Stevens A Series User manual

TYPE A

RECORDER

Model 71, 2004

Publication 93566A

August 2004

DISCONTINUED

Contents

1. Introduction............................................. 1

1.1 General Description................................. 1

1.2 Safety Information.................................. 1

1.3 Basic Instrument Specifications................ 2

2. Installation............................................... 4

2.1 Unpacking............................................. 4

2.2 Equipment & Tools Required.................... 4

2.3 Mounting............................................... 4

2.4 Installing the Chart................................. 5

2.5 Removing the Chart................................ 5

2.6 Positioning the Pen................................. 6

3. Operation................................................ 7

3.1 Quartz Multispeed Timer Drive................. 7

3.2 The Pen................................................ 8

3.3 Gage Scales.......................................... 9

4. Maintenance............................................ 10

4.1 Care of Clocks....................................... 10

4.2 Lubrication............................................ 10

4.3 Spare Parts............................................ 10

6. Technical Notes....................................... 11

6.1 Instrument Accuracy.............................. 11

TABLES

1. Time Scales, QMT.................................... 2

2. Gage Scale, Metric................................... 3

3. Gage Scale, English.................................. 3

4 - 7 Line Shift Error .......................………… 12

8 & 9. Float Lag Error...............…................ 14

Chart Remainder Multipliers....................... 15

Safety and Equipment Protection

WARNINGELECTRICAL POWER CAN RESULT IN

PERSONNEL INJURY/DEATH OR CAN CAUSE

DAMAGE TO EQUIPMENT.

If the instrument is driven by an external power source,

disconnect the instrument from its power source before

attempting any repairs. WARNING BATTERIES ARE

DANGEROUS. IF HANDLED IMPROPERLY, THEY CAN

RESULT IN PERSONNEL INJURY/ DEATH OR CAN

CAUSE DAMAGE TO EQUIPMENT.

Batteries can be hazardous when misused, mishandled,

or disposed of improperly. They may explode or omit

poisonous substances. Batteries contain potential

energy, even when partially discharged,

WARNING

ELECTRICAL SHOCK CAN RESULT IN PERSONNEL

INJURY OR DEATH.

Use extreme caution when handling cables, connectors,

or terminals; they may yield hazardous currents if

inadvertently brought into contact with conductive

materials, including water and the human body.

CAUTION

Be aware of protective measures against environmentally

caused electric-current surges.

In addition to the previous warnings and cautions, the

following safety activities should be carefully observed.

Children- Adolescents

NEVER give batteries to young people who may not be

aware of the hazards associated with batteries and their

improper

Jewelry. Watches, Metal Tags

To avoid severe burns, NEVER wear rings, necklaces,

metal watch bands, bracelets, or metal identification tags

near exposed battery terminals.

Heat, Fire

NEVER dispose of batteries in fire or locate them in

excessively heated spaces. Observe the temperature

limit listed in the Instrument specifications.

Charging

NEVER charge 'dry' cells or lithium batteries that are not

designed to be charged.

NEVER charge rechargeable batteries at currents higher

than recommended ratings.

NEVER recharge a frozen battery. Thaw it completely at

room temperature before connecting charger.

Unvented Container

NEVER store or charge batteries in a gas-tight container.

Doing so may lead to pressure buildup and explosive

concentrations of hydrogen.

Short Circuits

NEVER short circuit batteries. High current flow may

cause internal battery heating and/or explosion.

Damaged Batteries

Personnel injury may result from contact with hazardous

materials from a damaged or open battery. NEVER

attempt to open a battery enclosure. Wear appropriate

protective clothing, and handle damaged batteries

carefully.

Disposal

ALWAYS dispose of batteries in a responsible manner.

Observe all applicable federal, state, and local regulations

for disposal of the specific type of battery involved.

NOTICE

Stevens makes NO claims as to the immunity of its equipment against lightning strikes, either

direct or nearby. The following statement is required by the Federal Communications

Commission.

WARNING - This equipment generates, uses, and can radiate radio frequency energy and, if

not installed in accordance with the instructions manual, may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference when operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause interference

in which case the user at his own expense will be required to take whatever measures may

be required to correct the interference.

USER INFORMATION

Stevens makes no warranty as to the information furnished in these instructions and the

reader assumes all risk in the use thereof. No liability is assumed for damages resulting from

the use of these instructions. We reserve the right to make changes to products and/or

publications without prior notice.

