STINAR TV-550 Manual

sales@stinar.com |P651.454.5112 |F651.454.5143 |www.stinar.com

FLIGHT LINE TOW TRACTOR

OPERATION & MAINTENANCE MANUAL

MODEL: TV-550

RE V.07.2021

FLIGHT LINE TOW TRACTOR TV-550| 2

Table of Contents SECTION 1 | GENERAL INFORMATION & OPERATING

PROCEDURES � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

1�1 | Description � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

1.1.1 | Equipment Systems and Components . . . . . . . . . . . . . . . . . . . . 7

1.1.1.1 | Truck Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.1.2 | Modification to the cab include: . . . . . . . . . . . . . . . . . . . . . . . . . . 7

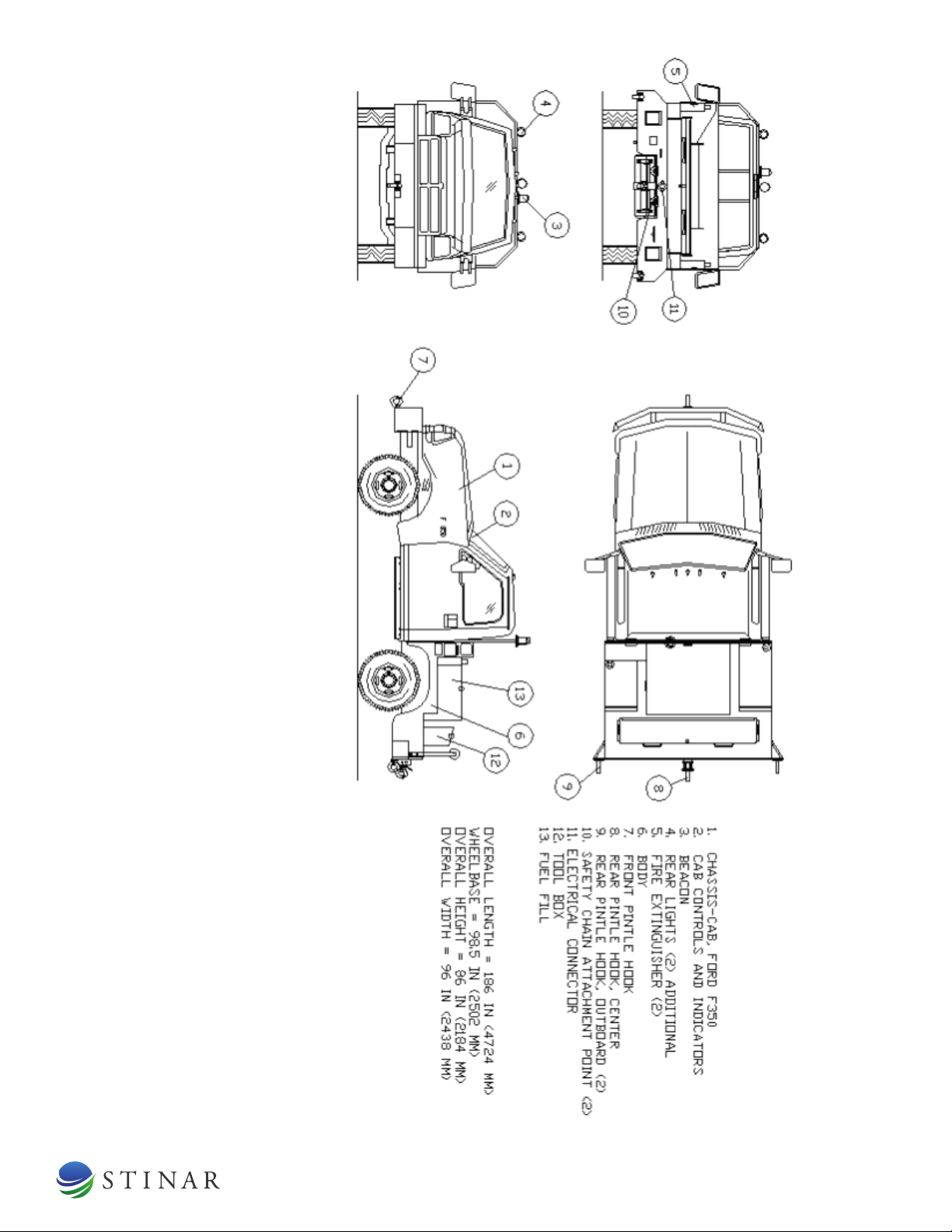

Figure 1.1.1 | Flight Line Tow Tractor, Model TV-550 . . . . . . . . . . . . . . . . . . .7

1.1.1.2 | Body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.1.3 | Pintle Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.2 | Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.2.1 | Relays and Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.2.2 | SAE J560b Receptacle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.3 | Winterization Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

