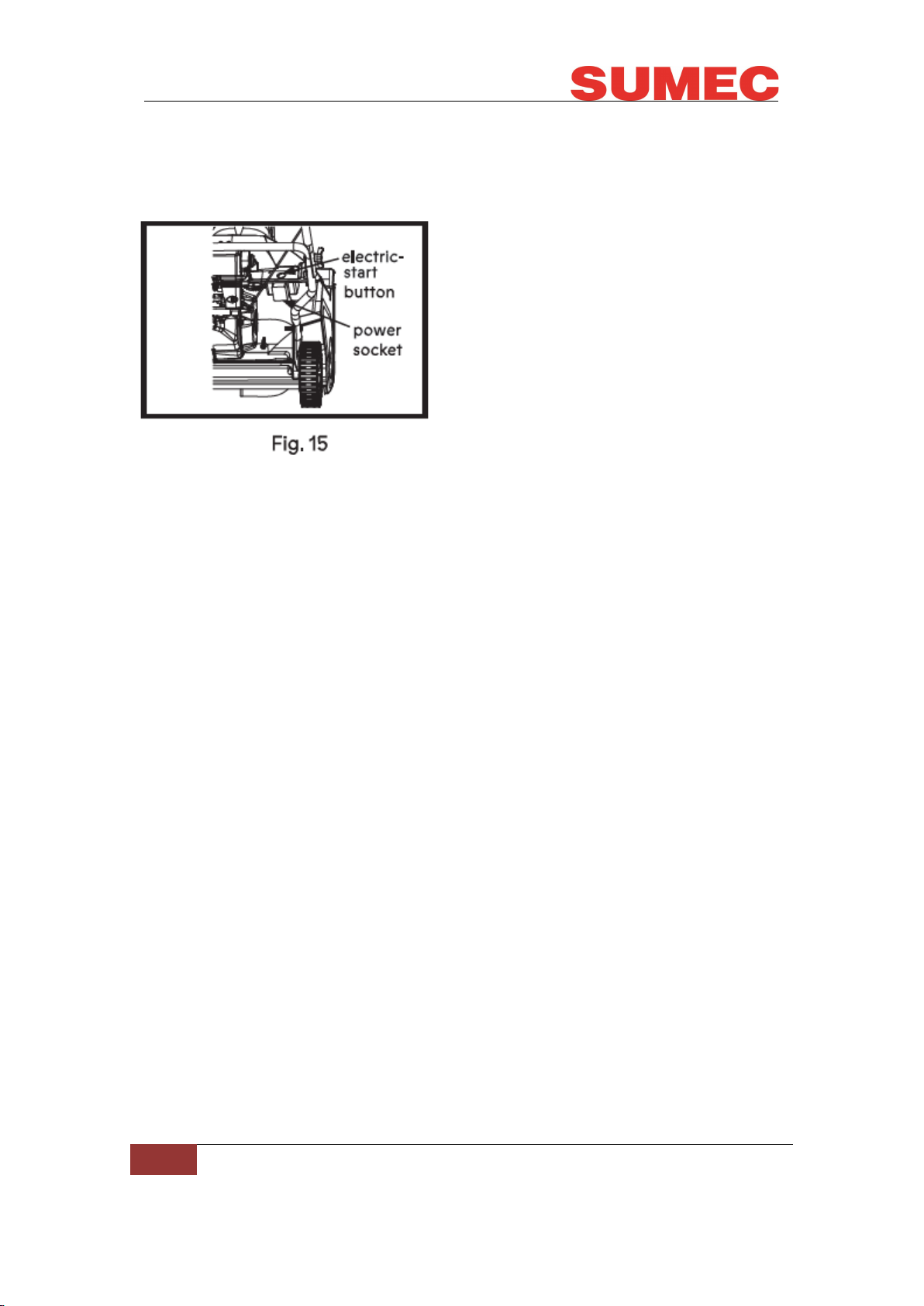

ELECTRIC START

NOTE: Use only a UL-Listed, 16-gauge extension cord recommended for

outdoor use that is not longer than 50 '/15m.

Connect an extension cord first to a power source and then to the power

socket of the machine, and press the electric-start button (Fig.15).

IMPORTANT: To prevent damaging the electric starter. Do not run the electric

starter more than 10 times at intervals of 5 seconds on, then 5 seconds off. If

the engine does not start after this series of attempts, allow the starter to cool

for at least 40 minutes before attempting to start it again. If the engine still does

not start after the second series of attempts, take the machine to an Authorized

Service Dealer for service. Once started, disconnect the plug from the power

supply and the starter.

RECOIL START

NOTE: If the recoil starter does not operate properly, it may be frozen. Thaw

out the starter before attempting to start the machine.

NOTE: If the engine fails to start after three pulls, repeat the process.

1. Pull the recoil start handle out approximately 4" to 6"/10 to 15 cm until you

feel a resistance and then start the engine with a sharp pull (Fig. 16)

2. Once the engine is running, put the starter rope into the rope guide (Fig. 16).

While the engine is running, move the choke lever gradually to the "RUN"

position;

STOP THE ENGINE

To stop the engine, pull the ignition key outward.

ENGAGING THE AUGER PADDLE

To engage the auger paddle, hold the auger control lever against the handle

(Fig. 17).