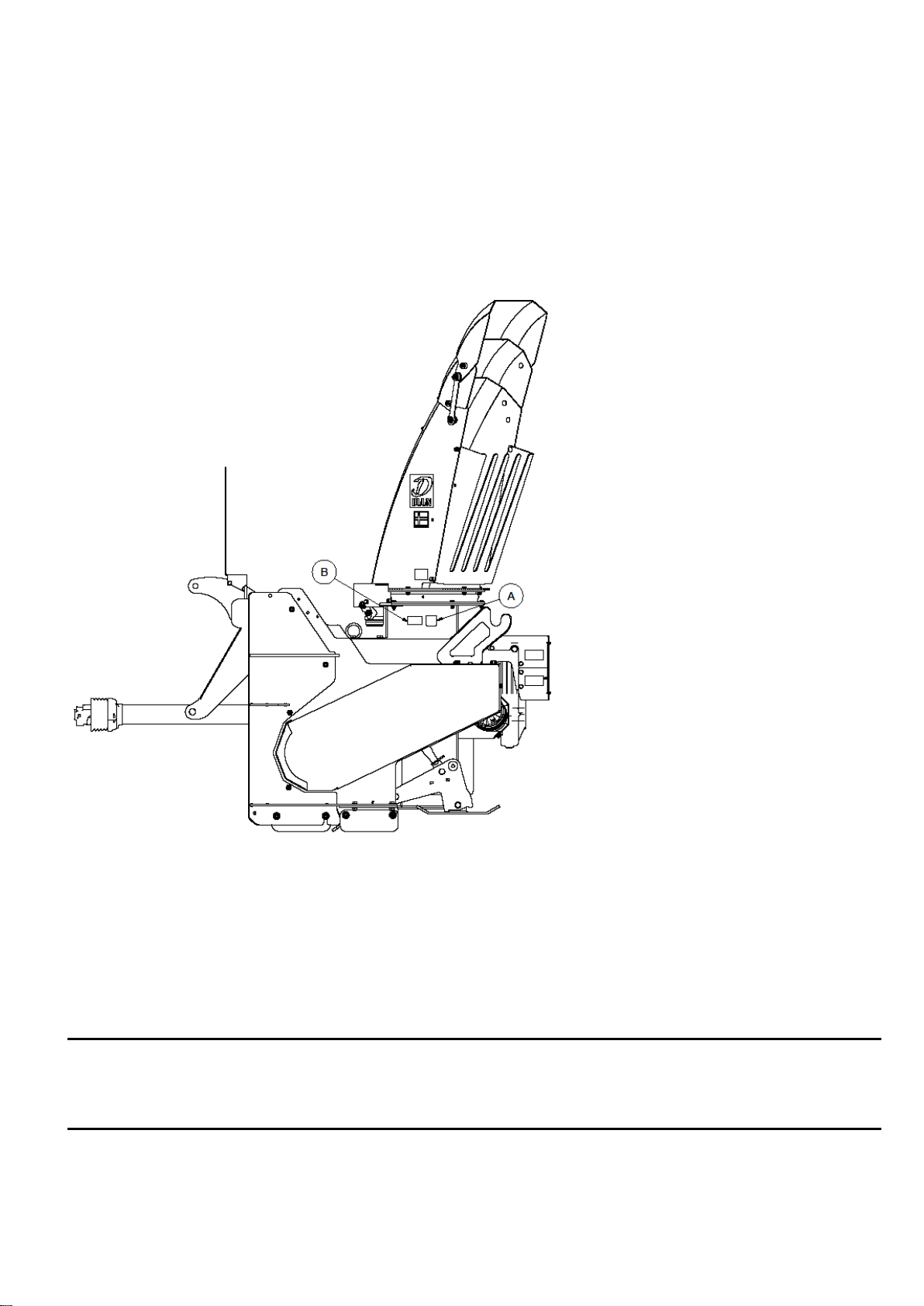

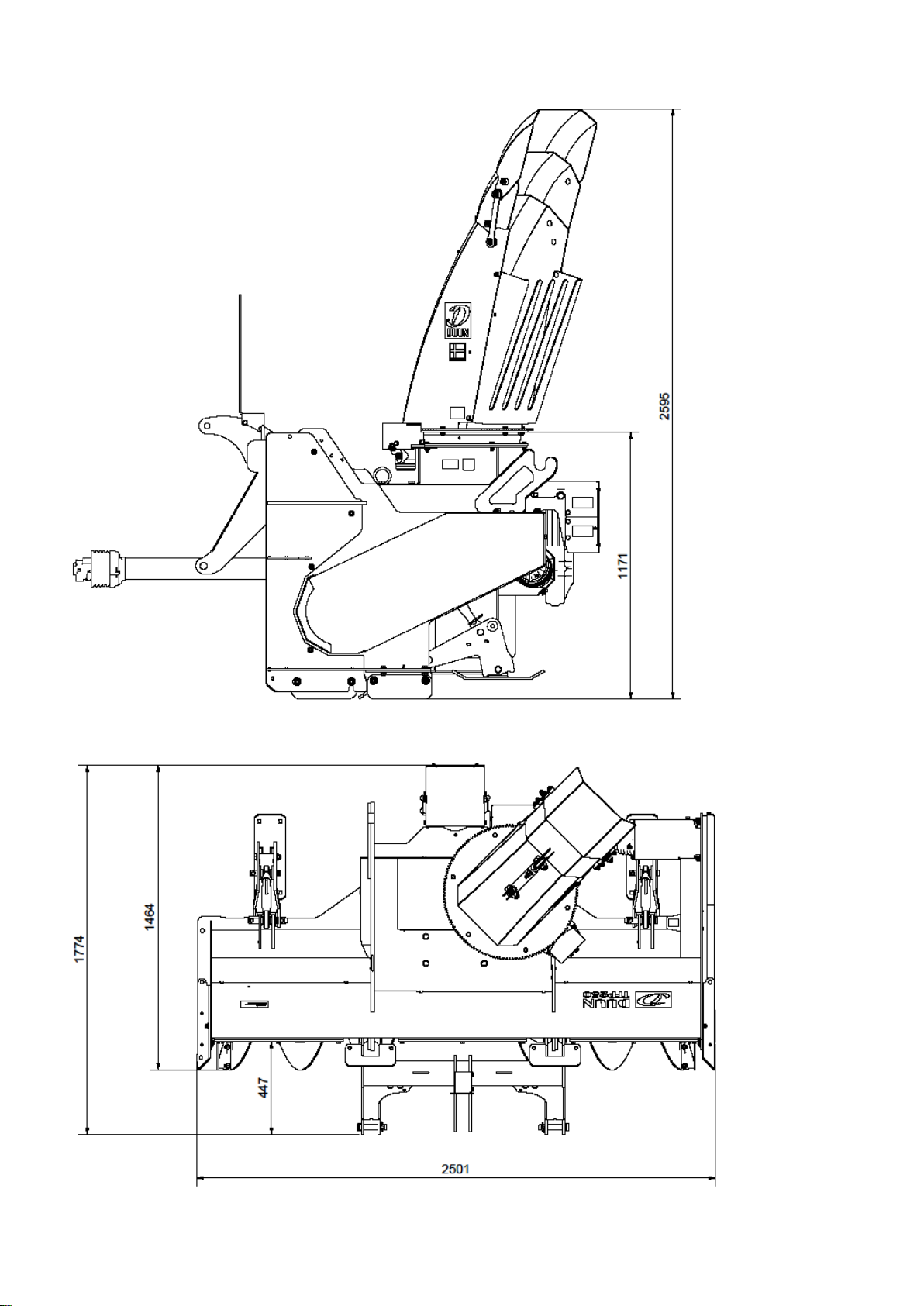

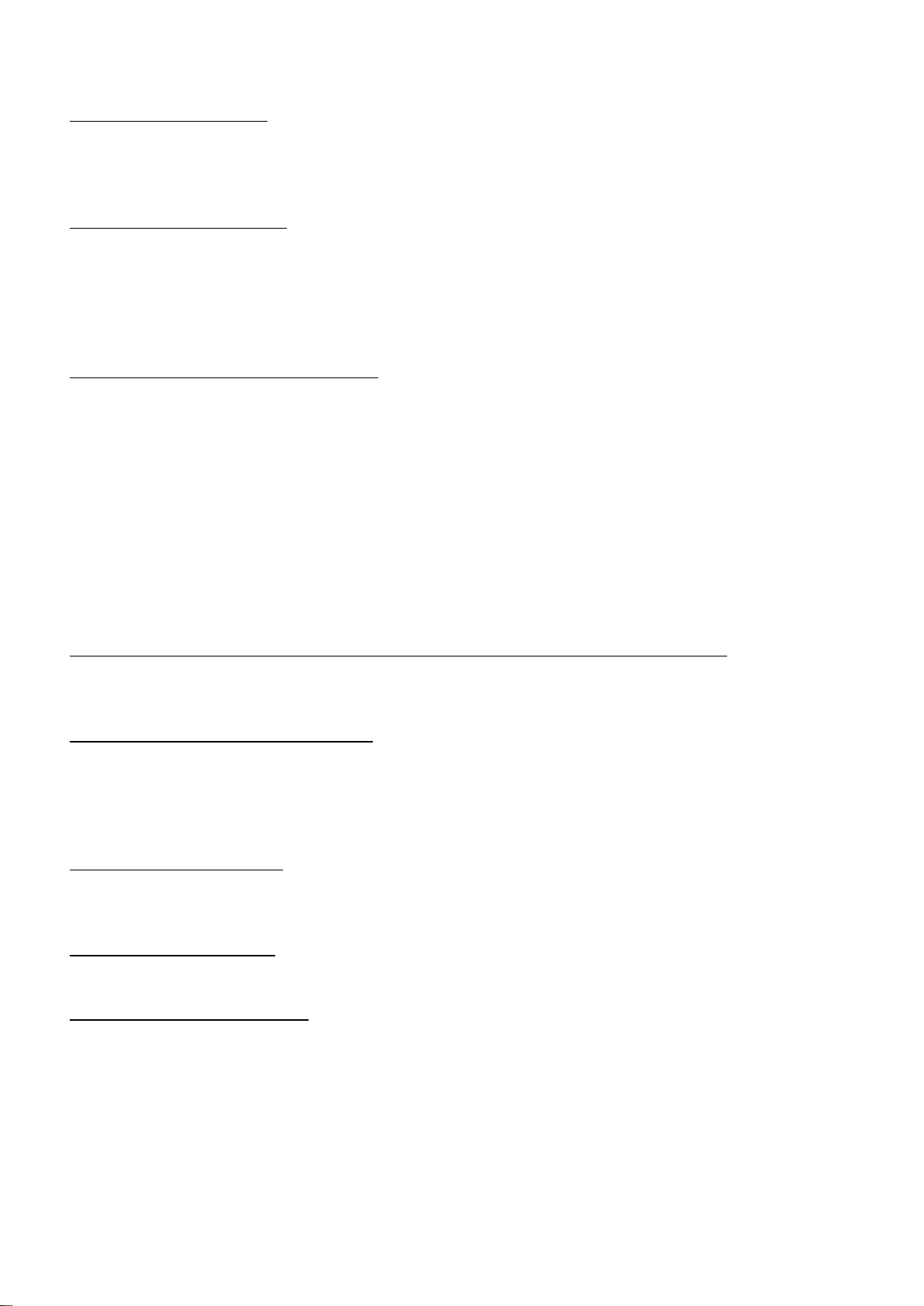

Preparation for use

Adjustment of skid pads

The snow blower is placed on a level surface and the skid pads are adjusted so that the wear

steels on both sides + the infeed steel in front of the fan housing have clearance above ground

level. Too small distance here will cause abnormal wear on both wear steel and feed steel.

