Tatu Marchesan SDA CP User manual

1

The No-Till Seed Drill, SDA CP model, is designed to the seeding over stubble

mulch, minimum or conventional tillage for Soybean, Wheat, Barley, Oats, Rice on

flood-irrigated or dryland and other small grains. As advantages, it stands out due

to high strength, accuracy on seed and fertilizer distribution, higher free articulation

of the drive wheels, besides optional for different applications.

The seeds are metered by helical fluted feed cup with simultaneous delivery

adjustment. The rates are reached by the scales displayed on the hoppers. In this

system, the seeds are gently placed to the soil in a continuous line pattern.

The fertilizer is metered by endless augers (coil springs), guaranteeing an

individual and accurate distribution in all the row units.

The setting of the different rates of fertilizer and seed population are easily

reached by the Fast Change Sprocket system - TRA.

In order to face higher usability, this model can be optionally supplied with:

- Box of small seeds for pastures;

- USG - Unit of Large Seeds for Corn, Soybean, Bean, Sorghum, Cotton, etc.,

using perforated horizontal plates;

- Wheels for Longitudinal Transport.

- Hydraulic row markers.

This manual contains the necessary information for the best seeder performance.

The Operator must read, with plenty attention, the whole manual before putting the

seeder in operation and be aware of the safety's recommendations.

To obtain any information, or in the eventuality of technical problems, consult

the Dealer, as well as Marchesan's customer service, that will guarantee the Seeder

full operation.

INTRODUCTIONINTRODUCTION

INTRODUCTIONINTRODUCTION

INTRODUCTION

2

INDEXINDEX

INDEXINDEX

INDEX

TO THE OWNER ..................................................................................................................... 3

TO THE OPERATOR ....................................................................................................... 4 to 7

Work with Safety - Transport of the Equipment ........................................... 4 to 6

Safety Stickers ........................................................................................................... 7

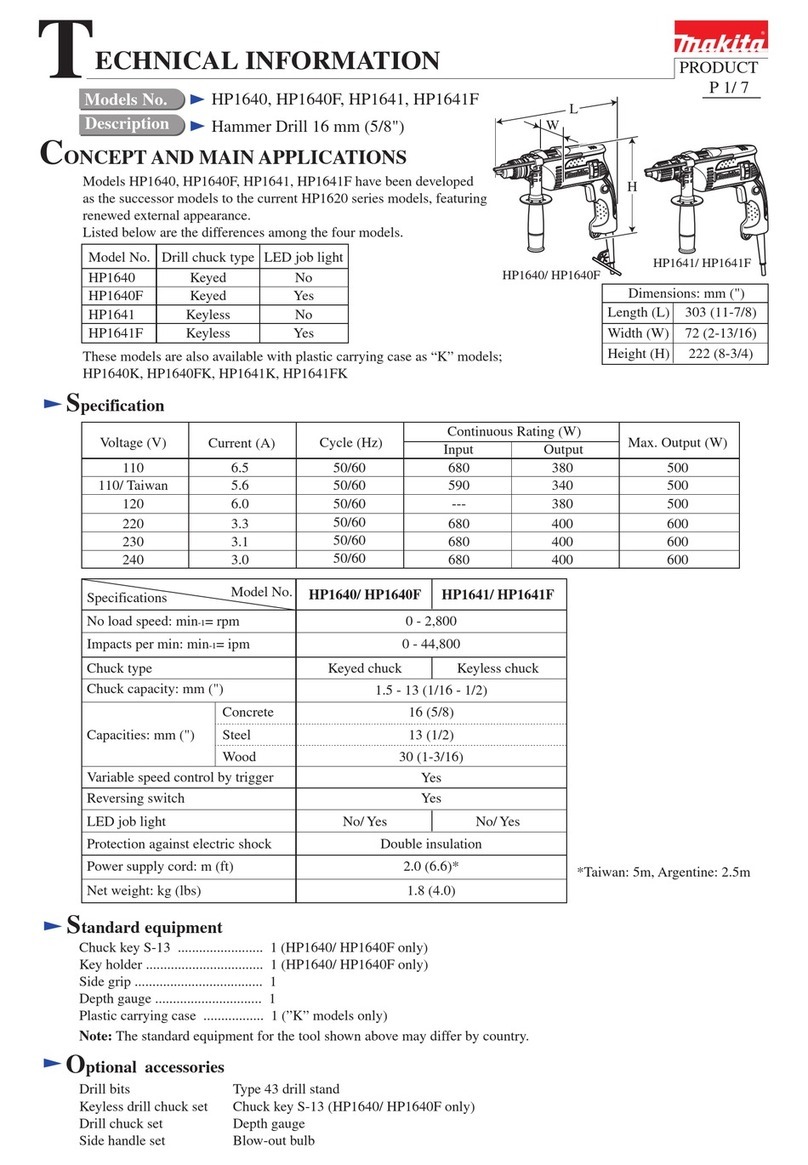

TECHNICAL SPECIFICATIONS.............................................................................................. 8

ASSEMBLY..................................................................................................................................9 to 12

Drawbar .................................................................................................................... 9

Hydraulic System......................................................................................... 10 to 12

SET-UP INSTRUCTIONS .............................................................................................. 13 to 30

Preparing the Tractor and Hitching to the tractor ........................................... 13

Leveling the Seeder ............................................................................................... 14

Spacing Between Rows ........................................................................................15

Positioning the Row Units in the Frame .................................................... 16 to 26

