STREIVOR DemandAire Bronze User manual

Striving for Excellence

Photo to Come

DemandAire Bronze

Kitchen Ventilation Control System

www.streivor.com

Installation and Operations Manual

2

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

General Information

Acronyms ................................................................................................................................................................................3

Pre-Installation Precautions ....................................................................................................................................................4

DemandAire Control Panel Drawing Sample ..........................................................................................................................4

DemandAire Control Panel: Hood Mounted ...........................................................................................................................5

DemandAire Control Panel: Wall Mounted .............................................................................................................................5

Installation Procedures

Control Circuit Input Power Wiring..........................................................................................................................................6

Motor Circuit Input Power Wiring (Motor Starters Provided by Streivor) ................................................................................6

Motor Circuit Output Power Wiring (Motor Starters Provided by Streivor) .............................................................................7

Overload Setting (Motor Starters Provided by Streivor)..........................................................................................................7

Recommended Overload Setting for Single-Phase Motors....................................................................................................8

Recommended Overload Setting for Three-Phase Motors.....................................................................................................8

Fan Control Signal Wiring (Motor Starters Not Provided by Streivor) .....................................................................................8

Light Power Circuit Wiring.......................................................................................................................................................9

Internal Hood Fan (IHF) Power Circuit Wiring for SmartAire Technology Hoods ....................................................................9

Fire Suppression System (FSS) Switch Circuit Wiring ..........................................................................................................10

Ambient Resistance Temperature Detector (ARTD) Wiring ...................................................................................................11

Hood Canopy and/or Duct Collar Temperature Monitor Wiring ............................................................................................12

Optional: Shunt Trip Breaker Wiring......................................................................................................................................13

Optional: Modbus TCP Communication Wiring ....................................................................................................................13

Electric Gas Valve Input Power Wiring ..................................................................................................................................14

Electric Gas Valve Output Power Wiring ...............................................................................................................................14

Operation Procedures

Start Up .................................................................................................................................................................................15

Human Machine Interface (HMI) Touch Screen Control........................................................................................................15

Home Screen.........................................................................................................................................................................15

Customer Service Screen......................................................................................................................................................16

System Information Screen ..................................................................................................................................................16

Temperature Status Screen...................................................................................................................................................16

Fan Motor Status Screens.....................................................................................................................................................16

Secure Settings .....................................................................................................................................................................17

Temperature Dierential Settings Screen (Management) ......................................................................................................17

Timer Settings (Management) ...............................................................................................................................................17

Fire Suppression System Settings (Management) ................................................................................................................18

USB Removal Screem...........................................................................................................................................................18

Restore Factory Settings (Management)...............................................................................................................................18

Electrical Gas Valve Reset Relay...........................................................................................................................................19

Alarms ...................................................................................................................................................................................20

Temperature Monitor Alarm...................................................................................................................................................20

High Temperature Alarm........................................................................................................................................................20

Fan Motor Overload Alarm ....................................................................................................................................................20

Fire Suppression System Alarm ............................................................................................................................................21

Warranty

Warranty Information.............................................................................................................................................................22

Table of Contents

3

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Acronyms

ARTD Ambient Resistance Temperature Detector

BMS Building Management System

CKV Commercial Kitchen Ventilation

DCKV Demand Control Kitchen Ventilation

DCP DemandAire Control Panel

EC Electronically Commutated

ECM Exhaust Collar Mounted

FSS Fire Suppression System

HCM Hood Canopy Mounted

HMI Human Machine Interface

IHF Internal Hood Fan

MBD Motorized Balance Damper

MUA Make Up Air

PLC Programmable Logic Controller

RTD Resistance Temperature Detector

VFD Variable Frequency Drive

General Information

4

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

General Information

Pre-Installation Precautions

Hood, Electrical, and Rough-In Schedules Field Wiring Diagram

Equipment Layout and Electrical Conduit RoutingInstallation Details

Serial

Number

DemandAire Control Panel Drawing Sample

WARNING

PRIOR TO MAKING ANY ELECTRICAL CONNECTIONS TO THE CONTROL PANEL, READ AND

UNDERSTAND THIS ENTIRE INSTALLATION AND OPERATIONS MANUAL. ALL WORK ON THE

CONTROL PANEL SHOULD BE PERFORMED BY QUALIFIED CONTRACTORS IN ACCORDANCE WITH

ALL APPLICABLE PREVAILING CODES AND STANDARDS.

THE CONTROL PANEL HAS MULTIPLE ELECTRICAL CONNECTIONS. VERIFY THAT ALL POWER HAS

BEEN DISCONNECTED TO THE CONTROL PANEL PRIOR TO WORKING ON OR NEAR THE CONTROL

PANEL. LOCK OUT / TAG OUT ALL OF THE DISCONNECT SWITCHES OR CIRCUIT BREAKERS TO

PREVENT ACCIDENTAL POWER UP.

ALL ELECTRICAL WIRING AND CONNECTIONS TO THE CONTROL PANEL SHALL BE IN ACCORDANCE

WITH THE PREVAILING CODES, THE NATIONAL ELECTRICAL CODES, AND ANSI/NFPA70.

VERIFY THAT THE SERIAL NUMBER ON THE WIRING DIAGRAM (SEE SAMPLE DRAWING) PROVIDED

WITH THE CONTROL PANEL MATCHES THE SERIAL NUMBER OF THE CONTROL PANEL BEFORE

USING THE WIRING DIAGRAM FOR REFERENCE.

VERIFY THAT THE VOLTAGE AND WIRE AMPERAGE CAPACITY AND WIRE INSULATION IS IN

ACCORDANCE WITH THE CONTROL PANEL NAMEPLATE.

