TCM MMCUT18AS2 User manual

1

Multi outdoor units

sErViCE MAnuAl Multi zone

CondEnsinG units

Revision E: ODMFI-E-1705

Model Numbers:

MMCUT18AS2 MMCUT27AS3 MMCUT36AS4

MMCUT48AS5

WARNING

•Installation MUST conform with local building codes or, in the absence of local

codes, with the National Electrical Code NFPA70/ANSI C1-1993 or current edition

and Canadian Electrical Code Part1 CSA C.22.1.

•The information contained in the manual is intended for use by a qualified service

technician familiar with safety procedures and equipped with the proper tools and

test instruments

•Installation or repairs made by unqualified persons can result in hazards to you

and others.

•Failure to carefully read and follow all instructions in this manual can result in

equipment malfunction, property damage, personal injury and/or death.

Table of Contents

1. Indoor Unit Combination

2. Dimension Of Outdoor Unit

3. Refrigerant Cycle Diagram

4. Installation Details

5. Electronic Function

6. Wiring Diagrams

7. Trouble Shooting

8. Disassembly Instructions

2

CONTENTS

1. Indoor Unit Combination.......................................................................................................................................... 4

2. Dimension Of Outdoor Unit...................................................................................................................................... 6

3. Refrigerant Cycle Diagram........................................................................................................................................ 8

4. Installation Details ..................................................................................................................................................11

4.1 Wrench torque sheet for installation ............................................................................................................... 11

4.2 Connecting the cables ...................................................................................................................................... 11

4.3 Pipe length and the elevation........................................................................................................................... 11

4.4 First-Time Installation....................................................................................................................................... 11

4.5 Adding Refrigerant after Long-Term System Operation...................................................................................13

4.6 Procedure when servicing the indoor unit refrigeration circuit.......................................................................13

4.7 Evacuation after servicing the outdoor unit refrigeration circuit ....................................................................14

5. Electronic Function.................................................................................................................................................16

5.1 Abbreviation ..................................................................................................................................................... 16

5.2 Electric Control Working Environment............................................................................................................. 16

5.3 Main Protection................................................................................................................................................16

5.4 Control and Functions ...................................................................................................................................... 18

6. Wiring Diagrams .....................................................................................................................................................23

7. Troubleshooting ..................................................................................................................................................... 30

7.1Safety................................................................................................................................................................. 30

7.2Indoor Unit Error Display...................................................................................................................................31

7.3 Outdoor Unit Display ........................................................................................................................................ 34

7.4 Diagnosis and Solution .....................................................................................................................................39

7.5 Trouble Criterion of Main Parts........................................................................................................................ 88

8. Disassembly Instructions ........................................................................................................................................ 99

MMCUT18AS2 (WCA30 metal plate)...................................................................................................99

MMCUT27AS3 (WD30 metal plate)....................................................................................................106