Procedures for Changing the Row Spacings ...................................... 27 and 28

Preparing the Seeder for Transportation ...........................................................29

Procedures Before Seeding and Ideal Speed of Operation ..........................30

ADJUSTMENTS AND OPERATIONS.......................................................................... 31 to 45

Seeds Distribution ........................................................................................ 31 to 33

Fertilizer Distribution...................................................................................... 34 to 37

Practical Test of Seed and Fertilizer Distribution ............................................... 38

Auxiliary Calculation for the Distribution of Seed and Fertilizer..................... 39

Opening the Furrows ............................................................................................ 40

Seeding Depth ...................................................................................................... 41

Lateral Depth Bands and Counterweights ....................................................... 42

Placement and Location of the Fertilizer in the Soil......................................... 43

Closing the Furrows ............................................................................................... 44

OPERATIONS - Important Points .......................................................................... 45

OPTIONAL .................................................................................................................. 46 to 68

Row Markers Assembly with Hydraulic Cylinders............................................. 46

Assembly of the Hydraulic System ............................................................ 47 to 50

Row Marker Adjustment and Disc Angle ............................................. 51 and 52

Boxes for Small Seeds (Pastures) ......................................................................... 53

Rate of Small Seeds ............................................................................................... 54

Row Unit for Fertilizer Banding (Soybean) ......................................................... 55

Horizontal Metering for Large Seeds - USG ......................................... 56 and 57

Assembling the Transmission of the USG ............................................. 58 and 59

Distribution and Rate for Large Seeds ...................................................... 60 to 63

Furrows Opening and Fertilizer Depth ................................................................64

Electronic Hectaremeter ........................................................................ 65 and 66

Wheel System for Longitudinal Transportation .................................... 67 and 68

MAINTENANCE ......................................................................................................... 69 to 76

Lubrication ................................................................................................... 69 to 71

Cleanness of the Systems of Fertilizer and Seeds............................................. 72

Maintenance of the Fertilizer Distributor ........................................................... 73

Double Discs Maintenance and Metering Cleanness.................................... 74

Valves Maintenance ............................................................................................. 75

Maintenance of the Seeder and Points for Hoisting ....................................... 76

IMPORTANT .......................................................................................................................... 77

3

TO THE OWNERTO THE OWNER

TO THE OWNERTO THE OWNER

TO THE OWNER

IMPORTANT:- ONLY PERSON WHO OWNS A FULL KNOWLEDGE OF THE TRACTOR AND

IMPLEMENT, MUST OPERATE THEM.

- MARCHESAN IS NOT RESPONSIBLE FOR ANY DAMAGE CAUSED BY

ACCIDENT ON TRANSPORT, INCORRECT UTILIZATION OR NO ADEQUATE

STORAGE.

- AFTER THE OPERATING SEASON, THOROUGHLY CLEAN YOUR IMPLEMENT

AND INSPECT IT. PREVENTIVE MAINTENANCE PAYS DIVIDENDS.

- YOUR DEALER HAS ORIGINAL EQUIPMENT PARTS WHICH ASSURE PROPER

FIT AND BEST PERFORMANCE.

Note: THE WARRANTY SHALL NOT BE APPLIED TO ANY EQUIPMENT, OR ANY PART THEREOF,

WHICH HAS BEEN ALTERED ELSEWHERE THAN AT THE PLACE OF MANUFACTURE OR

WHICH THE ORIGINAL PURCHASER THEREOF, AT RETAIL, HAS USED OR ALLOWED

TO BE USED PARTS, NOT MADE OR SUPPLIED BY MARCHESAN S/A.

General information

- The right-hand and left- hand sides of the planter are determinated by facing

in the direction the implement will travel when moving forward.

-When ordering parts please be sure to inform the quantity, part number and

name of each part wanted. It is also important to give the machine Serial Number,

which is placed on the mainframe.

The acquisition of any TATU product assures to the original purchaser the following

rights:

- Warranty certificate.

- Instructions manual.

- Technical assistance by the dealer on the equipment delivery.

- The owner has obligation to inspect the conditions of the product on delivery,

as well as knowing the warranty terms.

- Special attention should be given to safety recommendations, operation cares

and maintenance of the product.

- Be sure to read and understand the instructions for adjusting and operating

the equipment as reported in this manual. Check each item referred to obtain

efficient operation and maximum trouble free performance. Remember, an

equipment which is properly lubricated and adjusted saves you time, labor and fuel.

This manual should be directed to the operators and maintenance people.

4

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

Operation Safety

- ONLY WITH A COMPLETE CO-OPERATION OF IMPLEMENT OPERATOR THE

ACCIDENTS CAN BE PREVENTED.

- THIS SYMBOL IS A WARNING DEVICE WHICH SHOULD BE KEPT IN PLACE,

CLEAN AND VISIBLE, WHEN TRANSPORTING THE IMPLEMENT DURING THE

DAY OR NIGHT. USE ACCESSORY LIGHTS AND OTHER DEVICES IN ORDER

TO GIVE ADEQUATE WARNING TO OPERATORS OF OTHER VEHICLES .

The SDA CP Seeder is easy to operate,

therefore some basic and indispensable

cares are required on its handling.

Have always on mind that safety

requires constant attention, observation

and prudence during the operation,

transport, maintenance and storage of the

machine.

Dear User !

Respect the Ecology.

Do not throw the trash away.

This gesture of goodwill helps to

protect our Environment.

