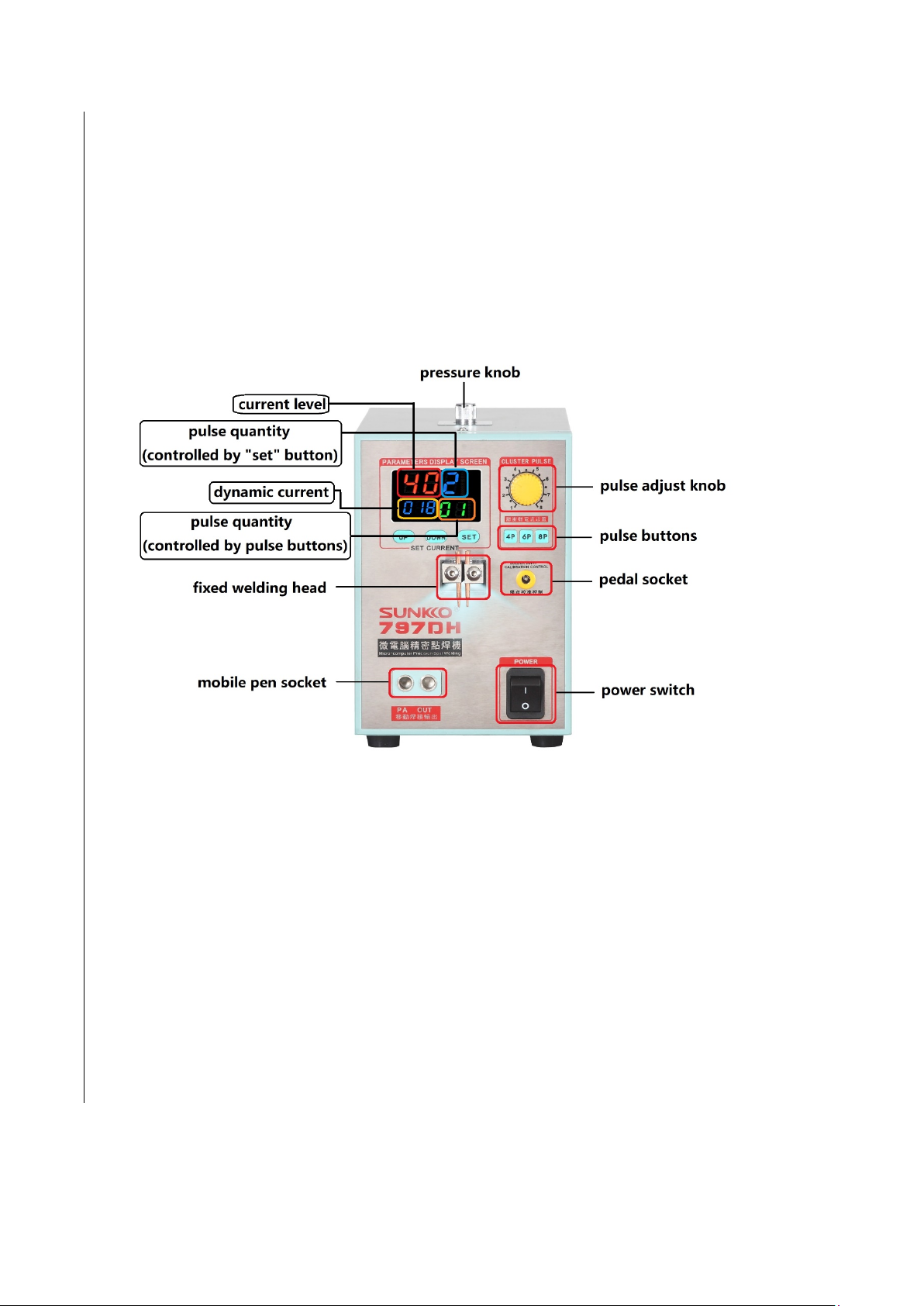

COOLING FAN: 797DH is also equipped with a temperature sensor and a

cooling fan, when the inner temperature gets higher than a certain value, the

cooling fan will work automatically.

Two ways of welding:

Fixed welding head with foot pedal: You can build your battery pack with the

fixed welding head and foot pedal. Coordinating hands and feet at the same time

will make the long-term welding process not so tiring, plus the use of foot pedal

during battery welding improves the precision of spot welding.

Welding range: 0.05~0.3mm for nickel plated steel, 0.05~0.25mm for pure nickel

strip;

Preparation steps:

1. Fit the fixed welding head with copper welding rods before the machine

powers on.

2. Plug in foot pedal.

3. Turn on the power switch.

4. Adjust the pulse quantity and welding current level to make the spots

more reliable and elegant.

5. Weld your batteries with fixed welding head along with the foot pedal.

Mobile welding pen with foot pedal: The mobile welding pen effectively extends

your welding area, and this design is popular among electric hobbyist, because

they can build large lithium battery packs for their e-bikes or other projects.

Welding range: 0.05~0.2mm for nickel plated steel, 0.05~0.15mm for pure nickel

strip;

Preparation steps:

1. Insert mobile welding pen.

2. Plug in foot pedal.

3. Turn on the main power switch.

4. Weld your batteries with mobile welding pen along with the foot pedal.

(Attention:

In all the steps mentioned above, please make sure that the copper welding rods of

the fixed head and the welding pins of the mobile welding pen are not in contact with

each other to avoid short circuit.

When users need to adjust the distance between welding pins on mobile welding pen

or distance between copper welding rods of fixed head, please turn off the welder first,

do not adjust the distance when the welder is on.

Welding with fixed welding head only is not supported.)

In general, there are three ways to increase the power output: You can adjust

the welding current, welding pulses or the cluster pulse knob to increase the

power output if you are welding a thicker nickel sheet. You may need to play

with them a bit to get the best combination for your specific use.