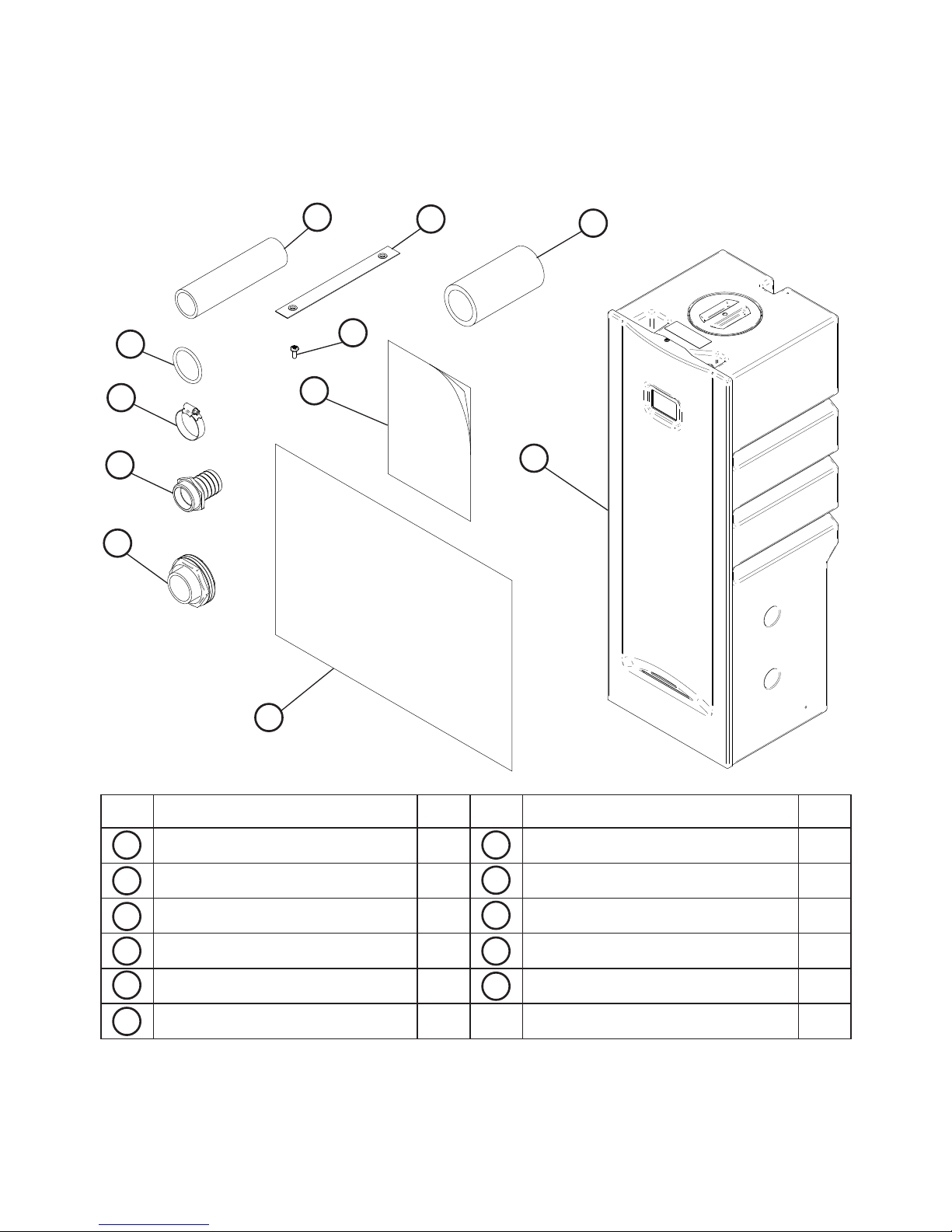

PRODUCT DESCRIPTION

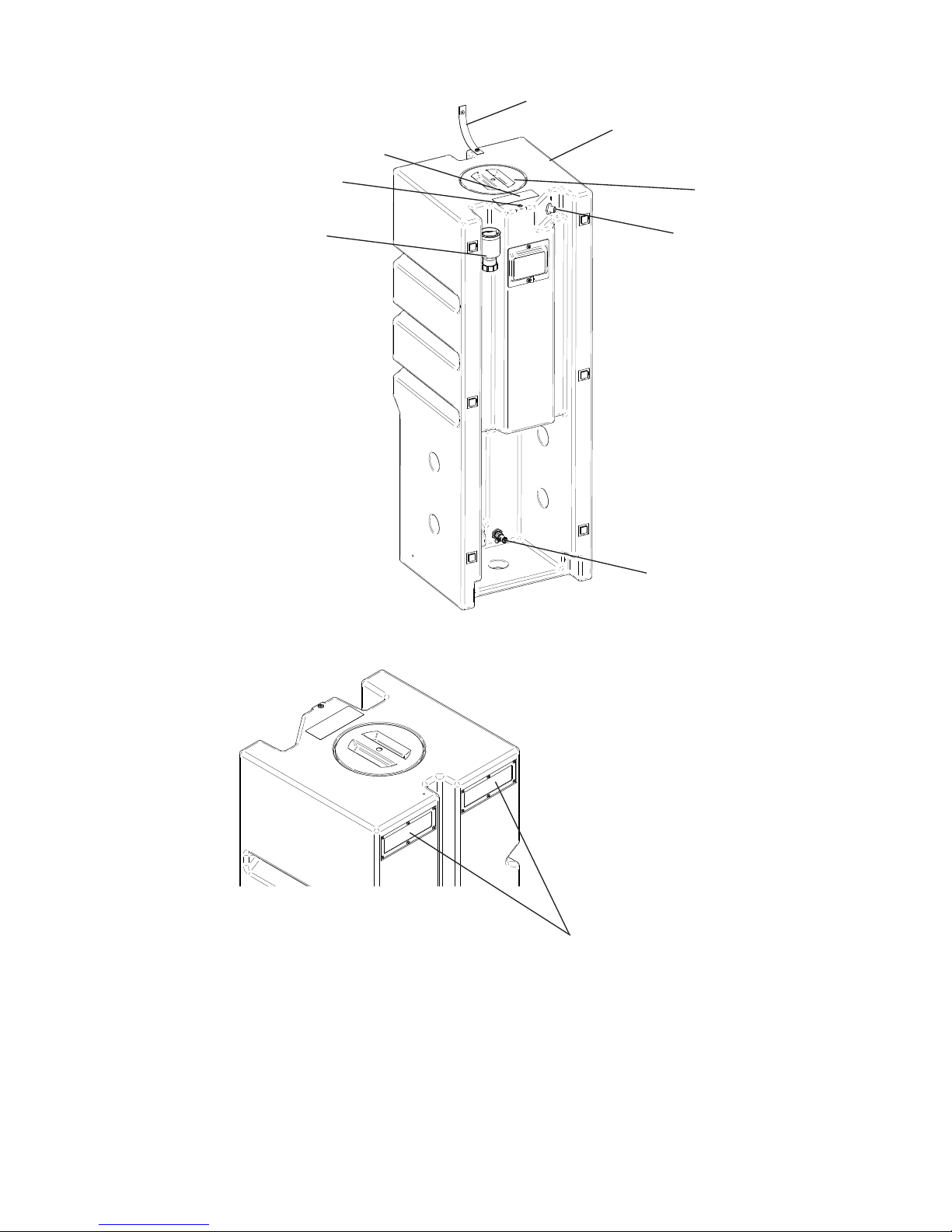

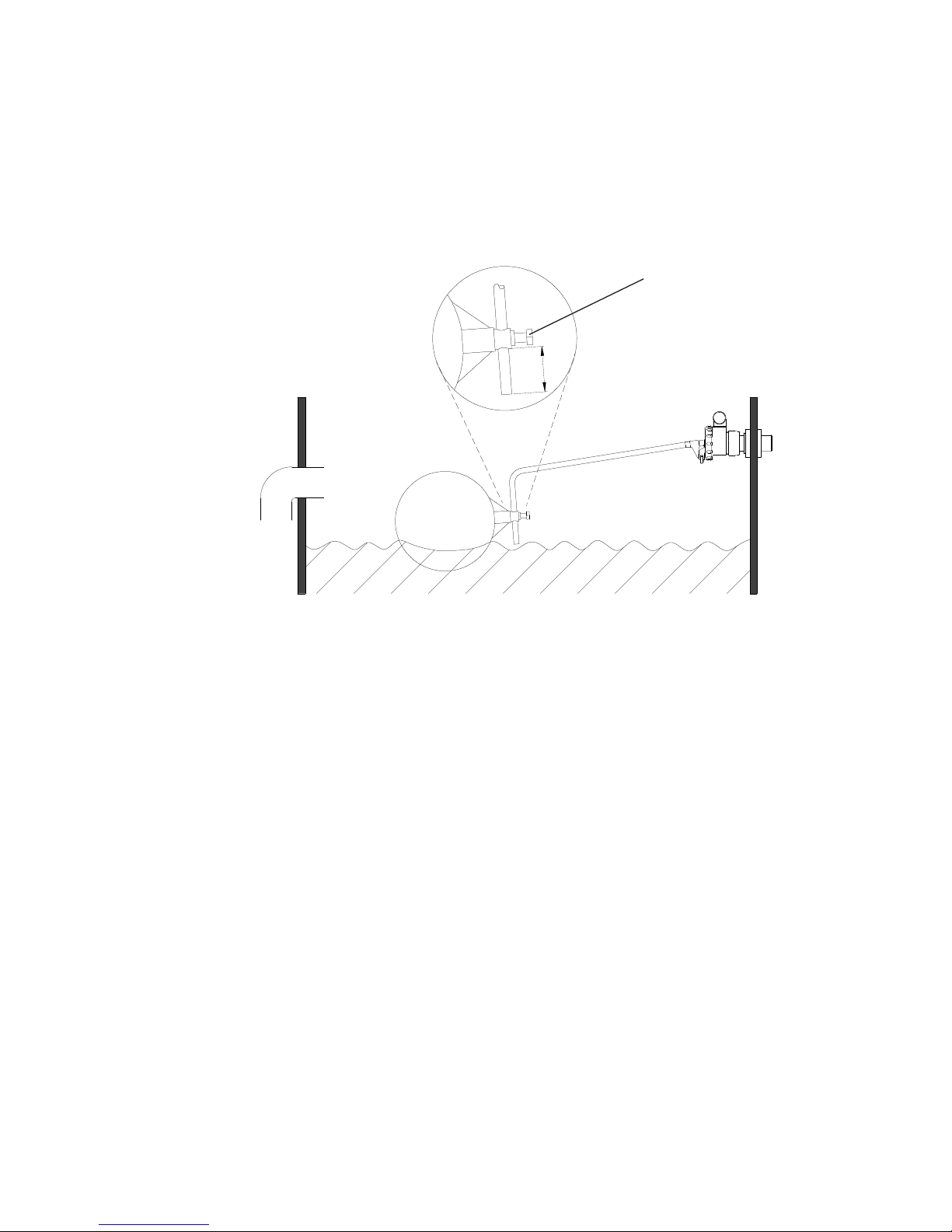

iBoost +200

Additional water storage tank consisting of fill valve, 200 litre water storage and coupling

for system integration to an iBoost 200. The design of the tank incorporates an AF air gap

for fluid isolation (BS EN 1717).

iBoost +200 CAT 5

Additional water storage tank consisting of fill valve, 200 litre water storage and coupling

for system integration to an iBoost 200 CAT 5. The design of the tank incorporates an AB

air gap for fluid isolation (BS EN 1717).