Do not spill combustible oil, battery and

filter residues in the soil. The trash in

contact with the soil reach the sub layer

which directly damage to the

Environment. Look for information to

delivery these contaminated elements to

whom knows to recycle or re-use them.

Be careful with the environment

Read and

understand the

informations

before realize

adjustments and

maintenance.

Raising or lowering

the seeder do not

allow any person

come closer to it,

especially in the row

markers action

area.

When working near

the PTO or driving

mechanisms have

a special care.

Never come closer

to rotating parts.

5

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

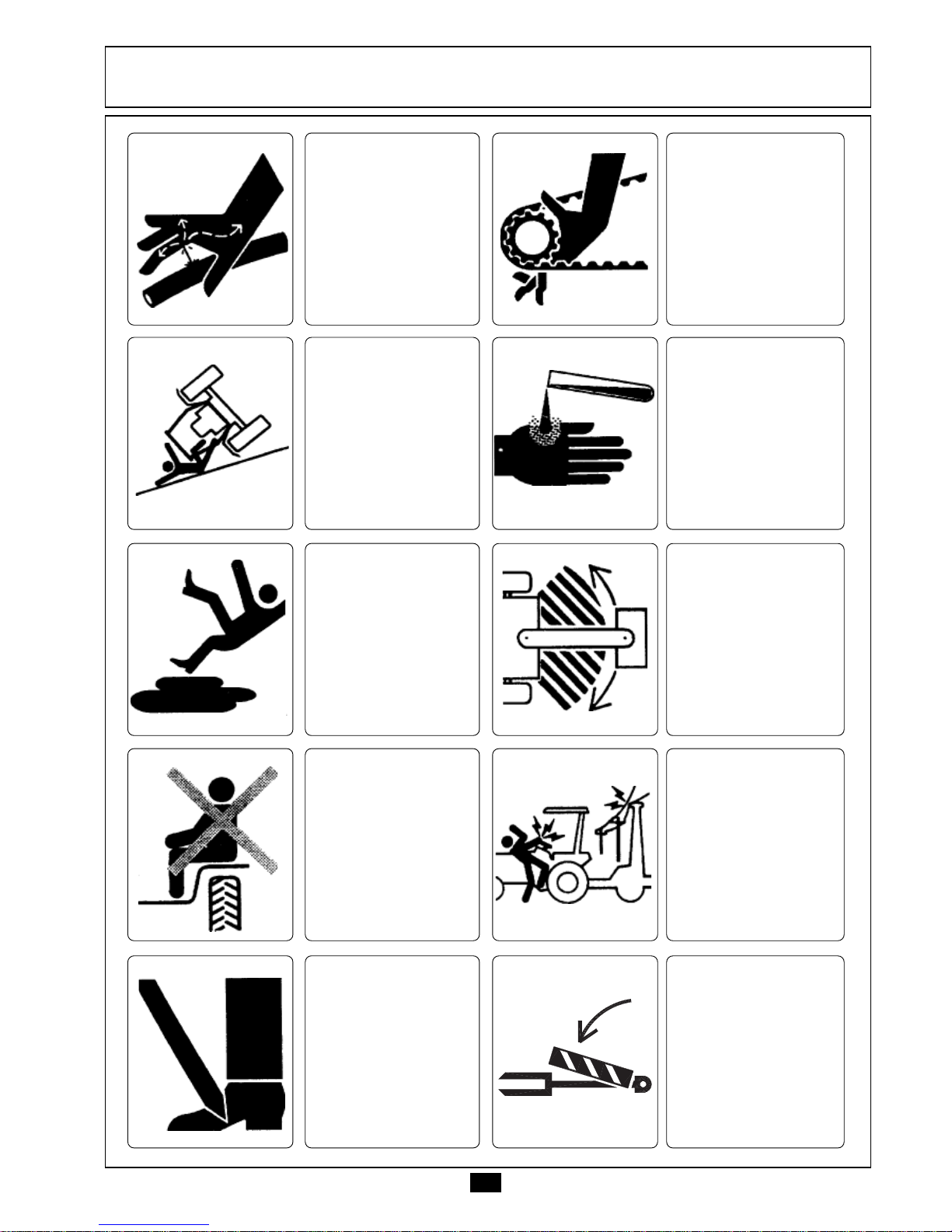

Be careful when

moving around

steep graders to

avoid overturn.

Be careful with use

of fertilizer or

chemicals.

These products in

contact with skin

could cause

personal injury to

the body.

Keep the

entrances and

places acessible

to working, clean

and free of the oil

and grease to

prevent

accidents.

Never allow riders

on the tractor or

implement unless

an additional seat

is available.

Use extreme

caution when

circulating with the

implement under

electrical power

lines, any contact

could result in

severe shock, injury

or death.

In order to protect

yourself always

wear adequate

clothes and shoes

during the

operations.

Always use the

cylinder transport

locks when

transporting the

implements.

Never attempt to

change the

adjustments, clean

or lubricate the

implement when in

movement.

Never use your

hands to check for

hydraulic leaks.

Escaping hydraulic

oil under pressure

can have sufficient

force to penetrate

the skin causing

personal injury.

Never transport

the implement on

rough roads during

the night. When

operating avoid to

make sharp turns

that may cause tire

to make contact

with implement.

6

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

- During the operation or transport do not allow riders on the tractor or

implement.

- Never allow children playing near the place that you are operating in, as

well as when transporting or stored.

