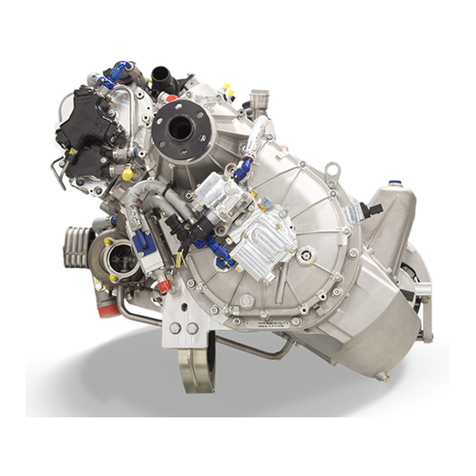

Technify Motors TAE 125-02-114 Configuration guide

Technify Motors GmbH

Platanenstraße 14

D - 09356 St. Egidien

Tel. +49-(0)37204/ 696-0

Fax +49-(0)37204/ 696-2912

www.continentaldiesel.de

support@ccontinentaldiesel.de

Doc.-No.: 50-0310-50022

Approved Airplane Flight Manual Supplement

for the

DA 40 D

Equipped with

TAE 125-02-114 Engine Installation

Issue 2/0

This supplement must be attached to the EASA approved

Airplane Flight Manual when the TAE 125-02-114 engine has

been installed in accordance with EASA STC 10036328.

The information contained in this supplement supersedes or

adds to the EASA approved Airplane Flight Manual only as set

forth herein.

For limitations, procedures, performance and loading

information not contained in this supplement, consult the basic

EASA approved Airplane Flight Manual.

ThisAirplaneFlightManualSupplementisapprovedwithEASA

STC 10036328.

SERIAL No. _______________

REGISTER No. _______________

This page intentionally left blank

AFM Supplement DA 40 D

Page iii

Issue 2

Revision -, Aug. 2015

LOG OF REVISIONS

Revision Chapter Description Approved

Date Endorsed

- All Initial Issue 1 Sept. 01,

2011 EASA STC

10036328

1/1 2 New fuel,

new gearboxoil March 16,

2012

Revision No. 1 to AFM supplement

ref. 50-0310-50021 is approved

under the authority of DOA

ref. EASA.21J.010.

Date: March 16, 2012

Office of Airworthiness

2/0 All Change of Ownership Aug. 15,

2015 EASA STC

10036328,

Rev. 3

2 New gearbox oil

New fuel,

new specs

5 splitted due to new

specs

5a New section

5b new section

6 Equipment list updated

Note: The parts of the text which changed are

marked with a vertical line on the margin of

the page.

AFM Supplement DA 40 D

Page iv

Issue 2

Revision -, Aug. 2015

LIST OF EFFECTIVE CHAPTERS

APPROVAL

The content of approved chapters is approved by EASA. All

other content is approved by TAE under the authority of EASA

DOA No. EASA.21J.010 in accordance with Part 21.

GENERAL REMARK

The content of this AFM supplement is developed on basis of

the EASA-approved AFM, DAI Document No. 6.01.05-E.

Chapter Issue/Revision Date

1 2/0 Aug., 2015

2 2/0 Aug., 2015

3 2/0 Aug., 2015

4A 2/0 Aug., 2015

4B 2/0 Aug., 2015

5a 2/0 Aug., 2015

5b 2/0 Aug., 2015

6 2/0 Aug., 2015

7 2/0 Aug., 2015

8 2/0 Aug., 2015

92/0 Aug., 2015

AFM Supplement DA 40 D

Page v

Issue 2

Revision -, Aug. 2015

TABLE OF CONTENTS

CHAPTER 1..........GENERAL

(a non-approved chapter)

CHAPTER 2..........OPERATING LIMITATIONS

(an approved chapter))

CHAPTER 3..........EMERGENCY PROCEDURES

(a non-approved chapter))

CHAPTER 4a........NORMAL OPERATING PROCEDURES

(a non-approved chapter)

CHAPTER 4b........ABNORMAL OPERATING PROCEDURES

(a non-approved chapter))

CHAPTER 5..........PERFORMANCE

(a non-approved chapter))

CHAPTER 6..........WEIGHT AND BALANCE /

EQUIPMENT LIST

(a non-approved chapter))

CHAPTER 7..........DESCRIPTION OF THE AIRPLANE AND

ITS SYSTEMS

(a non-approved chapter))

CHAPTER 8..........AIRPLANE HANDLING, CARE AND

MAINTENANCE

(a non-approved chapter))

CHAPTER 9..........SUPPLEMENTS

AFM Supplement DA 40 D

Page vi

Issue 2

Revision -, Aug. 2015

This page is intentionally left blank

AFM Supplement DA 40 D

Page 1-1

Issue 2

Revision -, Aug. 2015

CHAPTER 1

GENERAL

1.1 INTRODUCTION

This supplement must be attached to the EASA approved

Airplane Flight Manual when the TAE 125-02-114 engine has

been installed in accordance with EASA STC 10036328.

