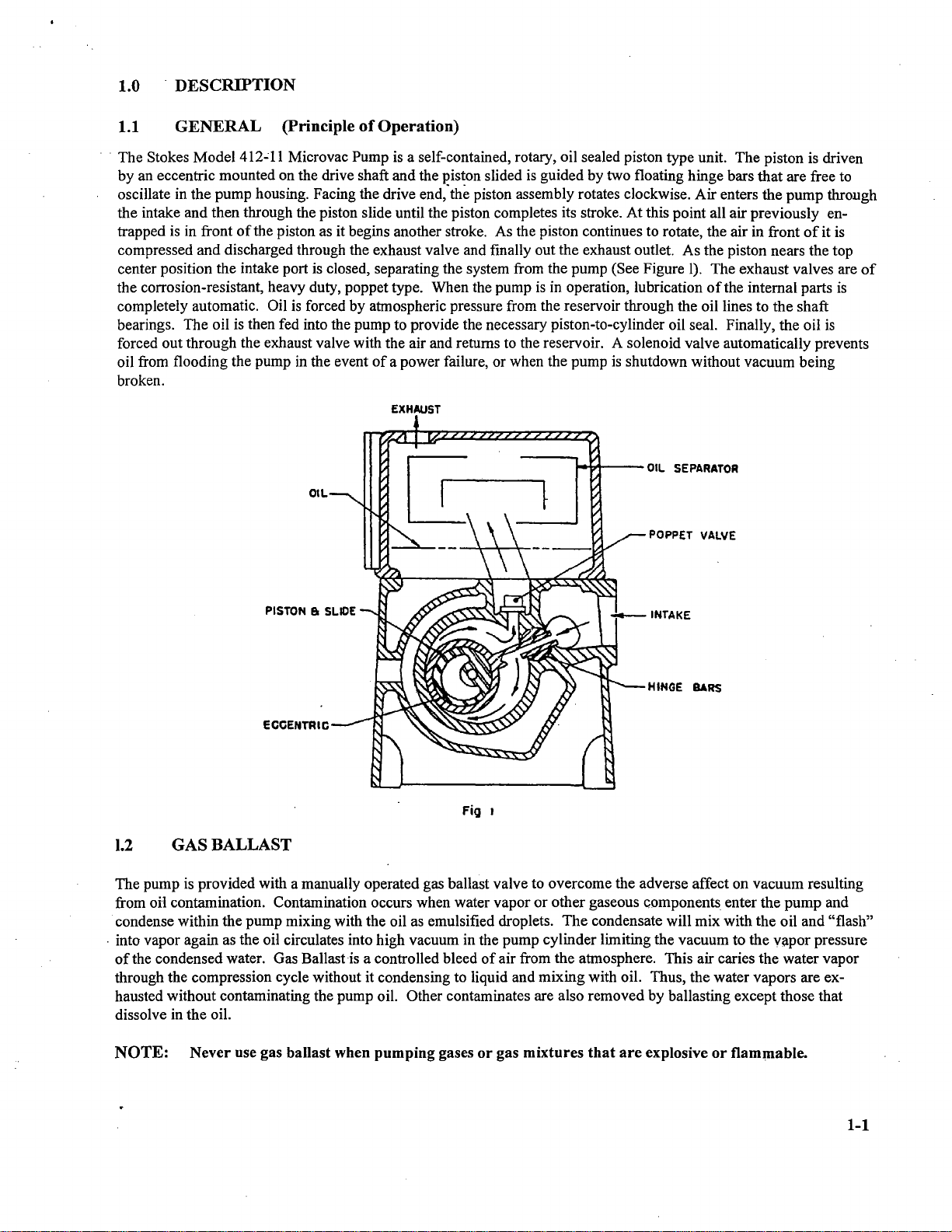

3.4

OPERA

TION

OF

GAS BALLAST

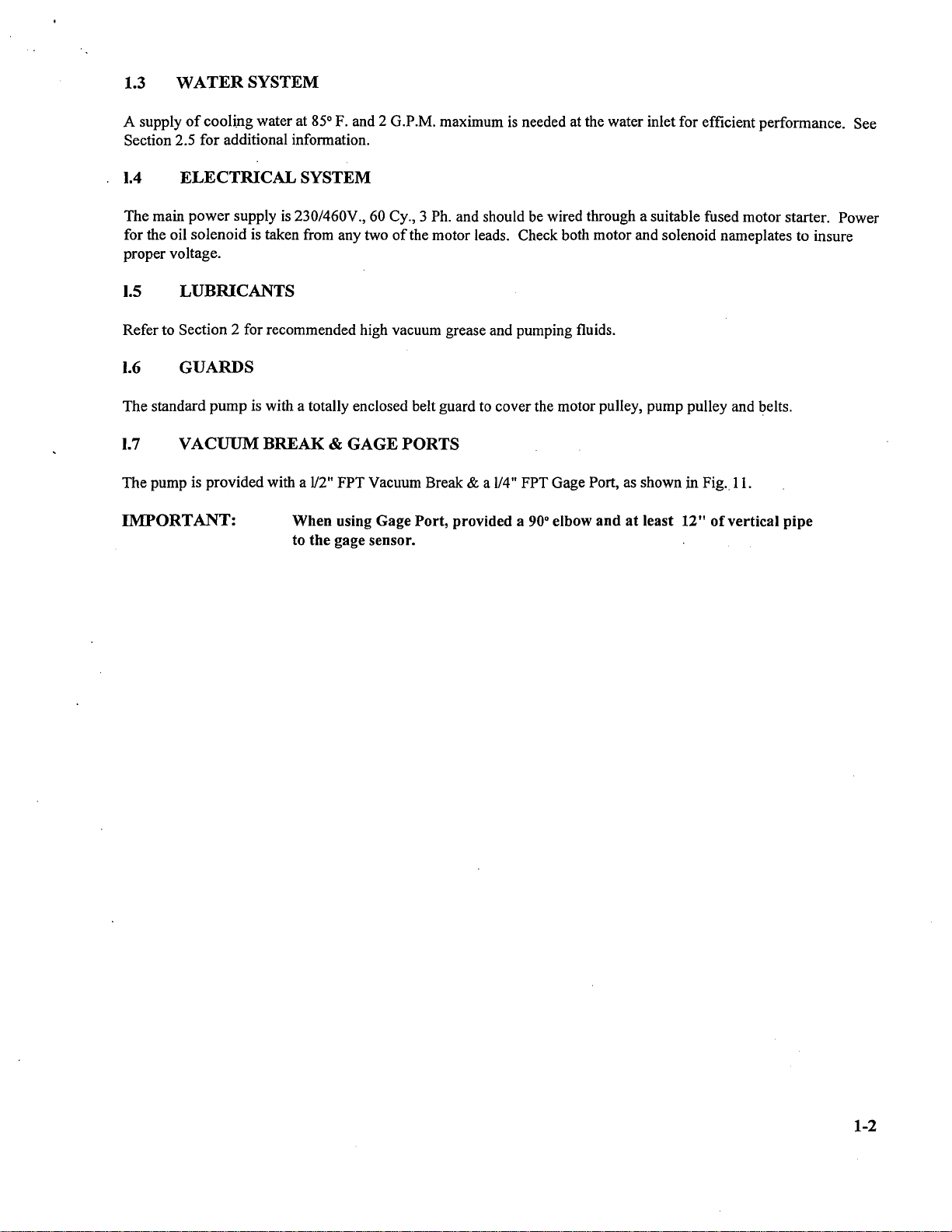

3.4.1

Open the Gas Ballast valve fully for maximum efficiency. For a lesser degree

of

ballasting,

tum

valve toward

close position. Full gas ballast will cause pump temperature to rise but this

is

nonnal. For maximum effect

of

gas

ballast, pump should

be

run approximately at

160

Deg.

F.

Operating temperature can be raised by throttling cooling

water. Oil Temperature Control Kits are available, consult factory.

NOTE: Be sure to remove the plastic plug in the Gas Ballast

air

intake lines. This plug

is

used

for

shipping

and

storage purposes ONLY

3.4.2

If

pumping water vapor in excessive quantities and the oil has become contaminated, it can be purified by

running the pump with Gas Ballast valve full open while the pump

is

shut-offfrom the system. When excessive

contaminants are present, indicated

by

high oil level, or thinning, formation

of

varnish, etc., the oil should be replaced.

NOTE: In dirty applications

where

condensable contaminants (asphalt, pitch, epoxies, etc.)

other

than

water

vapor

are

present,

the

pump

should be operated in the

range

of

160

Deg. F.