5

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

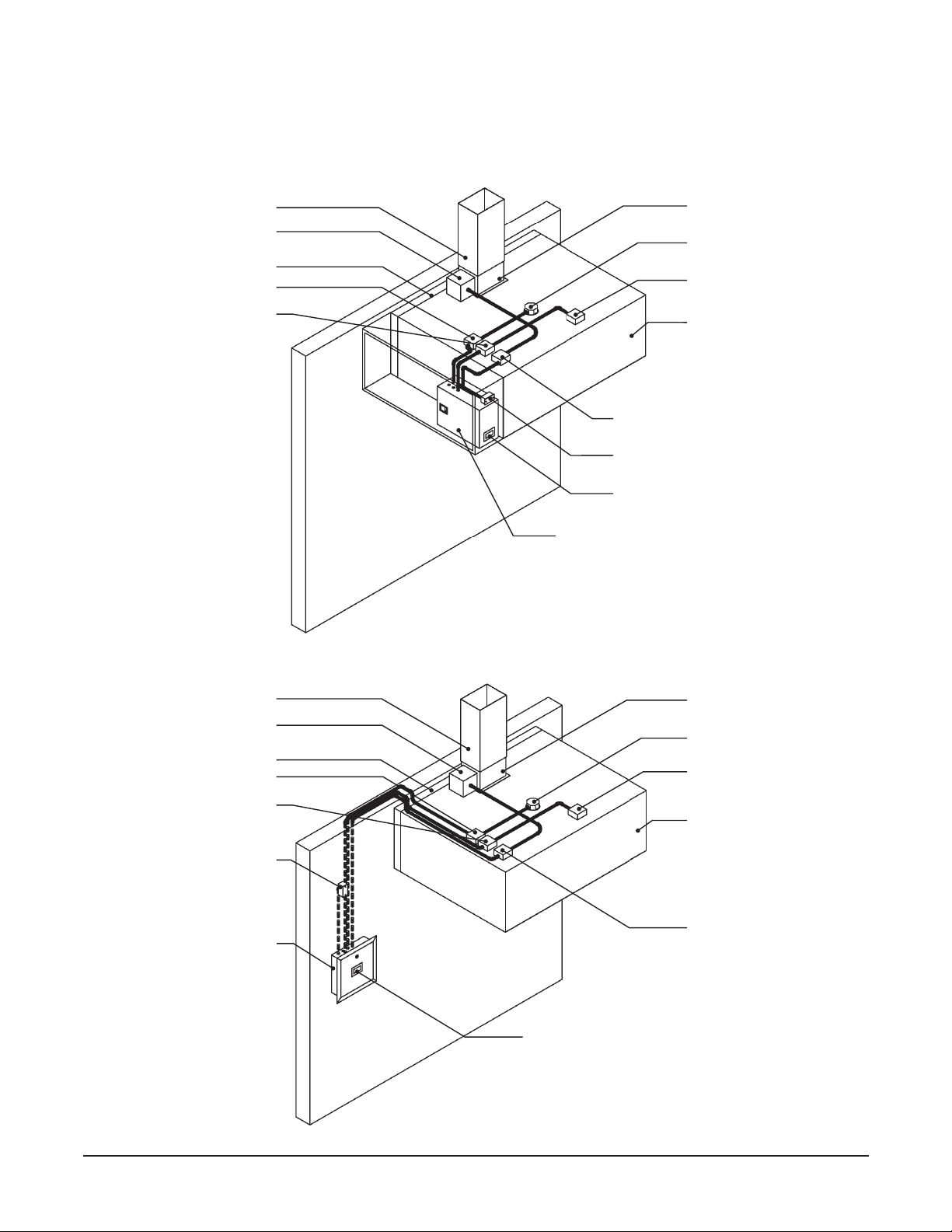

Wall Mounted DemandAire

Control Panel (Recessed)

Hood Duct Collar Access Enclosure

with Temperature Monitor Hood Light Fixture J-Box

Hood Light Fixture J-Box

SmartAire Internal Hood

Fan J-Box (optional)

SmartAire Internal Hood

Fan J-Box (optional)

Temperature Monitor J-Box (optional)

Temperature Monitor J-Box

(Optional)

Hood Light Power J-Box

Hood Light Power J-Box

SmartAire Internal Hood Fan

Power J-Box (optional)

SmartAire Internal Hood Fan

Power J-Box (optional)

Remote Ambient

Temperature Monitor

General Information

Exhaust Duct

Exhaust Duct

Rear Stando

Rear Stando

Hood Canopy

Hood Canopy

Hood Duct Collar

Hood Duct Collar

DemandAire Control Panel: Hood Mounted

DemandAire Control Panel: Wall Mounted

Cabinet Mounted Human Machine

Interface

Cabinet Mounted Ambient Temperature

Monitor

Hood Duct Collar Access Enclosure

with Temperature Monitor

Cabinet Mounted DemandAire Control

Panel

Control Panel Mounted

Human Machine Interface

6

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

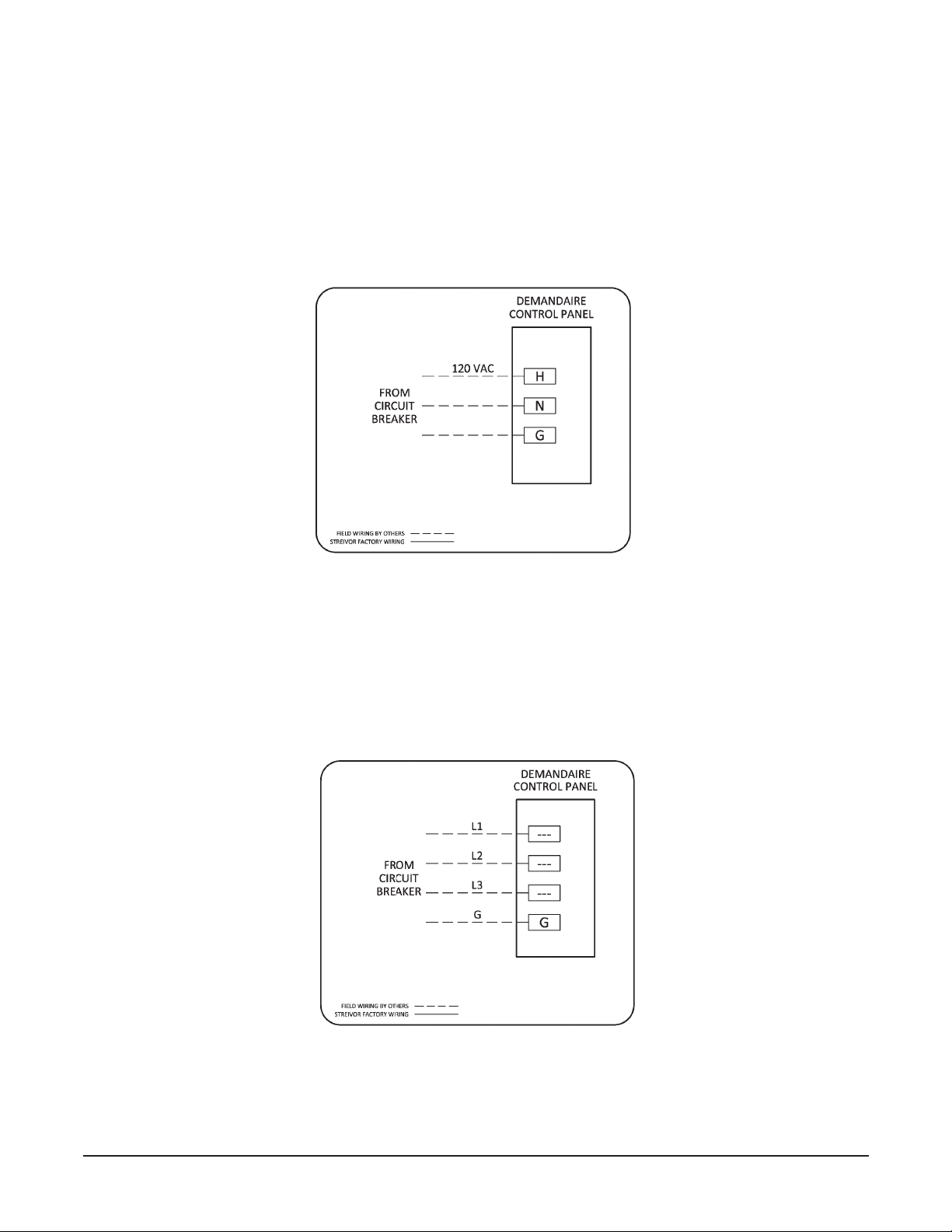

Control Circuit Input Power Wiring

a. Verify that all supply power to the control panel is locked out and tagged out.

b. Verify that the circuit breaker amperage is sized correctly for the control circuit per the DemandAire Control Panel

(DCP) drawings.

c. Connect 120 VAC single phase power to the terminal blocks in the control panel labeled H, N, and Ground (Figure 1).

d. The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

Motor Circuit Input Power Wiring (Motor Starters Provided by Streivor)

a. Verify that all power to the control panel is locked out and tagged out.

b. Verify that the circuit breaker amperage is sized correctly for each motor input power circuit.

c. Verify that the voltage and phase of each motor circuit is correct per the DCP drawings.

d. Connect input power to the input power terminal blocks as shown on the DCP drawings (Figure 2).

e. The wires should be torqued to 1.5-1.8 N•m at the terminal blocks.

