3

·

··

·MAIN STRUCTURE AND USE METHOD

Ⅰ

ⅠⅠ

ⅠSTRUCTURE

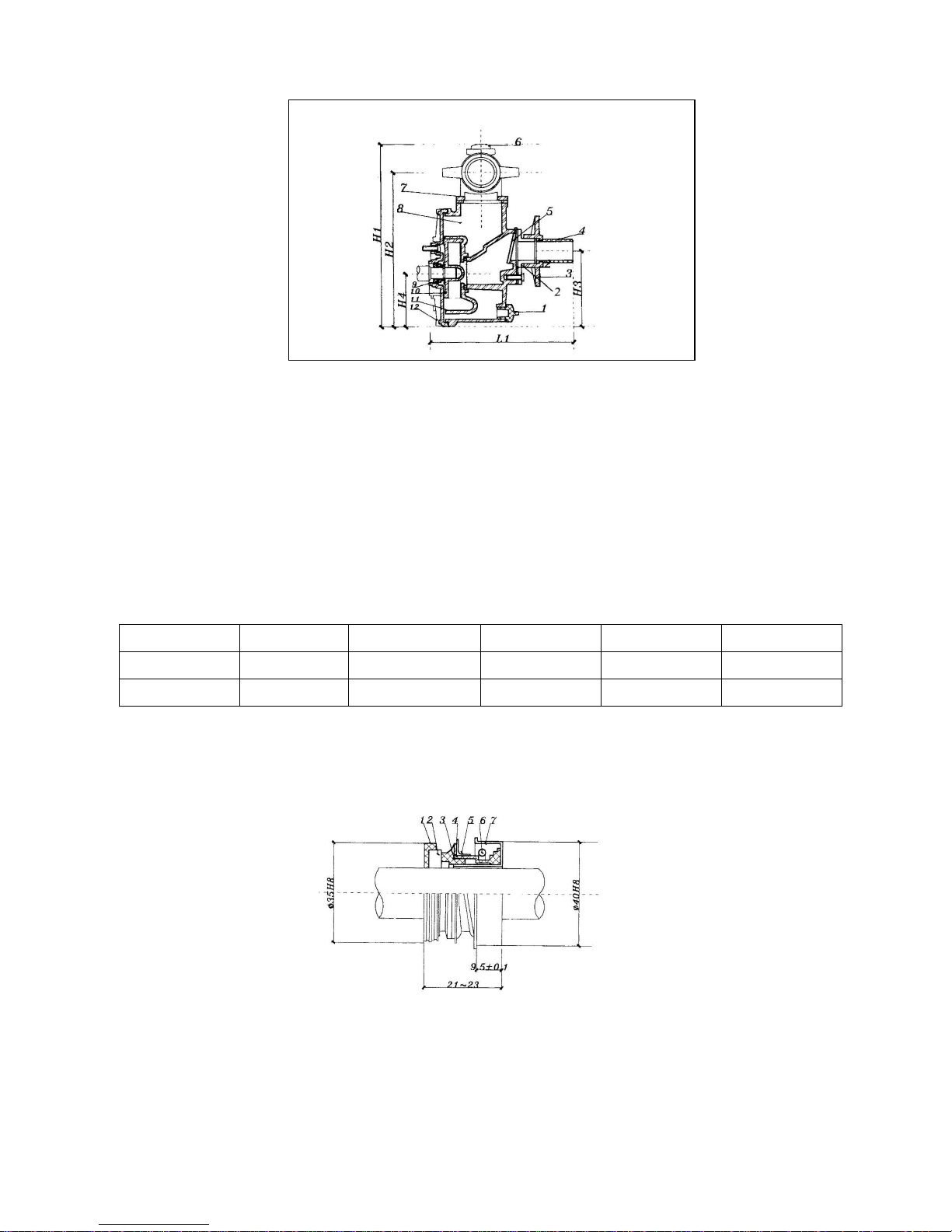

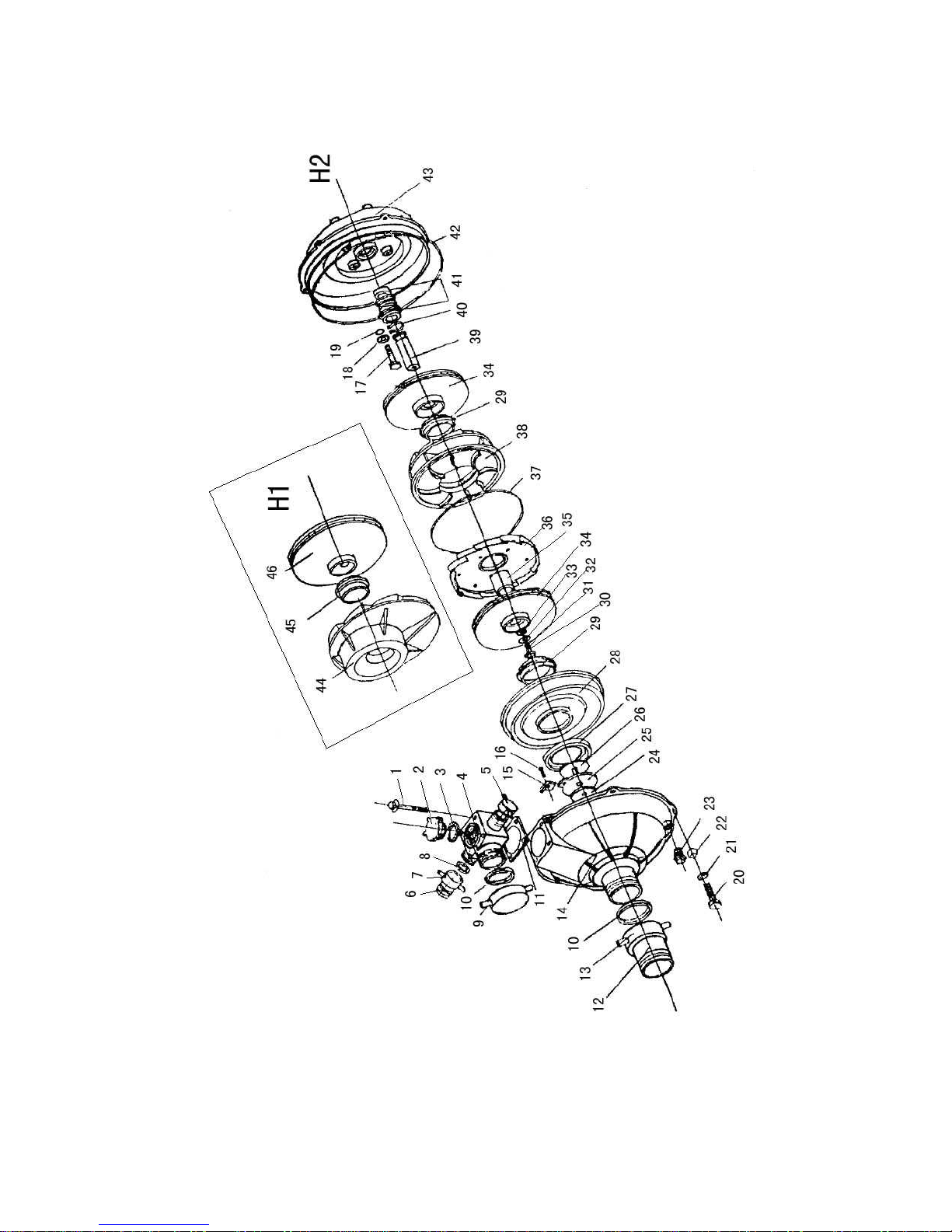

This type of pump consists of gasoline/diesel engine and water pump which drove by a same

driving axle. The pump is fixed on a frame through shock absorber device, so it compact in structure

and convenience for use of movement. For structure of self-priming pump.

The pump consists of pump body, pump cover, flow guidance, impeller and seal part etc. The

pump body and pump cover are made from high quality die-casting of aluminum alloy. The flow

guidance and impeller are made from high strength cast iron, shaft sealing is machinery type sealing.

The suction and discharge pipe connector are made from engineering plastic so it can be connected

with rubber pipe.

The outlet of pump is higher than the inlet of impeller so that it can start which only need fill

water into the body of the pump. The inlet of pump is fixed with a one-way valve to prevent liquid

from being drained into water pool from the pump body which action by siphon after stop the machine.

It must guarantee store enough liquid in the pump body for next start.

The rotary direction is anticlockwise as viewed from inlet direction of impeller.

Ⅱ

ⅡⅡ

ⅡMAIN POINT OF USE

The coupling of suction pipe to the pump must be tight, reliable and no leakage.

A filter net must be added into the inlet of suction pipe as a protection , so as to avoid impurity be

sucker into the pump and stick or damage the impeller.

Prime the pump until the water overflow.