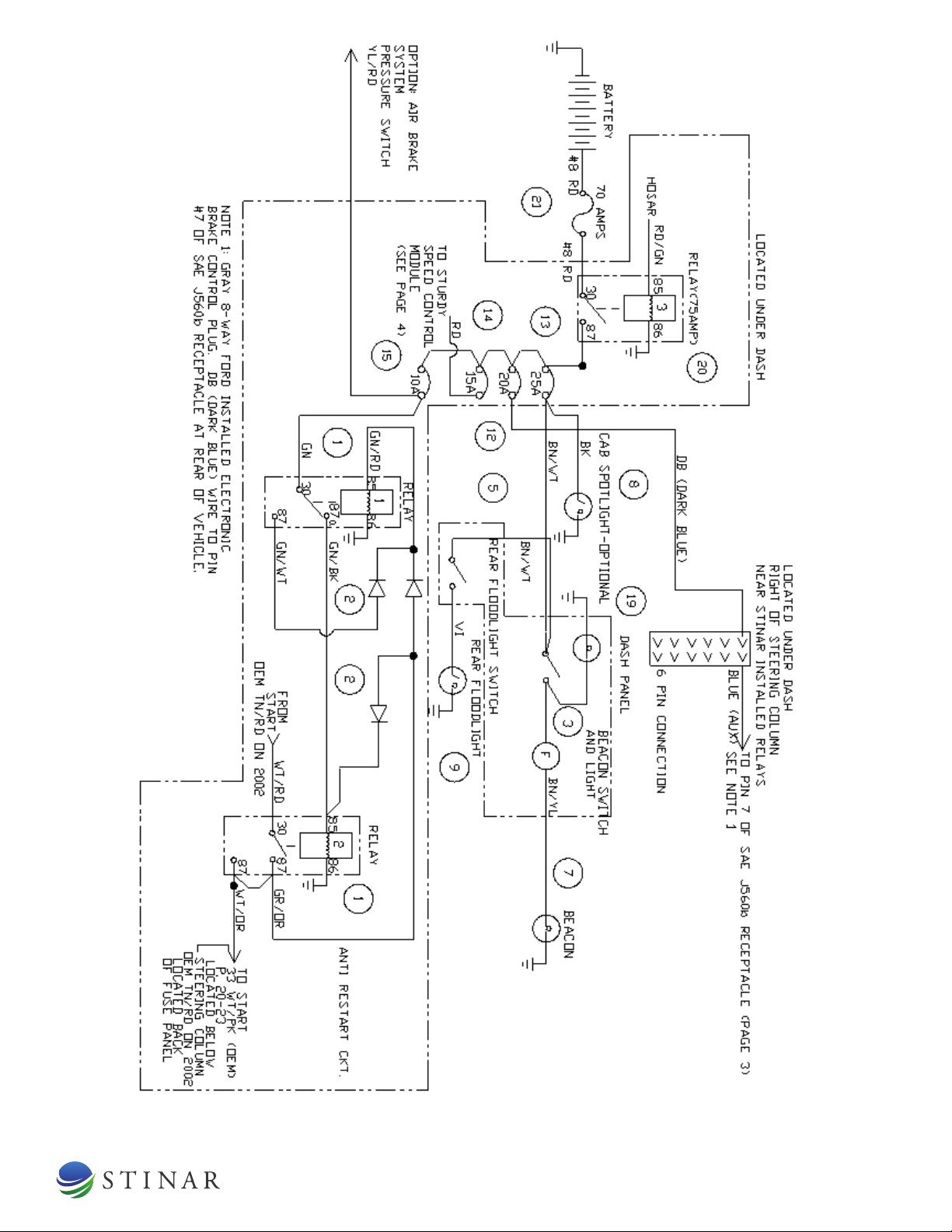

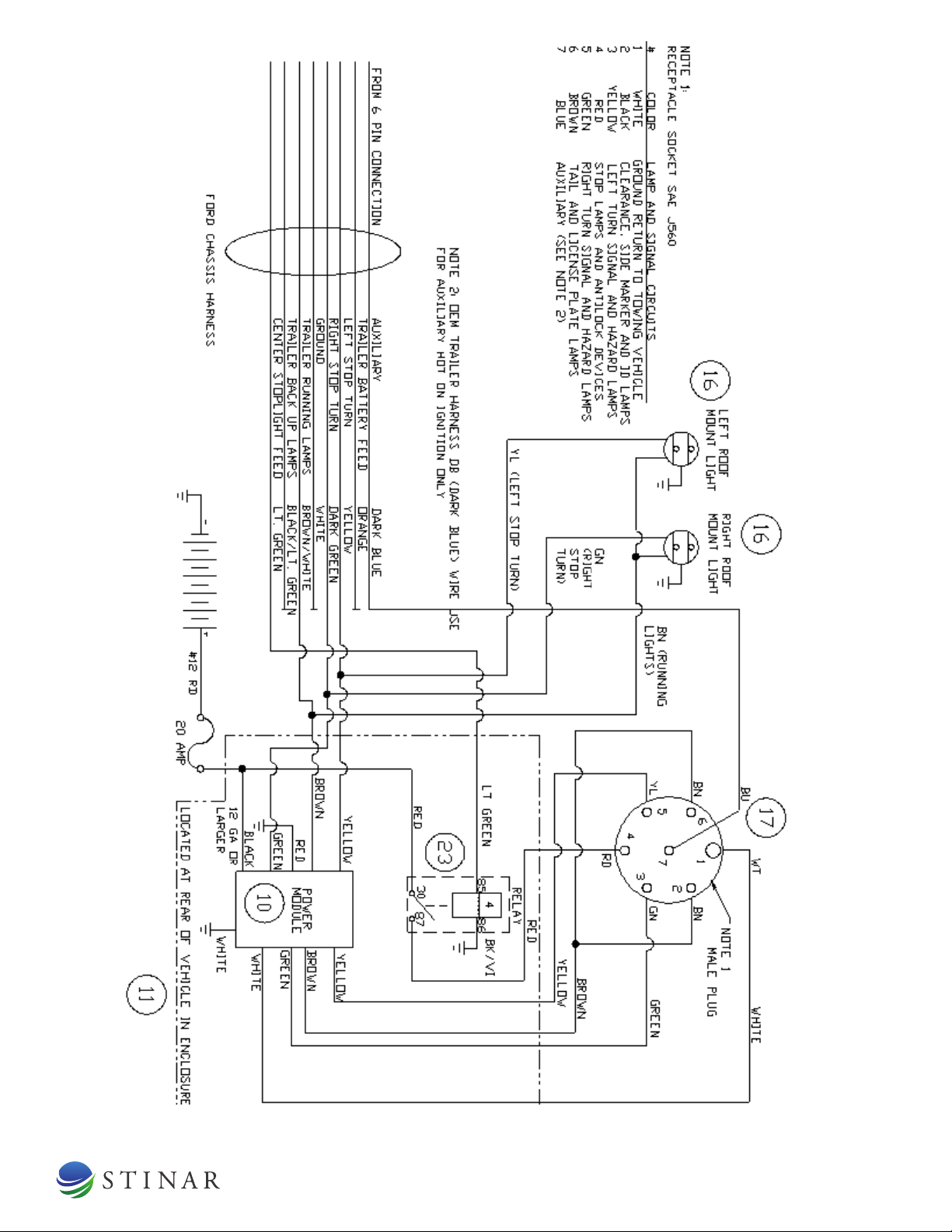

Figure 1.1.2 | Electrical Schematic (Page 1 of 4) . . . . . . . . . . . . . . . . . . . . . .12

Figure 1.1.2 | Electrical Schematic (Page 2 of 4) . . . . . . . . . . . . . . . . . . . . . .13

Figure 1.1.2 | Electrical Schematic (Page 3 of 4) . . . . . . . . . . . . . . . . . . . . . .14

Figure 1.1.2 | Electrical Schematic (Page 4 of 4) . . . . . . . . . . . . . . . . . . . . . .15

1�2 | Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

1.2.1 | Operating Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . 16

1.2.1.1 | Cab Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2.1.2 | Engine Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2.1.3 | Pintle Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.1.4 | Winterization Heaters (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.2.1.5 | Receptacle (120 VAC Winterization Heaters Optional) . . . . . . 18

1.2.1.6 | Service Floodlight Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.2.1.7 | Speed Limitier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 1.2.1.1 | Cab Controls and INdicators. . . . . . . . . . . . . . . . . . . . . . . . .19

Figure 1.2.1.3 | Rear Pintle Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1.2.2 | Pre-Operation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2.3 | Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2.3.1 | Engine and Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2.3.1.1 | Operating the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2.3.1.2 | Operating the Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2.3.1.3 | Towing the FLTT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2.4 | Operating Winterization Heaters (Optional). . . . . . . . . . . . . . 20