FIGURE 1: Control Circuit Input Power

Installation Procedures

FIGURE 2: Motor Circuit Input Power

7

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

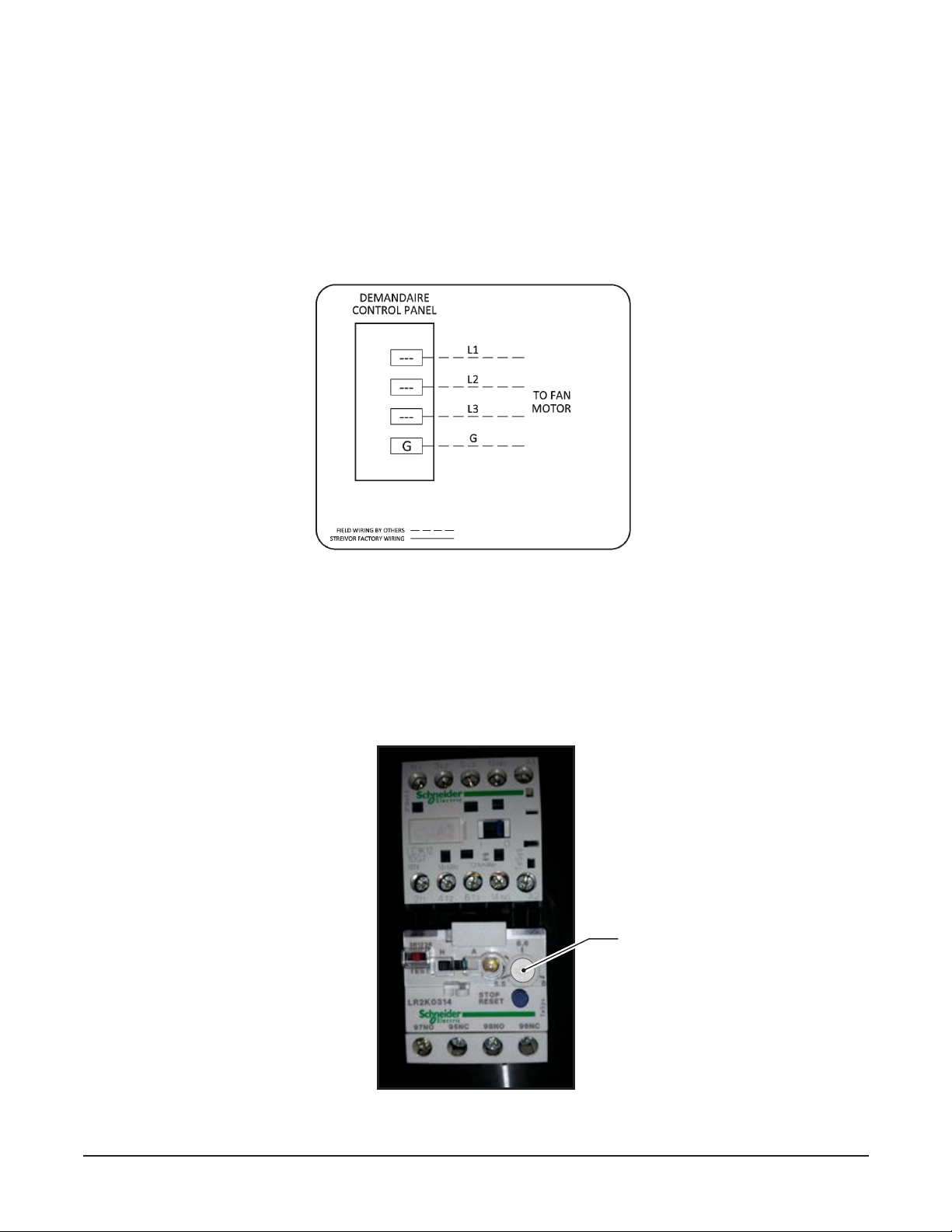

FIGURE 4: Motor Starter (If Provided by Streivor)

Overload Setting (Motor Starters Provided by Streivor)

a. Verify that all power to the control panel is

locked out and tagged out

.

b. Each overload should have been set by the factory to the recommended setting per the table(s) below.

c. Verify that each overload has been set to 125% of the full load amps displayed on the corresponding motor nameplate.

d. The overload setting can be adjusted as needed by rotating the dial to the desired amperage value (Figure 4).

Overload

Setting Dial

FIGURE 3: Motor Circuit Output Power

Motor Circuit Output Power Wiring (Motor Starters Provided by Streivor)

a. Verify that all power to the control panel is

locked out and tagged out

.

b. The output terminals located on the Motor Starter(s) have been pre-wired to the designated output power

terminal

blocks

in the control panel. Connect the output power

terminal blocks

to the designated fan motor(s) as shown on

the DCP drawings (Figure 3).

c. The wires should be torqued to 1.5-1.8 N•m at the

terminal blocks

.

Installation Procedures

8

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

HP 115V 208V 230V

1/6 5.5 3.0 2.8

1/4 7.3 4.0 3.7

1/3 9.0 5.0 4.5

1/2 12.3 6.8 6.1

3/4 17.3 9.5 8.6

1 20.0 11.0 10.0

HP 208V 230V 460V

1/2 3.0 2.8 1.4

3/4 4.4 4.0 2.0

1 5.8 5.3 2.6

1 1/2 8.3 7.5 3.8

2 9.4 8.5 4.3

3 13.3 12.0 6.0

5 20.9 19.0 9.5

7 1/2 30.3 27.5 13.8

10 38.5 35.0 17.5

15 57.8 52.5 26.3

Recommended Motor Overload Settings for Single-Phase Motors

Recommended Motor Overload Settings for Three-Phase Motors

Installation Procedures

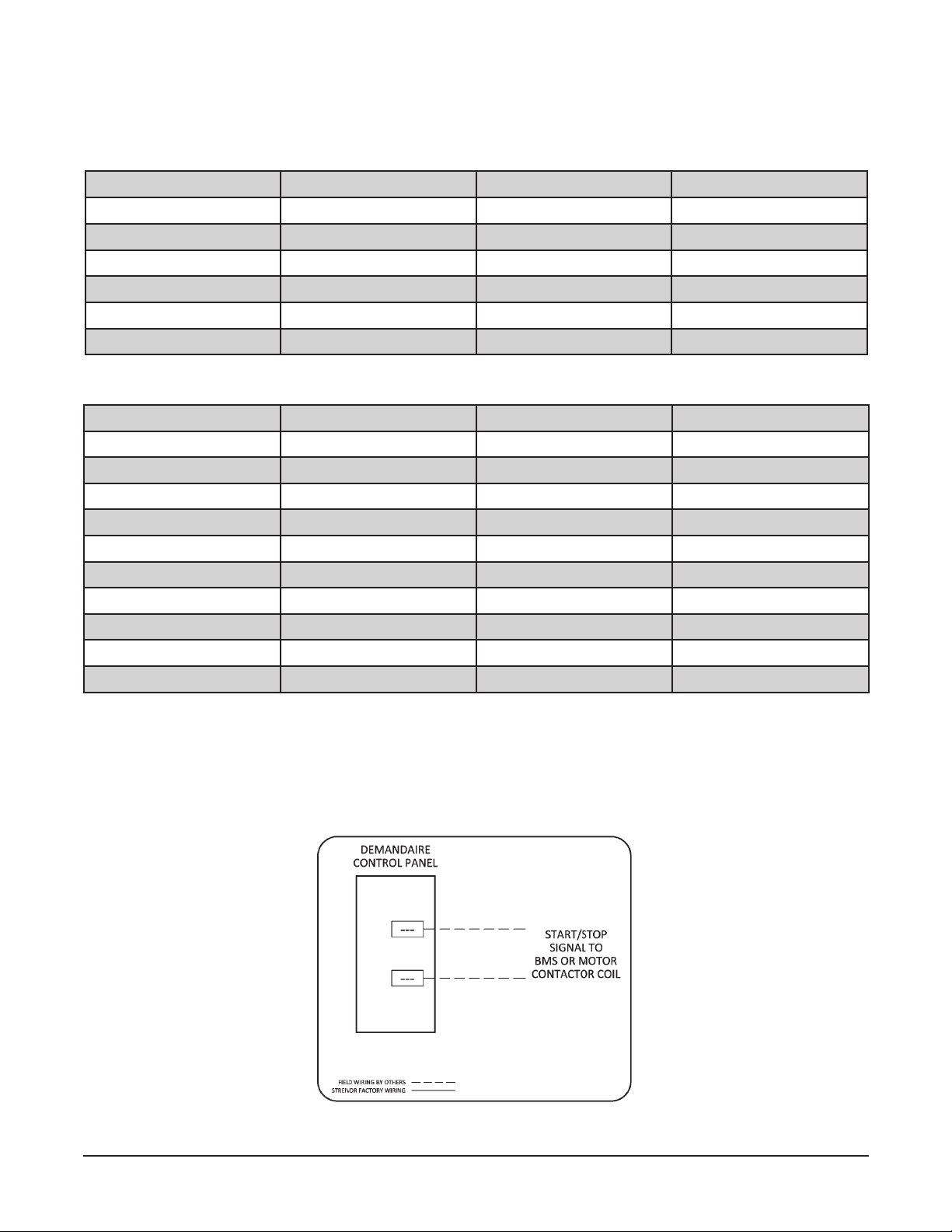

Fan Control Signal Wiring (Motor Starters Not Provided by Streivor)

