4 www.stryker.com

EN 6400-099-700 Rev-AA

Accessories (continued)

WARNINGS:

• DO NOT reuse, reprocess, or repackage a single use device.

A single use device is intended for a single use only. A single

use device may not withstand chemical, chemical vapor, or

high temperature sterilization reprocessing. Design features

may make cleaning difficult. Reuse may create a serious risk

of contamination and may compromise the structural integrity

of the single use device resulting in operational failure. Critical

product information may be lost if the single use device is

repackaged. Failure to comply may lead to infection or cross-

infection and result in patient and/or healthcare staff injury.

• All cutting accessories are intended for single use only. Reuse

significantly increases wear on the handpiece and attachment.

• Wobbling may cause inaccurate wire or pin placement and/

or bone or tissue damage. If wobbling occurs, see the

Troubleshooting section.

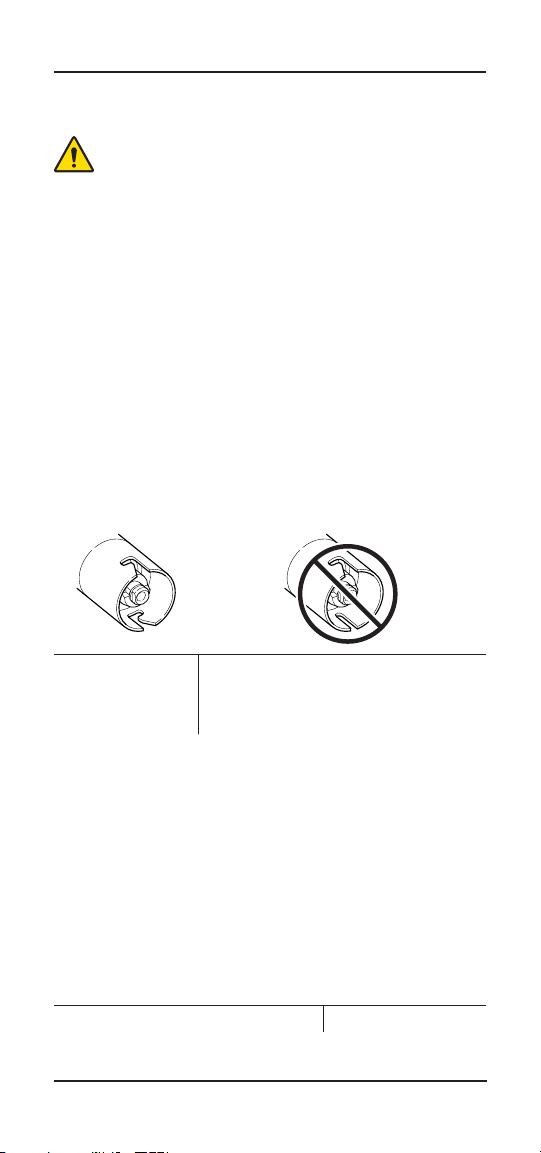

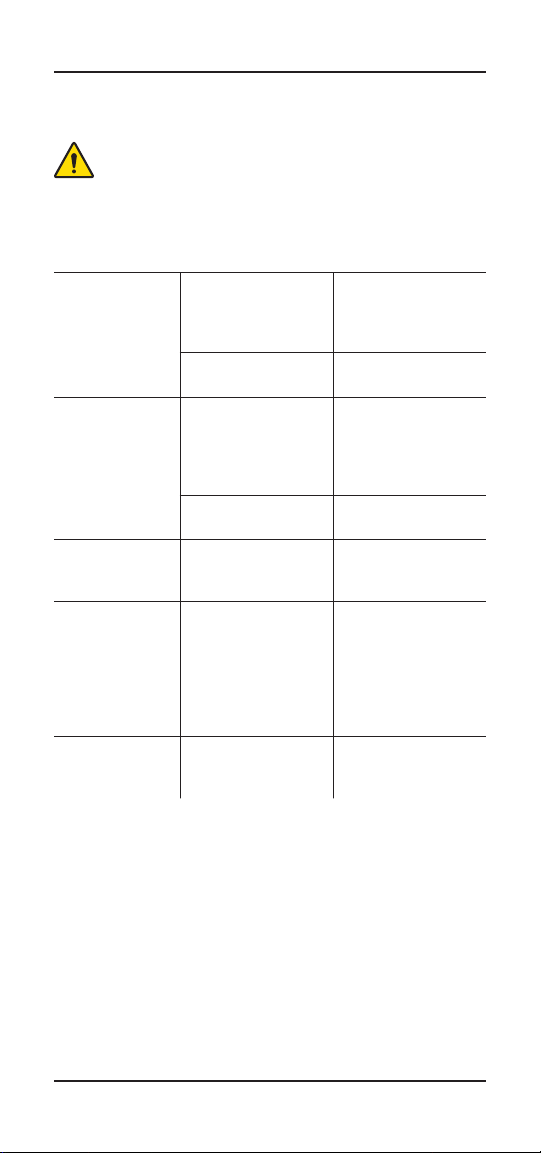