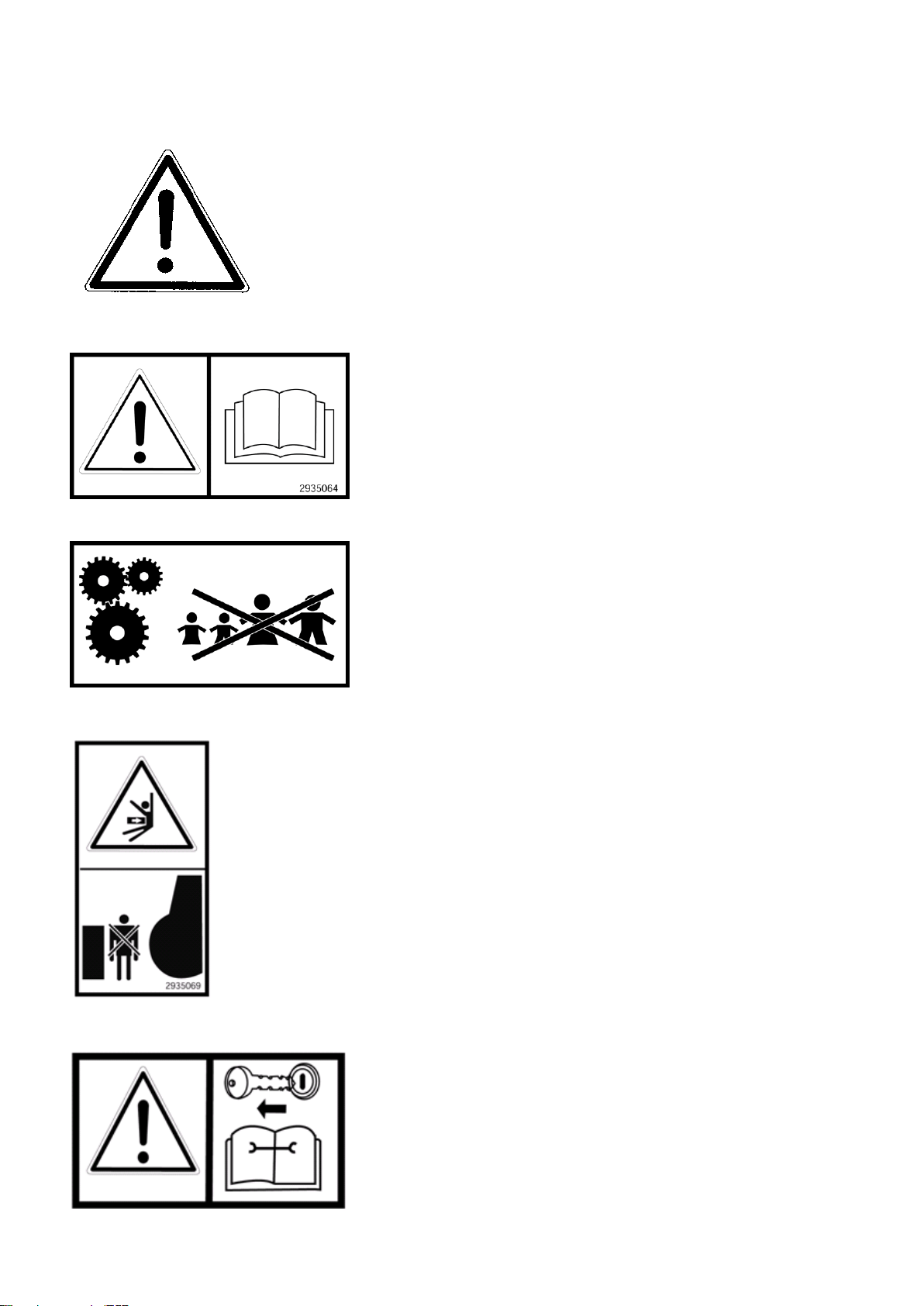

Power transmission shafts

The snow blower has a power transmission shaft between tractor and snow blower. It also has a

power transmission shaft between the gearbox and the feeder screw chain.

Please lubricate the power transmission shaft before use.

The power transmission shafts are maintained and used according to the attached instruction

manual.

Power transmission shaft from tractor

Make sure that the PTO shaft is of sufficient length. After any length adjustment, the profile pipes

in the shaft must overlap each other by half the pipe length. Any cutting of the shaft is carried out

accordance to the instructions for this –the cut point is chamfered inside and out, and the profile

tubes are lubricated with grease. Too short a telescopic length on the axle entails a risk of

overloading the tractor's power take-off and the snow blower's bearings. On the other hand, the

shaft must not be too long so that it presses on the front and rear bearings and destroys

them.

The shear bolt coupling on the shaft is mounted against the implement. The coupling has a

capacity of 4180 nm and in the event of a break in this, a hexagonal screw dim 12 mm qval 8.8

must be used as a breaking pin. The locking chains for the protective covers must always be

attached to suitable fasteners to prevent the covers from rotating.

Power transmission shaft between gearbox and chain drive for the feeder screw

It has been fully adapted and is mounted on the snow blower.

In case of a break in the shear bolt connection, sext. screw dim 10 mm qval 8.8 is used.

Save control of greasing (lubrication)

Check that the warehouses (front and back) are lubricated. Lack of lubrication entails a risk of

breakdown. Also, be careful not to "over-lubricate" the bearings as this entails the risk of heat

build-up and overheating in the bearing itself. In the case of too little lubrication, water can

penetrate (infiltrate) the bearings.

Lubrication of ball bearing

Check that this is lubricated and make sure it is lubricated before use if this is not the case. Too

little lubrication causes abnormal wear on the gears and chain.

Chain drive feeder screw

The feeder screw is driven by a chain that must be lubricated with thin engine oil.

Protection of hydraulic hoses

Check the hose connections and that they are not stretched or cut during use. Tighten loose hose

connections and secure/fasten the advance of the fittings.

Failure to secure hydraulic hoses can lead to leaks and consequential damage to tractors and

components.