a. Connect the terminal blocks in the control panel designated for the start/stop fan control signals to the appropriate

external destination — Motor Starter(s) (by others) or Building Management System (BMS) (Figure 5).

b. Refer to the DCP drawings for more information on the control signals available (24 VDC, 120 VAC, or Dry Contact).

c. The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

FIGURE 5: Fan Control Signal Wiring (if Motor Starters Not Provided by Streivor)

9

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Installation Procedures

Light Power Circuit Wiring

a. Verify that all power to the control panel is

locked out and tagged out

.

b. Connect 120 VAC single phase power from terminal block 11 (hot), terminal block 12 (neutral), and ground in the

control panel to the wires labeled “Lights” in the junction box on the hood (Figure 6).

c. The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

FIGURE 6: Light Power Circuit Wiring

Internal Hood Fan (IHF) Power Circuit Wiring for SmartAire Technology Hoods

Per NFPA 96 Section 8.3.2: When its re-extinguishing system discharges, makeup air supplied internally to a

hood shall be shut o.

a. Verify that all power to the control panel is locked out and tagged out.

b.Connect 120 VAC single phase power from terminal block 3(hot), terminal block 4(neutral), and ground in the

control panel to the wires labeled “IHF” in the junction box on each hood (Figure 7).

c. Internal Hood Fan power to terminal blocks 3and 4 will be automatically shunt during a re suppression system

activation to comply with NFPA 96 Section 8.3.2.

d.The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

FIGURE 7: Internal Hood Fan Power Circuit Wiring

10

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

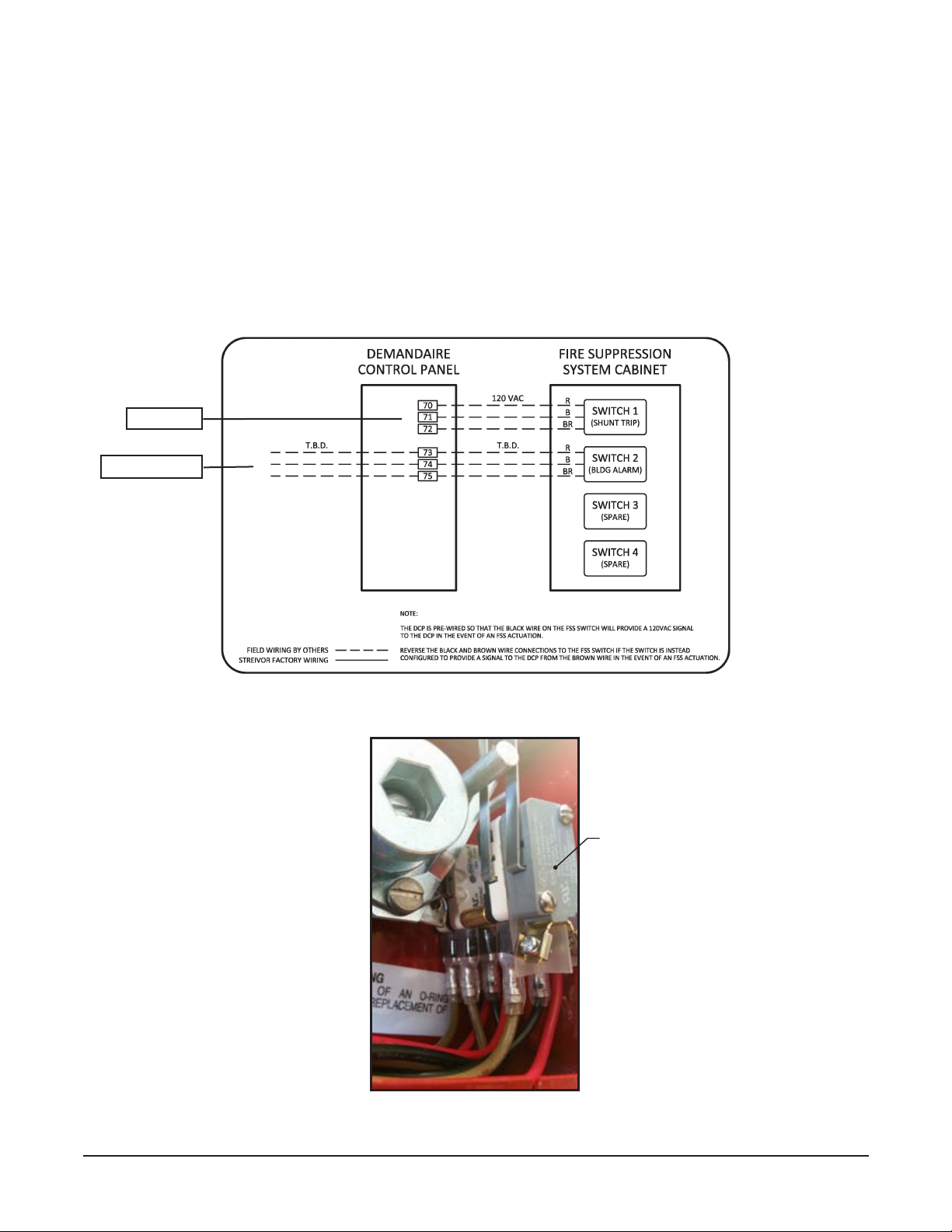

FIGURE 8A: Fire Suppression System (FSS) Switch Circuits

Installation Procedures

Terminal Blocks

Allocated for:

Shunt Trip

Building Alarm

{

{

FIGURE 8B: FSS Switch for Building Alarm Circuit

Note: Use FSS

Switch with Lugs

for Building Alarm

Circuit

Fire Suppression System (FSS) Switch Circuit Wiring

a. Verify that all power to the control panel is locked out and tagged out.

b. Locate the FSS switch in the FSS control panel. The FSS switch (also referred to as microswitch) shall have one set

of single-pole-double-throw contacts (Figure 8A).

c. Connect the terminal blocks in the control panel to the FSS Switch(es) (Figure 8A). The building alarm circuit must

be connected to the switch with lugs (Figure 8B).

d. Connect the building alarm circuit to the terminal blocks designated for the building alarm in the DCP (Figure 8A).

e. Refer to the DCP drawings for more detail regarding wiring additional FSS switches.

f. The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

11

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Ambient Resistance Temperature Detector (ARTD) Wiring (Cabinet Mounted)

a. ARTDs that are Control Panel or Cabinet Mounted are pre-wired by the factory. No eld connections are required.

b. Refer to DemandAire drawings to verify ARTD installation location.

