1. General Use

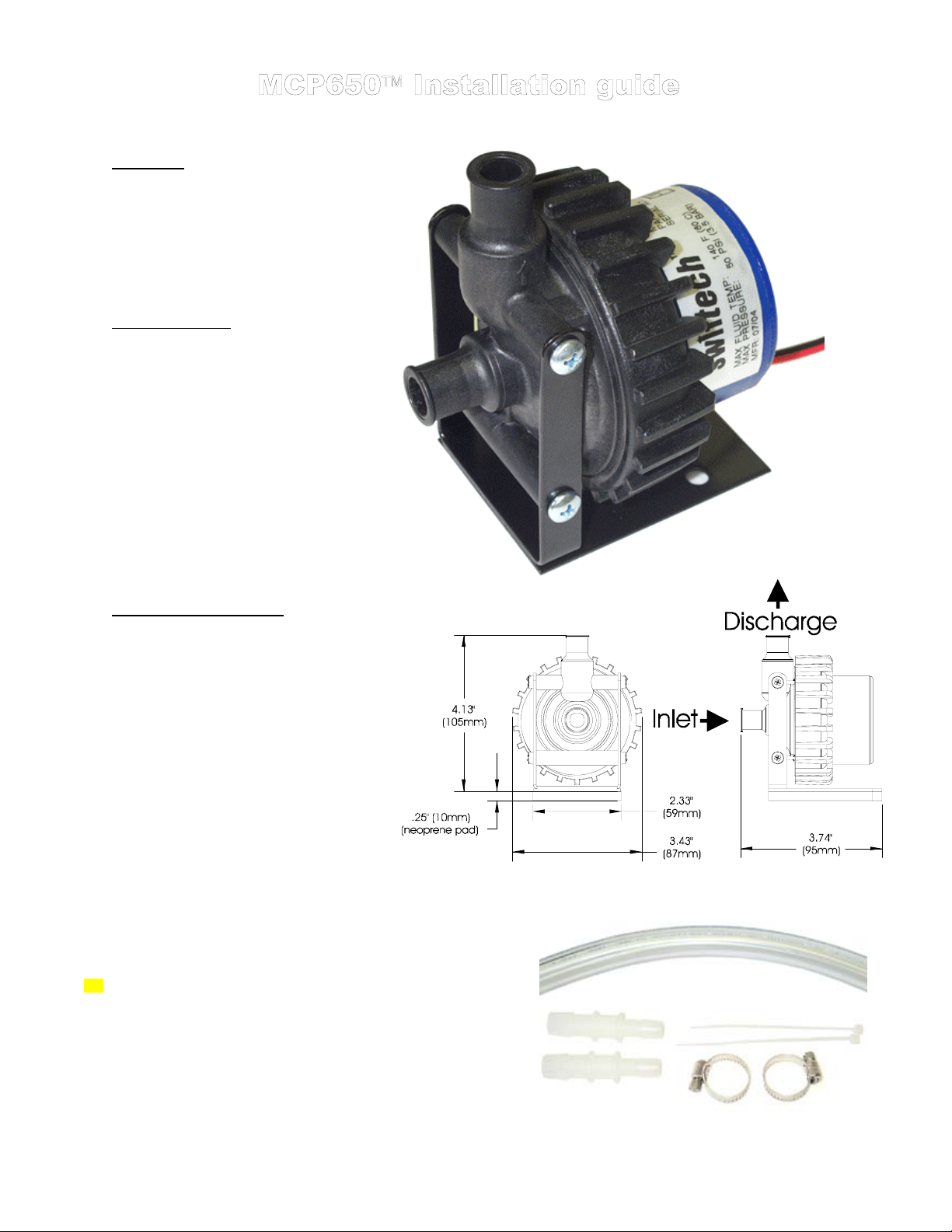

The MCP650 pump is a magnetically driven

centrifugal pump featuring a 12 V DC motor. It

requires no maintenance when used with de-

mineralized water and the appropriate anti-fungal

additives. We recommend using 5% Swiftech’s

HydrXas an additive. The pump is designed to be

connected to your computer power supply using the

standard Molex 4 pin connectors.

The MCP650 pump is not submersible.

2. Physical installation

Determine the best location for your pump by

observing how the tubing will be routed to the

rest of the circuit. Sharp bends in the tubing

should always be avoided to prevent kinks, which

will reduce or completely prevent flow of the

cooling fluid.

In general, we recommend installation of the

pump at the bottom of the chassis.

