Page 6of 20 V07.22

General

The following instructions enable authorised personnel to install the systems efficiently and safely. The

installation and safety instructions must be followed. The accident prevention regulations of the professional

associations must be observed, especially when working on the roof. If there is a risk of falling, precautions

must be taken. The entire solar energy system must be installed and operated in accordance with recognised

technical regulations. Errors and omissions excepted.

General specifications

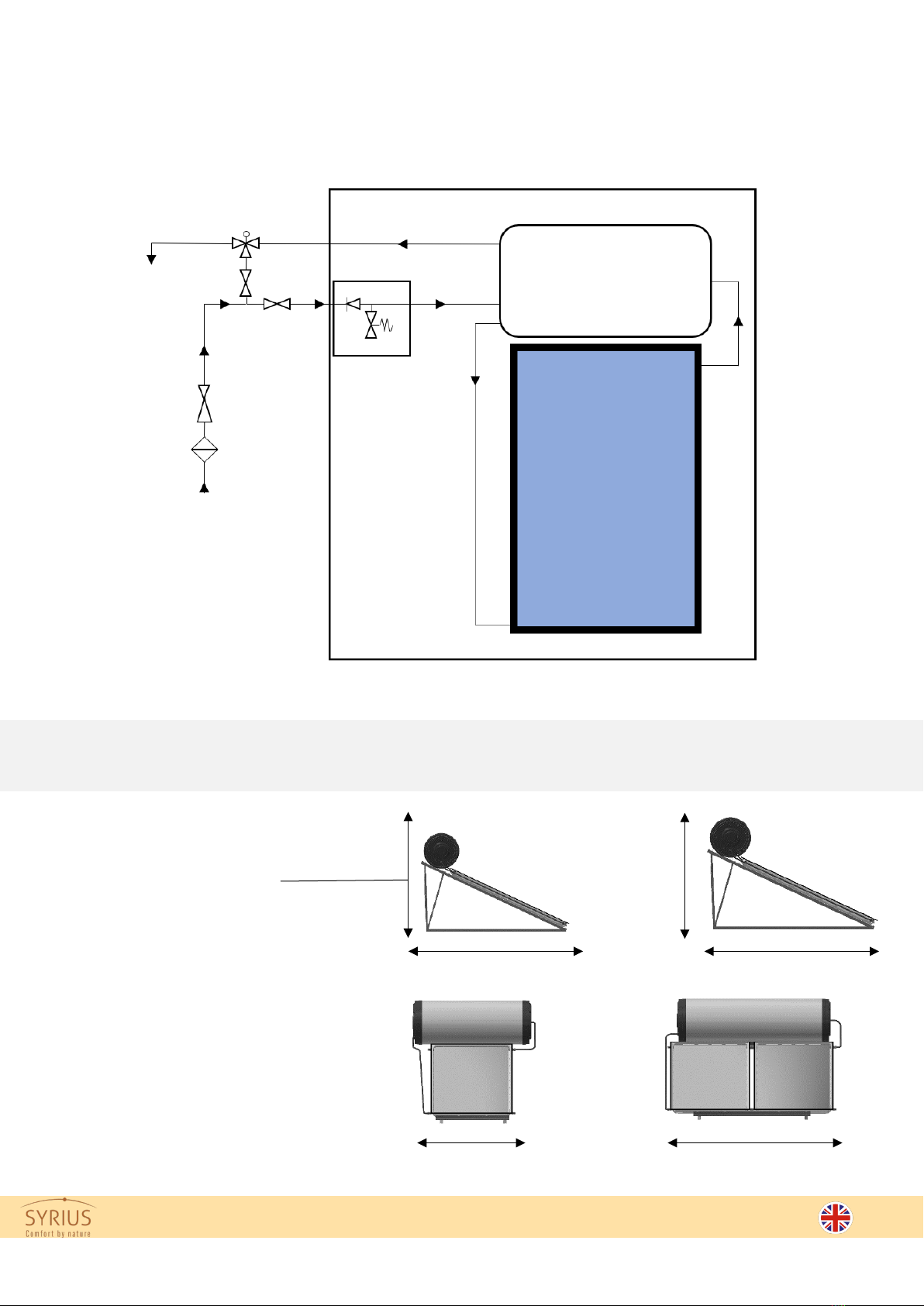

These installation instructions describe the installation of the TS-INOX solar water heater for a flating roof.

The main components of the system are as follows:

- Solar storage tank

- Solar collector(s)

- Mounting bracket

- Hydraulic kit

Detailed information can be found in the product nomenclature.

TS-INOX thermosiphon water heaters operate in direct circulation. The storage tank is protected against

corrosion (Inox 316L).

The hot water temperature in the storage tank can reach more than 100°C. The maximum operating pressure

is 7 bar. If the mains pressure is higher than 4 bar, it is necessary to use a pressure reducer.

For optimum performance, the solar collectors must face south in the northern hemisphere and north in the

southern hemisphere. To ensure the production of hot water all year round, it is possible to install an electric

back-up. To avoid burns and for greater comfort, it is necessary to install a solar thermostatic mixer.

How does a thermosiphon work?

The water, circulating inside the collectors heats up, expands and becomes lighter than cold water. It rises

naturally in the storage tank located above the collectors for the thermosiphon technology. This hot water

then replaces the cold water which goes back down to the collectors to be reheated, and so on.

It is a phenomenon of natural circulation of a liquid that uses the variation of its density with temperature.

Packaging, handling and storage

The collector is packaged in two cardboard covered, reinforced by honeycombed wedges on the corners.

The tank is wrapped in a protective foam, filmed with stretch plastic film. The supports are wrapped with

stretch film, as well as the tubes of the hydraulic kit. The products must be stored indoors. Do not handle the

collectors or the tank by the inlet/ outlet tubes. Protect the glass and the back of the collector during transport.

Maintenance

In order to ensure that the system functions properly over time, it is important to carry out all the maintenance

steps mentioned in the user manual. If these steps are not carried out, the longevity of the product and its

warranty may be affected.