4

1. Indoor Unit Combination

Multi DC

Outdoor Unit Nominal

capacity Suggested

Combination Limit

1drive 2 5.2kW

12

None

9+9

9+12

12+12

Multi DC

Outdoor Unit Nominal

capacity Suggested

Combination Limit

1 drive 5 14kW

18+18

None

18+24

24+24

9+9+18

9+9+24

9+12+12

9+12+18

9+12+24

9+18+18

9+18+24

9+24+24

12+12+12

12+12+18

12+12+24

12+18+18

12+18+24

12+24+24

18+18+18

Multi DC

Outdoor Unit Nominal

capacity Suggested

Combination Limit

1drive 3 7.8kW

9+9

None

9+12

9+18

12+12

12+18

18+18

9+9+9

9+9+12

9+9+18

9+12+12

9+12+18

12+12+12

Multi DC

Outdoor Unit Nominal

capacity Suggested

Combination Limit

1 drive 4 10.5kW

9+18

None

12+12

12+18

18+18

9+9+9

9+9+12

9+9+18

9+12+12

9+12+18

9+18+18

12+12+12

12+12+18

12+18+18

9+9+9+9

9+9+9+12

9+9+9+18

9+9+12+12

9+9+12+18

9+12+12+12

12+12+12+12

5

18+18+24

9+9+9+9

9+9+9+12

9+9+9+18

9+9+9+24

9+9+12+12

9+9+12+18

9+9+12+24

9+9+18+18

9+9+18+24

9+12+12+12

9+12+12+18

9+12+12+24

9+12+18+18

9+18+18+18

12+12+12+12

12+12+12+18

12+12+12+24

12+12+18+18

9+9+9+9+9

9+9+9+9+12

9+9+9+9+18

9+9+9+9+24

9+9+9+12+12

9+9+9+12+18

9+9+9+18+18

9+9+12+12+12

9+9+12+12+18

9+12+12+12+12

9+12+12+12+18

12+12+12+12+12

6

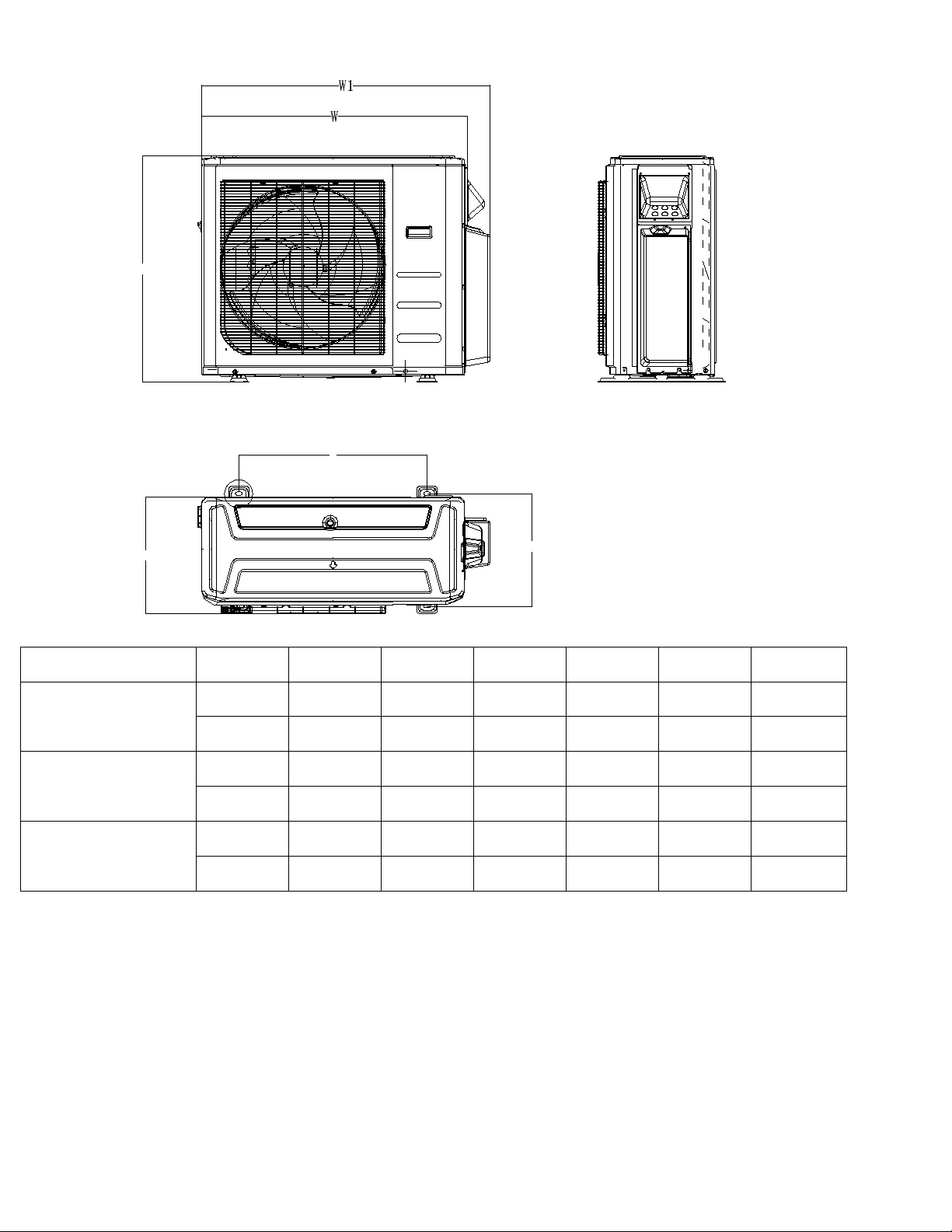

2. Dimension Of Outdoor Unit

H

D

A

B

Model

Unit:

W

D

H

W1

A

B

MMCUT18AS2

mm

845 363 702 923 540 350

inch

33.3

14.3

27.6

36.0

21.3

13.8

MMCUT27AS3

mm

946

410

810

1034

673

403

inch

37.2

16.5

31.9

40.6

26.5

15.9

MMCUT36AS4

mm

946

410

810

1034

673

403

inch

37.2

16.5

31.9

40.6

26.5

15.9

7

H

W

A

D

W1

B

Model

Unit:

W

D

H

W1

A

B

MMCUT48AS5

mm

952

415

1333

1060

634

404

inch

37.5

16.3

52.5

41.7

25.0

15.9

8

3. Refrigerant Cycle Diagram

3.1 Refrigeration circuit drawing of inverter 1 drive 2 type

LIQUID VALVE A

GAS VALVE A

HEAT

EXCHANGE

(EVAPORATOR) HEAT

EXCHANGE

(CONDENSER)

Compressor

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

middle

T1 Room

temp. sensor

T3

Condenser

temp. sensor

T5 Discharge

temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

EXV A CAPILLARY A

CHECK VALVE

CAPILLARY TUBE

EXV B CAPILLARY B

LIQUID VALVE B

GAS VALVE B

Accumulator

T2B-A

Evaporator

temp. sensor outlet

T2B-B

3.2 Refrigeration circuit drawing of inverter 1 drive 3 type

LIQUID VALVE A

GAS VALVE A

HEAT

EXCHANGE

(EVAPORATOR) HEAT

EXCHANGE

(CONDENSER)