1.2.5 | Opening and Closing Procedure for Pintle Hooks . . . . . . . . . 21

1.2.6 | Description of Extendable Hitch Function. . . . . . . . . . . . . . . . 22

1.2.6.1 | For Non-nuclear Towing Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.2.6.2 | For Nuclear Towing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.2.7 | Adjusting Procedure for Rear Center Pintle Hook . . . . . . . . . 22

1.2.8 | Safety Requirements for Rear Center Pintle Hook . . . . . . . . 23

1.2.9 | Hook-up Procedure for Rear Center Pintle Hook . . . . . . . . . . 23

1.2.10 | Truck Lubrication and Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . 24

FLIGHT LINE TOW TRACTOR TV-550| 3

Figure 1.2.1.10 | Truck Lubrication and Fluids. . . . . . . . . . . . . . . . . . . . . . . .25

1.3 | Specications & Capabilities � � � � � � � � � � � � � � � � � 26

1.3.1 | General Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.3.2 | Truck Cab and Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.3.3 | Winterization Heaters (Optional) . . . . . . . . . . . . . . . . . . . . . . . 27

1.4 | Air Transportability Information � � � � � � � � � � � � � � 28

1.4.1 | General Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.4.2 | Dimension and Weight Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.4.3 | Removal and Relocation of Components. . . . . . . . . . . . . . . . . 29

1.4.4 | Preparing Tow Tractor for Air Transport . . . . . . . . . . . . . . . . . 29