1 Introduction

1

1.1 General Description

The Stevens Type A is a float-operated

recorder that provides a permanent,

continuous, long-term graphic record of

water level fluctuations. A precision clock

movement controls the rate at which the

strip chart is advanced. The rise and fall in

of the float moves a marking stylus laterally

across the chart. The stylus or pen will

reverse at each margin so that any range

of water level stage change can be

accommodated.

The water level recording ratio, called

"gage scale", is also selectable. One

traverse across the chart width can

represent anywhere from .25 meters to

12.5 meters of water level change for

Metric models, and 1 foot to 50 feet for

English models (reference Table 5 & 6).

Chart drive is normally accomplished by

use of a battery-operated Quartz

Multispeed Timer unit, using an electronic

control circuit. A wide range of chart

speeds, called "time scales", may be

selected (reference Table 1).

1.2 Safety Information

Before performing any procedure in this

manual, read all applicable warnings and

cautions.

1 Introduction

2

1.3 Basic Instrument

Specifications

Chart Drive (options)

. Quartz Multispeed Timer (QMT)

Time Scale

. Refer to Table 1

Gage Scale

. Refer to Tables 5 and 6

Float Pulley

. 375 mm or 18 in. circumference for

beaded float line or perforated tape

. Optional 750 mm or 36 in.

circumference pulley ring for beaded

float line or perforated float tape

Operating Temperature

. QMT clock drive (alkaline batteries)

0 to +40 degrees Celsius

(+32 to +104 degrees Fahrenheit)

. QMT clock drive (lead-acid battery)

-30 to +50 degrees Celsius

(-22 to +122 degrees Fahrenheit)

Shipping Weight

. 20.5 Kg (45 pounds)

Float Line/Tape

. Stainless steel cable, 125mm or 6 in.

bead spacing

. Stainless steel tape, 125mm or 6 in.

perforation spacing

Recommended Float Size (Diameter)

203 mm (8 in), 254 mm (10 in)

Instrument Size (HxWxD, Cover open)

42 x 64 x 44 cm

(16.5 x 25.1 x 17 in)

Chart

. A-25 (Metric)

. A-10 (English)

Accessories (optional)

. Guide Pulley for float line or tape

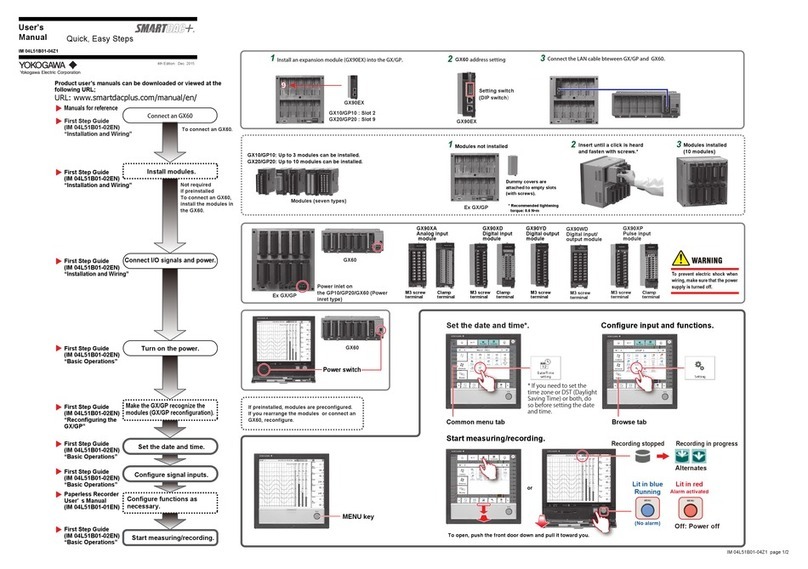

Table I

Time Scales, Quartz Multispeed Timer

(switch selectable)

Scale

cm/day

(in/day)

Major

Division

3.0 cm

(1.2 in.)

Minor

Division

.25 cm

(.1 in.)

Chart Life

1.5

(0.6)

48 hrs. 4 hrs. 4 yrs.

3.0

(1.2)

24 hrs. 2 hrs. 2 yrs.

