Stienen B.E. CL-5000 User manual

USER MANUAL

CL-5000(-i) CATTLE COMPUTER

EN

© StienenBE /CL-5000-G-EN02120

Shut down power before opening the cattle computer!

This cattle computer contains exposed live parts!

Only to be opened by authorized personnel!

WARNING

Although utmost care has been given to the quality of this equipment during the design and manufacturing stages,

technical malfunctions can never be ruled out. The user should provide for an adequate alarm system

and/or emergency provisions to prevent a technical failure of the equipment and peripheral facilities

leading to danger to persons, animals or property.

NOTE DOWN THE FOLLOWING IN CASE OF AN EMERGENCY

●Possible causes

●Circumstances in which the emergency occurred

●Date and software version number

●Installer settings

Please contact our Customer Service Department, if you have any questions. Be sure to have all necessary data at

hand. To ensure a speedy solution to the malfunction and to avoid any misunderstandings, it is advisable to note

down the cause and the circumstances in which the malfunction occurred before contacting us

(www.stienenbe.com).

No part of this document may be reproduced or transmitted in any form or by any means, electronic or

mechanical, for any purpose, without the express written permission of StienenBE

StienenBE accepts no liability for the contents of this manual and explicitly waives all implicit guarantees of

merchantability or fitness for a certain use. StienenBE also reserves the right to improve or change this manual

without being under the obligation to inform any person or organisation of any such improvement or change.

StienenBE cannot be held liable for any damage, loss or injury resulting from improper use or from use not in

accordance with the instructions in this manual.

CONTENTS PAGE

INTRODUCTION 5

Window 6

Keyboard 6

Alarm key 8

Overview 9

Symbols 9

MAIN MENU 10

Access code 10

CLIMATE CONTROLS 11

House temperature 11

Relatieve of absolute temperatuurinstelling 11

Ventilation groups 12

Cooling 14

Miscellaneous 15

Compensations 16

Overviews 22

Alarm 23

TIMERS 26

Controlled timer 26

On/off timer 27

Close curtains 27

Date/Time 27

Overview 27

COUNTERS 28

Clear all counters 28

Water counter 28

Feed counter 28

Counter 3 28

Overview 28

Alarm 29

ALARM 30

Alarm status 30

Latest alarms 30

Communication alarm 30

Alarm codes 31

SYSTEM 32

Device data 32

Fahrenheit 32

Display 32

If the software version of a module or peripheral device does not comply with the

requirements of the operating software, you have to perform a software update for the

module and/or peripheral device.

CLEANING HR-SENSOR OR MEASURING FAN

WITH A HIGH-PRESSURE SPRAY GUN IS NOT ALLOWED

Remove the RH-sensor from the room and store them somewhere safe

before cleaning the room. Also screw the protection cap onto the plug of

the extension cables to prevent water from penetrating into the plug. When

connecting the sensor via a fixed socket outlet (FSO), push on the flap of

the fixed socket outlet until you hear it click (lock).

Page 5 from 32

INTRODUCTION

I/O MODULES

I/O module: You can use I/O modules to extend the number of outputs of the CL-5000 cattle computer, via

the MODULE bus. The control computer indicates which output must be driven by the CL-5000 cattle computer.

VENTILATION GROUPS

The CL-5000 cattle computer has a maximum of 9 ventilation groups divided into:

1x main ventilation group;

8x ventilation group;

MAIN VENTILATION GROUP

The 1st ventilation control in this group is the main ventilation; this serves as the reference for house

temperature and pressure control compensation. The 2nd and 3rd ventilation controls in this group are only

switched on in support of the first control and they both have their own adjustable initial percentages. All

ventilation controls have an adjustable ventilation capacity (m3/h) which is combined together the total

ventilation capacity.

CONTROLS

The cattle computer lets you choose from the following controls:

Ventilation controls

●For every control group, the cattle computer has various types of ventilation control to choose from:

●Main ventilation control, with or without measuring fans.

●Ventilation control with AQC units (automatic control flaps).