The information contained in this supplement supersedes or

adds to the EASA approved Airplane Flight Manual only as set

forth herein.

For limitations, procedures, performance and loading

information not contained in this supplement, consult the basic

EASA approved Airplane Flight Manual.

1.2 CERTIFICATION BASIS

The certification basis for the TAE 125-02-114 engine

installation is CS-23, dated November 14, 2003.

1.5 DEFINITIONS AND ABBREVIATIONS

(i) Miscellaneous

EASA: European Aviation Safety Agency

1.8 SOURCE DOCUMENTATION

UPDATE AND REVISION OF THE MANUAL

WARNING: A safe operation is only assured with an up

to date AFM supplement. Information about

actual AFM, supplement issues and

revisions are published in the Service

Bulletin TM TAE 000-0004.

Note: The Doc.-No of this AFM supplement is

published on the cover sheet of this

supplement.

AFM Supplement DA 40 D

Page 1-2

Issue 2

Revision -, Aug. 2015

This page intentionally left blank

AFM Supplement DA 40 D

Page 2-1

Issue 2

Revision -, Aug. 2015

CHAPTER 2

OPERATING LIMITATIONS

2.4 POWERPLANT LIMITATIONS

a) Engine manufacturer: .......................Technify Motors GmbH

b) Engine designation:.....................................TAE 125-02-114

c) RPM limitations (shown as propeller PRM)

Maximum: .................................................................2300 RPM

Maximum overspeed:..........................2500 RPM (max 20 sec)

d) Engine Power

Max. take-off power: ................ 114 kW (155 HP) at 2300 RPM

Max. continuous power:........... 114 kW (155 HP) at 2300 RPM

Max. recommended cruise power:......................................85%

e) Oil Pressure

Min. oil pressure:.............................................................1.2 bar

Min. oil pressure (at Take-off power): .............................2.3 bar

Min. oil pressure (in flight):..............................................2.3 bar

Max. oil pressure:............................................................6.0 bar

Max. oil pressure (cold start < 20 sec.):..........................6.5 bar

g) Oil Temperature

Min. oil temperature (engine starting temp.): ....................-32°C

Min. oil temperature (min. operating limit temp.):...............50°C

Max. oil temperature:.......................................................140°C

h) Coolant Temperature

Min. coolant temp. (engine starting temp.):.......................-32°C

Min. coolant temp. (min. operating limit temp.):.................60°C

Max. coolant temperature:...............................................105°C

AFM Supplement DA 40 D

Page 2-2

Issue 2

Revision -, Aug. 2015

j) Manufacturer:......................MT Propeller Entwicklung GmbH

k) Model: ....................................................... MTV-6-A/187-129

........................................................................ MTV-6-A/190-69

l) Propellerdiameter:........................1.87 m (MTV-6-A/187-129)

..........................................................1.90 m (MTV-6-A/190-69)

m) Propeller pitch angle (0.75R):............................13.5° to 28°

n) Oil Specification:............AERO SHELL OIL DIESEL ULTRA

....................................................SHELL HELIX ULTRA 5W-30

....................................................SHELL HELIX ULTRA 5W-40

..........................................AERO SHELL OIL DIESEL 10W-40

o) Coolant: ...........Water/Radiator Protection at a ratio of 50:50

Radiator Protection:............. BASF Glysantin Protect Plus/G48

........................................................Mobil Antifreeze Extra/G48

.......................................................ESSO Antifreeze Extra/G48

.............................. Comma Xstream Green - Concentrate/G48

..................................................................Zerex Glysantin G48

p) Gearbox Oil:..........................Shell Spirax S6 GXME75W-80

.........................................................Shell Spirax S4 G 75W-90

......................................Shell Getriebeöl EP 75W-90 API GL-4

............................................................ Shell Spirax EP 75W-90

CAUTION: The use of water which does not meet the

specifications according to the applicable

OM-02-02 may cause engine damage.