Compressor

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

middle

T1 Room

temp. sensor

T3

Condenser

temp. sensor

T5 Discharge

temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

EXV A CAPILLARY A

CHECK VALVE

CAPILLARY TUBE

EXV B CAPILLARY B

LIQUID VALVE B

GAS VALVE B

EXV C CAPILLARY C

LIQUID VALVE C

GAS VALVE C Accumulator

T2B-A

Evaporator

temp. sensor outlet

T2B-B

T2B-C

9

3.3 Refrigeration circuit drawing of inverter 1 drive 4 type

LIQUID VALVE A

GAS VALVE A

HEAT

EXCHANGE

(EVAPORATOR) HEAT

EXCHANGE

(CONDENSER)

Compressor

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

middle

T1 Room

temp. sensor

T3

Condenser

temp. sensor

T5 Discharge

temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

EXV A CAPILLARY A

CHECK VALVE

CAPILLARY TUBE

EXV B CAPILLARY B

LIQUID VALVE B

GAS VALVE B

EXV C CAPILLARY C

LIQUID VALVE C

GAS VALVE C

EXV D CAPILLARY D

LIQUID VALVE D

GAS VALVE D

Accumulator High pressure

switch

Low pressure

switch

T2B-A Evaporator

temp. sensor outlet

T2B-B

T2B-C

T2B-D

3.4 Refrigeration circuit drawing of inverter 1 drive 5 type

LIQUID VALVE A

GAS VALVE A

HEAT

EXCHANGE

(EVAPORATOR) HEAT

EXCHANGE

(CONDENSER)

COOLING

HEATING

T2 Evaporator

temp. sensor

T1 Room

temp. sensor

T3

Condenser

temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

EXV A CAPILLARY A

CHECK VALVE

CAPILLARY TUBE

EXV B CAPILLARY B

LIQUID VALVE B

GAS VALVE B

EXV C CAPILLARY C

LIQUID VALVE C

GAS VALVE C

EXV D CAPILLARY D

LIQUID VALVE D

GAS VALVE D

EXV E CAPILLARY E

LIQUID VALVE E

GAS VALVE E Compressor

4-WAY VALVE

T5 Discharge

temp. sensor

Accumulator High pressure

switch

Low pressure

switch

T2B-A Evaporator

temp. sensor outlet

T2B-B

T2B-C

T2B-D

T2B-E

10

11

4. Installation Details

4.1 Wrench torque sheet for installation

Outside diameter Torque Additional tightening torque

mm inch N.cm N.cm

Ф6.35 1/4 1500(153kgf.cm) 1600(163kgf.cm)

Ф9.52 3/8 2500(255kgf.cm) 2600(265kgf.cm)

Ф12.7 1/2 3500(357kgf.cm) 3600(367kgf.cm)

4.2 Connecting the cables

The power cord connection should be

selected according to the following

specifications sheet.

Unit AWG

1 drive 2 type (18K outdoor unit) 14

1 drive 3 type (27K outdoor unit). 14

1 drive 4 type (36K outdoor unit) 12

1 drive 5 type (48K outdoor unit) 10

For indoor unit and outdoor unit connection

line, 16AWG is ok for all.

4.3 Pipe length and the elevation

Maximum piping length and height difference

1 drive 2

1 drive 3

1 drive 4

1 drive 5

Max. length for all

rooms (m)

40

(131ft)

60

(197ft)

80

(262ft)

80

(262ft)

Max. length for

one IU (m)

25 (82ft) 30 (98ft)

35

(115ft)

35

(115ft)

Max. height

difference between

IU and OU (m)

15

(49.2ft) 15

(49.2ft) 15

(49.2ft) 15

(49.2ft)

Max. height

difference between

IUs (m)

10 (33ft) 10 (33ft) 10 (33ft) 10 (33ft)

Additional refrigerant charge

1 drive 2

1 drive 3

1 drive 4

1 drive 5

Pre-charge pipe

length (m)

15

(49.2ft)

22.5

(73.8ft)

30

(98.4ft)

37.5

(123ft)

Additiona

l

refrigeran

t charge

g

15 x

(length

for all

rooms -

15)

15 x

(length

for all

rooms –

22.5)

15 x

(length

for all

rooms -

30)

15 x

(length

for all

rooms –

37.5)

oz

0.161

x(length

for all

rooms –

49.2)

(0.161

x(length

for all

rooms –

73.8)

0.161x(le

ngth for

all rooms

–98.4)

.0.161x(le

ngth for

all rooms

–123)

Caution:

●Refrigerant pipe diameter is different

according to indoor unit to be connected.

When using the extension pipe, refer to the

tables below.

●When refrigerant pipe diameter is different

from that of the outdoor unit connector (18K

indoor unit) an additional adapter is required.

Indoor unit

Extension pipe diameter

(mm/inch)

Model

Pipe diameter

(mm/inch)

9K

Liquid

6.35(1/4)

Liquid

6.35(1/4)

Gas

9.52(3/8)

Gas

9.52(3/8)

12K 18K

Liquid

6.35(1/4)

Liquid

6.35(1/4)

Gas

12.7(1/2)

Gas

12.7(1/2)

24K

Liquid

9.52 (3/8)

Liquid

9.52 (3/8)

Gas

15.9(5/8)

Gas

15.9(5/8)

Outdoor unit union diameter (mm/inch)

1 drive 2

Liquid

6.35(1/4) *2

Gas

9.52(3/8) *2

1 drive 3

Liquid

6.35(1/4) *3

Gas

9.52(3/8) *3

1 drive 4

Liquid

6.35(1/4) *4

Gas

9.52(3/8) *3

12.7(1/2) *1

1 drive 5

Liquid

6.35(1/4) *5

Gas

9.52(3/8) *3

12.7(1/2) *2

4.4 First-Time Installation

Air and moisture in the refrigerant system cause

the following problems:

●Increases in system pressure

●Increases in operating current

●Decreases in cooling and heating efficiency

●Blocks in capillary tubing caused by moisture

in the refrigerant circuit freezing

●Corrosion of parts in the refrigerant system

caused by water

The indoor units and the pipes between

indoor and outdoor units must be tested for

leakages and evacuated to remove gas and

moisture from the system.