Ambient Resistance Temperature Detector (ARTD) Wiring (Remote)

a. Verify that all power to the control panel is

locked out and tagged out

.

b. The ARTD requires a 2x4 J-Box to which it may be directly mounted (Figure 10).

c. Connect the terminal blocks labeled T0-A, T0-B, etc., in the control panel to the ARTD using UL-Listed 22 AWG Three

Strand Shielded Communication Cable (Figure 9). Connect the black lead on the monitor to the red wire leading to

the DemandAire control panel. Connect one of the brown leads on the monitor to the black wire leading to the control

panel and connect the other brown lead on the monitor to the white wire leading to the control panel (Figure 10).

d. The ARTD should be installed in the location shown on the DemandAire drawings or in the kitchen space at least 80’’

above nished oor (A.F.F.), away from direct sunlight, makeup air diusers airstreams, and other sources of heated or

cooled air. The ARTD should be located within 20 ft. of at least one hood controlled by the DemandAire system.

e. The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

Installation Procedures

FIGURE 10: ARTD Installation Details

Figure 9: ARTD Wiring Connections in DCP

ARTD Shield(s)

Must be Grounded

in the DCP

12

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Installation Procedures

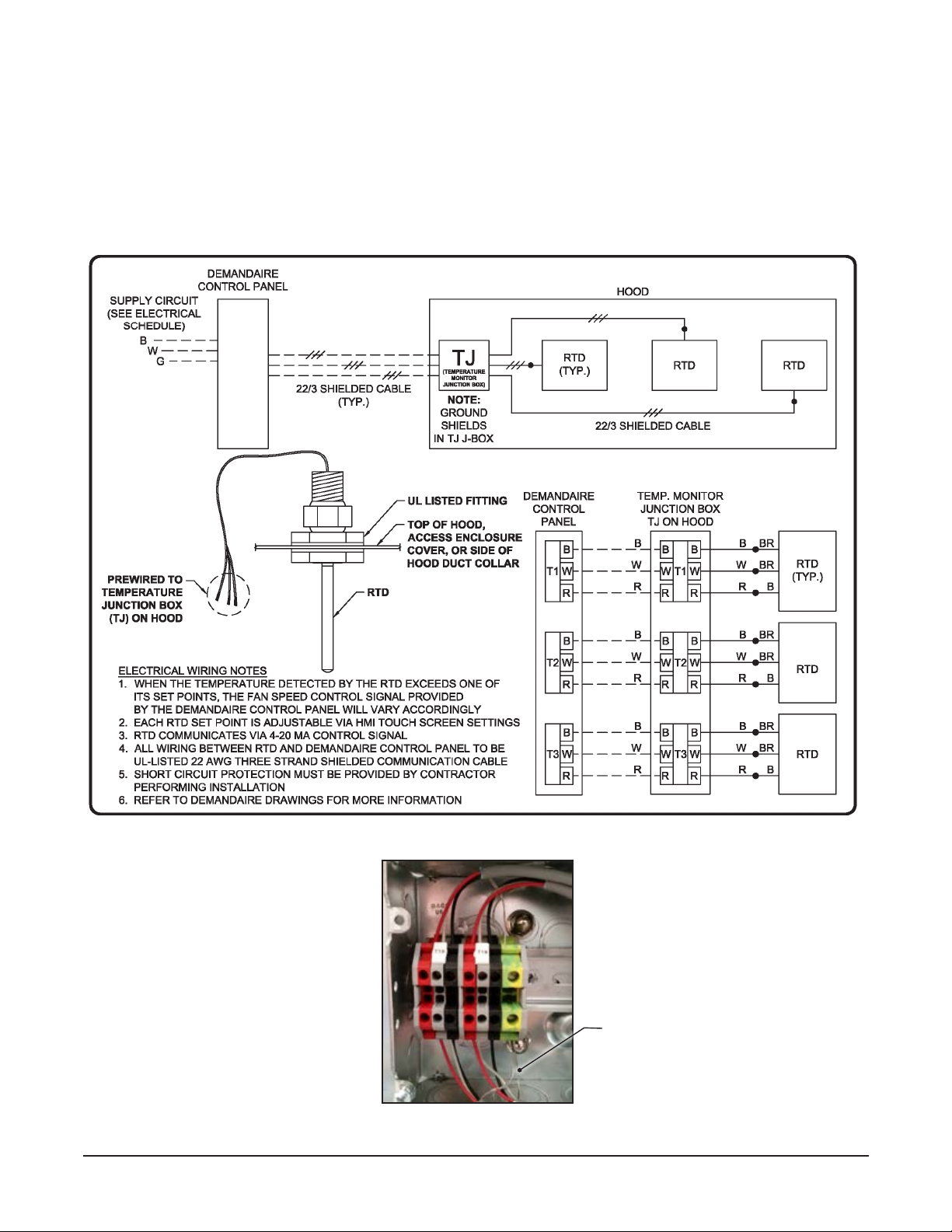

Figure 11: Hood Canopy and/or Duct Collar Resistance Temperature Detector (RTD) Wiring

Hood Canopy and/or Duct Collar Temperature Monitor Wiring

a. Verify that all supply power to the control panel is locked out and tagged out.

b. Connect the terminal blocks labeled T1, T2, T3, etc., in the control panel to the corresponding terminal blocks in

the J-Box on the hood using the UL-Listed 22 AWG Three-Strand Shielded Communication Cable (Figure 11, 12).

