expense directly or indirectly from the use of its product or from any other cause.

Defective parts must be returned freight paid each way by the User to the Manufacturer.

Travel time to uplift or deliver the mower is specifically excluded from this warranty.

This warranty shall not apply to any parts which must be replaced because of normal wear, or

which have been subject to misuse, negligence or accident or which have been repaired or altered

outside of the Manufacturer’s factory, unless authorised by the Manufacturer.

This warranty should not be construed as a free service period during the warranty period.

No person, agent or dealer is authorised to give any warranties on behalf of the manufacturer or to

assume from the Manufacturer any other liability in connection with any of its products unless

made in writing from the Manufacturer.

The engine is covered by a separate Engine Manufacturer’s Warranty; see Engine Manual

enclosed for details or warranty period and servicing requirements.

Stevens Products Ltd

12 Andrew Baxter Drive

Airport Oaks

Auckland 2022

New Zealand

Ph: +649 275 0443

3

Owner Information: Date of Purchase:

Purchased From:

Serial Number:

The model of your machine is CON660III

Safety Guide

Protect yourself and others by following these safety steps:

a) Know your controls. Learn how to stop the engine quickly in an emergency.

b) NEVER MOW WITH THE DISCHARGE FLAP OPEN OR BELT GUARD OFF.

c) Make sure the lawn is clear of sticks, stones, wire and debris. They could be thrown by the

blade and cause serious injury.

d) Add fuel BEFORE starting the engine. Avoid spilling petrol and do not fill the tank while the

engine is running or while you are smoking.

e) Avoid mowing while people, especially children, or pets are nearby.

f) Disengage blade and drive clutches before starting.

g) Start the engine carefully with feet well away from the blades.

h) Do not operate the engine in a confined space where carbon monoxide fumes can collect.

i) Stop the engine whenever you leave the mower, even for a moment.

j) Check all nuts, bolts, and screws often. Always be sure that the mower is in a safe

operating condition.

k) Stop the blade before driving the mower across gravel drives, walks or roads.

l) Do not allow children or people unfamiliar with the mower to operate it.

m) On slopes or wet grass, be extra careful of your footing.

n) Avoid cutting grass by pulling the mower towards you; you could pull the mower back on

top of yourself.

o) Stop the engine and disconnect the spark plug wire before checking or working on the

mower.

4

Operating your Mower

Starting the Engine

Fill the fuel tank with clean unleaded fuel and check the oil level on the dipstick before attempting

to start the engine. Open the fuel tap under the fuel tank by pushing it backward as shown on the

pictorial diagram on the top of the air cleaner cover.

Ensure the blade drive is disengaged and then open the throttle to full choke if the engine is cold.

If starting a warm engine full choke will not be necessary. Pull briskly on the starter rope and once

the engine starts throttle back to mid- revs than back to idle and allow the engine to warm up for a

few minutes.

Engaging and disengaging the Blade

To engage the blade drive belt, shift the lever at the centre rear of the mower (just below the

engine) to the right and down into the locked on position with your foot.

Use low to mid engine revs to engage and disengage. Never engage/disengage at full revs; belt

damage will occur and belt life will be shortened considerably.

Easing the drive in gently will help belt life and provide a smooth take-up for the blade drive.

To disengage, bring the engine revs back to low, then flick the lever up with your foot and push it

gently to the left to bring the blade to a complete stop.

Operator Presence Park Brake

The unit is equipped with an Operator Presence Park Brake which uses a locking pawl on both the

rear wheels. Note! It is not intended as a service brake to slow the unit down.

This brake is operated by the lever on top of the right-hand handle.

To release the brake and achieve neutral, press the operator presence handle all the way down

with the palm of your hand as you take hold of the handle bars.

Self-Propelled Forward Drive

The unit is independent rear wheel drive meaning the rear wheels can be powered independently

to aid steering and hillside traction.

To engage the drive, squeeze the levers up under the handles. To make a turn, release the side

you wish to turn towards, and the other wheel will steer the unit round.

To back up or simply push the mower without self-propel, just actuate the operator presence lever

only and the unit will free-wheel both directions.

Cutting Height Adjustment

The MKIII Contractor uses a single lever height adjustment for all four wheels. The most forward

position is the highest cutting position, the most rearward position is the lowest position. The

height of cut ranges from 1” to 4” in ½” increments. The adjusting lever is located at the left hand

rear of the machine, beside the fuel tank.

To adjust the height, pull the lever away from the body of the machine to disengage the locking pin

then while holding it out slide the lever forward or rear to the desired height and lock the handle

back into one of the available hole positions.

5

Adjustments

Blade Drive Belt Tension

The blade drive belt tension is adjustable by shifting the idler pulleys into different holes on the

arm. Setting the belt with the minimum tension required to drive will increase service life.