APPLICATION

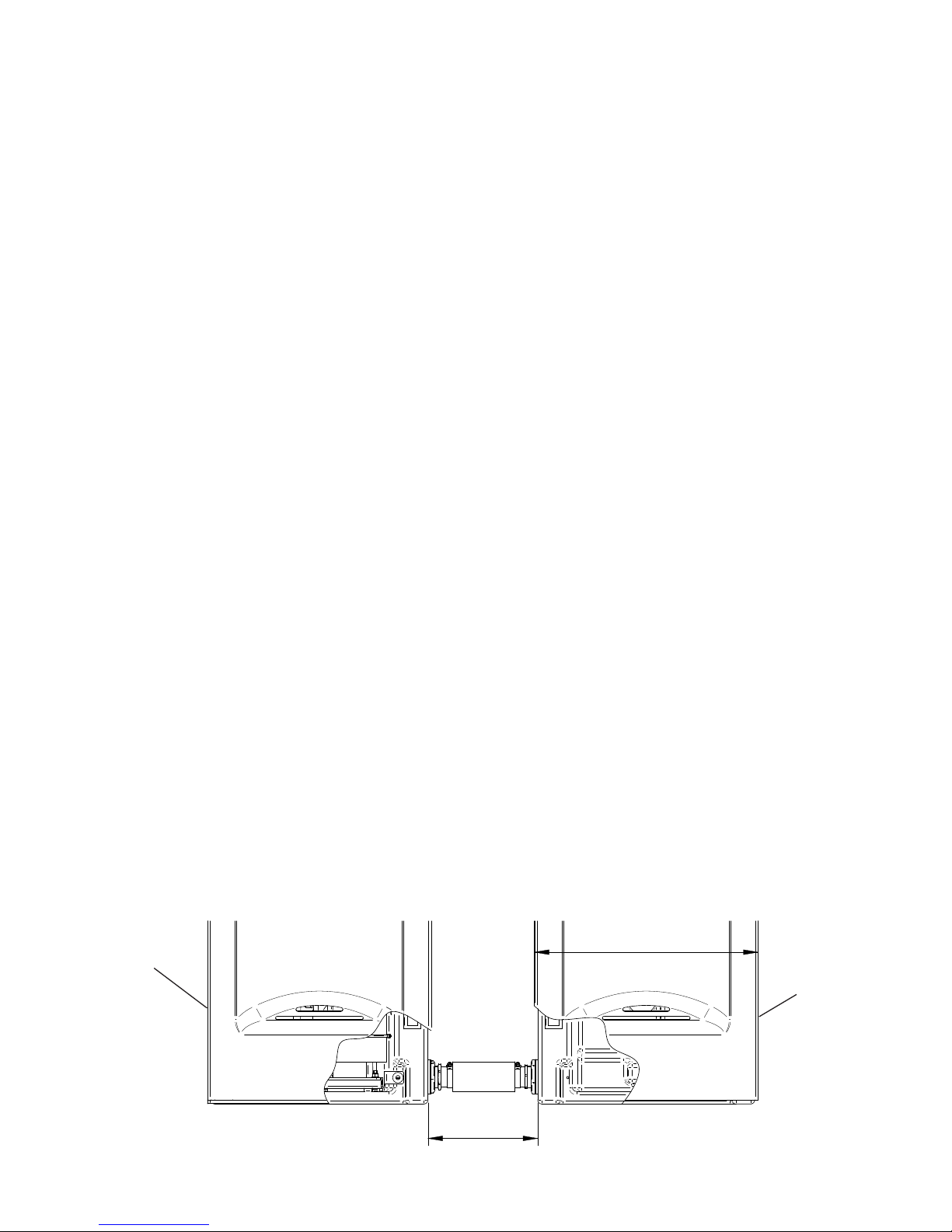

The Aquaboost iBoost +200 is designed to meet the demand of pressurised systems in

larger domestic applications where the existing mains water supply is insufficient. Inlet

pressures to the tank and ambient temperatures must not exceed the values

given in the technical specifications.

zThis appliance must not be used for any other

application without the written consent of Stuart

Turner Limited.

zThis appliance can be used by children

aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they have

been given supervision or instruction concerning

use of the appliance in a safe way and understand

the hazards involved. Children shall not play with

the appliance. Cleaning and user maintenance

shall not be made by children without supervision.

zChildren should be supervised to ensure that they

do not play with the appliance.

zThis product should not be used for the supply of

water to more than one dwelling (house,

apartment, flat).

Please read installation details carefully as they are intended to ensure this

product provides long, trouble free service. Failure to install the unit in

accordance with the installation instructions will lead to invalidation of the

warranty.

STORAGE

If this product is not to be installed immediately on receipt, ensure that it is stored in a dry,

frost and vibration free location in its original packaging.