6.1

(2.4)

12 hrs. 1 hr. 1 yr.

12.2

(4.8)

6 hrs. 30 min. 6 mos.

24.4

(9.6)

3 hrs. 15 min. 3 mos.

48.8

(19.2)

1.5 hrs. 7.5

min.

1.5

mos.

97.5

(38.4)

45 min. 3.75

min.

22.5 days

1 Introduction

3

METRIC

GAGE

SCALE

WATER LEVEL

CHANGE, ONE

TRAVERSE OF

CHART

PEN CHG.

PER

METER

OF WATER

VALUE OF

MINOR

DIVISION

FLOAT

PULLEY

SIZE

1:1 .25 m 100 cm .2 cm 375 mm

1:2 .50 m 50 cm .4 cm 750 mm

1:5 1.25 m 20 cm 1.0 cm 375 mm

1:10 2.50 m 10 cm 2.0 cm 750 mm

1:10 2.50 m 10 cm 2.0 cm 375 mm

1:20 5.00 m 5 cm 4.0 cm 750 mm

1:25 6.25 m 4 cm 5.0 cm 375 mm

1:50 12.5 m 2 cm 10.0 cm 750 mm

ENGLISH

GAGE

SCALE

WATER LEVEL

CHANGE, ONE

TRAVERSE OF

CHART

PEN CHG.

PER FOOT

OF WATER

VALUE OF

MINOR

DIVISION

FLOAT

PULLEY

SIZE

10:12 1 ft. 10 in. .01 ft. 18 in.

5:12 2 ft. 5 in. .02 ft. 36 in.

1:6 5 ft. 2 in. .05 ft. 18 in.

1:12 10 ft. 1 in. .1 ft. 36 in.

1:12 10 ft. 1 in. .1 ft. 18 in.

1:24 20 ft. .5 in. .2 ft. 36 in.

1:30 25 ft. .4 in. .25 ft. 18 in.

1:60 50 ft. .2 in. .5 ft. 36 in.

Table II. Gage Scale, Metric

Table III. Gage Scale, English

2 Installation

4

2.1 Unpacking

Remove all shipping tie-downs, packing

pieces, etc. Several parts and accessories

are individually wrapped. Check the Sales

Order to insure that all items are accounted

for before disposing of the packing

materials.

2.2 Equipment and tools required

The following equipment and tools are

usually required for proper installation of

the Type A Recorder:

Float, float pulley, counterweight, float

line or tape, and a set of end hooks.

Guide pulley (if required) and mounting

hardware.

Necessary mounting hardware and tools

(screw drivers, screws, drill, combination

pliers, etc.) as required.

2.3 Mounting

The surface on which the recorder is to be

mounted should be reasonably level. The

recorder's feet are adjustable to

compensate for minor variations. The

recorder can be positioned so that the

input pulley will hang over the edge of the

surface, or holes can be drilled in the

surface to allow for the float line or tape to

pass through. Because the carriage

reverses at each margin, the float pulley

can rotate in either direction for rising water

levels; thus the float can hang off of either

side of the pulley. Position the recorder in

its approximate final position. Final

positioning and securing will be done after

float and counterweight clearance is

checked.

Install the float pulley on the recorder input

shaft. Install the cupped washer with the

recessed side toward the pulley. Thread

the clamping disk onto the pulley shaft.

Thread the hex nut onto the shaft, and

tighten it against the pulley clamp. Loosely

tighten the right- and left-hand screws

down onto the washer, clamping the pulley

in place.

Attach the float line or tape to the two

adjustable end hooks. Adjust the length so

the counterweight does not touch bottom

when the float is at its highest point. Also

verify that the length is great enough so the

counterweight does not run into the

support shelf when the float is at its lowest

position.

A guide pulley can be used to route the

float line or tape for a vertical drop different

than just straight off the float pulley. It is

normally mounted on the underside of the

shelf, and used to shift the counterweight

drop. This is typically done to route the

counterweight out, so it does not hit a large

diameter float, or in closer, for small

diameter stilling wells.

If necessary, extra float line or tape may be

removed. Tape may be broken by sharply

bending it. Beaded float line should be cut

6mm (1/4 in.) beyond a bead to reduce

raveling. Non-beaded cable should be

heated until red hot at the desired point for

annealing, and then cut.