Remove the top spindle guard to access the two idler pulleys. The factory setting for the pulleys is

the forward one nearest the inside of the machine and the rear one nearest the outside of the

machine.

As the belt wears and stretches, it can be compensated by shifting the rear idler pulley nearer the

centre. One hole of adjustment will normally be sufficient. Any more than this will result in the belt

not disengaging when the brake is applied and will burn out the belt prematurely.

Wheel Drive Belt Tension

The cables from the operating levers to the drive levers are adjustable at both ends. Stevens

recommend adjusting the top end at the handle. You should not need to adjust the bottom end

ever. If the drive belts are slipping frequently or the levers are pulling right up to the hand grips,

Adjust the nuts to tighten the cable. Check the unit does not drive when in neutral (see ‘Operator

Presence Lever – Neutral Position’).

If replacing the cables, fit the bottom end first with the nuts backed off as far as they can go then

adjust the top end to achieve correct tension.

Gearbox Belt Tension

The gearbox belt is tensioned by a spring idler so no adjustment is necessary.

Periodically check the belt for wear; access is by removing the four bolts holding the rear closure

plate on. Check the idler bearings for free motion at the same time.

Operator Presence Lever - Neutral Adjustment

The operator presence lever can be adjusted by loosening the locknut on the countersunk bolt and

screwing the bolt further in or out as necessary. Winding the bolt further in will tighten the drive

belts and lift the levers higher; winding the bolt further out will slacken the belts and drop the

handles.

The ideal setting is as tight as can be achieved before the belts begin to drive the mower forward

with only the operator presence lever pressed down.

Tyre Pressures

The front tyres are solid rubber and not inflatable.

The rear tyres are pneumatic and should be inflated to 20 PSI. Do not inflate to the maximum

shown on the sidewall of the tyre; this will not be the ideal pressure for this application.

Throttle Cable

Periodically the throttle cable will need adjusting. With the lever pushed all the way to the left the

bottom end of the cable should just activate the rubber cover stop plunger. It will make a small

‘click’ if operating correctly. Full throttle will open the choke for starting. Hard starting may

indicate the choke is not being fully opened. To adjust the throttle, loosen the clamp over the

outer cable sheath at the engine and slide up or down as necessary to get the correct position.

Sliding it up will increase the choke and sliding it down will do vice versa.

6

Maintenance

Greasing

Grease front wheels and spindle top nipple every 25hrs. The spindle is fitted with a grease relief

valve (under the deck) so supply sufficient grease until the excess pushes out the valve.

Belts

Adjust belt tension as described under ‘Adjustments’ and replace belts when excessive wear or

damage begins to show. As belt lengths vary from different manufacturers, ensure replacement

belts are performing correctly when fitted.

Engine Oil

Check the engine oil level daily; see separate engine owner’s manual for details.

Replace engine oil at the intervals specified in the Engine Owner’s Manual.

The oil specification the units are filled with at the factory is Mineral Oil 10W30.

Spare Parts

Availability

All spare parts are available from the manufacturer should you be unable to obtain them through

your local dealer. It is the manufacturer’s objective to assist to ensure any downtime is kept to a

minimum.

Part Numbers

Ordering by part numbers will help, but we will always endeavour to have trained sales persons

familiar with your machine available to assist with parts identification.

