10 0.043 2.15 1.91 1.72 1.56 1.43 1.32 1.23

20 0.061 3.02 2.69 2.42 2.20 2.02 1.86 1.73

30 0.075 3.72 3.31 2.98 2.71 2.48 2.29 2.13

40 0.087 4.29 3.82 3.43 3.12 2.86 2.64 2.45

50 0.097 4.82 4.28 3.85 3.50 3.21 2.97 2.75

60 0.106 5.26 4.67 4.21 3.82 3.50 3.23 3.00

10 0.070 3.46 3.08 2.77 2.52 2.31 2.13 1.98

20 0.098 4.86 4.32 3.89 3.54 3.24 2.99 2.78

30 0.120 5.96 5.30 4.77 4.33 3.97 3.67 3.40

40 0.139 6.88 6.11 5.50 5.00 4.58 4.23 3.93

50 0.156 7.71 6.85 6.17 5.61 5.14 4.74 4.41

60 0.170 8.41 7.48 6.73 6.12 5.61 5.18 4.81

10 0.090 4.47 3.97 3.57 3.25 2.98 2.75 2.55

20 0.127 6.31 5.61 5.05 4.59 4.21 3.88 3.60

30 0.157 7.75 6.89 6.20 5.64 5.17 4.77 4.43

40 0.181 8.94 7.94 7.15 6.50 5.96 5.50 5.11

50 0.202 9.99 8.88 7.99 7.26 6.66 6.15 5.71

60 0.221 10.95 9.73 8.76 7.96 7.30 6.74 6.26

10 0.119 5.91 5.26 4.73 4.30 3.94 3.64 3.38

20 0.169 8.37 7.44 6.69 6.08 5.58 5.15 4.78

30 0.207 10.25 9.11 8.20 7.45 6.83 6.31 5.86

40 0.239 11.83 10.51 9.46 8.60 7.88 7.28 6.76

50 0.267 13.23 11.76 10.58 9.62 8.82 8.14 7.56

60 0.293 14.50 12.89 11.60 10.55 9.67 8.92 8.29

10 0.149 7.36 6.54 5.89 5.35 4.91 4.53 4.21

20 0.210 10.38 9.23 8.31 7.55 6.92 6.39 5.93

30 0.257 12.70 11.29 10.16 9.24 8.47 7.82 7.26

40 0.296 14.67 13.04 11.74 10.67 9.78 9.03 8.39

50 0.332 16.43 14.60 13.14 11.95 10.95 10.11 9.39

60 0.363 17.96 15.96 14.37 13.06 11.97 11.05 10.26

10 0.218 10.78 9.58 8.62 7.84 7.18 6.63 6.16

20 0.307 15.20 13.51 12.16 11.05 10.13 9.35 8.69

30 0.376 18.62 16.55 14.89 13.54 12.41 11.46 10.64

40 0.435 21.51 19.12 17.21 15.64 14.34 13.24 12.29

50 0.486 24.05 21.38 19.24 17.49 16.03 14.80 13.74

60 0.532 26.33 23.40 21.06 19.15 17.55 16.20 15.04

10 0.341 16.87 14.99 13.49 12.27 11.24 10.38 9.64

20 0.481 23.83 21.18 19.06 17.33 15.89 14.66 13.62

30 0.590 29.22 25.97 23.37 21.25 19.48 17.98 16.70

40 0.681 33.73 29.98 26.98 24.53 22.49 20.76 19.27

50 0.762 37.72 33.53 30.17 27.43 25.14 23.21 21.55

60 0.835 41.31 36.72 33.05 30.04 27.54 25.42 23.60

10 0.553 27.38 24.34 21.90 19.91 18.25 16.85 15.64

20 0.782 38.72 34.42 30.98 28.16 25.82 23.83 22.13

30 0.956 47.31 42.05 37.85 34.41 31.54 29.11 27.03

40 1.106 54.76 48.67 43.81 39.82 36.50 33.70 31.29

50 1.239 61.33 54.51 49.06 44.60 40.88 37.74 35.04

60 1.354 67.02 59.58 53.62 48.74 44.68 41.24 38.30

10 0.649 32.11 28.54 25.69 23.35 21.41 19.76 18.35

20 0.920 45.56 40.50 36.45 33.13 30.37 28.04 26.03

30 1.124 55.63 49.45 44.51 40.46 37.09 34.24 31.79

40 1.301 64.39 57.24 51.52 46.83 42.93 39.63 36.80

50 1.451 71.84 63.86 57.47 52.25 47.89 44.21 41.05

60 1.584 78.41 69.70 62.73 57.03 52.27 48.25 44.81

10 0.938 46.43 41.27 37.15 33.77 30.96 28.57 26.53

20 1.319 65.27 58.02 52.22 47.47 43.51 40.17 37.30

30 1.619 80.16 71.26 64.13 58.30 53.44 49.33 45.81

40 1.867 92.43 82.16 73.94 67.22 61.62 56.88 52.82

50 2.088 103.38 91.89 82.70 75.19 68.92 63.62 59.07

60 2.292 113.46 100.85 90.76 82.51 75.64 69.82 64.83

All application rates (gallons/acres) are estimates based on 0-28-0 (10.65 lbs/gallon) at 70 degrees F.

