EN 8Document ref.: 428016 03

Contact with live conductors can cause electrical arcing.

Explosions, fires or poisoning in the event of gas leaking

from a damaged duct.

Damage to existing installations. Flooding in the event of

water leaking from damaged ducts.

Protect connection cables to prevent them from being

damaged.

Contact with live conductors can cause electrocution

Flooding caused by water escaping from damaged pipes

Check that the part and the installations to which the

appliance will be connected comply with the current

applicable regulations.

Contact with incorrectly installed live conductors can

cause electrocution.

Damage to the appliance due to unsuitable operating

conditions.

Use accessories and manual equipment suitable for the

usage (ensure that the tool is not damaged and the

handle is securely attached and in good condition), use

this equipment correctly, protect it against being

accidentally dropped and store it after use.

Injury may be caused by flying debris or fragments, dust

inhalation, impacts, cuts, pricks and abrasions.

Damage to the appliance or to nearby objects caused by

flying debris or fragments, impacts or incisions

Use suitable electrical equipment (in particular, check

that the supply cable and connector plug are in good

condition and that rotating or alternating parts are

properly secured).

Use the equipment correctly, do not allow a trailing

supply cable to obstruct access, secure it to prevent

falling, and disconnect and store it after use

Injury can be caused by electrocution, projected shards

or fragments, inhaling dust, being hit, or cuts, pricks,

abrasions, noise or vibrations.

Damage to the appliance or to objects nearby caused by

projected debris or fragments, cuts, incisions.

Ensure that portable ladders are stable and sturdy and

will not slip, and that the rungs are in good condition.

Ensure that someone is present to ensure that ladders

cannot move when someone else is using them.

Injury due to falling or folding of the ladder (double

ladder).

Ensure that materials, components or equipment used

during installation cannot fall from height.

Injury or death due to collapsing and/or falling parts.

Ensure that mobile ladders are correctly supported and

sufficiently sturdy, that the rungs are in good condition

and not slippery, and that the rungs and platforms are

fitted with rails.

Injury due to falling.

When working at height (generally during use with

height differences of more than 2 m), ensure that there

is a safety rail surrounding the working area or that

personal equipment is used to prevent falling, that the

route of any potential fall is not obstructed by

dangerous objects and that any possible impact would

be cushioned by semi-rigid or deformable supports.

Injury due to falling.

Ensure that the health and safety conditions are

adequate in terms of lighting, ventilation, structural

soundness and emergency exits.

Injury caused by being hit, tripping, etc.

During work, wear personal protective equipment and

clothing.

Injury can be caused by electrocution, projected shards

or fragments,

inhaling dust, being hit, or cuts, pricks, abrasions, noise

or vibrations.

The utmost care must be taken during operations

inside the appliance, and contact with sharp edges

avoided.

Injury caused by cuts, pricks and abrasions.

Do not use insecticides, solvents or harsh cleaning

products for maintenance of the appliance.

Painted or plastic parts can be damaged.

Do not use the appliance for any use other than

standard household use.

The appliance may be damaged by operation overload.

Damage to incorrectly treated objects.

Do not allow children or inexperienced persons to use

the appliance.

Damage to the appliance may be caused by improper

use.