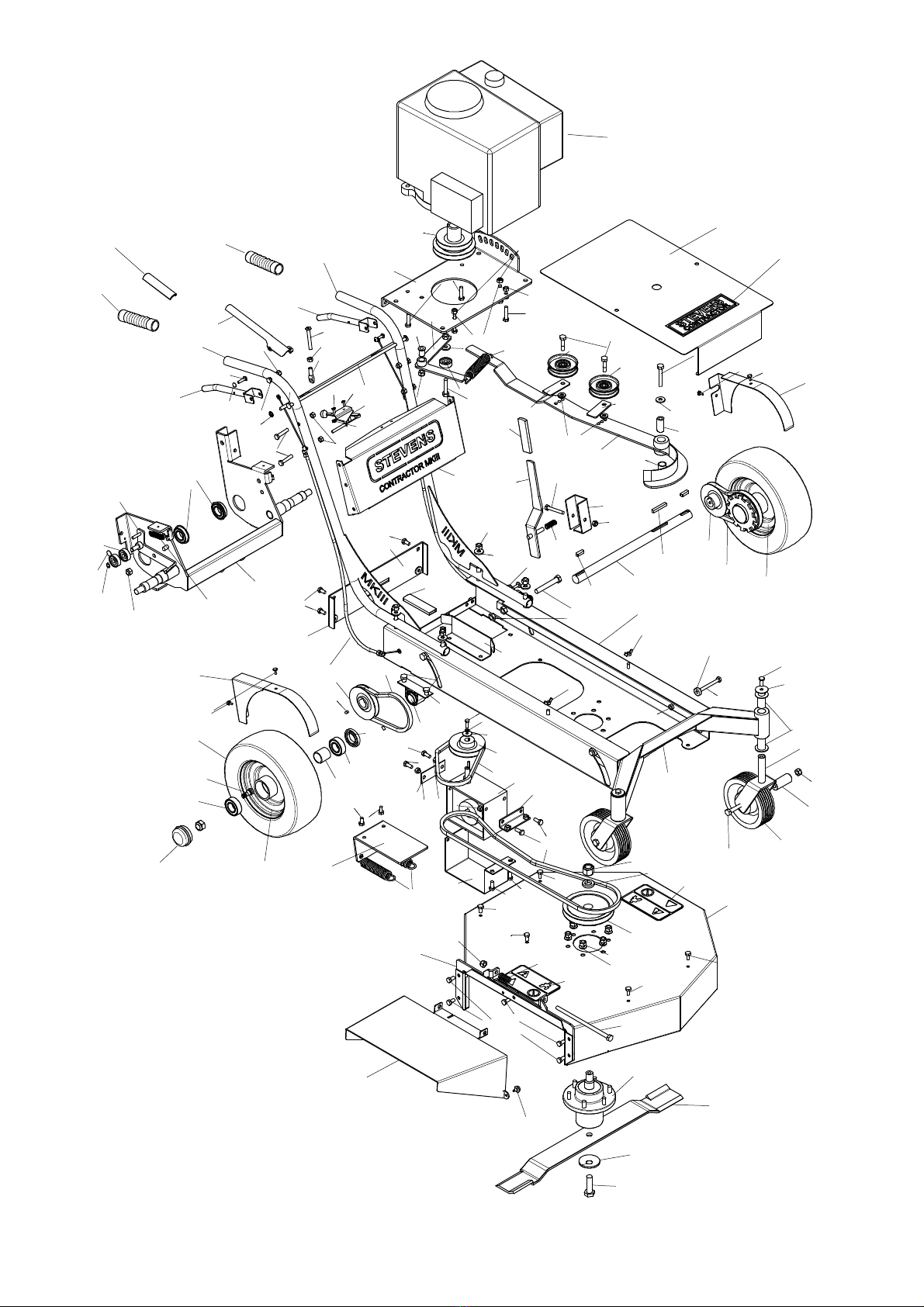

The diagram and list at the rear of this book is current at time of printing however specifications

are subject to change without notice.

Options

Mulching Kit

Stevens make a mulch kit which is available for any 660MKIII. This blocks the discharge to

provide recycling of the clippings for a well maintained lawn mowed regularly.

This kit consists of a baffle and mulch blade. The baffle can be fitted with no tools required. The

blade requires the use of a 24mm socket to remove the blade bolt and refit. If desired, the mulch

blade can be left on for side discharge as well, but it does use more horsepower.

Mud Grip Rear Tyres

Optional mud-grip rear tyres can be fitted at the factory for no extra charge or purchased as an

option later.

They provide better grip in wet or slippery situations where the regular turf pattern may clog and

lose traction.