PumpRight Pressure Recommendations

(with 10 lb check valves):

• Minimum 20 PSI

• Maximum 80 PSI

Tower Electric Pump Pressure

Recommendations (with 4 lb check valves):

• Minimum 10 PSI

• Maximum 30 PSI

Chart is for 28-0-0 Fertilizer @ 70°

• Heavier fertilizers (like 10-34-0) will

have 5-15% less flow than chart

indicates for a certain pressure

• Cold fertilizers will cause system

pressure to increase at a given

application rate.

• Tower Electric Pump Systems will have

reduced flow and increased electrical

current draw due to cold fertilizer

increasing operating pressure. Use the

largest orifice possible for cold

weather operation.

B

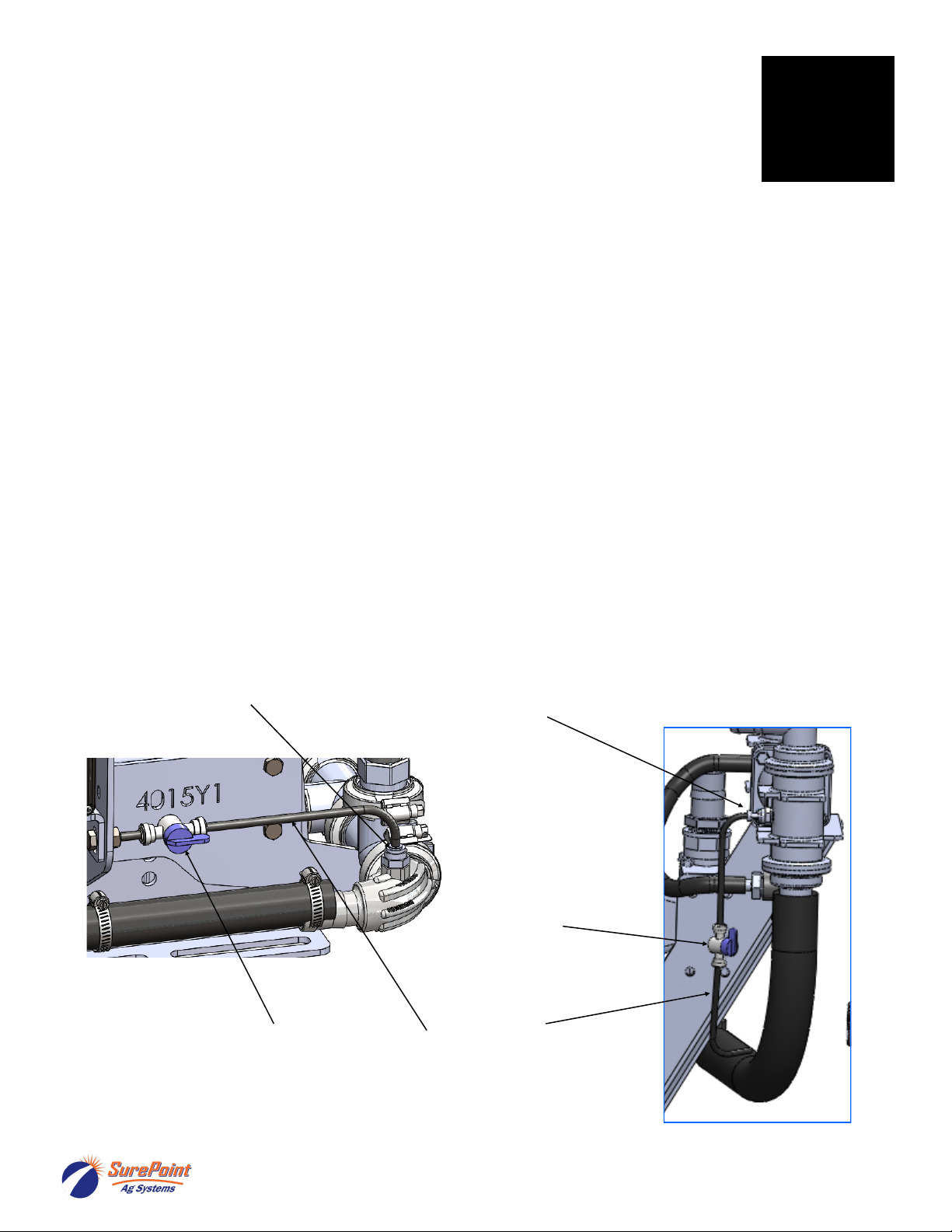

Components

Liquid

30” Spacing

Remove top fitting

of each column.

Then push the

metering orifice into

bottom of each

outlet fitting. (This is

not used very

often.)

If using a metering

orifice in the flow

indicator, the orifice

replaces the ball

retainer. If not using

an orifice here, the

ball retainer must

be in place.

Ball

retainer Orifice

or