c. The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

Figure 12: Hood Canopy and/or Duct Collar RTD Wiring

Connections in Temperature Monitor Junction Box

RTD Shields Must be

Grounded in Temperature

Monitor Junction

Box TJ on Hood

13

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

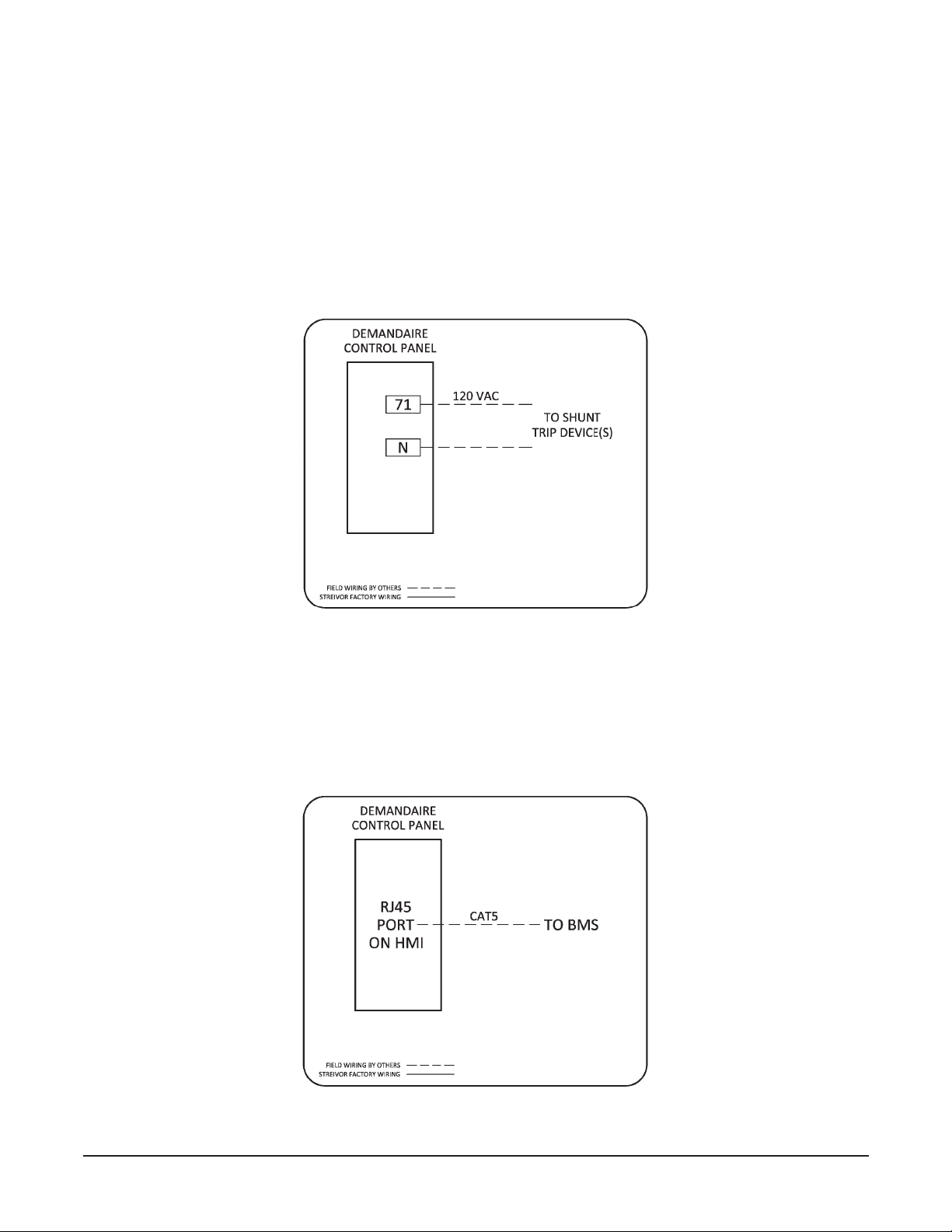

Optional: Modbus TCP Communication Wiring

a. Verify that all supply power to the control panel is locked out and tagged out.

b. A CAT5 or greater Ethernet communication cable may be connected to the RJ45 port on the HMI in the control

panel for Modbus TCP communication with Building Management System(s) (Figure 14).

c. Contact Streivor for Modbus TCP communication points list and associated communication setup parameters.

FIGURE 14: Optional Modbus TCP Communication Wiring

Optional: Shunt Trip Breaker Wiring

Per NFPA 96 Section 10.4.1: Upon activation of any re-extinguishing system for a cooking operation, all sources

of fuel and electrical power that produce heat to all equipment requiring protection by that system and all

electrical outlets located under the exhaust hood shall automatically shut o.

a. Verify that all power to the control panel is locked out and tagged out.

b. Terminal block 71 can be used to provide power to a shunt trip device to comply with NFPA 96 Section 10.4.1.

Terminal block 71 provides 120 VAC power upon re suppression system activation (Figure 13).

c. The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

FIGURE 13: Optional Shunt Trip Wiring

Installation Procedures

14

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Electric Gas Valve Input Power Wiring

a. Verify that all supply power to the control panel is locked out and tagged out.

b. Verify that the circuit breaker amperage is sized correctly for the electric gas valve power circuit per the DCP

drawings.

c. Connect 120 VAC single phase power to the terminal blocks in the control panel labeled H1, N1, and Ground

(Figure 15). Note: The electric gas valve circuit input power is separate from the control circuit input power.

d. The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

e. Repeat for additional electric gas shuto valve circuits if applicable. Refer to DCP drawings for more information.

Installation Procedures

Electric Gas Valve Output Power Wiring

a. Verify that all supply power to the control panel is locked out and tagged out.

b. Connect 120 VAC single phase power from terminal blocks 130, 131, and ground in the control panel to the

corresponding pre-wired leads on the electric gas valve solenoid(s) (Figure 16).

c. The wires should be torqued to 0.6-0.8 N•m at the terminal blocks.

d. Repeat for additional electric gas shuto valve circuits if applicable. Refer to DCP drawings for more information.

e. Note: A manual keylock bypass switch is pre-wired in the DCP to provide power to the electric gas valve circuit

during commissioning and troubleshooting if necessary.

FIGURE 16: Electric Gas Valve Circuit Output Power Wiring

FIGURE 15: Electric Gas Valve Circuit Input Power Wiring

15

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Operation Procedures

Start Up

1. Apply power to the DemandAire Control Panel CONTROL circuit via the appropriate circuit breaker protecting the DCP.

a. Verify that 120 VAC is applied between terminal blocks H and N.

2. If the re suppression system includes an electric gas valve(s), apply power to the GAS VALVE circuit via the

appropriate circuit breaker protecting the electric gas valves.

a. To open the electric gas valve(s) via the HMI touch screen, refer to the Electric Gas Valve Reset Relay section.

3. If the control panel includes motor starter(s), apply power to the MOTOR circuits via the appropriate circuit breakers

protecting the fan motors.

a. Verify that the specied fan motor power is applied to incoming power terminal blocks of each corresponding

motor starter(s).

b. Refer to the DCP drawings for voltage, phase, and designated terminal blocks for each fan motor.

Human Machine Interface (HMI) Touch Screen Control

The HMI touch screen should be installed in a location where it is readily accessible as it contains all of the switches

required to operate the DemandAire system. The HMI also serves as an interface where programming changes are made

to temperature monitor set points. Fan delay settings, fan operation history and current temperature in each hood system

can be viewed on the HMI as well.

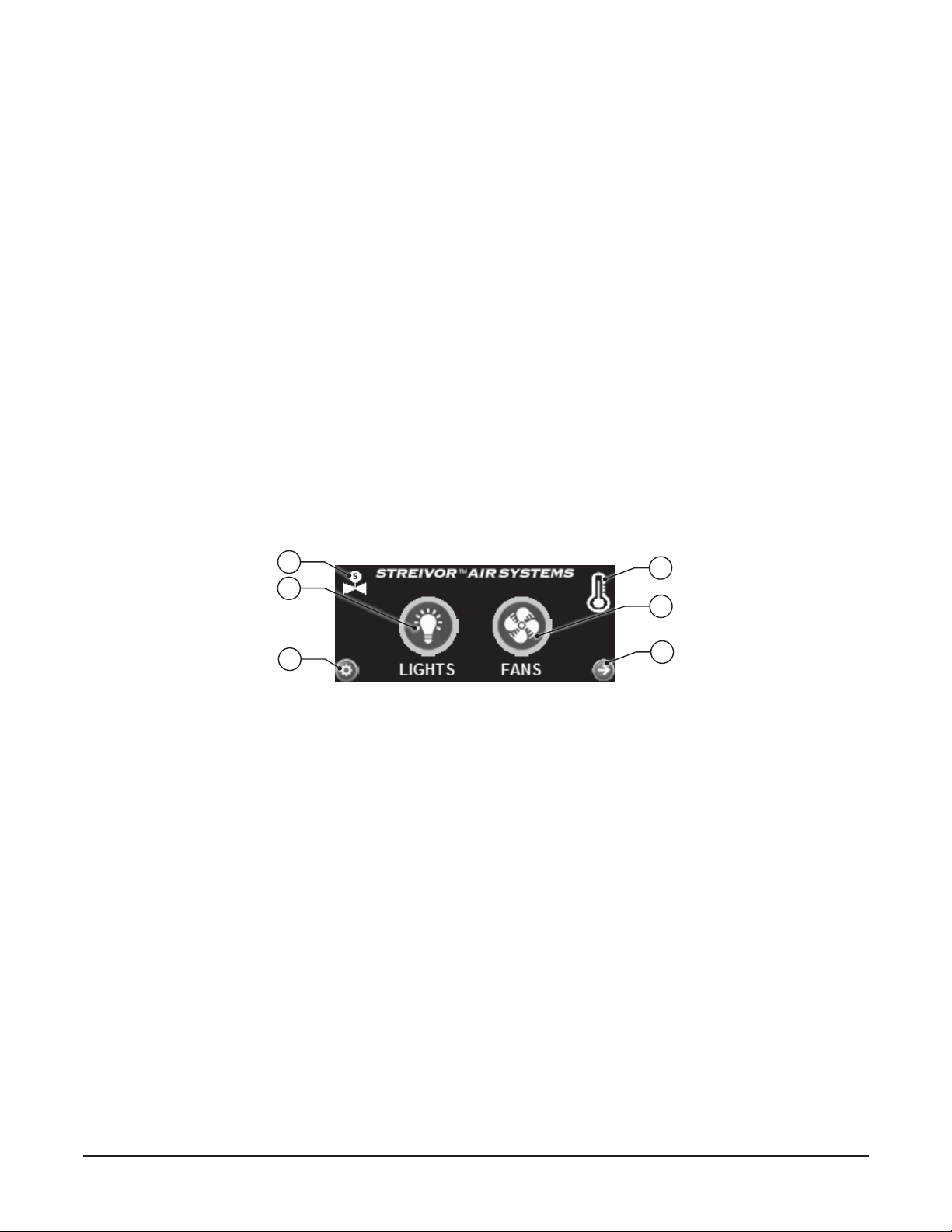

Home Screen

The home screen is the default screen for the HMI which provides the switches required for normal operation of the

DemandAire system.