- Learn about the area before starting the operation. Delimit the dangerous

places or the obstacles.

- Use the most appropriate speed according to the land conditions or roads

to travel.

- Use personal protective equipment for your own protection.

- Wear clothes and adequate shoes. Avoid large or loosen clothes that could

twine on the movable parts.

- Never operate without the machine protection devices.

- Be careful when hitching the implement to the tractor. Hands or fingers

can be injured when caught between the hitch and tractor drawbar.

- Before starting to raise or move the seeder check for people or animals

near or under the seeder.

- Verify with attention the transport width in narrow places.

- When disconnecting the implement move it to level area, preferably a hard

surface, on the field or at the warehouse. Certify that the machine is properly

stationed.

- See the general safety instructions in the back-cover of this Manual.

When Transporting the Implement on Truck or Trailer

To transport the equipment at long distances use a truck or trailer. However,

the safety instructions should be followed carefully:

- Use adequate loading dock to load and unload the equipment. Never use

a ditch bank, this practice could result in serious personal injury.

- In the event of lifting up with hoist use the appropriate points to hold.

- Use the seeder stands to prop it correctly.

- The seeder drawbar should be rised and locked in the vertical position or it

should be moved away and tied to the cargo.

- Tie the hopper covers and other mobile parts that can come unfastened

causing accidents.

- Use chock blocks and safety chains to secure the implement to the truck or

trailer during the transport.

- After 8 to 10 km transporting, please inspect the condition of the cargo.

Repeat this procedure every 80 to 100 km. Give more attention when

transporting the implement on rough roads, steep graders and other adverse

conditions.

- Be careful with transport height, specially when passing under electrical

power lines. Any contact could result in severe shock, injury or death.

- Observe all laws and regulations as to the height limits and cargo width while

transporting the implement on truck or trailer. If necessary use banners, lights

and other devices in order to give adequate warning to the drivers of other

vehicles.

7

TO THE OPERATO THE OPERA

TO THE OPERATO THE OPERA

TO THE OPERATORTOR

TORTOR

TOR

Safety Stickers

The safety stickers are used to alert you to hazards in the most dangerous parts

of the seeder. Keep the stickers clean and replace them when it's necessary.

When the machine is equipped with row

marker.

CACA

CACA

CAUTIONUTION

UTIONUTION

UTION

AA

AA

ATENCIONTENCION

TENCIONTENCION

TENCION

Read the manual before

attempting to work with the

equipment.

Lea el manual antes de iniciar el

uso del equipo.

0503031779

DANGER

PELIGRO

AVOID ACCIDENTS

EVITE ACCIDENTES

NEVER USE THE REAR PLATFORM FOR

OTHER MEANS THAN REFILL THE SEEDER.

BE SURE THAT BYSTANDERS ARE

STANDING CLEAR WHEN OPERATING OR

TRANSPORTING THE MACHINE.

LA PLATAFORMA SOLO DEBE SER USADA

PARA ABASTECER LA SEMBRADORA.

DURANTE LA OPERACIÓN O

TRANSPORTE, NO PERMITA LA

PERMANENCIA DE PERSONAS SOBRE LA

MÁQUINA.

0503032073

WARNINGWARNING

WARNINGWARNING

WARNING

ADAD

ADAD

ADVERVER

VERVER

VERTENCIATENCIA

TENCIATENCIA

TENCIA

Use the SAFETY LOCKS before adjusting

or servicing under the planter.

Utilice las TRABAS DE SEGURIDAD antes

de efectuar ajustes o mantenimiento

debajo de la sembradora.

AVOID ACCIDENTS.

EVITE ACCIDENTES.

0503031780

Before starting to raise or move the planter

check for people or animals near or under

the planter, especially in the row markers

action area.

Place the hydraulic cylinders lock before

transporting, servicing or storing the planter.

Antes de accionar la sembradora observe si

no hay personas o animales en el área de

acción de los marcadores de línea o debajo

de la sembradora.

Coloque las trabas en los cilindros

hidráulicos antes de transportar, almacenar

o efectuar servicios de mantenimiento.

0503031782

WARNINGWARNING

WARNINGWARNING

WARNING

ADAD

ADAD

ADVERVER

VERVER

VERTENCIATENCIA

TENCIATENCIA

TENCIA

8

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATECHNICAL SPECIFICA

TECHNICAL SPECIFICATIONSTIONS

TIONSTIONS

TIONS

Note.: Gotten average performance with the work speed = 8 km/h

15 and 19 Rows SDA CP, equipped with two 12.4/11-28 (30 PSI) Tires;

23, 27 and 29 Rows SDA CP, equipped with two 14.9/13-28 (30 PSI) Tires.