●Switching on a second and/or third fan, with or without measuring fans.

●Ventilation control with air inlet flaps.

●Ventilation control based on RH.

●Ventilation control based on wind direction and wind speed.

Temperature controls

A number of control functions are available for heating/cooling in every house; they can be applied as you like:

●2x cooling.

●4x temperature controls (for cooling/heating).

●Temperature monitoring.

Miscellaneous controls

●6x timers (can be configured as switched and/or controlled timers).

- Every timer can be provided with a twilight switch.

●1x sequential timer for brief sequential closing of the curtains (“Close curtains”).

●3x digital inputs, e.g. for twilight switches and/or counters.

The cattle computershas a memory chip which saves all settings to ensure that they are retained, even when the power is down. You will only

have to set the date and time again if the power has been down for a couple of days.

Counter positions, burning hours, current day number in the curve etc. are not stored in the memory chip. These values may be lost if the

power supply to the cattle computer has been down for a couple of days. You may then have to set the day number etc. again.

Page 6 from 32

WINDOW

When the symbol is shown in the title bar and you press function key F3, the settings are displayed

graphically with the dot (●) showing the calculated value. Press F3 again to switch off the graphic display.

Whenever a key is pressed, the display will be lit for a couple of seconds so that you can also see the settings

and measurements in a dark animal house.

SCROLL-WINDOW

If a window contains more lines than the screen can display, the title bar will show the symbol. This symbol

indicates that you can call up the remaining settings and/or measurements using the up and down cursor keys

().

KEYBOARD

2

Caution:

Only press the keys with the tip of

your finger. Sharp objects such as a

pen, pencil or screwdriver may

damage the keys!

The keyboard can be divided into

four basic groups:

1. Function keys

2. Numerical keys

3. Navigation keys

3

1

Screen number

Title bar

Column with settings and/or measurements

Column with calculated and/or

corrected settings

Graphic (function key F3)

Time & Date

You can use the

key to select the

previous control number.

You can use the

key to

select the next control

number.

Page 7 from 32

3 NUMERICAL KEYS (0..9)

The numerical keys can be used to enter a

screen number, a value or text

Entering text

Numerical keys 2..9 can be used to change

the name of a control group (left, right,

front, rear etc.), a timer or a counter. The

maximum text length is 15 characters

(including spaces). The character you enter

is shown in a little box. Press the numerical

key repeatedly until the required character is

shown. You can enter a punctuation mark by

repeatedly pressing numerical key 1 until the

required punctuation mark is shown. You can

enter a space using the 0 key.

Press once for a, twice for b etc. You can move the cursor with the and keys. Where relevant, e.g. for

menu options etc., the text will automatically start with an initial capital.

2 FUNCTIETOETSEN (GRAFIEK, ALARM, VORIGE / VOLGENDE REGELING ETC.)

Function key F1 (change language)

Changing language:

Hold down F1 and press on the left or right cursor key.

Function key F2 (change house status)

Use this function key to call up the house status.

Function key F3 (graphic)

Use this function key to place a graph on a window. The “graph” function is active when the LED in the

function key lights.

You can switch off the “graph” function by pressing the function key again (the LED

in the key is off then).

The values in a graph are linked to the window on the basis of which the graph was drawn up. The graph is

updated automatically when you change the details in the window.

If the details in the window are displayed in graph form, the symbol will be displayed in the top right corner

of the menu line.

Select previous / next control

Select previous / next control.

If controls of the same type, e.g. ventilation groups (left, right, recirculation etc.), are

available, you can use these keys to select the previous or next control.

deféčęë3DEFÉČĘË

abcŕâćç2ABCŔÂĆÇ

mnońôöś6MNOŃÔÖŚ

jkl5JKL

wxyz9WXYZ

tuvű8TUVŰ

.,1'-:+

ghiîď4

GHIÎĎ

pqrs7

PQRS

_0

Page 8 from 32

ALARM KEY

Hot key for alarm screen. The LED in the alarm key lights if there is an alarm on one of the controls.