1. Light Switch

Provides power to the light(s) manually.

2. Fan Switch

Provides power to the fan motor(s) manually.

3. Temperature Indicator

Appears in the top right corner of the home screen when the fans are activated automatically due to an increase in

temperature sensed below the hood(s).

4. Next or Previous Buttons

Allows cycling through each HMI screen.

5. Secure Settings Button

Allows access to password protected system settings. Contact Streivor for help accessing secure settings.

6. Electric Gas Valve Power Indicator

Appears on the top left corner of the home screen when power to the electric gas shuto valve is on.

1

3

2

4

Home Screen

5

6

16

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Operation Procedures

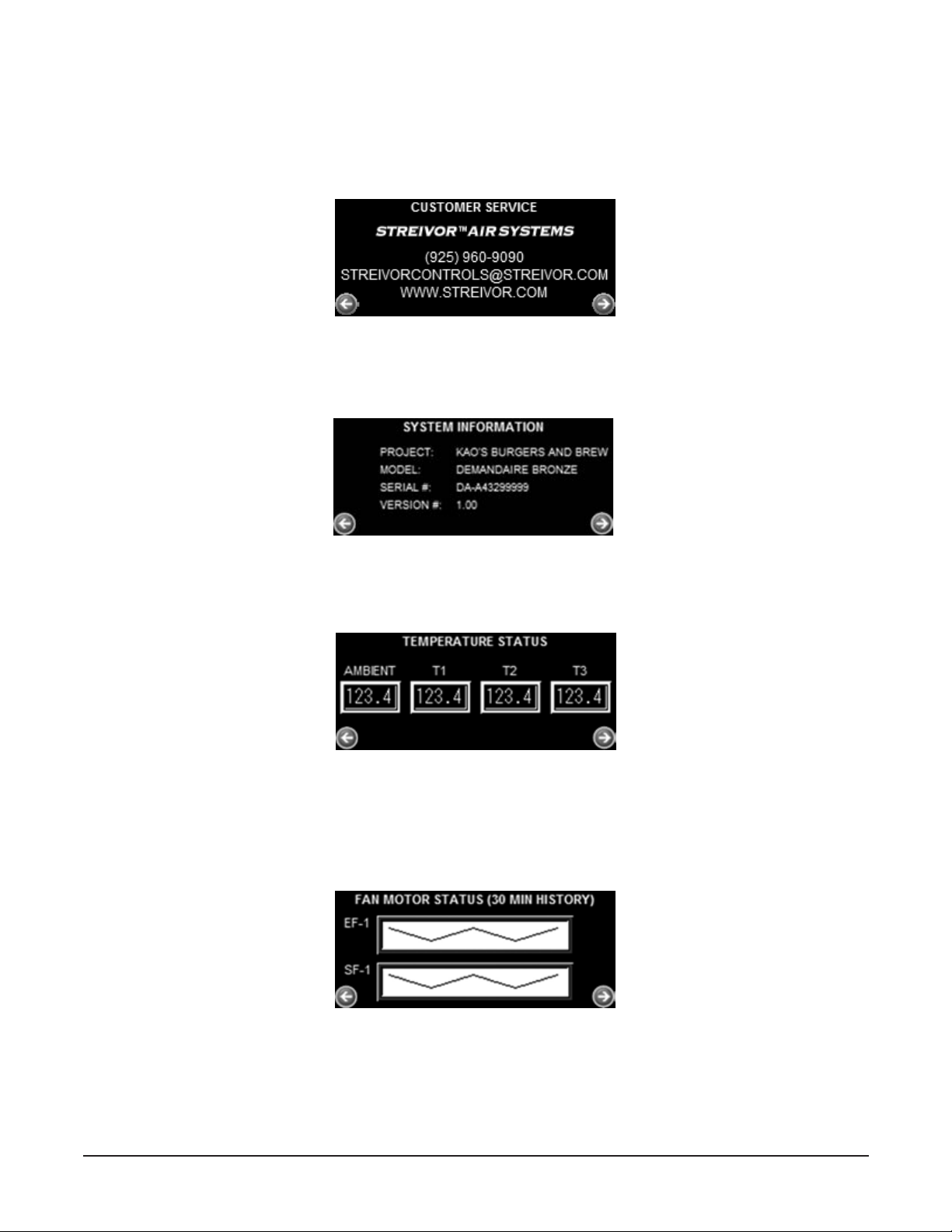

System Information Screen

Customer Service Screen

Temperature Status Screen

Customer Service Screen

Displays Streivor’s company phone number, email address, and website information.

Temperature Status Screen

Displays the current temperature (ºF) readings of the ambient and the hood temperature monitors.

Fan Motor Status Screens

Display the percentage of maximum motor power provided to each fan. 30-minute and 24-hour history graphs are

available.

Fan Motor Status Screen

System Information Screen

Displays the project name, model number, serial number and other pertinent information that indenties this specic

DemandAire system that has been installed.