1.4.5 | Loading Vehicle on to Aircraft . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.4.6 | Tie-Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.4.6.1 | Tie-Down Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1.4.6.2 | Tie-Down Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 1.4.6.2 | Tie-Down Locations and Instructions . . . . . . . . . . . . . . . .31

SECTION 2 | MAINTENANCE & OVERHAUL � � � � � � � � � � � � � 32

2.1 | General � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

2.2 | Truck Chassis-Cab � � � � � � � � � � � � � � � � � � � � � � � 32

2.3 | 120 VAC Winterization Heaters (Optional) � � � � � � � � � 32

2.4 | Spring Shackle U-bolts � � � � � � � � � � � � � � � � � � � � 32

2.5 | Front End Alignment Specications � � � � � � � � � � � � 32

2.6 | Tires and Wheels � � � � � � � � � � � � � � � � � � � � � � � 32

SECTION 3 | PARTS LIST � � � � � � � � � � � � � � � � � � � � � � � �34

3.1 | Manufacturer Identication List � � � � � � � � � � � � � � � 35

3.2 | Detailed Parts List � � � � � � � � � � � � � � � � � � � � � � � 36

3.2.1 | Understanding the Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.1.1 | Figure/Item No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.1.2 | Stinar Part No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.1.3 | Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.1.4 | Vendor Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.1.5 | QTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.2.2 | Instructions for Ordering Parts and Assemblies . . . . . . . . . . 36

PARTS ORDER FORM � � � � � � � � � � � � � � � � � � � � � � � � � � 37

Figure 3.3.1 | Flight Line Tow Tractor, Model TV-550 . . . . . . . . . . . . . . . . .38

Figure 3.3.2 | Cab Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 3.3.3 | Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 3.3.4 | Electrical System (Page 1 of 3) . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 3.3.4 | Electrical System (Page 2 of 3) . . . . . . . . . . . . . . . . . . . . . . . .45

Figure 3.3.4 | Electrical System (Page 3 of 3) . . . . . . . . . . . . . . . . . . . . . . . .46

Figure 3.3.5 | AC Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

FLIGHT LINE TOW TRACTOR TV-550| 4

1– General Information and Operating

Instructions

This publication provides operating and maintenance instructions, including

detailed part lists for the Flight Line Tow Tractor, Model TV-550. This

truck was manufactured by:

Stinar Corporation

3255 Sibley Memorial Highway

St. Paul, MN 55121 USA

Chapter 1 – Contains general information describing the unit and

recommended procedures for its operation, as well as specifications and

capabilities of the unit.

Chapter 2 - Provides information for maintaining the unit.

Chapter 3 – Contains a list of manufacturers and illustrated parts lists of

the assemblies, subassemblies, and systems within the unit.

Chapter 4 - Contains vendor data for overhaul and repair of major

vendor-manufactured components, which are installed on these units.

Definition of Terms

SAFETY ALERT SYMBOL – Look for this symbol to point out

important safety precautions.

DANGER: The word “DANGER” denotes a most serious specific

potential hazard. A forbidden practice should definitely be avoided in

connection with a serious hazard.

WARNING: The word “WARNING” is used to denote a specific potential

or hidden hazard which, if not avoided, has the potential for serious injury.

CAUTION: The word “CAUTION” is used to denote a general reminder

of good safety practices or to direct attention to unsafe practices. Following

safe behavioral practices consistent with operating and maintenance

instructions will help the operator and others avoid accident involvement.

NOTE: The word “NOTE” is used to denote something that can cause

minor machine damage, or poor performance if ignored.

IMPORTANT: The word “IMPORTANT” informs the reader of

something he needs to know to prevent minor machine damage if a certain

procedure is not followed.

General Safety:

- Do not rush

- Do not alter your machine

- Read and follow all warning labels. Replace any labels that are

missing or illegible.

- Check all controls and operating functions of the machine in a safe area

before starting work

This manual applies to the Flight

Line Tow Tractors built under

T.O. 36A10-3-54-1 dtd 28 Oct.

2004, supplied to Defense

Support Services

Safety Section

FLIGHT LINE TOW TRACTOR TV-550| 5

- Never allow unauthorized persons around machinery when performing

operation functions

- A fire extinguisher and first aid kit should be carried in the truck at all

times

Before Operation

1. Perform a general all-around visual inspection and equipment check of

the entire unit.

2. Check all markings and nameplates for legibility.

3. Perform any checks required by airport or airline regulations.

4. Always determine hydraulic oil level and fill tank to proper level with

all hydraulic cylinders fully retracted. Overfilling may occur if cylinders

are not retracted which may damage the system

5. If operating at night, check compartment lights for proper operation.

6. Check lights, horn, mirrors, wipers, safety belt, and all other safety

equipment for proper operation.

During Operation

Engine and Transmission

• To operate the engine, refer to the truck operator's manual for

recommended engine starting and operating procedures.

• Failure to follow towing procedure may result in transmission

damage. Please check the manufacturer’s recommendations before

towing your unit.