Here you can switch the main alarm on and off. When the main alarm is off, the LED in the alarm key will flash

to indicate that the main alarm is off. No alarm is generated anymore.

Test (alarm test)

Test “yes”: This enables you to test the operation of

the alarm relay (siren). If you enter "yes" in the line

Test, the alarm relay (siren) will be switched on for

10 seconds.

You can clear the alarm test time by setting "no" in

the line Test.

(alarm temporary off)

Off “yes”:This enables you to temporarily switch off

the alarm (siren). This does not apply to the hardware

alarms which cannot be switched off temporarily. The

main alarm is switched off for 30 minutes (the lamp

will blink irregularly). The main alarm is switched on

automatically again after 30 minutes. The alarm relay

will then de-energize again, causing an alarm, if the

cause of the alarm has not been removed.

You can clear the temporary alarm deactivation time

by setting "no" in the line .

If no access code has been installed or if you have already entered the correct access code, you can switch off

the main alarm.

Attention:

NEVER FORGET TO SWITCH THE ALARM BACK "ON" when you have switched this feature off

'temporarily', e.g. to solve a problem. Failing to switch it back on may have adverse effects for

humans, animals, equipment or property.

Preferably use the (alarm retard) function to solve a problem.

3 NAVIGATION KEYS (MENU, CURSOR, MODE)

(Cancel)

This key cancels changes or menu option selections.

Press and hold this key to select the main menu.

(Move cursor)

Move cursor

Holding down: move cursor to first/last setting on the screen.

Move cursor or change value

(Confirm)

Menu option selection

Start change

Confirm change

●The cursor is displayed as a black rectangle, e.g. .

●While a change is being made, the cursor is displayed as a black border, e.g. .

Page 9 from 32

OVERVIEW

Column number 1 2 3 4 5 6

SYMBOLS

Column

number

Symbol Description

1 Alarm ventilation group (alarm delay time is not yet elapse)

1 Alarm ventilation group (alarm delay time is elapse)

1 Alarm ventilation group is switch off

2 “” Name ventilation group

3 Temperature ventilation group in °C

4

Graphic bar current temperature ventilation group

5 Ventilation of the ventilation group in %

6

Graphic bar current ventilation of the ventilation group

The current house temperature is shown on the display. If an outdoor sensor has been installed, the current

outside temperature is also shown. If the CL-5000 has an RH sensor, the display shows the current RH.

Page 10 from 32

MAIN MENU

If you use access codes, it is advisable to write the code down and store it

somewhere safe. If you forget the access code, you can no longer change

any settings. As soon as one access code is active, you can only change

the setting by entering the correct access code. The access code remains

active until you select the “Overview” window. After selecting this window

you will have to enter the access code again to be able to change a

setting.

ACCESS CODE

You can use an access code to protect your computer against unauthorized access. If you want to prevent non-

authorized users from changing settings on your cattle computer, you can have an access code set.

An access code consists of a combination of 4 figures. You can have an maximum of 2 access codes set by your

installer.

Page 11 from 32

CLIMATE CONTROLS

HOUSE TEMPERATURE

The temperature used as the reference value for controlling the

ventilation groups, coolers and heaters is called the house temperature.

Note!

If you set a low house temperature, take into account that

there is a risk of the water freezing in winter.

RELATIEVE OF ABSOLUTE TEMPERATUURINSTELLING

Control Relative setting Absolute setting

Fans

Always relative to temperature in

the house

n.a.

Ventilation groups

(left/right/front/ etc.)

Always relative to temperature in

the house

n.a.

Cooling 1 and 2

n.a.

These are always absolute

temperature settings.

Recirculation

Temperature 2 .. 4

n.a.

These are always absolute

temperature settings.

Relative

:

The temperature control works with a differential temperature compared to the preset house

temperature. The temperature control is based on the preset house temperature. E.g. if you set a

differential temperature of 5.0ºC and the preset house temperature is 20.0ºC, the temperature

control will work as follows: 20.0ºC+5.0ºC = 25.0ºC. If you now change the house temperature to

18.0ºC, the temperature control will change the temperature as follows: 18.0ºC+5.0ºC = 23.0ºC.