17

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

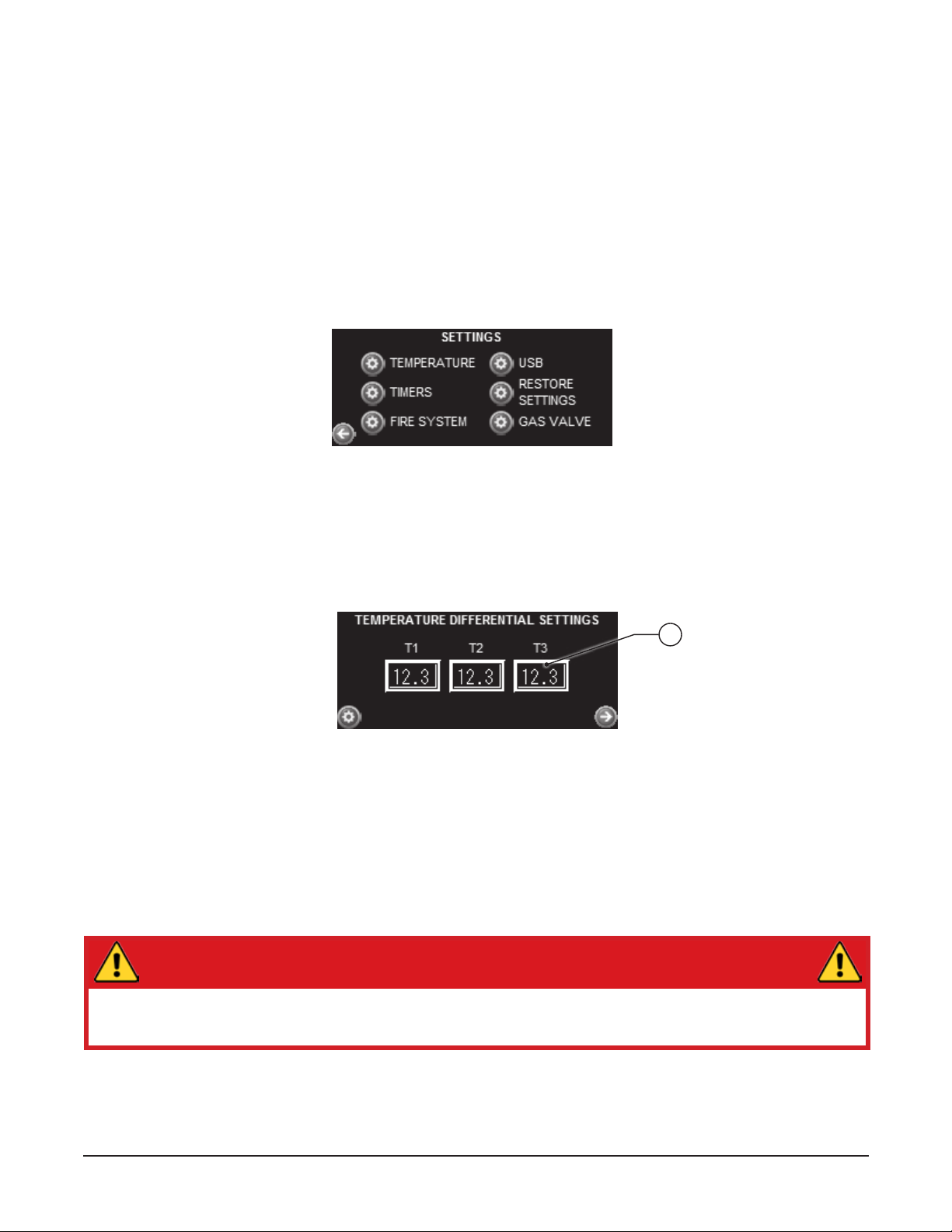

Operation Procedures

NOTE: HOOD(S) WHICH INCLUDE TEMPERATURE MONITOR(S) MAY AUTOMATICALLY PROVIDE POWER

TO THE FAN(S) CONTROLLED BY THE DCP EVEN IF THE FAN SWITCH IS IN THE OFF POSITION.

Temperature Dierential Settings Screen

7

Secure Settings (Password Protected)

The DemandAire system provides password protection of secure system settings, such as settings for the

temperature monitors, timers, etc. Only password holders have access to the secure system settings. Adjustments to

secure settings may be necessary due to changes to or around the CKV System and/or the cooking appliances after

initial startup. Consult Streivor for information on accessing or adjusting secure settings.

Settings Screen

Displays access to all secure system settings. Press the settings button next to the settings description, select the

user, and input the password to view and/or adjust the secure settings.

Secure Settings Screen

7. Temperature Monitor Dierential Set Point

Each temperature monitor has an adjustable temperature dierential set point. The set point(s) have been preset by the

factory; however, depending on eld conditions and cooking appliances below the hood, further adjustment may be

necessary in the eld to maintain optimal operation. The recommended temperature dierential set point is approximately

5°F - 15°F above the ambient temperature in the kitchen. WARNING: Consult Streivor prior to modifying temperature

dierential set points. Setting the temperature dierentials too high may result in inadequate exhaust airow

which may result in the loss of capture and containment and/or activation of the re suppression system.

Temperature Dierential Settings Screen (Management)

Displays the temperature monitor dierential settings. The temperature monitor(s) located in each hood are engineered

to automatically turn on the fan(s) controlled by the DemandAire system once the adjustable set point of at least one

temperature monitor has been reached. Temperature dierential set points may be adjusted from the Temperature

Dierential Setting Screen.

18

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Operation Procedures

Fire Suppression Systems Settings Screen

Restore Factory Settings Screen

Restore Factory Settings (Management)

11. Restore Factory Settings Button

Restores all settings preset by the factory.

USB Removal Screen

10. USB Safe Removal Button

Allows USB drive to be safely removed from HMI touch screen.

USB Removal Screen

Timer Settings (Management)

8. Fan Ramp Down Delay

Displays the fan ramp down delay time duration which provides power to the fan(s) for a designated time after the

temperature in the hood(s) decreases below the temperature monitor dierential set point.

Fire Suppression System Settings (Management)

9. Lights Operation Settings

Allows the hood lights to remain on (1) or o (0) in the event of a re suppression system actuation.

Timer Settings Screen

8

9

10

11

19

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Electric Gas Valve Reset Relay

The electric gas valve power can be reset from the HMI touch screen for DemandAire systems which include an inte-

grated Electric Gas Valve Reset Relay. In the event of a re suppression system actuation, the DemandAire system will

shunt power being provided to the electric gas shuto valve. The valve will close to discontinue the supply of gas to

cooking appliances and will remain in the closed position until manually reset. Contact a certied plumbing technician

to inspect the system following a re suppression system actuation. Upon approval by certied plumbing technician,

proceed to reset power to the electric gas shuto valve.

Following a power outage, the popup screen below will automatically appear over the Home Screen indicating that the

electric gas valve power has been shut o.

Press the arrow button to proceed to reset the electric gas shuto valve(s), following the on-screen instructions until

arriving at the Electric Gas Valve Reset screen below. Press the Reset button to manually reset power to the electric

gas shuto valve. The Electric Gas Valve Reset screen can also be accessed directly from the Secure Settings screen

or through the on-screen instructions following a re suppression system actuation.

After power has been reset to the electric gas shuto valve(s), a conrmation screen will appear and the Electric Gas

Valve Power Indicator will appear in the top left corner of the Home screen.

Operation Procedures

Electric Gas Valve Power O Popup Screen

Electric Gas Valve Reset Screen

20

Streivor DemandAire Bronze Control Panel Installation and Operations Manual

2150 Kitty Hawk Road, Livermore, CA 94551 | (925) 960-9090 | Fax: (925) 960-9055

Operation Procedures

Alarms

The DemandAire Bronze control system provides audible and/or visual indicators on the HMI touch screen in the event

of an alarm condition. Alarms include Temperature Monitor Faults, High Temperature, Fan Motor Overload, and Fire

Suppression System Activation.

Temperature Monitor Alarm

In the event of a temperature monitor alarm, the alarm screen will appear on the HMI indicating which temperature

monitor is not functioning properly. The temperature monitor alarm may occur if the temperature monitor has been

damaged or if it is not wired correctly. The exhaust and supply fan(s) controlled by the DCP will automatically go to full

capacity upon sensing a temperature monitor alarm. Once the alarm has been resolved, press the Reset button to return

to the home screen to resume normal operation.

Temperature Monitor Alarm Screen

High Temperature Alarm

This screen will appear when the temperature below the hood exceeds a predetermined alarm setpoint. If the high

temperature alarm occurs, turn o all cooking appliances below the hood that is activating the alarm and verify that the

exhaust fan is working as specied. Failure to turn o cooking appliances generating heat may result in loss of capture

and containment and/or an actuation of the re suppression system. Contact a qualied HVAC technician to inspect the

exhaust system to determine the reason for the alarm. Once the hood temperature decreases below the high temperature

alarm setpoint, press the Reset button to return to the home screen to resume normal operation.

High Temperature Alarm Screen

Fan Motor Overload Alarm

When motor starters for the fan(s) are provided by Streivor in the DCP, a fan motor overload alarm can occur due to an

overcurrent condition. The fan motor overload alarm will indicate which fan motor overload has tripped. When a fan

motor overload alarm occurs, turn o all cooking appliances and contact a qualied electrician to inspect fan motors and

overloads. Failure to turn o the cooking appliances generating heat may result in loss of capture and containment and/or

an actuation of the re suppression system. Once the fan motor overload has been inspected, resolved and reset, press the

Reset button on the HMI to return to the home screen to resume normal operation.

Fan Motor Overload Alarm Screen

Table of contents

Popular Fan manuals by other brands

IHP

IHP VENT-KIT-6X12 installation instructions

AccuraSEE

AccuraSEE MINI user manual

National Ventilation

National Ventilation monsoon MONS100HT Installation and wiring instructions

Vent-Axia

Vent-Axia 45 40 55B Installation and wiring instructions

Hunter

Hunter Bardot installation manual

Maico

Maico EZF B Series Mounting and operating instructions