• These procedures are suggested general operating procedures. For

specific aircraft servicing, follow procedures specified by your

airline.

Emergency Shutdown Procedure

In case of emergency, this unit may be shut down by pressing the stop

switch on the unit. This stop switch is located at (location). To shut down

the unit, press the above switch and hold until truck engine stalls.

After Operation

- Stop engine and allow machine to come to a complete stop before

leaving the cab or allowing anyone near the unit.

- Remove ignition key when parked

Service Safety

- Do not clean, adjust or service this unit while it is in motion.

- Periodically check tightness of nuts and bolts, and check for loose,

worn or misaligned parts. Use only approved replacement parts.

- Any new components installed during repair must include the current

safety signs specified by Stinar Corp.

FLIGHT LINE TOW TRACTOR TV-550| 6

- Perform all work in accordance with authorized standard shop

practices.

- Perform no welding, cutting, patching, and such on any load bearing or

supporting structure. If such repairs are necessary, contact the

Engineering department of Stinar Corporation before making any

alterations.

- Do not mix hydraulic oils of different specifications. Oils may not be

compatible and could result in damage to hydraulic system

components.

- A thin oil film should be visible on the hydraulic cylinder shaft. A

steady drip of oil indicates a need for service.

- Should there be a hydraulic system associated with this unit, always

determine hydraulic oil level and fill tank to the proper level with all

hydraulic actuating cylinders fully retracted. Otherwise, damage may

occur to the tank when the system is operated.

- The hydraulic actuating cylinder exerts a very powerful force. Always

inspect any jammed components carefully for condition, distortion, and

other irregularities after the equipment has been jammed.

Your safety and the safety of those around you depend upon the operator

using care and good judgment in the operation of this unit. Know the

positions and functions of all controls before attempting to operate.

All equipment has limitations. Understand the speed, braking, steering,

stability and load characteristics of the unit before starting operation.

READ YOUR OPERATOR’S MANUAL!

FLIGHT LINE TOW TRACTOR TV-550| 7

The Stinar Flight Line Tow Tractor, Model TV-550, is a modified Ford

Model F-350 truck equipped to tow loaded cargo carts or trailers over

airport ramps and service roads

The vehicle has a towing capacity (draw bar pull or DBP) of 4500 pounds

(2,045 kilograms) for support equipment (SE). It tows aircraft (AC) up to

70,000 pounds or trailers up to 40,000 pounds on grades up to 2.5%. It is

capable of towing trailers (on grades up to 2.5%) from a stop to 10 MPH

(minimum) and aircraft from a stop to 5 MPH (minimum). It has a

minimum reverse speed of 2.5 MPH.

1.1.1 Equipment Systems and Components

The major operating systems and components of the Flight Line Tow

Vehicle are described in the paragraphs below. See Figure 1.1.1 for

locations of components.

1.1.1.1 Truck Chassis

The Tow Vehicle is built on a Ford F-350 chassis-cab and is powered by a

366 cubic inch (6.0 liter) 8-cylinder diesel engine. The transmission is a 5-

speed automatic. Most units have rear wheel drive. A few units have four

wheel drive. There is a receptacle box for Type A winterization heaters, and

a plug for Type C heaters.

The chassis has been shortened to a 98.5-inch (2502 mm) wheelbase. The

engine has been lowered by 2 degrees at the rear transmission mount, by

lowering the rear cross member. This was done to keep the angle of the

shortened drive shaft within OEM tolerances. Also, shims have been

installed under the rear leaf spring assemblies as part of the drive train

realignment.

Two double-faced signal lamps and an adjustable floodlight are mounted on

a light bar behind the cab. Some units may be equipped with an adjustable

spotlight on the driver's side, controlled from inside the cab at the driver's

position.

1.1.1.2 Modifications to the cab include:

-Beacon ON/OFF switch and indicator

-Heaters ON indicator (on type A winterized units)

-Floodlight ON/OFF switch

1.1 Description

FLIGHT LINE TOW TRACTOR TV-550| 8

Figure 1.1.1 – Flight Line Tow Tractor, Model TV-550

FLIGHT LINE TOW TRACTOR TV-550| 9

1.1.1.2 Body

A special body is mounted aft of the cab over the rear wheels. A steel

toolbox with a lid is part of the body. Two 5 lb. Dry Chemical, Type 1,

Class 1, Size 5 fire extinguishers, in accordance with CID A-A-393, are

provided with a minimum UL rating of 2A:10B:C. They are located at the

left and right rear of the vehicle.

1.1.1.3 Pintle Hooks

There are three rear pintle hooks and one front pintle hook on each truck.

Component Description

Front Pintle Hook

Equipped with a retaining pin.

Rear Outboard Pintle

Hook (2)

Equipped with a retaining pin.

Rear Center Pintle

Hook

Extendable and height adjustable. Also

capable of swinging left and right.

Safety Chain

Attachment Point

(2)

5000-pound maximum shock load (each)

Trailer Emergency

Breakaway Cable

Hookup

Mates with NAS 1281C10 spring snap

hook

Electrical Connection SAE J560b receptacle

1.1.2 Electrical System

The electrical system is the OEM Ford 12-volt electrical system except for

the additions noted below.