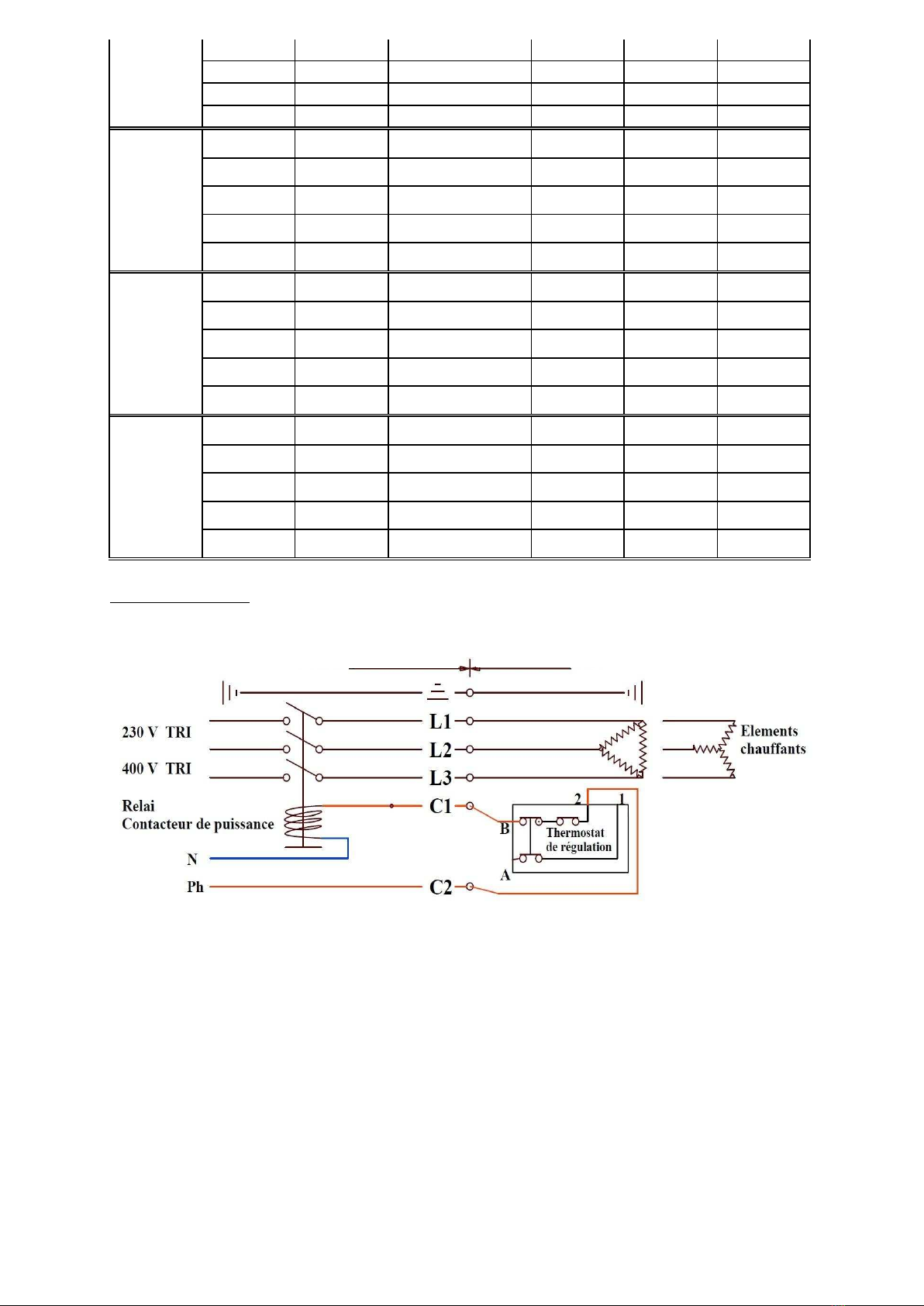

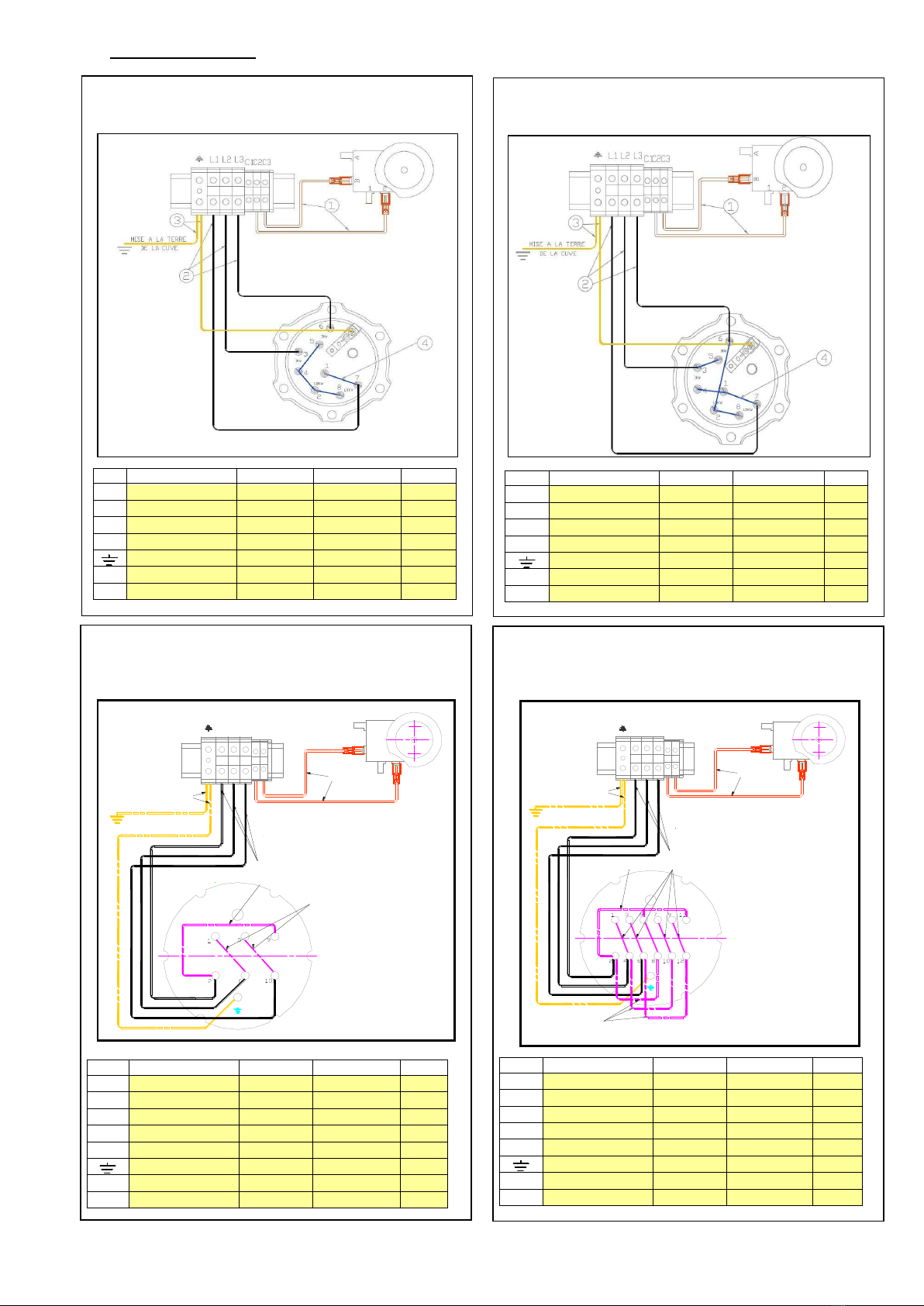

Electrical connections must be made using conductors

with a suitable cross section.

Fire due to overheating caused by current passing

through cables which are too small.

Protect appliances and nearby areas using suitable

equipment.

Damage to the appliance or to objects nearby caused by

projected debris or fragments, cuts, incisions.

Move the appliance using the necessary protective

equipment and with the utmost care.

Damage to appliances or nearby objects caused by

impacts, incisions or crushing.

Ensure that all equipment is stored in a way that makes

it simple and safe to handle; avoid creating piles which

are in danger of collapsing.

Damage to appliances or nearby objects caused by

impacts, incisions or crushing.

Reset any safety and control functions affected by an

operation on the appliance, and make sure that they

are operating correctly before it is put back in service.

Damage to or stoppage of the appliance due to

uncontrolled operating conditions.

Before working on roofs, structures, surfaces, etc.,

ensure that they are stable and suitable for the work to

be carried out.

Injury or death due to collapsing and/or falling from

height.

SAFETY STANDARDS SPECIFIC TO THE PRODUCT

Drain any components which contain hot water by

activating the drain before using them.

Injury caused by burns

Descale components in accordance with the

instructions in the safety sheet for the product in

question. Carry out the operation in a well-ventilated

area and wear protective clothing.

Avoid mixing different products and protect the

appliance and nearby objects.

Personal injury through skin and eyes coming into

contact with acidic substances, inhalation of ingestion of

harmful chemical agents.

Damage to the appliance or objects nearby due to

corrosion caused by acidic substances.

Do not carry out work on the product in strong

sunlight.

Injury caused by burns