• When using the Universal Driver, always use Stryker

attachments with two J-slots. The Universal Driver will not fully

retain Stryker attachments with only one J-slot.

Use attachments

with two J-slots.

DO NOT use earlier versions of the

Stryker Wire Collet (REF 4100-062-000)

or Pin Collet (REF 4100-125-000). Both

collets have only one J-slot.

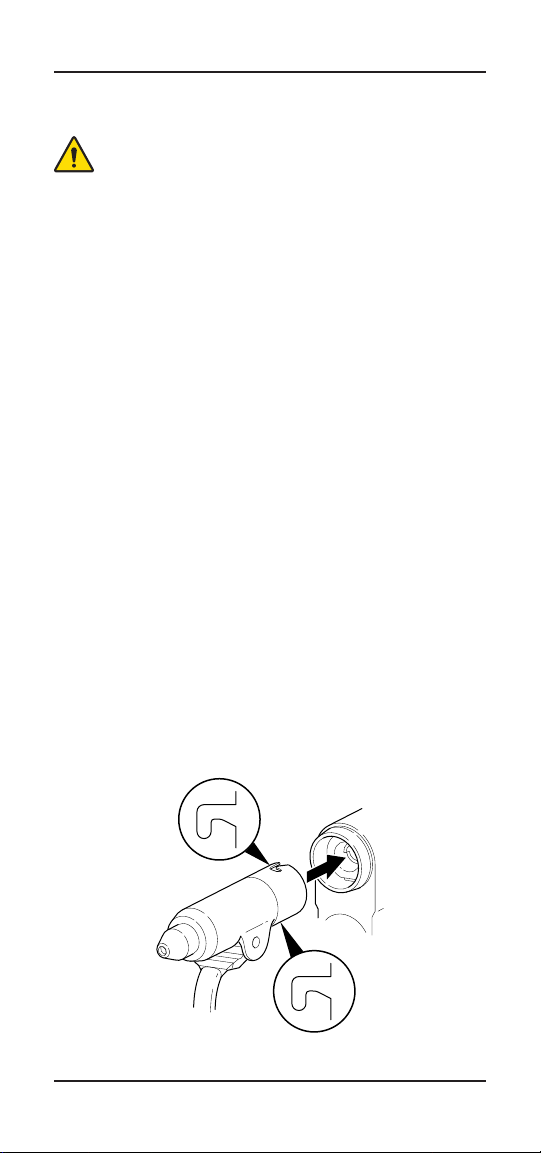

A variety of specialized attachments are available for use with

the handpiece. Each attachment has a specialized retainer for

wires, pins, tools or cutting accessories. See the Cordless Driver

and Universal Driver Attachments Instructions For Use for specific

attachment and accessory instructions.

NOTES:

• Cutting accessories are sterilized using irradiation.

• For a complete list of accessories, contact your Stryker sales

representative or call Stryker customer service. Outside the US,

contact your nearest Stryker subsidiary.

The following Stryker-approved accessories are sold separately:

DESCRIPTION REF

Handpiece Cord 5100-004-000