Component Description

Flashing Amber

Beacon

Located on light bar. The control switch,

indicator, and flasher are installed in cab.

Rear Taillights

Duplicated on light bar.

Front Spotlight Located by driver's door on cab.

Rear Spotlight Located on light bar. Illuminates pintle

hook for night operation.

Trailer Lights

Receptacle

An SAE J560b electrical receptacle for

connecting trailer lights is located on the

rear bumper.

Speed Control

Module

The speed control module is located under

the instrument panel near the OEM truck

fuse panel.

NOTE : Winterized units

have a separate electrical

system for the heaters.

FLIGHT LINE TOW TRACTOR TV-550| 10

Component

Description

Heavy Duty Power

Module

Located in enclosure at rear of vehicle.

Provides power to trailer lights directly

from tow vehicle battery.

Power Control Relay

(K4)

Located in enclosure at rear of vehicle.

Isolates and powers stop lamps, 12 VDC

current to pin 4 of SAE J560b receptacle.

Fuse, 70 amp Located under hood near battery. Protects

the Main Power Relay (K3)

Main Power Relay

(K3)

This 75-amp relay powers and isolates

three Stinar added circuits from the Ford

OEM equipment.

1.1.2.1 Relays and Circuit Breakers

Relays and circuit breakers for Stinar-added electrical components are

located under the truck instrument panel behind the OEM fuse panel. These

include the following. See electrical schematic for functions.

Component Description

Relays Two SPDT relays (Relay 1 and Relay 2) for

the anti-restart circuit are located under

the dash behind the OEM truck fuse panel.

They prevent engaging the starter when

the engine is running.

Circuit Breaker, 25

ampere

This 25-ampere circuit breaker is for the

spotlights and beacon circuit.

Circuit Breaker, 15

ampere

This 15-ampere circuit breaker is for the

speed control module only.

Circuit Breaker, 10

ampere

This 10-ampere circuit breaker is for the

anti-restart relays.

Circuit Breaker, 20

ampere

This 20-ampere circuit breaker is for the

Auxiliary blue wire

1.1.2.2 SAE J560b Receptacle

Use the following table for reference on the SAE J560b receptacle at the

rear of the vehicle.

Number Color Lamp and Signal Circuits

1 White Ground return to towing vehicle.

2

Black

Clearance, side marker and ID lamps

3

Yellow

Left turn signal and hazard lamps

4

Red

Stop lamps and antilock devices

5 Green Right turn signal and hazard lamps

6

Brown

Tail and license plate lamps

7 Blue Auxiliary

FLIGHT LINE TOW TRACTOR TV-550| 11

1.1.3 Winterization Heaters

All units have winterization heaters to allow their operation in cold climates.

All winterized type A units have a three-prong male slave receptacle for

receiving external power. Type A units also have a 25-foot connecting

cable, and provisions for storing the cable in the cab.

Component

Location

Type A, Storage to –65 degrees F, Starting to –40 degrees F

Engine Block Heater

Located in engine block.

Battery Warmer Located around truck battery

Fuel Preheater Located on frame rail.

Type C, Starting to –20 degrees F, Operation to +125 degrees F

Engine Block Heater Located in engine block.

Fuel Preheater Located on frame rail.

FLIGHT LINE TOW TRACTOR TV-550| 12

Figure 1.1.2 – Electrical Schematic (Page 1 of 4)

FLIGHT LINE TOW TRACTOR TV-550| 13

Figure 1.1.2 – Electrical Schematic (Page 2 of 4)

FLIGHT LINE TOW TRACTOR TV-550| 14

Figure 1.1.2 – Electrical Schematic (Page 3 of 4)

FLIGHT LINE TOW TRACTOR TV-550| 15

Figure 1.1.2 – Electrical Schematic (Page 4 of 4) (AC system)

FLIGHT LINE TOW TRACTOR TV-550| 16

Prior to operating the Flight Line Tow Tractor, all operators and

maintenance personnel should become thoroughly familiar with the

instructions given in this manual. No instructions listed in this section cover

driving the vehicle. The truck owner’s manual includes this information.

1.2.1 Operating Controls and Indicators

All controls for operating the unit are located in convenient places and are

clearly marked. A description of each control and indicator follows.

1.2.1.1 Cab Controls and Indicators (See Figure 1.2.1.1)

Component Description

Beacon ON/OFF

toggle switch Turns beacon on light bar on and off.

Beacon ON Indicator When illuminated, this amber light

indicates the beacon is on.

Floodlight ON/OFF

toggle switch

Turns floodlight on light bar on and off.

Winterization

Heaters ON

Indicator

When illuminated, this green light

indicates the winterization heaters are on.

Used on type A winterization units only.

1.2.1.2 Engine Hour Meter (See figure 1.2.1.2)

This function has now been incorporated into the Ford Chassis. Select this

function from the INFO menu to display the total accumulated running time

of the engine. Press in the selector knob to change from Odometer to Trip

Odometer until Engine Hours appears on the display.