Gas leak check with soap water:

Apply soap water or a liquid neutral

detergent on the connections with a soft brush to

check for leakage in the pipe connecting points. If

bubbles emerge, the pipes are leaking.

1. Air Purging Using the Vacuum Pump

12

1. Completely tighten the flare nuts on the

indoor and outdoor units. Confirm that both

the2-way and 3-way valves are set to the

closed position.

2. Connect the charge hose with the push pin of

the Handle Lo to the 3-way valve gas service

port.

3. Connect the charge hose of the Handle Hi to

the vacuum pump.

4. Fully open the Handle Lo of the manifold

valve.

5. Turn on the vacuum pump to begin

evacuation.

6. Conduct a 30-minute evacuation. Check

whether the compound meter indicates -

0.1Mpa(14.5Psi). If the meter does not

indicate -0.1Mpa(14.5Psi) after 30 minutes

has elapsed, continue evacuation for 20 more

minutes. If the pressure does not reach -

0.1Mpa(14.5Psi) after 50 minutes has

elapsed, check if there are any leaks.

Fully close the Handle Lo valve of the manifold

valve and turn off the vacuum pump. After 5

minutes, confirm that the gauge needle is not

moving.

7. Turn the flare nut on the 3-way valve45°

counterclockwise for 6-7 seconds. Once gas

begins to come out, tighten the flare nut.

Make sure the pressure display on the

pressure indicator is higher than atmospheric

pressure. Then remove the charge hose from

the 3-way valve.

8. Fully open the 2-wayand 3-way valves and

securely tighten the cap on the 3-way valve.

2. Adding refrigerant if the pipe length

exceeds chargeless pipe length

Procedure:

1) Connect the charge hose to the charging cylinder

and open the 2-way and 3-way valves.

With the charge hose you disconnected from the

vacuum pump, connect it to the valve at the

bottom of the cylinder.

If the refrigerant is R410A, place the cylinder

bottom-up to ensure liquid charging is possible.

2). Purge the air from the charge hose.

Open the valve at the bottom of the cylinder and

press the check valve on the charge set (be

careful of the liquid refrigerant).

3) Place the charging cylinder onto the electronic

scale and record the weight.

4) Turn on the air conditioner in cooling mode.

5) Open the valves (Low side) on the charge set.

Charge the system with liquid refrigerant.

6).When the electronic scale displays the proper

weight (refer to the table), disconnect the charge

hose from the 3-way valve’s service port

immediately and turn off the air conditioner before

disconnecting the hose.

7). Mount the valve stem caps and the service port

Use a torque wrench to tighten the service port

cap to a torque of 18N.m(13.27 ft·lbs).

Be sure to check for gas leaks.

13

4.5 Adding Refrigerant after Long-Term

System Operation

Procedure

1) Connect the charge hose to the 3-way service

port and open the 2-way and 3-way valve.

Connect the charge hose to the valve at the

bottom of the cylinder. If the refrigerant is R410A,

place the cylinder bottom-up to ensure liquid

charge.

2). Purge the air from the charge hose.

Open the valve at the bottom of the cylinder and

press the check valve on the charge set to purge

the air (be careful of the liquid refrigerant).

3) Place the charging cylinder onto the electronic

scale and record the weight.

4) Turn on the air conditioner in cooling mode.

5) Open the valves (Low side)on the charge set and

charge the system with liquid refrigerant.

6).When the electronic scale displays the proper

weight (refer to the gauge and the pressure of the

low side), disconnect the charge hose from the 3-

way valve’s service port immediately and turn off

the air conditioner before disconnecting the hose.

7). Mount the valve stem caps and the service port.

Use torque wrench to tighten the service port cap

to a torque of 18N.m(13.27 ft·lbs).

Be sure to check for gas leaks.

4.6 Procedure when servicing the indoor

unit refrigeration circuit.

1. Collecting the refrigerant into the outdoor

unit

Procedure

1). Confirm that both the 2-way and 3-way valves

are set to the opened position

Remove the valve stem caps and confirm that the

valve stems are in the opened position.

Be sure to use a hexagonal wrench to operate the

valve stems.

2). Connect the charge hose with the push pin of

handle lo to the 3-way valves gas service port.

3).Air purging of the charge hose.

Open the handle Lo valve of the manifold valve

slightly to purge air from the charge hose for 5

seconds and then close it quickly.

4). Set t e 2-way valve to the close position.

5). Operate the air conditioner at the cooling cycle

and stop it when the gauge indicates 0.1MPa.

6). Set the 3-way valve to the closed position

immediately

Do this quickly so that the gauge ends up indicating

0.3 to 0.5Mpa.