Attach the float and counterweight to

opposite ends of the float line or tape using

the end hooks. Lower the float into the

well. Pass the float line or tape over the

float pulley, engaging the beads or

perforations into their proper position on

the pulley. Lower the counterweight down

the opposite side.

3 Operation

5

Check the final position of the recorder to

be sure the float and counterweight can

move up and down freely, without

interference from the side of the well or any

protuberances. Secure the recorder to the

mounting surface with screws, using the

holes in the recorder feet.

2.4 Installing the Chart

Rotate the pen off the chart. Pull the

friction roller assembly away from the chart

cylinder. Lock it in place by sliding it in the

direction of the "lock" arrow. Remove the

two thumb screw from the sides of the

writing plate and lift the plate out. Remove

the take-up cylinder from the recorder.

Remove the supply cylinder (middle

cylinder) from the recorder, and remove

the large knurled nut from the end.

Observe that the core of the new chart is

flush at one end and protrudes at the other.

Slip the chart onto the supply cylinder,

flush end toward the flange, and tighten the

knurled nut firmly in place. Place the

supply cylinder in its bearings, with the

flange to the left so the chart comes off of

the top of the cylinder. Replace the take-

up cylinder.

Pass the chart behind the drive cylinder

(bottom drum) and out between the

cylinder and the friction rollers. Pull the

chart upward about 1 1/2 inches beyond

the take-up cylinder with the right edge

square to the flange. Reinstall the writing

plate. Pass the chart over the writing plate

and around the front of the take-up

cylinder. Install the half-round paper clamp

from the bottom, pressing downward.

Take the slack out of the chart by winding

the take-up cylinder upward, using the

white knurled flange. Rotate the take-up

cylinder until the chart and pen are

properly positioned for the desired start

point for recording. Unlock the friction

roller assembly and allow it to hold the

paper in place.

2.5 Removing the Chart

Lift the pen from the chart drive cylinder by

simply tilting it back. Pull the friction roller

aware from the chart and slide it in the

direction of the "Lock" arrow. Manually

advance the chart by turning the large,

white knurled disk on the left end of the

take-up cylinder. Do this until the graphic

record is just beyond the edge of the

writing plate. Using the edge of the writing

plate as a guide, cut the chart with a knife.

Lift the take-up cylinder out of the

instrument and slip off the chart. This may

require a firm twisting motion if the chart is

tightly wound. Pull or shake the chart

clamp out of the chart roll. Re-attach the

remaining chart, or install a new chart as

described in section 1.6, above. The A-10

(English) charts have a diagonal blue line

marked at the end of the chart fastened to

the core. When this line appears during

use, the remaining days of supply can be

calculated. On the A-10 chart, count the

number of small divisions (0.1 in) between

the left margin and the blue line. At a chart

speed of 2.4 inches per day, the number of

Take-up Cylinder

Supply Cylinder

Advance Cylinder

Friction

Roller

Chart

Figure 3. Chart Routing

3 Operation

6

days of chart remaining is equal to the

number of divisions counted.

The pen is a replaceable cartridge pen,

which should be replaced periodically, as

the chart line begins to dim. Simply slide

the pen out of its holder and replace it with

a new unit.

2.6 Positioning the Pen

Turn the float pulley shaft to raise the float

a short distance. Check that the pen is

moving in the desired direction. If it does

not, disengage the float line or tape from

the pulley, and rotate the pulley until the

pen is moving in the desired direction.

Then re-engage the float line or tape.

Loosen the right-and left-hand threaded

pulley clamp screws. Move the pen

carriage until the pen indicates the correct

water level, or head (do not go through a

reversal). This should be determined from

a staff gage water level reading, or by use

of a contact meter to determine well depth

at the time of installation. Retighten the

float pulley clamp screws and re-check that

nothing has slipped during tightening.

Because this sets the starting point for the

instrument, any error would affect the

complete recording.

It is good practice to write on the chart the

location, date, time scale and any other

pertinent data. These notations become

invaluable later when it comes time to

"read" the chart record.

Your recorder is now properly set up, and

recording can begin. All that is needed is

to start the clock and, if appropriate, set the

desired chart speed. Quartz Multispeed

Timer-drive units have switch selectable

chart speeds.

