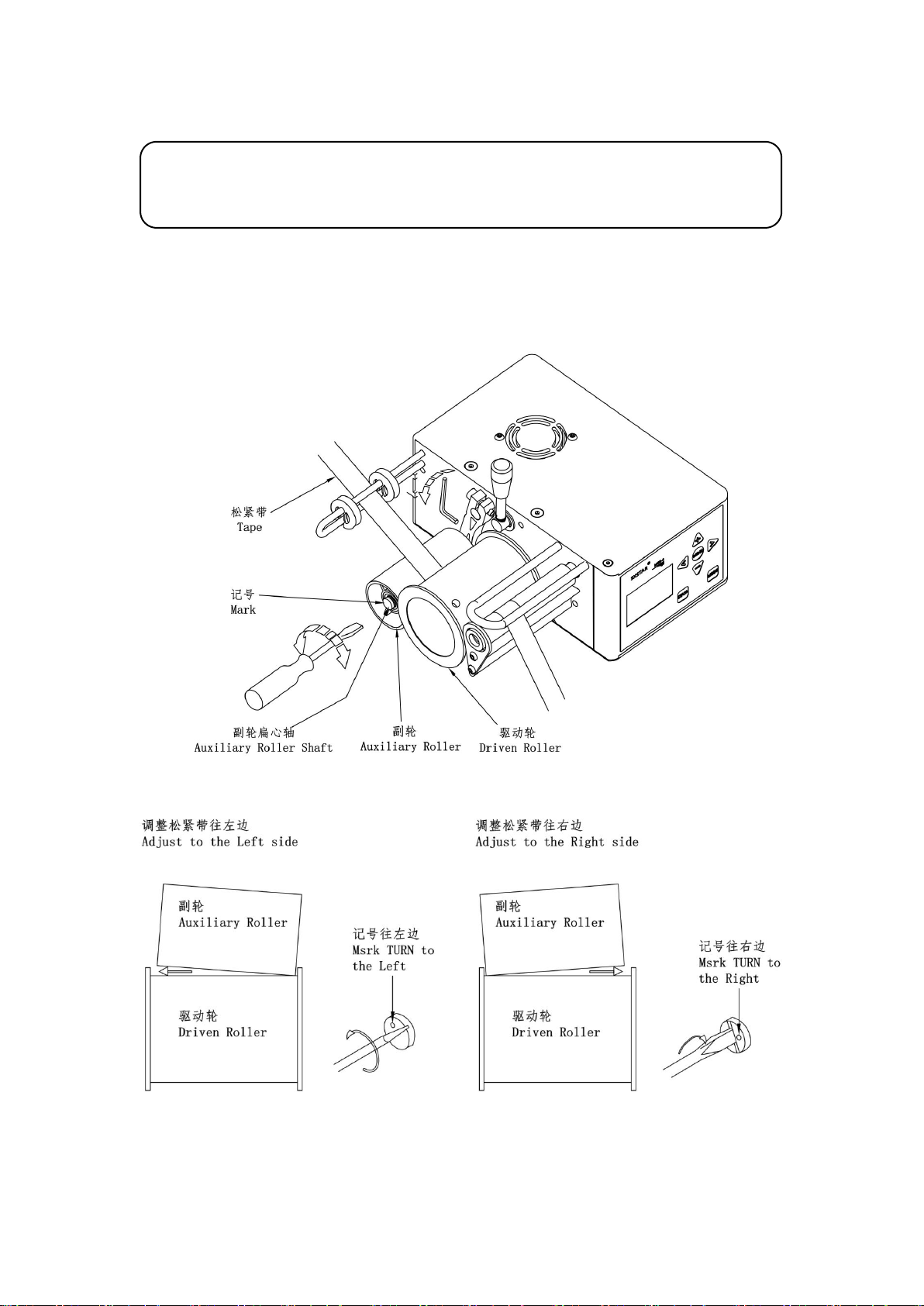

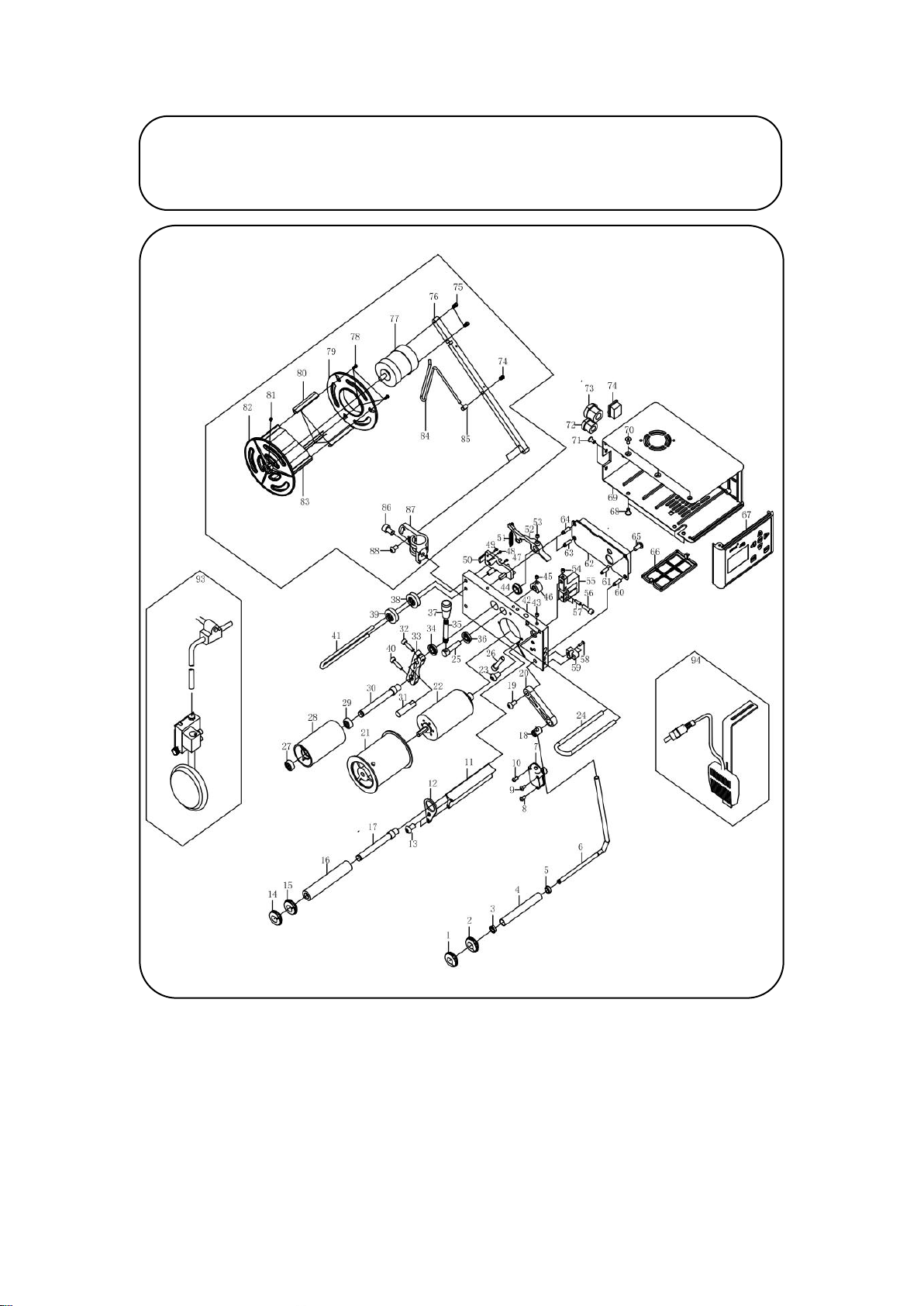

1.驱动组连结架 1.Joint 9.辅助轮 9.Auxiliary Roller

2.把手 2.Handle Bar 10.换段开关 10.Section Switching

3.导带杆 3.Holder 11.横杆 11.Arm

4.副轮 4.Auxiliary Roller 12.连结架 12.Joint Stand

5.副轮偏心轴 5.Auxiliary Roller Shaft 13.支柱 13.Holder

6.驱动轮 6.Driven Roller 14.夹座 14.Clamping Base

7.保护架 7.Secure Holder 15.控制面板 15.Control Panel

8.感应轮 8.Secure Roller