Disconnect the charge set, and tighten the 2-way

and 3-way valve’s stem nuts.

Use a torque wrench to tighten the 3-way valves

service port cap to a torque of 18N.m.

Be sure to check for gas leakage.

2.Air purging with vacuum pump

14

1) Completely tighten the flare nuts of the indoor

and outdoor units, confirm that both the 2-way

and 3-way valves are set to the closed

position.

2) Connect the charge hose with the push pin of

handle lo to the 3-way valves gas service

port.

3) Connect the charge hose of handle hi

connection to the vacuum pump.

4) Fully open the handle Lo of the manifold

valve.

5) Operate the vacuum pump to evacuate.

6) Make evacuation for 30 minutes and check

whether the compound meter indicates -

0.1Mpa. If the meter does not indicate -

0.1Mpa after pumping 30 minutes, it should

be pumped 20 minutes more. If the pressure

can’t achieve -0.1Mpa after pumping 50

minutes, please check if there are some

leakage points.

Fully close the handle Lo valve of the manifold

valve and stop the operation of the vacuum

pump. Confirm that the gauge needle does not

move (approximately 5 minutes after turning off

the vacuum pump).

7) Turn the flare nut of the 3-way valves about

45° counterclockwise for 6 or 7seconds after

the gas

coming out, then tighten the flare nut again. Make

sure the pressure display in the pressure

indicator is a little higher than the atmosphere

pressure. Then remove the charge hose from the

3 way valve.

8) Fully open the 2 way valve and 3 way valve

and securely tighten the cap of the 3 way

valve.

4.7 Evacuation after servicing the outdoor

unit refrigeration circuit

1. Evacuation of the complete refrigeration

circuit, Indoor and outdoor unit.

Procedure:

1). Confirm that both the 2-way and 3-way valves

are set to the opened position.

2). Connect the vacuum pump to 3-way valve’s

service port.

3). Evacuation for approximately one hour.

Confirm that the compound meter indicates -

0.1Mpa (500 Microns / 29.9 in,hg).

4). Close the valve (Low side) on the charge set,

turn off the vacuum pump, and confirm that the

gauge needle does not move (approximately 5

minutes after turning off the vacuum pump).

5). Disconnect the charge hose from the vacuum

pump.

2. Refrigerant charging

Procedure:

1). Connect the charge hose to the charging

cylinder, open the 2-way valve and the 3-way

valve.

15

Connect the charge hose which you disconnected

from the vacuum pump to the valve at the bottom

of the cylinder. If the refrigerant isR410A, make

the cylinder bottom up toensure liquid charge.

2). Purge the airfrom the charge hose

Open the valve at the bottom ofthe cylinder and

press the check valve on the charge setto purge

the air (be careful ofthe liquid refrigerant).

3) Put the charging cylinder ontothe electronic

scale and record the weight.

4).Open the valves (Low side) on the charge set

and charge the system with liquid refrigerant

If the system cannot be charge with the specified

amount ofrefrigerant, orcanbe charged with a

little at atime (approximately 150g each time) ,

operating the air conditioner in the cooling cycle;

however, one time isnot sufficient, wait

approximately 1 minute and then repeat the

procedure.

5).When the electronic scale displays the proper

weight, disconnect the charge hose from the 3-

way valve’sservice portimmediately

If the system has been charged with liquid

refrigerant while operating the air conditioner, turn

off the air conditioner before disconnecting the

hose.

6). Mounted the valve stem caps and the service

port. Use torque wrench to tighten the service

port cap to a torque of18N·m (13.27 ft·lbs).

Always leak check after servicing the refrigerant

system.

For MMCUT27AS3 / MMCUT36AS4 /

MMCUT48AS5

There are one low-pressure centralized valve and

one high-pressure centralized valve, it will be

more time saving when vacuum and recycle

refrigerant. But refer to the previous instruction

when vacuum and recycle refrigerant.

16

5. Electronic Function

5.1 Abbreviation

T1: Indoor ambient temperature

T2: Middle indoor heat exchanger coil

temperature

T2B: Indoor heat exchanger exhaust coil

temperature (located on the outdoor unit)

T3: Outdoor heat exchanger pipe temperature

T4: Outdoor ambient temperature

T5: Compressor discharge temperature

5.2 Electric Control Working Environment.

5.2.1 Input voltage: 230V.

5.2.2 Input power frequency: 60Hz.

5.2.3 Indoor fan standard working amp.: <1A

5.2.4 Outdoor fan standard working amp.: <1.5A.

5.2.5 Four-way valve standard amp.: <1A.

5.3 Main Protection

5.3.1 Compressor Restart Delay

---- The compressor takes 1 minute to start up the

first time. Further restarts take 3 minutes.

5.3.2 Temperature Protection of Compressor

Discharge.

When the discharge temperature of the

compressor rises, the running frequency is limited

according to the following rules:

----If 105℃(221 ℉)≦T5<110℃(230 ℉),

maintain the current frequency.

----If the temperature increase and T5≧110℃

(230 ℉), decrease the frequency to a lower level

every 2 minutes till to F1.

---If T5≧115℃(239 ℉) for 10 seconds, the

compressor stops and then restart untill T5<90℃

(194 ℉).

5.3.3 Fan Speed Malfunction

---- If outdoor fan speed is lower than 100RPM or

higher than 2400RPM for 60 seconds or more,

the unit stops and LED displays E8 failure code.