Absolute

:

The temperature control works with absolute temperature settings. E.g. if you set the temperature

to 5.0ºC, the output control operation will also be based on 5.0ºC. The temperature control works

independently of the preset house temperature.

Page 12 from 32

VENTILATION GROUPS

With fan group

TEMPERATURE SETTING

The temperature on the basis of which the main ventilation group controls; this setting is relative to the house

temperature. The calculated temperature on the basis of which the ventilation group controls is shown behind

the temperature setting.

BANDWIDTH

The bandwidth determines the 'sensitivity' of the fan. A short bandwidth will cause the fan to react to a rise in

temperature very quickly. This is not good for the climate in the house, since it will result in too many

ventilation variations.

MINIMUM VENTILATION

You set the lower limit for ventilation in the “Minimum ventilation” line.

MAXIMUM VENTILATION

You set the upper limit for ventilation in the “Maximum ventilation” line.

CURRENT TEMPERATURE

This line shows the current temperature on the basis of which the ventilation group is controlling.

CURRENT VENTILATION

If the fans are controlled using a measuring fan, the measured and calculated ventilation values will be shown in

this line. If the fans do not have measuring fans or if a measuring fan is defective, the calculated ventilation will

be equal to the “measured” ventilation.

The current ventilation is calculated on the basis of the bandwidth and the minimum and maximum ventilation

settings.

CAPACITEIT

The calculated ventilation is expressed here in m3/h.

Bandwith

Minimum

Maximum

Ventilation [%]

Temperature setting

Temperature [°C]

Current temperature

Current ventilation

House temperature

Page 13 from 32

OPTIONS

START FAN 2 / FAN 3

If the fan group consists of multiple fan controls, you have to set the

percentage at which the 2

nd / 3rd fan control have to be switched on

(switch

-on percentage relative to the total capacity of the controlled fan

group) behind “Start fan 2” and/or “Start fan 3”.

Behind ”Proportional

Step” the number of the fan controls which is

currently switched on (

1= 1st fan control, 2= 1st and 2nd fan control, 3

=

1

st, 2nd and 3rd fan control) is displayed.

AQC-FLAP

Minimum flap opening

Maximum flap opening = 100%

Flap opening [%]

Minimum

at ventilation

Main ventilation [%]

Current

ventilation

Current flap opening

Maximum

at ventilation

The AQC flap controls on the basis of the calculated ventilation of the 1st fan control. The maximum flap position

is 100% and is not adjustable.

Without fan group

Emergency stop active

TEMPERATURE SETTING

The temperature on the basis of which the ventilation group controls; this setting is always relative to the house

temperature. The calculated temperature on the basis of which the ventilation group controls is shown behind

the temperature setting.

BANDWIDTH

The bandwidth determines the 'sensitivity' of the control. A short bandwidth will cause the control to react to a

rise in temperature very quickly. This is not good for the climate in the house, since it will result in too many

ventilation variations.

MINIMUM AND MAXIMUM FLAP OPENING

The minimum and maximum flap opening can be set here.

CURRENT TEMPERATURE

The flap opening requirement is calculated on the basis of the temperature measured, the bandwidth, the

minimum and maximum flap opening.

CALCULATED FLAP OPENING

The flap opening requirement is calculated on the basis of the temperature measured, the bandwidth, the

minimum and maximum flap opening

Page 14 from 32

CURRENT FLAP OPENING

The current flap opening of the ventilation group is shown in this line.

The ventilation groups “Left/Right/Front and Rear” are identical as regards their settings and they

are all set in a similar manner.

COOLING

On/Off cooling

Proportional cooling

COOLING

This line enables you to switch the cooling on or off.

TEMPERATURE SETTING

The temperature setting is relative to the house temperature if the setting is below 10.0ºC. If a temperature

equal to or higher than 10.0ºC is set, this will be an absolute temperature setting.