CAUTION: If the coolant level is too low the reason

must be determined and the problem must

be corrected by authorized personnel.

AFM Supplement DA 40 D

Page 2-3

Issue 2

Revision -, Aug. 2015

.................................................Shell Spirax GSX 75W-80 GL-4

............................................................ Shell Spirax S6 ATF ZM

..........................................................Centurion Gearbox Oil N1

q) Maximum restart altitude: .........................................14000 ft

2.5 ENGINE INSTRUMENT MARKINGS

Engine instrument markings and their color code significance

are shown in the tables below:

CAUTION: Use approved oil with exact designation

only!

CAUTION: If the gearbox oil level is too low the reason

must be determined and the problem must

be corrected by authorized personnel.

Indi-cation

Red

arc/bar

=

lower

prohibited

range

Yellow

arc/bar

=

caution

range

Green

arc/bar

=

normal

operating

range

Yellow

arc/bar

=

caution

range

Red

arc/bar

=

upper

prohibited

range

RPM [RPM] -- -- 0-2300 -- above

2300

Oil

pressure [bar] below 1.2 1.2 to 2.2 2.3 to 5.1 5.2 to 6.5 above 6.5

Oil temp. [°C] below -32 -32 to 49 50 to 129 130 to 140 above 140

Coolant

temp. [°C] below -32 -32 to 59 60 to 100 101 to 105 above 105

Gearbox

temp. [°C] -- -- below 115 115 to 120 above 120

Load [%] -- -- 0 - 100 -- --

Fuel

temp. [°C] below -30 -30 to +4 +5 to 69 70 to 75 above 75

Ammeter [A] -- -- below 85 85 to 90 above 90

AFM Supplement DA 40 D

Page 2-4

Issue 2

Revision -, Aug. 2015

From -30 °C to -6 °C the lower yellow bar of the fuel temp bar

flashes, from -5 °C to +4 °C the lower yellow bar of the fuel temp

is continuously on. This applies only to conventional instrument

panel versions.

2.9 APPROVED MANEUVRES

Refer to basic AFM.

2.14 FUEL

Approved fuel grades:.........................JET A-1 (ASTM D 1655)

............................................................... JET A (ASTM D 1655)

.....................................................JET Fuel No. 3 (GB6537-94)

.............................................................JP-8 (MIL-DTL-83133E)

.....................................................JP-8+100 (MIL-DTL-83133E)

........................................................... Diesel Fuel (DIN EN590)

............................................................. TS-1 (GOST 10227-86)

..........................................TS-1 (GSTU 320.00149943.011-99)

....................................................................SASOL GTL Diesel

Volt-

meter [V] below 11 11 to 12.5

12.6 to 14.9

15.0to 15.5

above 15.5

Fuel qty. [US

gal] below 0.45 -- 0.45 to 14 -- --

CAUTION: Intentionally initiating negative G

maneuvers is prohibited.

CAUTION: Additional temperature must be observed if

the airplane is operated with Diesel Fuel or

blends of Diesel Fuel with JET Fuel. If there

is uncertainty about which fuel is in the

tank, it must be assumed that it is Diesel.

Indi-cation

Red

arc/bar

=

lower

prohibited

range

Yellow

arc/bar

=

caution

range

Green

arc/bar

=

normal

operating

range

Yellow

arc/bar

=

caution

range

Red

arc/bar

=

upper

prohibited

range

AFM Supplement DA 40 D

Page 2-5

Issue 2

Revision -, Aug. 2015

2.16 OTHER LIMITATIONS

Fuel Temperature

The fuel temperature limitations applicable for the

TAE 125-02-99 engine are valid for the TAE 125-02-114.

Refer to basic AFM.

AFM Supplement DA 40 D

Page 3-1

Issue 2

Revision -, Aug. 2015

CHAPTER 3

EMERGENCY PROCEDURES

The emergency procedures included in this chapter supersede

the procedures in the basic AFM.

For emergency procedures not included in this chapter refer to

basic AFM.

AFM Supplement DA 40 D

Page 3-2

Issue 2

Revision -, Aug. 2015

3.2.4. RESTARTING THE ENGINE WITH WINDMILLING

PROPELLER

(1) Airspeed for best glide angle...73 KIAS (1150 kg, 2535 lb)

........................................................68 KIAS (1000 kg, 2205 lb)

..........................................................60 KIAS (850 kg, 1874 lb)

(2) Power lever.................................................................IDLE

(3) Emergency fuel valve ...............................check NORMAL

(4) Alternate air ..............................................................OPEN

(5) Fuel transfer pump.........................................................ON

(6) AVIONIC MASTER......................................................OFF

(7) ELECTRIC MASTER.....................................................ON

(8) Airspeed .........................................................70-110 KIAS

continued next page

Note: As long as an airspeed of at least 70 KIAS

is maintained, and there is no major

mechanical engine defect, the propeller will

continue to windmill. After a complete stop

the propeller starts to windmill at airspeeds

above 115 KIAS.