Figure 1.2.1.2 Engine Hour Meter Display

1.2 Operation

FLIGHT LINE TOW TRACTOR TV-550| 17

1.2.1.3 Pintle Hooks (See Figure 1.2.1.3)

There are three pintle hooks at the rear of the truck, along with other safety

hardware and an electrical connector. There is one pintle hook at the front.

Component

Description

Front Pintle Hook Used for towing truck. The mount is

capable of withstanding 18000 pounds of

DBP. Mounted 18-1/2 inches above the

ground.

Outboard Rear Pintle

Hooks (2)

Capable of withstanding 6000 pounds of

DBP each. Mounted 18-1/2 inches above

the ground and 43.5 inches (plus 1.5

inches) outboard of vehicle center line.

Center Rear Pintle

Hook

Consists of a self-locking bar, which can

extend approximately 12 inches and swing

45 degrees to either side. Features four

height positions between 12 and 18-1/2

inches above the ground. Capable of

withstanding 6000 pounds of DBP

extended and 18000 pounds of DBP

retracted.

(2) Safety Chain

Attachment Points

Capable of withstanding a 5000-pound

shock load (each).

Trailer Emergency

Breakaway Cable

Mates with a NAS 1281C10 spring snap

hook

Electrical receptacle SAE J560b. Located within 14 inches of

center pintle hook.

Heavy Duty Power

Module

Provides power to trailer lights directly

from tow vehicle battery.

Power Control Relay

(K4)

Isolates and powers stop lamps, 12 VDC

current to pin 4 of SAE J560b receptacle.

FLIGHT LINE TOW TRACTOR TV-550| 18

1.2.1.4 Winterization Heaters (Optional)

Trucks designed to operate in cold climates have one of two different

winterization heater packages installed. Type A winterization is rated to –65

degrees F for storage and –40 degrees F for starting. Type C winterization is

rated to –20 degrees F for starting. The heaters operate any time the external

power supply line is plugged in. They have no ON/OFF switches.

Component

Description

Type A winterization

Engine Block Heater Electric heating element in engine block.

Keeps engine warm.

Battery Warmer Electric heating blanket around each truck

battery. Keeps each battery warm to

maintain adequate power level.

Fuel Heater Warms diesel fuel before it reaches engine

to ensure good fuel flow and good

combustion in the engine.

Type C winterization

Engine Block Heater Electric heating element in engine block.

Keeps engine warm.

Fuel Heater Warms diesel fuel before it reaches engine

to ensure good fuel flow and good

combustion in the engine.

1.2.1.5 Receptacle (120 VAC Winterization Heaters

Optional)

This receptacle is marked 120 VAC Input and is located at the front of the

truck. When connected to an external power cable, this receptacle provides

current to operate the winterization heaters. The receptacle is rated at 30

amps and 120 volts. It accepts a standard 30 amp, 30 pole, 3-wire locking

twist plug. The receptacle has a weatherproof lift cover. Only trucks with

type A winterization have this receptacle. Trucks with type C winterization

have a plug in the truck's front grille for heater power.

1.2.1.6 Service Floodlight Controls

The floodlight at the rear of the truck is controlled by a switch on the cab

dash. The floodlight by the cab is controlled by a switch on the floodlight.