CAUTION: Gas Ballast should never be used

ifvapors

being pumped

are

explosive, e.g.

Methane

Gas, Hydrogen,

and

certain

solvent vapors. When gases

of

an explosive

nature

are

being

handled. the safest

procedure

is

to remove the gas ballast valve entirely

and

plug

or

cap

the

pipe to which the gas ballast valve

is

attached.

Opening the gas ballast slightly will quiet valve noise when pump

is

blanked-off, but will prevent reaching the lowest

final pressure.

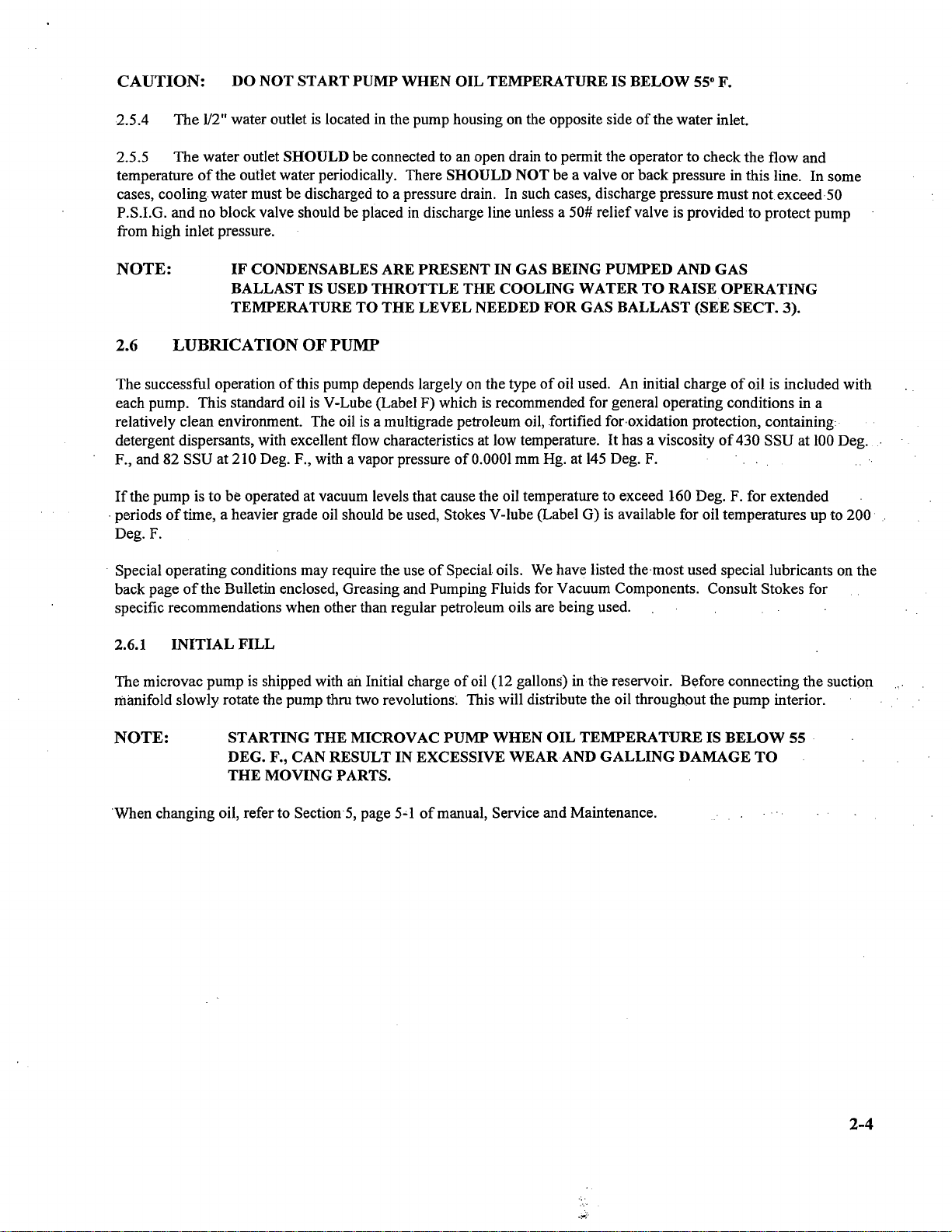