CAUTION: The maximum airspeed for windmilling is

120 KIAS. Higher airspeeds may result in

propeller overspeed.

Note: Restarting the engine with windmilling

propeller is possible at airspeeds between

70 and 110 KIAS and altitudes below

14000 ft pressure altitude.

AFM Supplement DA 40 D

Page 3-3

Issue 2

Revision -, Aug. 2015

(9) ENGINE MASTER .............................................OFF - ON

(10)AVIONIC MASTER......................................ON, if required

Note: If it is not possible to start the engine:

- adopt glide configuration

- carry out emergency landing

Refer to basic AFM

CAUTION: Engine restart following an engine fire

should only be attempted if it is unlikely that

a safe emergency landing can be made. It

must be expected that engine restart is

impossible after an engine fire.

AFM Supplement DA 40 D

Page 3-4

Issue 2

Revision -, Aug. 2015

3.2.5. RESTARTING THE ENGINE WITH STATIONARY

PROPELLER

(1) Airspeed for best glide angle...73 KIAS (1150 kg, 2535 lb)

........................................................68 KIAS (1000 kg, 2205 lb)

..........................................................60 KIAS (850 kg, 1874 lb)

(2) ENGINE MASTER.......................................................OFF

(3) Power lever.................................................................IDLE

(4) Emergency fuel valve ...............................check NORMAL

(5) Alternate air ..............................................................OPEN

(6) Fuel transfer pump.........................................................ON

(7) AVIONIC MASTER......................................................OFF

(8) ELECTRIC MASTER.....................................................ON

(9) ENGINE MASTER ........................................................ON

continued next page

Note: Restarting the engine with stationary

propeller is possible at altitudes below

14000 ft pressure altitude.

Note: Restarting the engine with windmilling

propeller is possible at airspeeds between

70 and 110 KIAS and altitudes below

14000 ft.

Note: Only if the ENGINE MASTER is switched

OFF and ON again, glowing will be initiated.

Glowing must be initiated shortly before the

restart attempt.

AFM Supplement DA 40 D

Page 3-5

Issue 2

Revision -, Aug. 2015

(10)ELECTRIC MASTER..............................................START

(release when engine running)

Note: By increasing the airspeed above

approximately 115KIAS, the propeller will

begin to rotate due to windmilling and the

engine can thus be started. For this, the

ELECTRIC MASTER should be set to ON

(see 3.2.4 - RESTARTING THE ENGINE

WITH WINDMILLING PROPELLER of this

supplement). A loss of altitude of at least

1000 ft (300 meters) must be expected.

If it is not possible to start the engine:

- adopt glide configuration

- carry out emergency landing

Refer to basic AFM

CAUTION: Engine restart following an engine fire

should only be attempted if it is unlikely that

a safe emergency landing can be made. It

must be expected that engine restart is

impossible after an engine fire.

AFM Supplement DA 40 D

Page 3-6

Issue 2

Revision -, Aug. 2015

This page intentionally left blank

AFM Supplement DA 40 D

Page 4A-1

Issue 2

Revision -, Aug. 2015

CHAPTER 4A

NORMAL OPERATING PROCEDURES

4A.2 AIRSPEEDS FOR NORMAL OPERATING

PROCEDURES

For take-off, climb, cruise climb and go-around the following

airspeeds apply for the TAE 125-02-114 engine installation

For normal operating procedures refer to basic AFM.

Flight Mass 980 kg

(2160 lb) 1000 kg

(2205 lb) 1150 kg

(2535 lb)

Airspeed for rotation

Take-off run (VR)

(Flaps T/O) 54 KIAS 55 KIAS 59 KIAS

A

irspeed for take-off climb

(VX)

(Flaps T/O) 59 KIAS 60 KIAS 66 KIAS

Airspeed for cruise climb

Best rate of climb (VY)

(Flaps UP) 78 KIAS 78 KIAS 78 KIAS

Min. speed during go-around

(Flaps T/O) 59 KIAS 60 KIAS 66 KIAS

Table of contents

Other Technify Motors Engine manuals