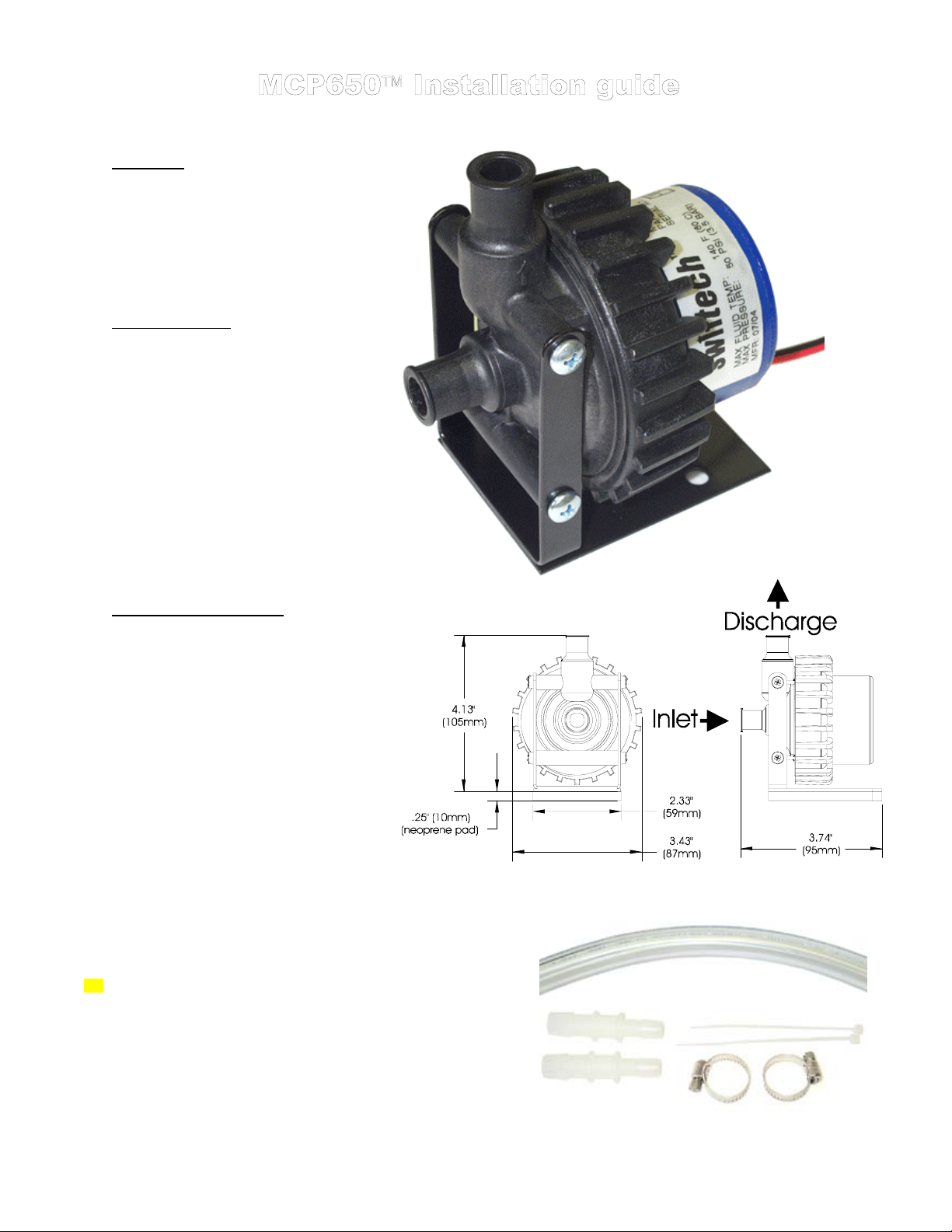

The base of the pump features a soft neoprene

pad coated with strong adhesive material. Once

an appropriate location for the pump has been

determined, simply peel-off the pad’s protective

paper, and press the pump against the chassis

surface. The surface should be clean, and non

greasy. Thru-bolts are also provided for

permanent installation, and require drilling holes

in the chassis (see permanent installation page

2).

3. Pump operating precautions:

The MCP650 pump should never be run dry, even

for a quick test. You should always prime the pump

with fluid before you start operating it (see warranty

note *).

Use of coloring die or fluorescent additives

containing particulate fillers will cause excessive wear

to the pump’s impeller bearing (see warranty note **).

Do not utilize small diameter or flow restrictive fittings in the pump inlet line. Minimum line inner diameter is 3/8”. An example would be a

reservoir with ¼” fittings. This will cause the pump impeller to cavitate, lose prime, stop pumping and damage the pump (see warranty note ***).

Connecting the pump to the circuit:

The pump’s inlet and outlet are ½” in outside diameter. An optional adapter kit

is available to connect the MCP650 to a circuit using ½” ODx3/8”ID tubing. This

kit consists in: 1 foot supply of ¾”ODx½”ID tubing and two reducers to make

the transition to the ½”ODx3/8”ID circuit.

TIP: when connecting the MCP650 pump to a ½”ODx3/8”ID circuit, always use

the longest possible ¾”ODx½”ID tube section at the inlet.

Rouchon Industries, Inc., dbA Swiftech™ – 1703 E. 28th St, signal Hill, CA 90755, USA – T (562) 595-8009 – F (562) 595-8769 – All content Copyright

Swiftech 2004 – Last edited 7-26-04 – Subject to revision without notice - 1 of 2 -