BANDWIDTH

The bandwidth determines the 'sensitivity' of the cooling. A short bandwidth will cause the cooling to react to a

rise in temperature very quickly. This is not good for the climate in the house, since it will result in too many

temperature variations.

MINIMUM AND MAXIMUM COOLING

You set the lower limit for the cooling at “Minimum cooling” and you set the upper limit at “Maximum cooling”.

MAXIMUM/CURRENT RH

To prevent the humidity in the house from becoming too high due to cooling, the cooling can be switched off by

the RH. If the relative humidity rises to above the preset value, the cooling will be switched off. If the relative

humidity rises to above the preset value + hysteresis, the cooling will be switched off. If the RH falls to below

the preset value afterwards, the cooling will be switched on again. The default hysteresis setting is 2%.

CURRENT TEMPERATURE

The current average cooling control temperature is shown in this line.

Current cooling

This line displays the current status, on / off, of the cooling. The current cooling rate is also shown in this line. If

-0% is calculated for the current cooling rate, the drive signal generated will be 0V instead of the minimum

voltage setting.

Running hours

At an on/off controlled (not modulating) cooling it is possible to g

et an

overview of the running hours (time cooling on). Beside the hours of

today the running hours of the past 7 days and the total number of hours

is shown.

If you changed the setting “Clear running hours” to “yes”, the running

hours of the selected

cooling will be cleared.

Page 15 from 32

MISCELLANEOUS

HUMIDIFICATION

This window enables you to switch the humidification control on or off and

to set the relative humidity percentage. Below this percentage the

humidification control is active.

TEMPERATURE MONITORING (THERMO-DIFFERENTIAL)

The temperature monitoring function is activated by your installer (max. 4 sensors).

The current measurement of each sensor is compared with the

measurement of one minute ago. Is the temperature increase in tha

t

minute greater or equal than the relative limits an alarm is given. If the

measurement is within the limits, the previous measurement is made

equal to the current measurement and a new measurement is started.

Increases the temperature of the sensor abov

e the absolute limit, then

there is also alarm.

The temperature monitor alarm occurs only when a positive difference is

detected (not when the temperature drops down).

RECIRCULATION

One of the purposes of using the recirculation control is

to cool the house.

If the temperature rises to above the temperature setting, the

recirculation control will be switched on. If the temperature then drops to

below the pre

-set value – the hysteresis setting -

, the recirculation control

will be switched of

f again (your installer can set a switching hysteresis of

a maximum of 5.0 °C).

1 minute

Current measurement

Measurement of 1 minute ago

Temp. difference

Page 16 from 32

TEMPERATURE 2/3/4

Heating/cooling

You can switch the heating/cooling On/Off here.

Temperature setting

This is the temperature at which the heating/cooling controls. This setting is always an absolute setting.

Bandwidth

The bandwidth determines the 'sensitivity' of the heating/cooling. A short bandwidth will cause the

heating/cooling to react to a rise in temperature very quickly. This is not good for the climate in the house, since

it will result in too many temperature variations.

Minimum/maximum

Heating:

You can use the "Minimum heating" setting to limit the minimum force (heating capacity) of a

controlled heating to a minimum percentage. You can use the "Maximum h

eating" setting to limit

the maximum force (heating capacity) of a controlled heating to a maximum percentage.

Cooling:

You can use the "Minimum cooling" setting to limit the minimum force (cooling capacity) of a

controlled cooling to a minimum percentage. You can use the "Maximum cooling" setting to limit the

maximum force (cooling capacity) of a controlled cooling to a maximum percentage.

Current temperature

The current average heating/cooling temperature is shown in this line.

Current heating/cooling

The current status of the heating/cooling is displayed. If -0% is calculated for the current heating/cooling, the

drive signal generated will be 0V instead of the minimum voltage setting. This line is only shown with 0-10V

controlled cooling/heating.

COMPENSATIONS

If both RH compensation and CO2compensation are active, the highest compensation value is used for

ventilation correction.