5.3.4 Inverter Module Protection.

---- The inverter protection module ensures that

faults related to current, voltage, or temperature

does not damage the inverter.

If these protections are triggered, the A/C unit

stops and the LED displays the failure code.

The unit restarts 3 minutes after the protection

mechanism has turned off.

5.3.5 Low Voltage Protection

VOLTAGE

No limit

VOLT_LTM_FREQ1_ADD

VOLT_LTM_FREQ2_ADD

Note: If low voltage protection triggers and

voltage is not restored to normal within 3

minutes, the protection remains active even

after a machine restart.

5.3.6 Compressor Current Limit Protection

The temperature interval for the current limit is

the same as the range of the T4 frequency limit.

Cooling mode:

17

CoolReturnI

The difference between current limit

and shutdown current

CoolT4Zone5I

Cooling T4

≥

50

℃

current limit value

CoolT4Zone4I

Cooling 49

>

T4

≥

45

℃

current limit

value

CoolT4Zone3I

Cooling 44

>

T4

≥

41

℃

current limit

value

CoolT4Zone2I

Cooling 40

﹥

T4

≥

33

℃

current limit

value

CoolT4Zone1I

Cooling 32

>

T4

℃

current limit value

CoolStopI

Cooling stop protection current value

Heating mode:

℃

15

14 HeatT4Zone4I

10

9 HeatT4Zone3I

6

5 HeatT4Zone2I

HeatT4Zone1I

HeatReturnI

The difference between current limit

and shutdown current

HeatT4Zone4I

Heating

T4

≥

15

℃current limit

value

HeatT4Zone3I

Heating

14

>

T4

≥

10

℃current

limit value

HeatT4Zone2I

Heating

9

>

T4

≥

6

℃current limit

value

HeatT4Zone1I

Heating 5

>

T4 current limit value

HeatStopI

Heating stop protection current

value

5.3.7 Indoor / Outdoor Units Communication

Protection

If the indoor units do not receive the feedback

signal from the outdoor units for 2 consecutive

minutes, the unit stops. The unit displays the

failure code.

5.3.8 High Condenser Coil Temp. Protection

5.3.9 Outdoor Unit Anti-Freezing Protection

When T2<4℃for 250seconds or T2<0℃, the

indoor unit capacity demand is zero and resumes

normal operation when T2>8℃and the protection

time is no less than 3 minutes.

5.3.10 Oil Return

Rules for Operation

1. If the compressor frequency continues to be

lower than the frequency set for setting time, the

unit raises the frequency to the frequency set for

setting time and then resumes with the former

frequency.

2. The EXV continues at 300p while indoor units

maintain their operation.

T3

Resume

Off

Decrease

Hold

℃CoolT4Zone5I

50

49

45 CoolT4Zone4I

44

41

40 CoolT4Zone3I

33

32

CoolT4Zone2I

18

If the outdoor ambient temperature is higher than

the set frequency during oil return, the unit stops

the oil return process.

5.3.11 Low Outdoor Ambient Temperature

Protection

When the compressor is off and T4 is lower than -

35℃for 10 seconds, the unit stops and displays

“LP.”

When the compressor is on and T4 remains lower

than -40℃for 10 seconds, the unit stops and

displays “LP.”

When T4 is no lower than -32℃for 10 seconds,

the unit exits protection.

5.4 Control and Functions

5.4.1 Capacity Request Calculation

Cooling Mode:

T1 Ts

3

1

1e

c

a4

2

0

2

3

01

f

d

b

Capacity area a b c d e f

Norm code (N)

3

2

1.5

1

0.5

0

Model

9K

12K

18K

24K

HP

1.0

1.2

1.5

2.5

Note: The final result is an integer.

Use the following table and final capacity

request to confirm the operating frequency.

Frequency (Hz) 0

COO

L_F1 COO

L_F2 …

…COOL

_F24

COO

L_F2

5

Amendatory

capacity

demand.

0

1 2 …

…24 25

The maximum running frequency is adjusted

according to the outdoor ambient temperature

℃

55

54

Fmax=

T4FREMAXC0

51.5

50.5

Fmax= T4FREMAXC1

45.5

44.5

Fmax= T4FREMAXC2

39

38

Fmax= T4FREMAXC3

33

32

Fmax= T4FREMAXC4

30

29

Fmax= T4FREMAXC5

22

20

Fmax= T4FREMAXC6

10

8

Fmax= T4FREMAXC7

0

-2

Fmax= T4FREMAXC8

-10

-12

Fmax= T4FREMAXC9

Fmax= T4FREMAXC10

Heating Mode

T1 Ts

4

0

a

3

1

-1

3

12

0

b

c

d

e

f

2

Capacity area a b c d e f

Norm code (N) 3 2 1.5 1 0.5 0

Model

9K

12K

18K

24K

HP

1.0

1.2

1.5

2.5

Note: The final result is an integer.

Then modify it according to a T2 average

(correction):

19

Note:Average value of T2:Sum T2 value of all

indoor units)/ (indoor units number

℃

T2 average

Decrease frequency

47

Keep frequency

40

Increase frequency

Use the following table and final capacity

request to confirm the operating frequency.