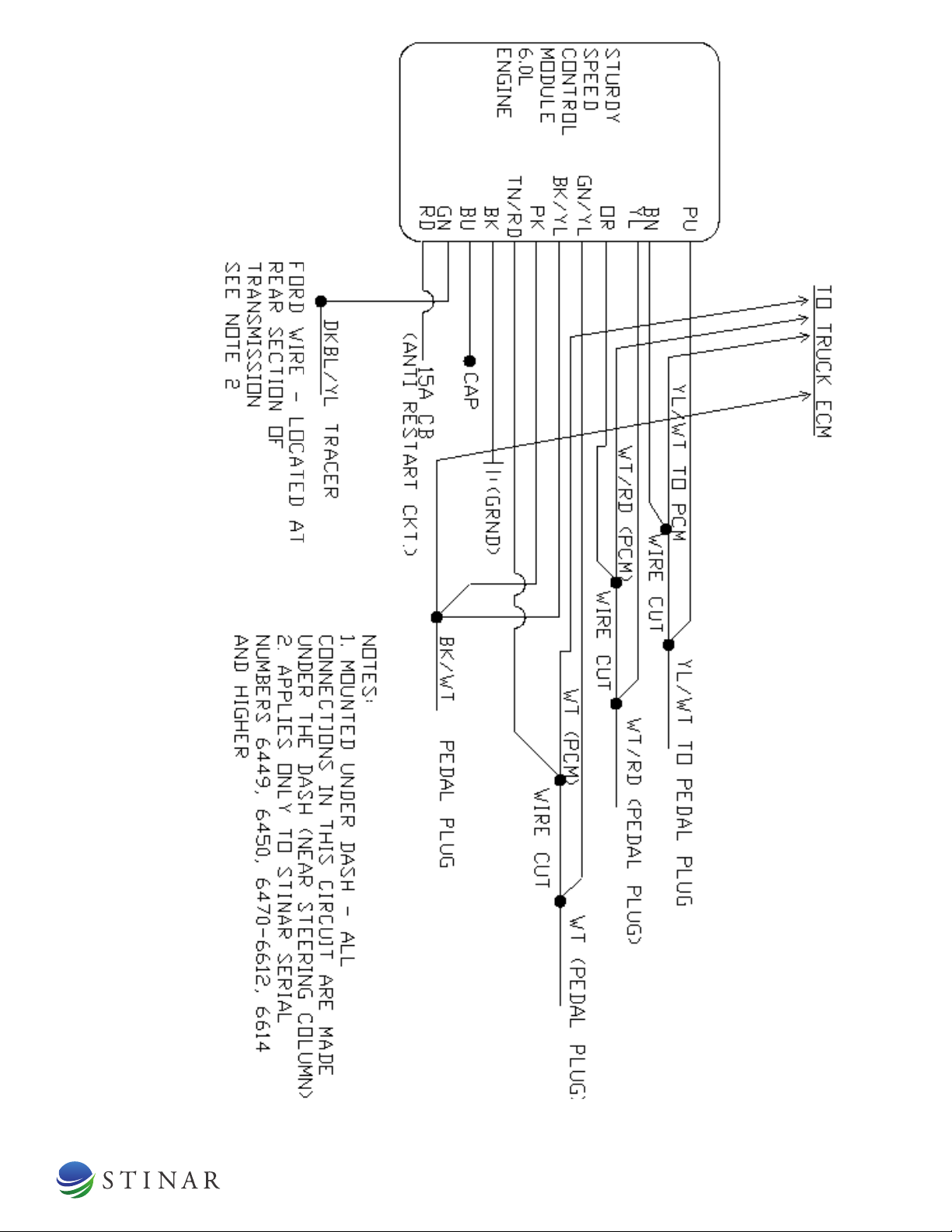

1.2.1.7 Speed Limiter

A Sturdy Corporation ER-06 speed limiter (Stinar MPR number 509890)

works with the truck's electronic engine throttle control to limit maximum

vehicle speed to 40 MPH (plus 0, minus 3). This unit is located under the

cab dash to the right of the steering column, and does not need any service.

The "Service Engine Soon" light may illuminate when the accelerator is

held at full throttle due to the installation of the Sturdy speed control. This

condition does not require service. The vehicle's ability to operate safely is

not a concern unless the light is blinking or remains on continuously. See

the Owners' Guide.

FLIGHT LINE TOW TRACTOR TV-550| 19

Figure 1.2.1.1 – Cab Controls and Indicators

Figure 1.2.1.3 – Rear Pintle Hooks

FLIGHT LINE TOW TRACTOR TV-550| 20

1.2.2 Pre-Operation Checks

1. Check truck engine oil and coolant levels.

2. Perform an all-around visual inspection and equipment check of the

entire tow tractor.

3. If operating at night, check rear floodlight for proper operation.

4. Inspect chassis-cab in accordance with the guidelines of your air base.

5. Check lights, horn, mirrors, wipers, safety belt, and all other safety

equipment for proper operation.

1.2.3 Operating Procedures

1.2.3.1 Engine and Transmission

1.2.3.1.1 Operating the Engine

To operate the engine, refer to the Ford operator’s manual for recommended

engine starting and operating procedures.

A Sturdy speed control unit that works with the truck's electronically

controlled engine throttle limits maximum truck speed to 40 MPH (plus 0,

minus 3).

1.2.3.1.2 Operating the Transmission

The transmission is a 5-speed automatic. When in the drive position, the

transmission will shift automatically through all forward gears. Shifting

between drive, neutral, and reverse should be done when the engine idles.

1.2.3.1.3 Towing the FLTT

It is not possible to start the engine by towing the truck. Take extreme care

when towing the vehicle. Before towing or pushing a disabled vehicle,

disconnect the driveline or lift the drive wheels off the ground.

1.2.4 Operating Winterization Heaters (Optional)

1. Make sure the unit is parked. Operate the 120 VAC engine, battery, and

fuel line heater as follows:

2. Connect the power cord to the 120 VAC receptacle at the front of the

unit (Type A winterization) or the plug in the front grille (Type C units).

Connect the other end to a 120 VAC power source. The 120 VAC

heaters operate whenever the power cord is connected to facility power.

There are no ON/OFF switches.

3. Disconnect the power cord before moving the vehicle. Failure to do so

will damage the power cord and the vehicle.

CAUTION! Before placing

the unit into service, check fuel

level, engine crankcase oil, and

coolant levels.

CAUTION! Failure to

follow this procedure may

result in transmission damage.

NOTE Use the winterization

heaters whenever the truck is

operated in temperatures of

32°F (0°C) or lower.

CAUTION! Do not drive

unit without first disconnecting

heater power cord.

Table of contents