Min.

Max.

Bandwidth

Temperature setting

RH-compensation

Page 17 from 32

RH

RH compensation only influences ventilation/flap position. This means that the ventilation/flap position effort will

be greater if the value measured is higher than the value set for “RH compensation”.

If 0.0 is set, this means that RH

compensation does not affect the

ventilation and/or the flap position.

If 9.9 is set, RH compensation has a

maximum effect on the ventilation

and/or the flap position.

The corrected ventilation and/or the

flap position is limited by the pre-

set maximum (Max.).

Compensation = (((current RH – RH compensation start) * RH-compensation factor ) / 100%) * calculated

ventilation

CO2

CO2 compensation only influences ventilation/flap position. This means that the ventilation/flap position effort

will be greater if the value measured is higher than the value set for “CO2 compensation”.

If 0.0 is set, this means that CO2

compensation does not affect the

ventilation and/or the flap position.

If 9.9 is set, CO2 compensation has

a maximum effect on the ventilation

and/or the flap position.

The corrected ventilation and/or the

flap position is limited by the pre-

set maximum (Max.).

Compensation = (((current RH – RH compensation start) * factor *(current absolute air humidity house air -

current absolute air humidity outside air)) / 100%) * calculated ventilation.

Before cleaning the room, remove the HR and or CO2 sensor and screw the

protection cap onto the extension cables

METEO

Wind compensation takes place

after RH compensation, if

applicable.

With weather station (wind sensor)

Without weather station (wind sensor)

Wind influence (default)

Wind influence from

The ventilation/flap positions are not influenced until the wind exceeds

this value.

Wind speed

This line shows the current wind speed.

Wind direction

This shows the current wind direction.

Page 18 from 32

Wind influence of outside temp.

Here you can set whether the outside temperature should influence the wind compensation.

0,0

1,0

Outside temp. correction

Max. influence below

Temperature [°C]

Current outside temperature

No influence above

Max. influence below

Ventilation/flap positions will experience

maximum influence of the wind if the actual

outside temperature is lower than this value.

No influence a

bove

Ventilation/flap positions will not experience any

influence of the wind if the actual outside

temperature is higher than this value.

Outside temperature: Current outside temperature.

Wind influence (for all ventilation groups)

The wind influence can be adjusted from 0 to 9 (0 = no influence, 9 = maximum influence). You can set specific

factors for the individual sides (wind side, sheltered side and perpendicular side). The wind influence can be

corrected by the outside temperature.

Wind influence (can be set for every individual ventilation group)

You can set the influence of the wind on the ventilation per ventilation group. You can only set the "Influence

wind per ventilation group" if your installer has activate this option.

Influence of wind (absolute)

The influence of the wind is adjustable between 0..9 per ventilation group (0 = no influence, 9 = maximum

influence). You can set a factor for each side (Windward side, Leeward side and Crosswind). The wind influence

can be corrected by the outside temperature (see "Influence of wind outside temp." on previous page).

Example:

Calculated ventilation on the left:

30%

Calculated ventilation on the right:

30%

Calculated ventilation front:

5%

Calculated ventilation rear:

5%

Wind influence from:

3.0 m/s

Current wind speed:

7.5 m/s

Current wind direction

right

Wind influence

(factor)

Wind side:

6

((7.5-3.0) / (10-3.0))*6.0 * 10 = 39% (38.57%)

Sheltered side:

2

((7.5-3.0) / (10-3.0))*2.0 * 10= 13% (12.86%)

Perpendicular side:

2

((7.5-3.0) / (10-3.0))*2.0 * 10= 13% (12.86%)

Corrected ventilation on the left:

30 – 13 = 17%

Corrected ventilation on the right:

30 - 39 = -9% becomes 0%

Corrected ventilation front:

5 - 13 = -8% becomes 0%

Corrected ventilation rear:

5 - 13 = -8% becomes 0%

Influence of outside temperature:

yes

Current outside temperature:

-2.0 °C

Max. influence below:

-10.0 °C

No influence above: +10.0 °C

Outside temperature correction:

(10.0 - -2.0)/(10.0 - -10.0) = 0.6

Corrected ventilation on the left:

30 - (12,86*0,6) = 22,3% becomes 22%

Corrected ventilation on the right:

30 - (38,57*0,6) = 6,86% becomes 7%

Page 19 from 32

Corrected ventilation front:

5 - (12,86*0,6) = -2,72% becomes 0%

Corrected ventilation rear:

5 - (12,86*0,6) = -2,72% becomes 0%

Wind compensation (absolute) = ((Cur. wind speed – Wind influence from) / (10 – Wind influence from)) * 10 *

factor

Influence of outside temperature = (No influence above – Cur. outside temp.) / (No influence above – Max.

influence below)

Influence wind (relative)

Example:

Calculated ventilation on the left:

30%

Calculated ventilation on the right:

30%

Calculated ventilation front:

5%

Calculated ventilation rear:

5%

Wind influence from:

3.0 m/s

Current wind speed:

7.5 m/s

Current wind direction

right

Wind influence (factor)

Wind side:

6

((7.5-3.0) / (10-3.0))*6.0 * 10 = 39% (38.57%)

Sheltered side:

2

((7.5-3.0) / (10-3.0))*2.0 * 10= 13% (12.86%)

Perpendicular side:

2

((7.5-3.0) / (10-3.0))*2.0 * 10= 13% (12.86%)

Corrected ventilation on the left:

30-((30*12,86)/100)=30-3,86 becomes 26%

Corrected ventilation on the right:

30-((30*38.57)/100)=30-11,57 becomes 18%

Corrected ventilation front:

5-((5*12,86)/100)=5-0,63 becomes 4%

Corrected ventilation rear:

5-((5*12,86)/100)=5-0,63 becomes 4%

Influence of outside temperature:

yes

Current outside temperature:

-2.0 °C

Max. influence below:

-10.0 °C

No influence above:

+10.0 °C

Outside temperature correction:

(10.0 - -2.0)/(10.0 - -10.0) = 0.6

Corrected ventilation on the left:

30 - (3,86*0,6) = 27,7% becomes 28%

Corrected ventilation on the right:

30 - (11,57*0,6) = 23,1% becomes 23%

Corrected ventilation front:

5 - (0,63*0,6) = -4,6% becomes 5%

Corrected ventilation rear:

5 - (0,63*0,6) = -4,6% becomes 5%

Wind compensation (relative) = Calculated flap position - ((ABS(((Current wind speed – Wind influence from) /

(10 – Wind influence from)) * 10 * factor) * Calculated flap position)/100

Influence of outside temperature = (No influence above – Cur. outside temp.) / (No influence above – Max.

influence below)

Flap closes when wind

If it blows more than the set value,

the flap (curtain) is sent to the set

"Minimum flap opening" (default

value is 000%).

If the installer has set at the selected flap (curtain) to close if it is blowing more than behind "Wind influence

from", the text "Flap closes when wind" appears on the screen.

Page 20 from 32

No influence

If the installer has disabled the ventilation group compensation, the text

"No influence" is displayed.

Rain influence (can not be adjusted per ventilation group)

Without an anemometer (weather station)

With an anemometer (weather station)

If the rain influence has been activated by the installer and the current rain level increases to above the rain

level setting, the calculated flap position will be made equal to “Max. vent.” (the desired flap position when it

rains). This is only done if the rain flap position is lower than the current calculated flap position based on

temperature.

Rain influence

This control limits the curtain openings (ventilation) on the rain and perpendicular sides to prevent rain

entering. You can activate/deactivate the influence of the rain on the curtain opening in this line.

Current rain level

This line shows the current rain level.

Rain level setting

Here you set the rain level at which the control should become active (1= minor rain, 9 = heavy downpour).

Wait after rain

After rain, the CL-5000 will wait for a certain time before the flaps are sent a control signal again, based on

temperature. You can enter this waiting time in this line. The remaining waiting time is shown next to this (is

only shown after rain).