Sequence for chart installation

3 Operation

7

3.1 Quartz Multispeed Timer

Drive (QMT)

The Quartz Multispeed Timer unit (QMT) is

designed to operate from 6 alkaline "D" cell

batteries, which were included with the

recorder when shipped. To install the

batteries, first be sure the timer switch is

set to the "OFF" position. Remove the

QMT cover by sliding the latching plate on

the front cover to the right. Check that the

battery contacts are clean.

Observing the polarity markings in the case

(see guide, Figure 5) place the six batteries

in the main body of the timer. Note the

batteries should alternate polarity direction.

Replace the QMT cover and re-latch.

NOTE:

BE SURE THAT THE

BATTERIES ARE INSTALLED

PROPERLY (ALTERNATING POLARITY).

IF ALL BATTERIES ARE REVERSED,

THE TIMER WILL NOT RUN. HOWEVER,

IF ONLY ONE BATTERY IS REVERSED,

THE TIMER WILL RUN, BUT OVERALL

BATTERY LIFE WILL BE GREATLY

REDUCED.

Set the speed select switches to the fastest

chart speed. At this speed, the timer motor

will be pulsed approximately once a

second. By listening closely, you should

be able to hear a short, "clicking" sound

each time the motor is pulsed. If you hear

this sound, the clock is operating properly.

Set the timer to the desired chart speed to

begin recording.

If desired, the QMT can be powered from

an external source, such as a lead-acid

battery or AC power converter. Any power

source supplying 8 to 14 VDC with a peak

current capability of 300 mA can be used

to power the timer.

NOTE:

THE TIMER SHOULD NEVER

BE CONNECTED TO AN EXTERNAL

POWER SOURCE WHILE

SIMULTANEOUSLY USING INTERNAL

BATTERIES.

Remove the QMT cover by sliding the

latching plate on the front cover to the right

and remove all batteries. Referring to

Figure 6, remove the knock-out from the

main body, using a small screwdriver or

awl. Select an appropriate 2-wire cable (or

two individual wires) for the power

connection. Note: the wires should NOT

be connected to a power source while

doing this installation. Prepare the cable

end for connection to the QMT by stripping

back each wire about 6mm (1/4 in.).

Thread the cable through the knock-out as

shown in Figure 6. Loosen terminal

connection 1 and 4 on the QMT terminal

strip. Insert the negative (-) wire into

terminal 1 and the positive (+)into terminal

4. The existing wires need not be

removed. Tighten the terminal screws

back down.

If the external power source is to be

located outside the Type A Recorder,

remove the 6mm (1/1 4 in.) hole plug and

run the cable through the recorder base to

the external source.

3 Operation

8

NEW STEVENS QMT

Stevens has redesigned the Quartz

Multispeed Timer to allow for a more

efficient switch configuration for setting of

chart speeds. Below is a layout of the new

switch, located on the timer circuit board.

The switch is accessed by removing the

cover of the QMT. The chart speed switch

selections are listed on the table below.

Quartz Multispeed Timer

Switch Settings

Switch Number

Type A Type A

1 2 3 4 inches/day cm/day

ON ON ON OFF 38.4 97.5

OFF ON ON OFF 19.2 48.8

ON OFF ON OFF 9.6 24.4

OFF OFF ON OFF 4.8 12.2

ON ON OFF OFF 2.4 6.1

OFF ON OFF OFF 1.2 3

ON

OFF

OFF

OFF

0.06

1.5

NOTE:

A 1 AMP, IN-LINE FUSE IS

RECOMMENDED FOR SAFETY AND

CIRCUIT PROTECTION

WHEN POWERING THE TIMER

EXTERNALLY.

Connect the cable to the external source,

with the wire coming from QMT terminal 1

connected to the negative (-) terminal of the

source. Similarly, connect the wire from

QMT terminal 4 to the positive (+) terminal

of the source.

Replace the cover on the QMT. Set

the timer to the fastest chart speed

and listen for the "clicking" as

described previously. If operating

properly, set the timer to the desired

chart speed to begin recording.