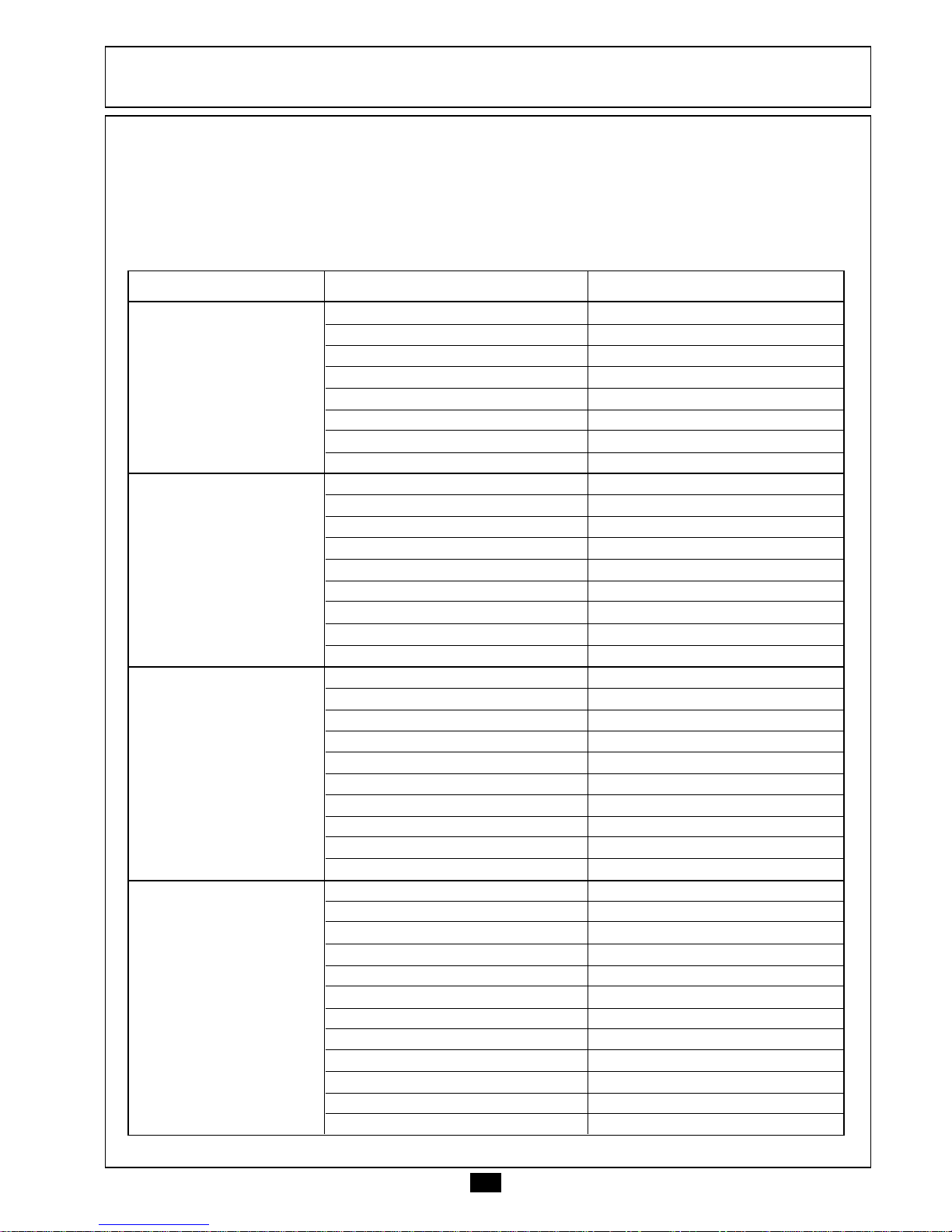

MODEL SDA CP

Number of Rows 15 19 21 23 27 29

Row Spacing (mm) 158 158 175 158 175 158

Working Width (mm) 2212 2844 3500 3476 4550 4424

Seeding Depth 0 a 60 mm

Seed Hoppers Capacity 610 Liters 770 Liters 910 Liters 910 Liters 1160 Liters 1160 Liters

490 kg 620 kg 730 kg 730 kg 930 kg 930 kg

Fertilizer Hoppers Capacity 700 Liters 880 Liters 1040 Liters 1040 Liters 1300 Liters 1300 Liters

780 kg 980 kg 1170 kg 1170 kg 1470 kg 1470 kg

Average Performance per Day

(10 Hours) ha

Tractor (HP) Required 80 - 90 90 - 95 95 - 105 95 - 105 120 - 140 120 - 140

Total Width (mm) 3780 4570 5200 5200 6280 6280

Length 3750 mm

Height 1810 mm

Double Disc

Diameter

Weight (kg) 3110 3800 4220 4300 5210 5300

13 17 21 21 27 27

Ø 15" x Ø 15"