1200

1201

1202

1203

1204

1206

1207

1208

1209

1210

1211

1212

1213

1214

1217

1218

1219

1224

1226

1228

1251

022

030

031

038

041-6

044

044

084

110

1028

1220

1221

1222

1223

1227

1229

1230

1231

1232

1233

1240

1241

1242

1242

1250

1253

1254

1255

1256

1257

70240

793778

14076-00

14076-00

14076-00

6005NR-2RS

608-2RS

6205-2N

6300-LLU

7705-1

8600-28

8600-28

A21

A21

A55

AS205

1225

SF027

SF117

SF118

SF039

SF039

SF039

SF039

SF039

SF006

SF006

SF005

SF005

SF005

SF016

SF099

SF093

SF100

SF016

SF101

SF103

SF007

SF007

SF004 SF007

SF004

SF007

SF027

SF104

SF006

SF105

SF041

SF120

SF012

SF044

SF002

SF109

SF062

SF058

SF002

SF016

SF108

SF058

SF028

SF024

SF106

SF002

SF110

5245

1233

SF024

5245

SF111

SF119

SF113

SF082

PP205

1258

SF114

782474

SF115

SF116

1261

1260

SF004

6205-2N

094

SF006

1216

1262

SF058

SF112

SF082

SF082

F002

F028

1263

SF058

029-1

SF107

SF058

1215

A21

1251

970-1

SF102

1205

6300-LLU

SF039

1028

PartNo.DescriptionQty

022FrontWheelBush2

029‐1StevensContractorDecal1

030EngineThrottleCable1

031GreaseCap2

038HondaGXV340engine1

041‐6Gearbox‐25:1ReductionRatio1

044RoundHandleGrip2

084RearWheelSeal2

094RearWheelBearingSpacer2

095SerialPlate1

110FrontWheel2

1028HeightAdjusterSpring/IdlerSpring3

1200660MKIIIChassis1

1201660MKIIIMowerBowl1

1202FrontWheelSub‐Frame1

1203RearWheelSub‐Frame1

1204EngineMountPlate1

1205GearboxBeltIdlerArm1

1206L.HHandle1

1207R.HHandle1

1208HeightAdjusterHandle1

1209L.HClutchLever1

1210R.HClutchLever1

1211L.HWheelDriveBeltTensioner1

1212R.HWheelDriveBeltTensioner1

1213GearboxAngleMountBracket1

1214OperatorPresenceActuator1

1215L.HWheelHub‐W/Pulley1

1216R.HWheelHub‐W/Pulley1

1217CastorFork2

1218DischargeOpeningStiffener1

1219RearClosurePlate1

1220DeckBeltGuide1

1221SpringAnchorPlate1

1222GearboxGuard1

1223Spindle1

1224BladeBeltTensioner1

1225SteelPivotBush1

1226EngineDrivePulley1

1227OperatorPresenceGrip1

1228GearboxInputPulley1

1229HandleFrameCrossStiffener1

1230ChuteReturnSpring1

PartNo.DescriptionQty

1231WheelDriveBeltTensionerSpring2

1232HeightAdjusterOuterGuide1

1233DeckBeltIdlerGuides2

1240DischargeChuteRubberBumper1

1241WheelDriveClutchCables2

1242CastorFork/DeckBeltBushes6

1250MainDriveShaft1

1251WheelDrivePulley2

1252DecalThrottle1

1253FabricatedChute1

1254DriveGuardL.H1

1255DriveGuardR.H1

1256TyreValve2

1257TopSpindleCover1

1258Gearboxpacker(variablethicknesstosuit)1

12607x8x50Key1

12617x8x25Key2

126210mmExternalCirclip2

1263NylonBush10x16x201

1264EngineShaftKey1/4"x40mmlong1

14076‐00FlatHandleGrip3

5245BladeIdlerPulley2

6005NR‐2RSRearHeightAdjusterBearing2

608‐2RSFrontHeightAdjusterBearing2

6205‐2NRearWheelBearing4

6300‐LLUBeltIdlerBearing6

70240RearTyre‐TurfPattern2

75440RearTyre‐MudGripPatternOPTIONAL2

7705‐1Blade1

7824745/8”DomedFlatWasher1

793778BladeSpindlePulley1

8600‐28Decal‐Warning2

970‐1HeightAdjusterHandleSpring1

A21WheelDriveBelt/GearboxDriveBelt3

A55DeckBelt1

AS205PillowBlockBearing1

PP205PillowBlockHousing1

F002F002StarLockNut2

F028F026PhilipsHeadScrew2

SF002M10HeavyFlatWasher6

SF003M8LightFlatWasher4

SF004M8NylocNut6

SF005M8x25mmHexHeadBolt6

PartNo.DescriptionQty

SF006M8x20mmHexHeadBolt6

SF007M8PlainNut8

SF012M6SpringWasher1

SF016M8x40mmHexHeadBolt6

SF0243/8"FlatWasher12

SF027M8WingNut2

SF0283/8”UNCNylocNut6

SF039M8x16mmHexHeadBolt10

SF041M10x20mmHexHeadBolt2

SF058M10NylocNut10

SF062M12Nut2

SF071M10x40mmHexHeadBolt1

SF082M6x20mmHexHeadBolt4

SF093M8x70mmHexHeadBolt2

SF099M8x60mmHexHeadBolt1

SF100M8x70mmCountersinkSocketHeadBolt1

SF1015/16"UNFx11/4"HexHeadBolt2

SF1025/16"UNFx11/2"HexHeadBolt2

SF1035/16"UNFNylocNut2

SF104M8FemaleTurnbuckleEnd1

SF105M8PanelWasher–35mmOD2

SF106M10x60mmHexHeadBolt1

SF107M10x80mmHexHeadBolt2

SF108M10x200mmHexHeadBolt1

SF109M12x80mmHexHeadBolt2

SF1103/8”UNCx1½”HexHeadBolt2

SF111M5StarDomeLockWasher2

SF112M6StarDomeLockWasher2

SF113M8StarDomeLockWasher2

SF1145/8”UNCx2”HexHeadBolt1

SF115¾”UNFNylocNut1

SF116¾”SpringWasher1

SF117M6x25mmSocketButtonHeadScrew2

SF118M6x10mmGrubscrew4

SF119M8PlainStarWasher1

SF120M6PanelWasher(1/4"x1"x16G)1

SF1217/16"UNFxHexHeadBolt1

SF1227/16"SpringWasher1