Frequency

(Hz) 0 HEAT

_F1 HEAT

_F2 … HEAT

_F24 HEAT

_F25

Amendatory

capacity

demand.

0 1 2 … 24 25

The maximum running frequency is adjusted

according to the outdoor ambient temperature

℃

34

33

Standby

28

27 Fmax=T4FREHEATMAX1

25

24 Fmax=T4FREHEATMAX2

22

21 Fmax=T4FREHEATMAX3

19

18 Fmax=T4FREHEATMAX4

17

16 Fmax=T4FREHEATMAX5

15

14 Fmax=T4FREHEATMAX6

12

11 Fmax=T4FREHEATMAX7

6

5 Fmax=T4FREHEATMAX8

1

0 Fmax=T4FREHEATMAX9

-3

-4 Fmax=F21

-7

-8 Fmax=F22

-11

-12 Fmax=F23

-15

-16 Fmax=F24

Fmax=F25

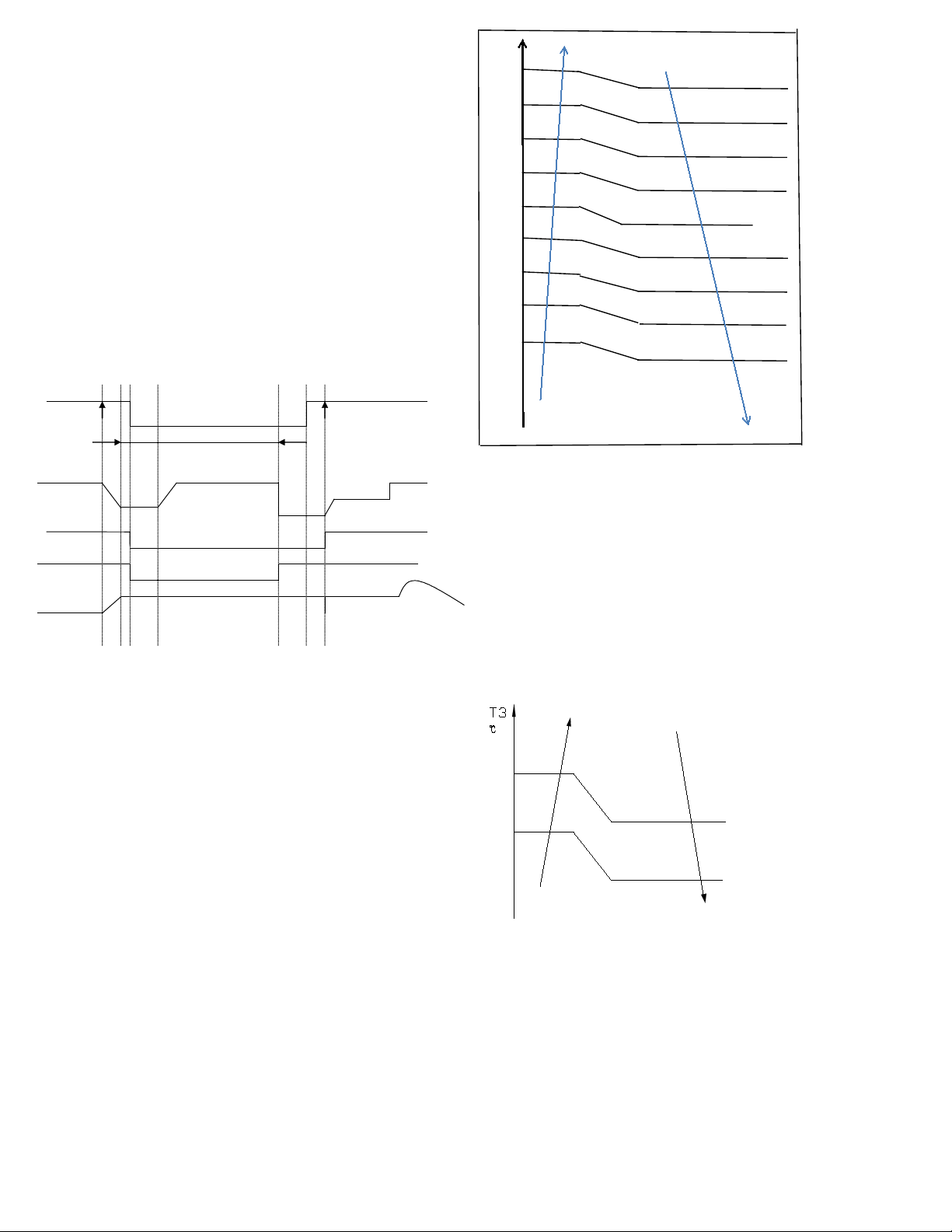

5.4.2 Defrosting Control

Conditions for Defrosting:

After the compressor starts and enters normal

operation, mark the minimum value of T3 from

the 10th to 15th minute as T30.

If any one of the following conditions is satisfied,

the unit enters defrosting mode:

1) If the compressor’s cumulative running time

reaches 29 minutes and T3< TCDI1 and T3+

T30SUBT3ONE≦T30.

2) If the compressor cumulative running time

reaches 35 minutes and T3< TCDI2 and T3+

T30SUBT3TWO≦T30.

3) If the compressor cumulative running time

reaches 40 minutes and T3< -24C for 3 minutes.