SDA CP - No-Till Seed Drill - Plastic Hoppers

9

ASSEMBLASSEMBL

ASSEMBLASSEMBL

ASSEMBLYY

YY

Y

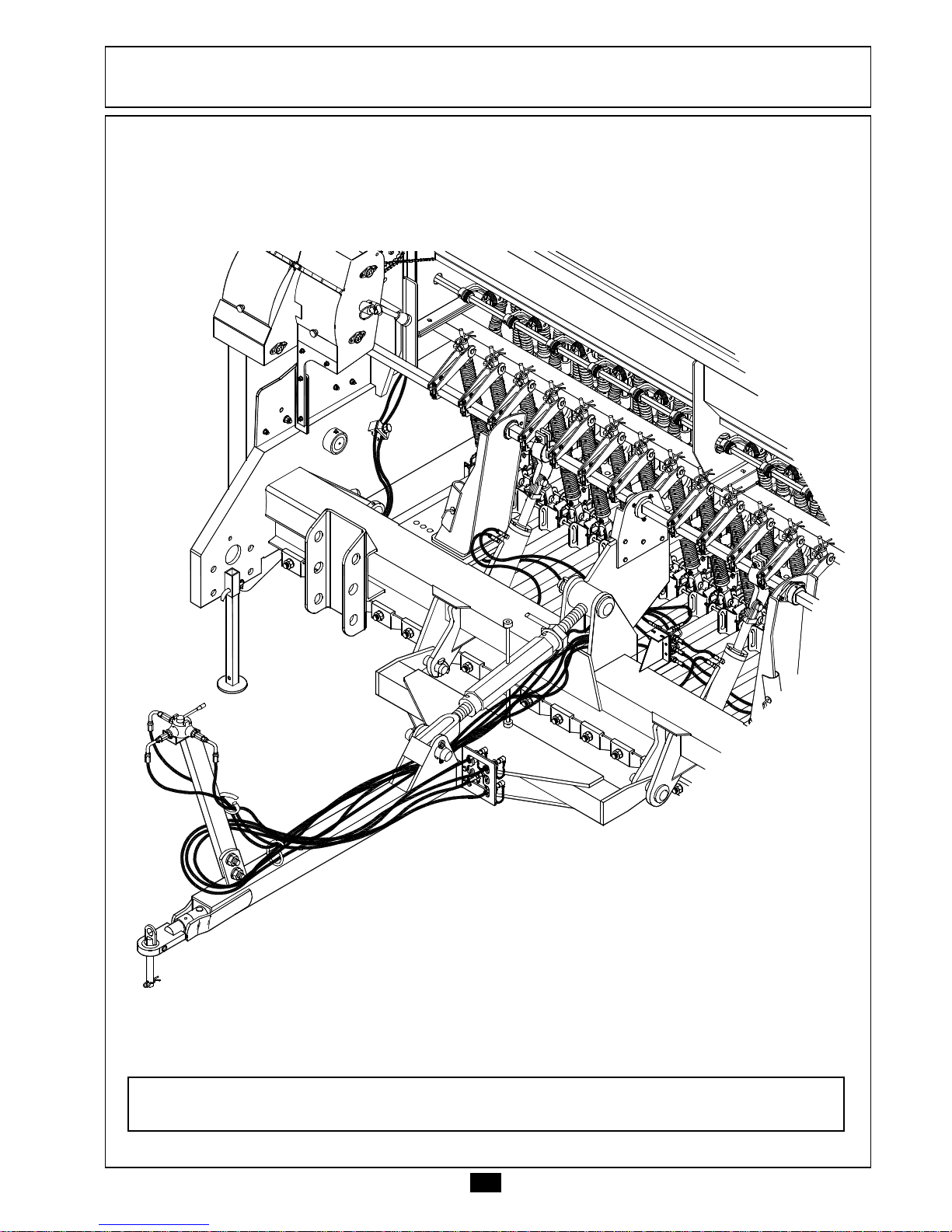

In order to make easy the transport, SDA CP leaves the factory semi-mounted,

remaining only the installation of a few components according to the following

instructions:

Drawbar Assembly

The drawbar is assembled and upward folded on the machine. It is enough

lowering and arresting it in the chassis of the machine, as illustrates the drawing below.

For eventual repairs or parts replacement consult the disassembled drawing.

10

ASSEMBLASSEMBL

ASSEMBLASSEMBL

ASSEMBLYY

YY

Y

Hydraulic System

The hydraulic system requires double control, it means, the tractor must be

equipped with four rear connections, being two each for oil inlet and outlet.

- Mount the support (A) of the triple valve (B) in the drawbar. (See p. 09).

A

B

11

ASSEMBLASSEMBL

ASSEMBLASSEMBL

ASSEMBLYY

YY

Y

Connect the hoses according to the illustrative drawing of the hydraulic system

on page 12.

Note: IF NECESSARY, USE THREAD SEAL TAPE TO CONNECT ALL THE HOSES. SEE THE

OPERATION OF THE TRIPLE VALVE IN THE FOLLOWING PAGE.

12

Wheel

Wheel

RowsLift

RowsLift

ASSEMBLASSEMBL

ASSEMBLASSEMBL

ASSEMBLYY

YY

Y

Operation of the Triple Valve

The positions 2 and 3, are used to make finishes, allowing to work only half of

the machine.

For safety precautions, after unloading the machine in the property, assemble

the central platform delivered attached to the lateral platform.

Position 1 - to

operate both cylinders

simultaneously.

Position 1 Position 2

Position 2 - to

operate the right

cylinder.

Position 3

Position 3 - to

operate the left

cylinder.

13

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

Preparing the Tractor

In order to avoid the excessive compaction of the soil in the rows that runs behind

the tractor tires, it is recommended installing wide rear tires without adding

counterweight.

Hitching to the Tractor

Attaches the drawbar to the

tractor by placing the hitch pin (A).

Lock with the cotter pin. Observe that

the tractor drawbar must remain on a

non-swinging way during operation

and transport.

Attention: AFTER HITCHING THE MACHINE TO THE TRACTOR, BEFORE ACTIVATING THE

HYDRAULIC SYSTEM, TAKE OUT THE SAFETY LOCKS (B) OF THE CYLINDERS

RODS, FASTEN IT IN THE DISUSE POSITION ACCORDING TO THE DETAIL.

B

Rows

Lifter B

A

14

Leveling the Seeder

Totally lift the rows activating the hydraulic cylinders.

Using the turnbuckle (A), adjust the level of the machine.