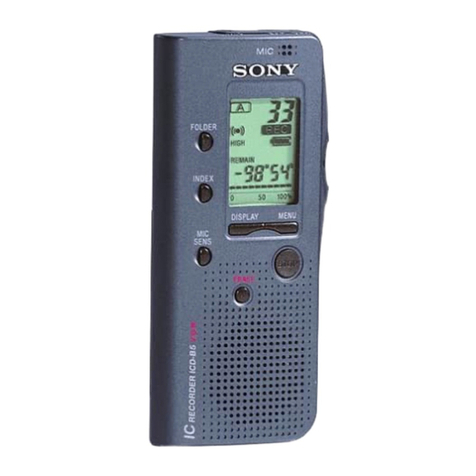

3.2 The Pen

A simple, disposable cartridge pen,

which uses a felt tip is used with the

Type A recorder. This disposable

pen uses an adapting arm to mount

3 Operation

9

between the adjustable arm's pivot screws.

Be careful not to tighten the pivot screws

too tight so as to bind the stylus arm.

The disposable cartridge pen clips into the

pen holder on the stylus arm. It is protected

by a plastic cover over the pen tip. Place

the pen in the clip, making sure it locks

firmly into place. Check for proper pen

position with reference to time and stage

level. Then remove the cover from the tip

to begin recording.

The stylus can be adjusted to insure that

reversals occur at the margin of the chart.

Loosen the adjusting arm clamp screw.

Reposition the arm and tighten the clamp

screw. It is best to align the stylus for

reversal on the left margin line, as chart

expansion due to humidity changes will

occur at the right side (the left edge of the

chart is against the flange on the take-up

and supply cylinders).

3.3 Gage Scales

Gage scales may be reconfigured by

changing either the float pulley size

or the float pulley standard, or both

(see Table 2 & 3). Standard pulleys

are either 375 mm (metric) or 18

inches (English) in circumference.

These can be doubled by the

addition of a pulley ring, thereby

doubling the amount of stage change

for one traverse of the pen across

the chart.

Several gage standards are also

available. The most common is a

direct drive standard, which provides

a moderate stage range of 1.25

meters (5 ft.) of stage recording for

each traverse of the pen. Gearing of

the gage standard makes it possible

to make the recorder more sensitive

(.25 meter or 1 ft. per pen traverse)

for greater resolution, or less

sensitive (6.25 meters or 25 ft. per

pen traverse) for greater range.

Standards can be easily

interchanged in the field for varying

conditions. However, accurate

information needs to be recorded on

the chart indicating which gage scale

was used during a particular

recording cycle. Otherwise, data will

be confusing and possibly

misinterpreted.

4 Maintenance

10

4.1 Care of clocks

4.1.1 Quartz Clocks.

Stevens Quartz Multispeed Timers

are designed for reliable operation

with very little maintenance required.

Batteries should be replaced on a

regular basis (typically every time the

chart is changed). Battery contacts

should be kept clean. No oil or other

lubricant should be used on any of

the clock's moving parts.

4.2 Lubrication

The Type A Recorder is designed

for long term operation with minimal

maintenance. Oil or other lubricants

should NOT be used on any of the

recorders mechanical parts. Sealed

ball bearings and precision

engineered plastic bearings do not

require lubrication. Oiling can cause

unwanted dust to collect.

4.3 Spare Parts

Spare parts can be ordered from

the factory. Be sure to include the

recorder serial number with any

order for parts.

5 Technical Notes

11

5.1 Instrument Accuracy

Standard float systems are subject

to small errors due to float lag and

line shift. These errors can be

minimized by selecting proper floats

and counterweights. Table 8

through 13 show the line shift errors

and float lag where standard float

systems are used. Line shift errors

can be eliminated by using special

loop line float configurations if higher

accuracy is required.

Further discussion on errors in float

operated systems can be found in

the Stevens Water Resources Data

Book, available from the factory at a

nominal cost.

5.1.1 Beaded Float Line

Standard beaded float line supplied

by Stevens is 1 mm (0.040 in.) in

diameter, and is beaded to match

the recessed grooves in the float

pulley. This stainless steel line is

slip proof, exceptionally strong, and

light weight to minimize errors.

5.1.2 Float Tape

Stainless steel float tapes are

perforated to match pulley spines at

regular intervals. Tapes are

available plain, or they may be

graduated in either English or metric

scaling (feet, tenths and hundredths

for English; meters, decimeters and

centimeters for metric). Also

available is a separate mounting

bracket with adjustable index pointer

to indicate a water level reading on

graduated tapes.

This manual suits for next models

1

Table of contents