Wind side / perpendicular side

Enter the maximum flap position for the wind side during rain here. When the rain level exceeds the pre-set

threshold (“rain level setting”) and the wind speed exceeds the pre-set value (“From”), the maximum flap

position is limited to the pre-set value (“Max.vent.”). You can set separate values for the wind side and for the

perpendicular side.

From

Enter the wind speed at which the curtains should go to their “maximum rain position”.

Maximum vent.

Enter the maximum position when it rains here.

Maximum ventilation

If no wind sensor (weather station) has been activated, you can set the maximum position of the curtains here.

This manual suits for next models

1

Table of contents

Other Stienen B.E. Desktop manuals

Popular Desktop manuals by other brands

Werner

Werner PROPLUS Base Pack 1 instruction manual

Dell

Dell Precision D490 Quick reference guide

GÜNZBURGER STEIGTECHNIK

GÜNZBURGER STEIGTECHNIK FlexxTower 125100 manual

Biostar

Biostar IDEQ 200S user manual

Steelcase

Steelcase RoomWizard user guide

Sony

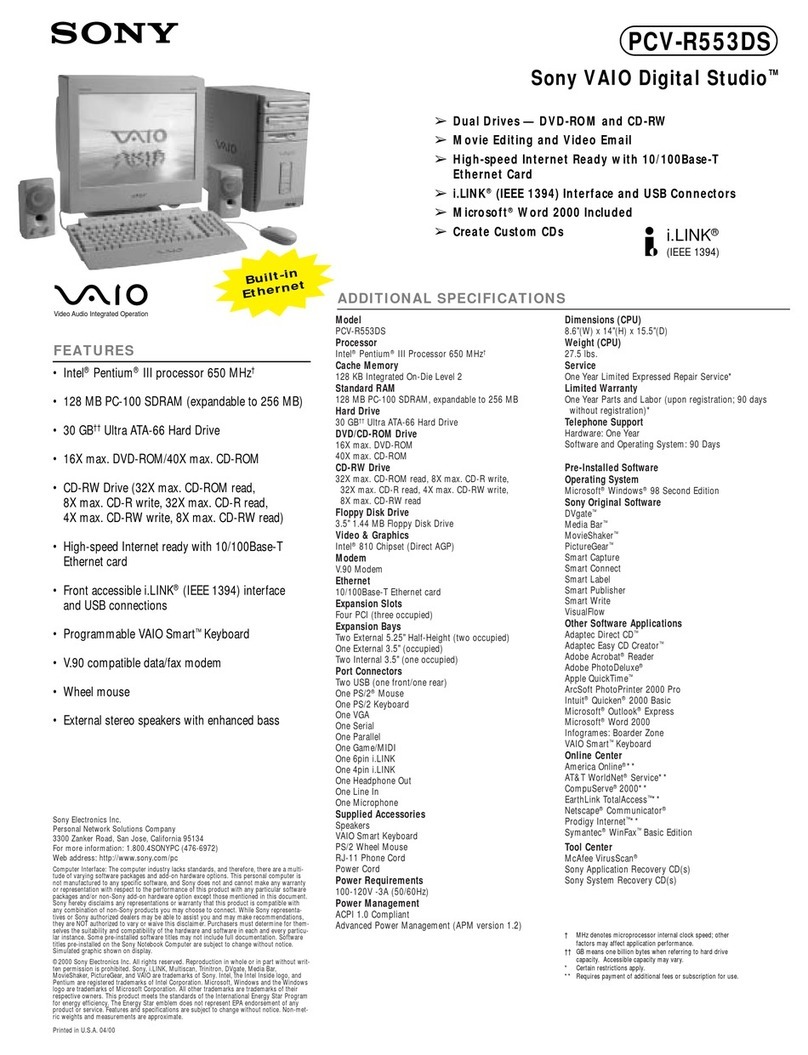

Sony PCV-R553DS - Vaio Digital Studio Desktop... Specifications