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

Plantadeiras

Implementos

Discos

Ferramentas

Agrícolas

CP

SDA

A

15

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

Spacing Between Rows

The seeder is normally supplied from plant assembled with 158 or 175 mm row

spacings, for sowing wheat, rice, oats, etc...; being possible to use other spacings as

shown below:

15 158

13 175

11 200

09 250

07 300 - 350

06 400

05 450 - 500 - 525

04 600 - 650

19 158

17 175

15 200

11 250

09 300 - 350

08 350 - 400

07 400 - 450

06 500

05 525 - 600 - 650

23 158

21 175

17 200

15 250

11 300

10 350

09 400

08 400 - 450 - 500

07 525

06 600 - 650

29 158

27 175

23 200

19 250

15 300

13 350

12 400

11 400- 450

10 500

09 525

08 600

07 650

SDA CP 21/23

SDA CP 27/29

SDA CP 19

SDA CP 15

Model Number of Rows Row Spacing (mm)

16

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

Positioning the Row Units in the Chassis

Check whether the number of rows to be assembled in the machine is odd or

even and follow the instructions below:

Even Number of Rows:

Mark the center of the chassis and

measures half of the spacing to the right

and half to the left, fastening in these

points both first rows. From these rows you

mark the others with a spacing from each

other.

Odd Number of Rows:

Install a row unit in the center of the

chassis. From this row you mark the others

with a spacing from each other.

Note: - OBSERVE THAT THE ROWS ARE RIGHT

AND LEFT . SEE ILLUSTRATIONS AT SIDE.

- THE CENTRAL ROW ALWAYS MUST BE

LONG.

- THE SPRING HOLDER HAS THE FUNCTION

OF KEEPING UNIFORM SPACINGS OF 158

OR 175 MM BETWEEN ROWS. FOR THE

OTHER SPACINGS IT DOES NOT HAVE

ANY UTILITY.

- FOR LARGER SPACINGS JUST USE LONG

ROWS.