Do not run it at high speed, unless you prime it.

Drain off the pump for storage.

Ⅲ

ⅢⅢ

ⅢPROCEDURE OF USE

1. Adding water

When start the pump for the first time, it only need to add a few water into the pump and self-priming

after start, so not necessary bottom valve.

2. Start the engine, Please see manual of diesel engine or gasoline engine.

Ⅳ

ⅣⅣ

ⅣUSE AND MAINTENANCE

1.According to normal stipulation, the vacuum of pump by suction be expressed with allowable NPSH

(Net Positive Suction Head). When the pump work at the area of lower than 250m altitude. It can

estimate suction head of pump which 10m minus allowable NPSH is it. Follow increasing with

altitude, the atmosphere should be decreased, so the suction head of pump also be decreased. The

value of decrease can be estimated which 10m minus local atmosphere value is it (m water column).

2.Pipeline is better with short pipe and straight pipe, so it can decrease unnecessary loss of pipeline.

The pipeline must be supported to avoid from vibrating and damaging the pump by oppressive.

Before operation it must check connection part between pump and pipeline whether there is loose

phenomenon and special pay attention to leakage of inlet pipeline.

3.The filter net must keep a certain distance between river surface, river bottom and river bank. The

net must dip into water no less than 0.3m to avoid suction air and to keep a distance, which is not

less than 0.2m from river bottom, river bank to avoid suction stone or weeds.

4.If the gap between impeller and the surface of flow guidance is over 1mm, so that it can be