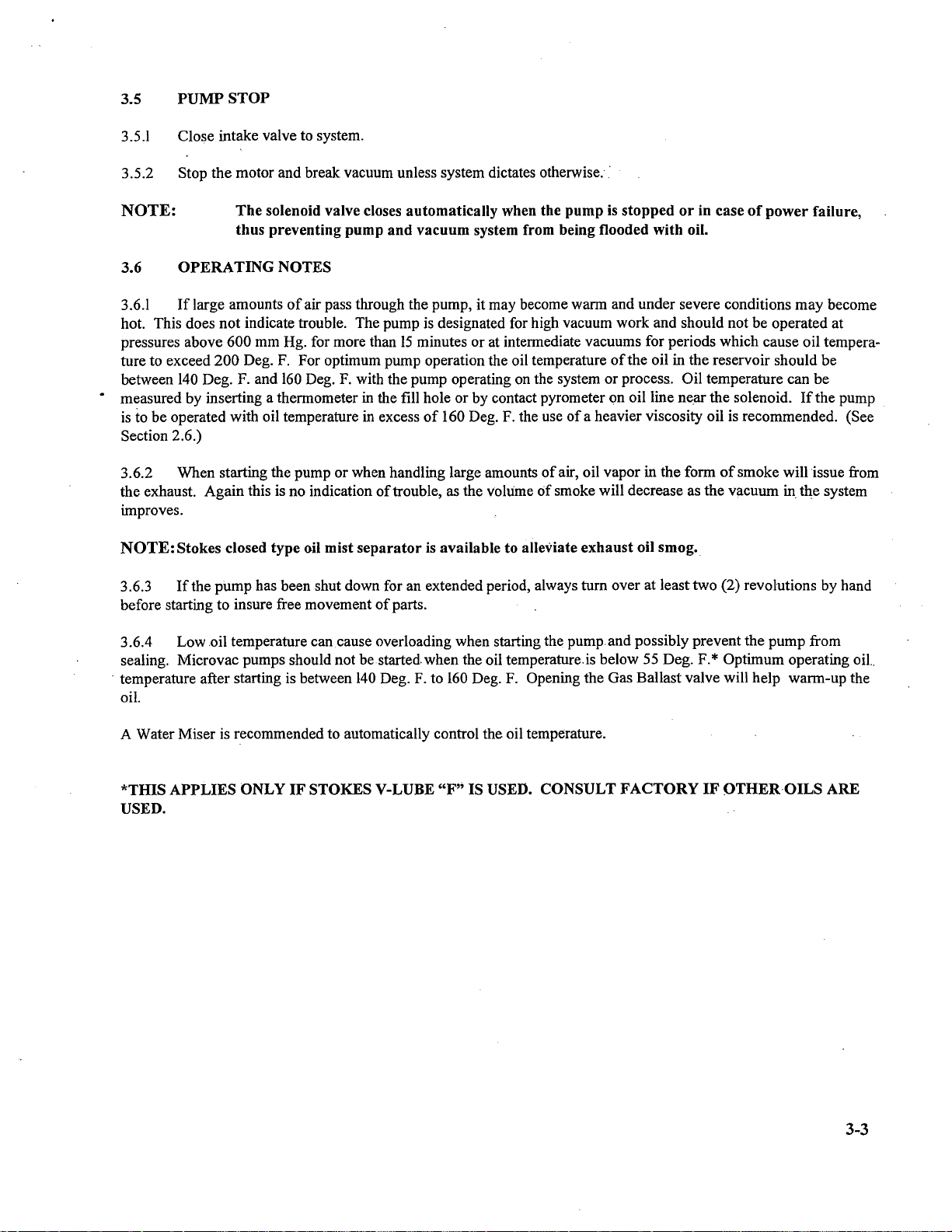

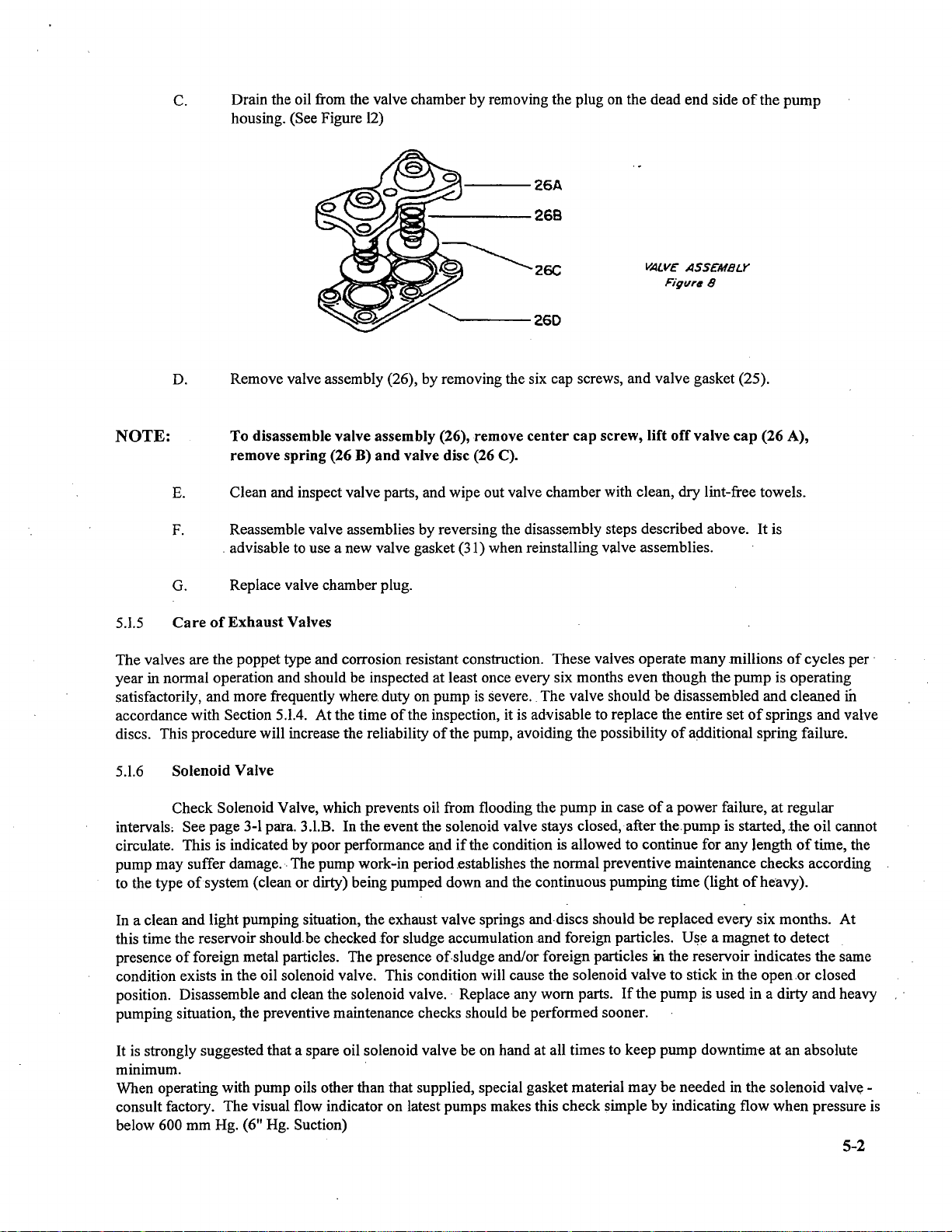

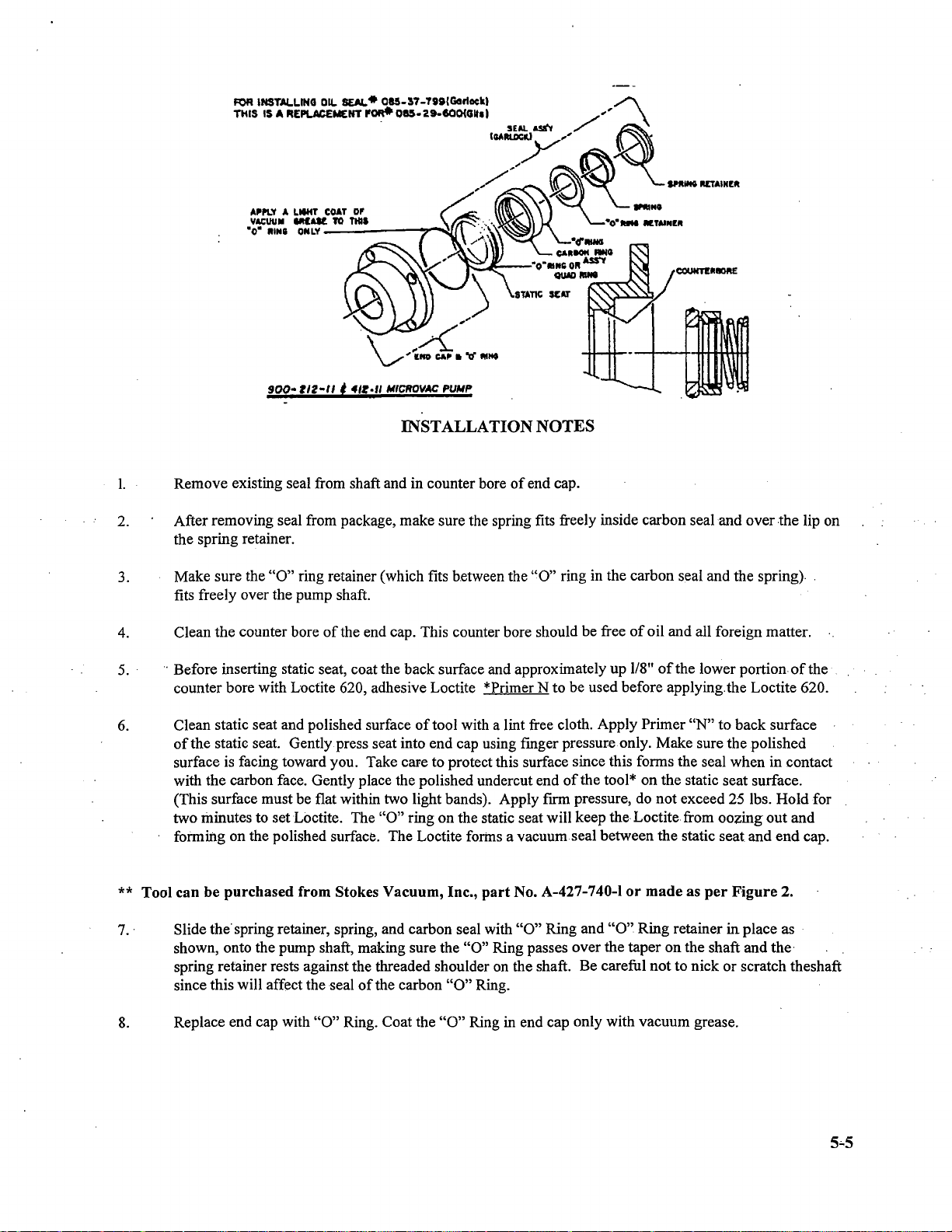

3.4.3 The check valve used for Gas Ballast should be inspected at least every six months for

we.ar

or a broken spring

when operating on an (8) hour a day basis; every 3 months for (24) hour a day operation.

TEFLON

BACK·

UP

lUNG \ &

STATIC

"0"

RING

\ \

~

t"\~

>

~\J'-J,~,/

L)~

"-""'.'C"O"

.,,'

~

\..

..

,,"'

SCREEN

(nor

r.".,vall/e

1

GAS

BALLAsr

CHECK

VALVE

Flgur.6

3.4.4 The gas ballast valve should be closed when the pump

is

stopped..

If

the valve

is

open, gas will be sucked into

the pump through the valve·and the vacuum manifold will be pressurized with atmospheric air. This air

goir).g

through

the pump will carry the oil in the pump cylinder system. A solenoid valve attached to the gas ballast piping and

connected across the motor can be used to tum the gas ballast automatically on pump shutdown. Contact local Stokes.

representative for additional infonnation.

3.4.5 When a pressurized gas is used to ballast the pump, the pressure must

be

reduced to 2 psi maximum. The used

of

higher pressures may damage the pump.

3.4.6 When pumping an explosive gas, (Le. hydrogen, silane, methane) or corrosive gas, (cl,

f,

ccl4, etc.) the pump

must be ballasted with an inert gas (nitrogen, argon). The used

of

air for ballasting under the above conditions can

..

result

in

an explosion or excessive corrosion inside the pump.

3-2