Spring

Holders

Right Rows

Left Rows Right RowsLeft Rows

17

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

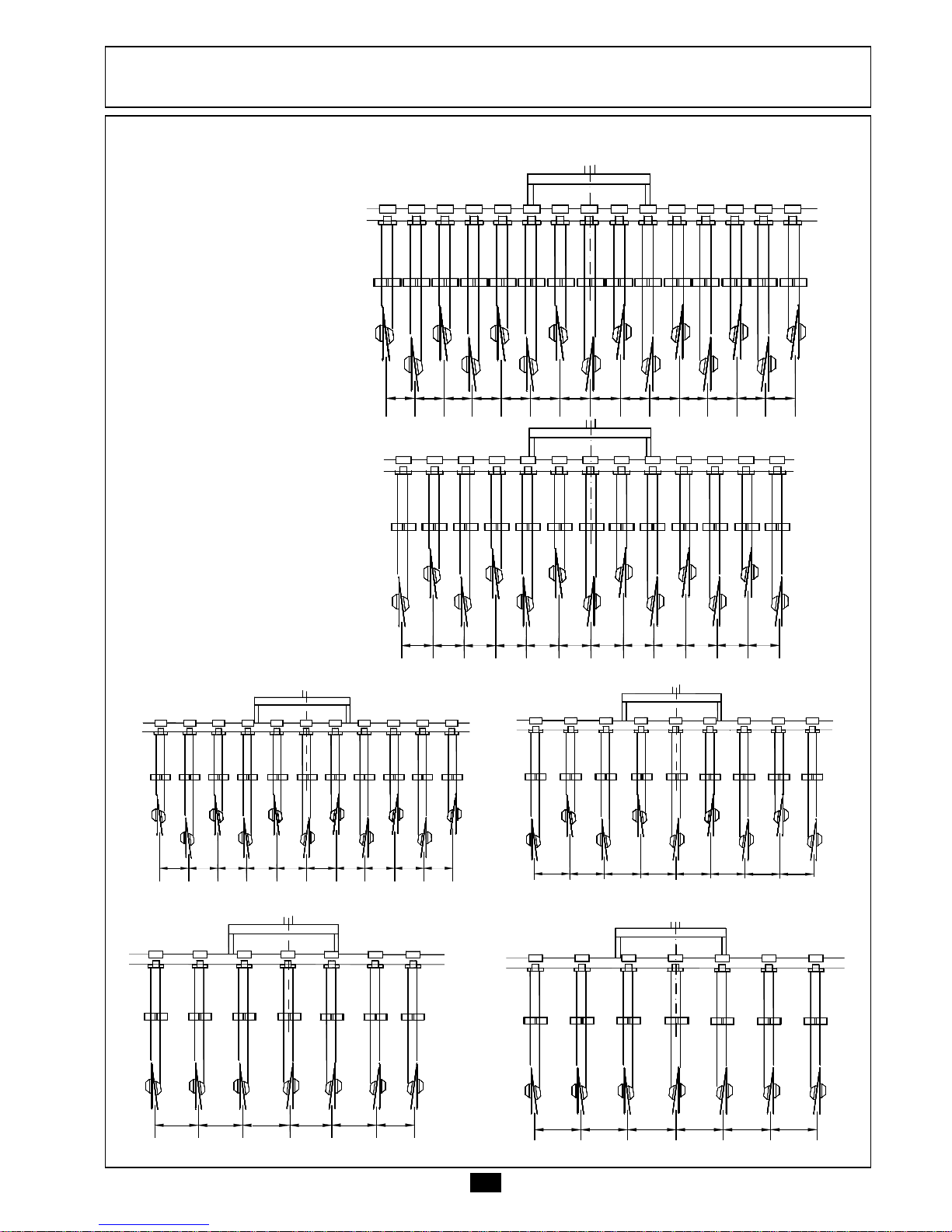

SDA CP - 15 Rows

15 rows with spacing of

158 mm

13 rows with spacing of

175 mm

11 rows with spacing of 200 mm 09 rows with spacing of 250 mm

07 rows with spacing of 300 mm 07 rows with spacing of 350 mm

158 158 158 158 158 158 158 158 158 158 158 158 158 158

175 175 175 175 175 175 175 175 175 175 175 175

200 200 200 200 200 200 200 200 200 200 250 250 250 250 250 250 250 250

300 300 300 300 300 300 350 350 350 350 350 350

18

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

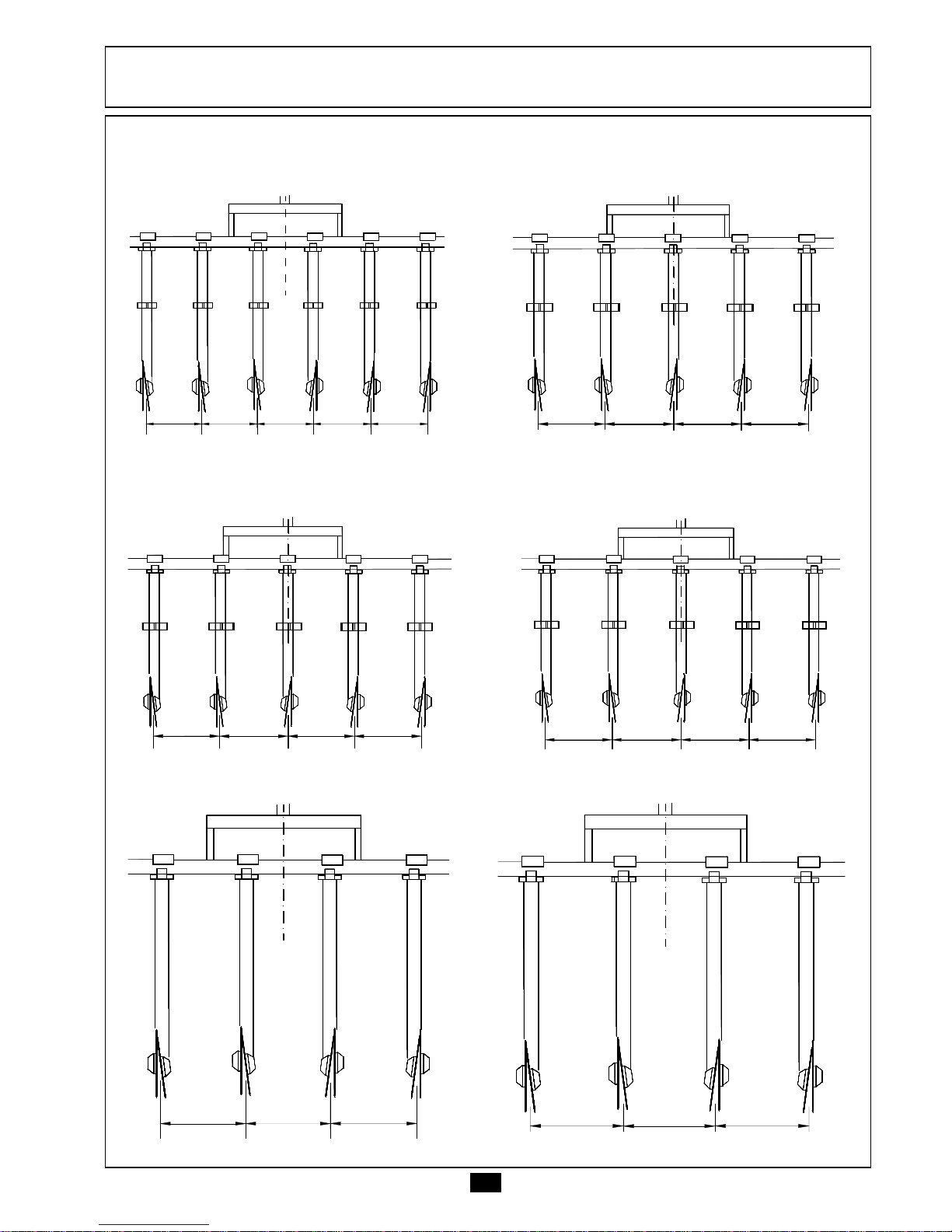

SDA CP - 15 Rows

06 rows with spacing of 400 mm 05 rows with spacing of 450 mm

05 rows with spacing of 500 mm 05 rows with spacing of 525 mm

04 rows with spacing of 600 mm 04 rows with spacing of 650 mm

400 400 400 400 400 450 450 450 450

500 500 500 500 525 525 525 525

600 600 600 650 650 650

19

SETSET

SETSET

SET-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS-UP INSTRUCTIONS

-UP INSTRUCTIONS

SDA CP - 19 Rows

19 rows with spacing of 158 mm

17 rows with spacing of 175 mm

15 rows with spacing of 200 mm

11 rows with spacing of 250 mm 09 rows with spacing of 300 mm

158 158 158 158 158 158 158 158 158 158 158 158 158 158 158 158 158 158

175 175 175 175 175 175 175 175 175 175 175 175 175 175 175 175

200 200 200 200 200 200 200 200 200 200 200 200 200 200

250 250 250 250 250 250 250 250 250 250 300 300 300 300 300 300 300 300

Table of contents