20

4) If the compressor cumulative running time

reaches 120 minutes and T3<-15℃.

Defrost Stop Conditions

If any one of the following conditions is satisfied,

defrosting ends and the unit returns to normal

heating mode:

----T3 rises above than TCDE1℃.

----T3 remains at TCDE2℃or above for 80

seconds.

----The machine runs for 10 consecutive minutes

in defrosting mode.

Defrosting Action

:

off

on

Cool-F9

10S

30S

TimeA

10S

4-way valve

defrosting

Defrosting over

compressor

Indoor fan

Outdoor fan

EXV open

frequency

Max 10 minutes

frequency

Compressor stops

off

Anti-cold control

off

480P

480P for 240s

Condition of ending defrosting:

If any one of following items is satisfied,

defrosting will stop and the machine will turn to

normal heating mode.

①T3 > TempQuitDefrost_ADD ℃;.

②The defrosting time achieves 10min.

③Turn to other modes or off.

5.4.3 Outdoor Fan Control

5.4.3.1 Cooling Mode

Under normal operating conditions, the system

chooses the running fan speed according to the

ambient temperature:

Outdoor

℃

45

43

Supper high fan speed

28

26 High fan speed

25

23

Middle fan speed

22

20

Low fan speed

19

17

Supper low fan speed

10

9

Breeze fan speed

0

-1 F fan speed

-5

-6

G fan speed

-10

-11

H fan speed

I fan speed

When low ambient cooling is in effect::

Outdoor fan speed control logic (low ambient

cooling)

When T4 <15 ℃(59 ℉) and T3 < 30 ℃(86 ℉),

the unit enters into low ambient cooling mode.

The outdoor fan chooses a speed according to T3.

When T3≥38 ℃(100.4 ℉) or when T4≥20 ℃

(68 ℉), the outdoor fan chooses a speed

according to T4 again.

38

Exit low ambient cooling

mode

,

run with high fan

for 1 minute

Low

30

27

23

off

This manual suits for next models

3

Table of contents

Popular Heat Pump manuals by other brands

Walter Roller

Walter Roller Silent Line WPV Mounting instructions

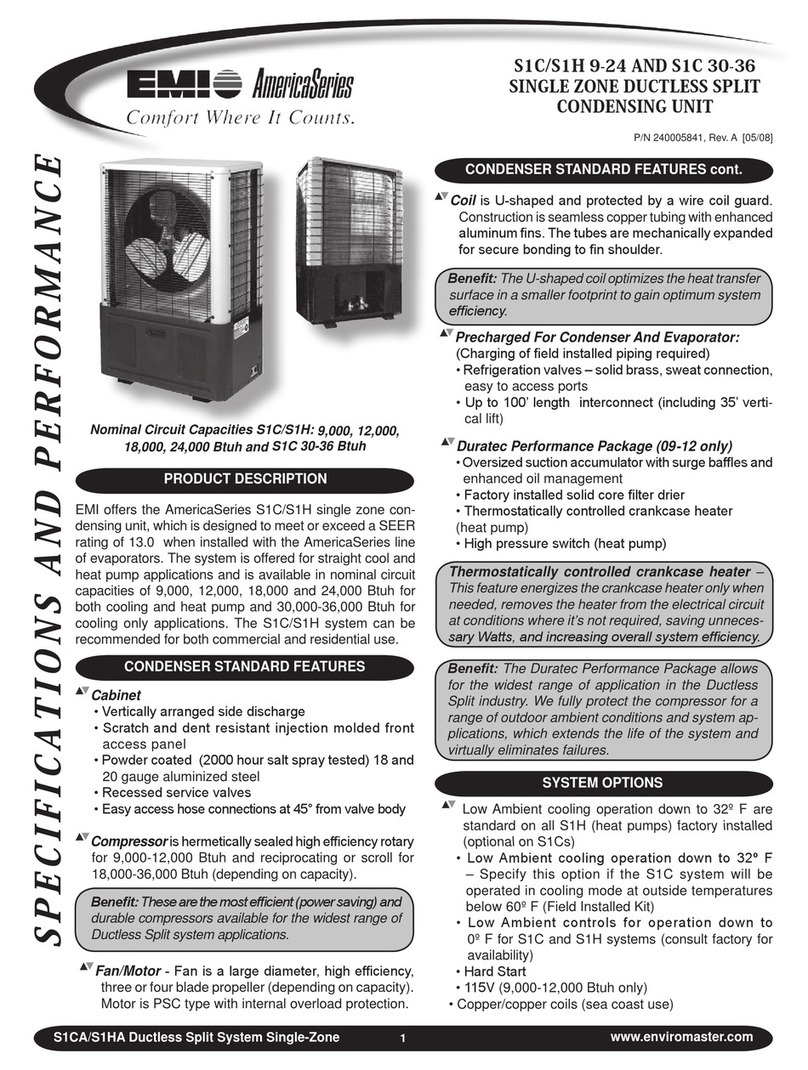

EMI

EMI AmericaSeries S1H9A Specifications and Performance

Heat Controller

Heat Controller RPHE-093G Series Installation & operation manual

Econar

Econar GeoSource DualTEK GV Series Installation and operating instructions

Airwell

Airwell XLM9 Installation and maintenance manual

Bryant

Bryant 548J Product data