TECMACH IC3 User manual

2

Before conducting any type of operation,

disconnect the machine from electrical mains.

This manual has been drawn up by the

manufacturer and is an integral part of the machine

supply. The information it contains is for

non-qualified (inexpert) and qualified personnel.

This manual defines the purpose for which the

machine was built and it contains all necessary

information to ensure its proper installation and

safe correct operation.

Other technical information that is not

included in this manual is an integral part of the

technical file prepared by EASY BEST and is

available at its facilities.

Constant observance of the regulations it

contains will guarantee personnel and machine

safety, low-cost operation and longer operating

life.

The careful analysis done by EASY BEST has

made it possible to eliminate most of the risks.

However, be sure to follow all the instructions

given in this manual. Always refer to the manual

before carrying out any operation. Safeguard this

manual and make sure it is always available next to

the machine or nearby.

The diagrams and drawings are furnished by

example. In pursuance to its policy of constant

development and updating. The manufacturer may

make any changes without giving advance notice.

This manual must be kept for the entire life of

the machine. If it is lost or destroyed, you can

request a copy from manufacturer. Be sure to

indicate the data listed on the nameplate (the price

will be established by the manufacture).

EASY BEST welcomes any comments from

clients concerning improvements to be made on

the machine and will assess their implementation.

This document is the exclusive property of

EASY BEST and cannot be divulged to third

parties, either in whole or in part, without the

written authorization of EASY BEST.

EASY BEST reserves all legal rights.

All the measurements listed in this manual are

expressed in mm.

GUIDE TO THE MANUAL

Be sure to consult this manual before

proceeding with installation, use and any

other work on the machine

0

1. CHARACTERISTIC AND TECHNICAL DATA……………………………………………………P1

2. ICE CREAM MACHINE MARKING DATE………………………………………………………P2

3. HOW TO USE AND PRESERVE THE INSTRUCTION MANUA…………………………………P2

4. HANDLING AND INSTALLING THE ICE CREAM VERTICAL BATCH FREEZE……………P3

5. INVISIONED USE…………………………………………………………………………………P4-5

6. POSITIONING………………………………………………………………………………………P5

7. INSTALLATION AND USE OF THE ICE CREAM VERTICAL BATCH FREEZER……………P6

8. MAINTENANCE……………………………………………………………………………………P6-7

9. TROUBLESHOOTING……………………………………………………………………………P8

10. DISMANTLING……………………………………………………………………………………P8

11. CUSTOMER FILE CARD…………………………………………………………………………P9

12. CONTACT US………………………………………………………………………………………P10

ATTENTION:The content such as shape, material and color can be changed without prior

notice because of products continuously improved.

INDEX

1

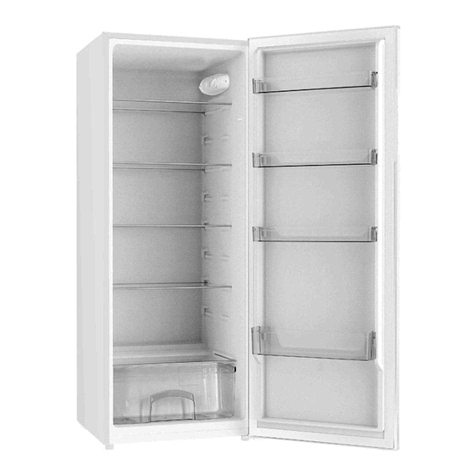

1)CHARACTERISTIC

1.1) Elegant and fashionable machine with humanization design, popular appearance and totally stainless

steel material for outer-shell

1.2) Hermetic compressor: high refrigerating capacity, low consumption and low noise levels.

1.3) Vertical mixing cylinder, during the process can see clearly the changement of ice cream, easy to add

ingredients. Flexible and removable agitator blade, that touch very well the cylinder to mix the ice cream

perfectly.

1.4) Microcomputer control system, digital display, easy to operate.

1.5) Direction wheels with brake for easy moving.

2) TECHNICAL DATE

Ice Cream Machine Range IC3

External Dimension L×W×H(mm) 547×552×430

Max. Amount Per Batch(Liter) 2

Working Cycle(min) 15~20

Hourly Production(Liter/Hour) 6-8

Refrigerant R404A 0.55Kg

Power (W) 1000

Power Supply(V/HZ/PH) 220-240V/50Hz/1PH

Net/Gross(kg) 60/70

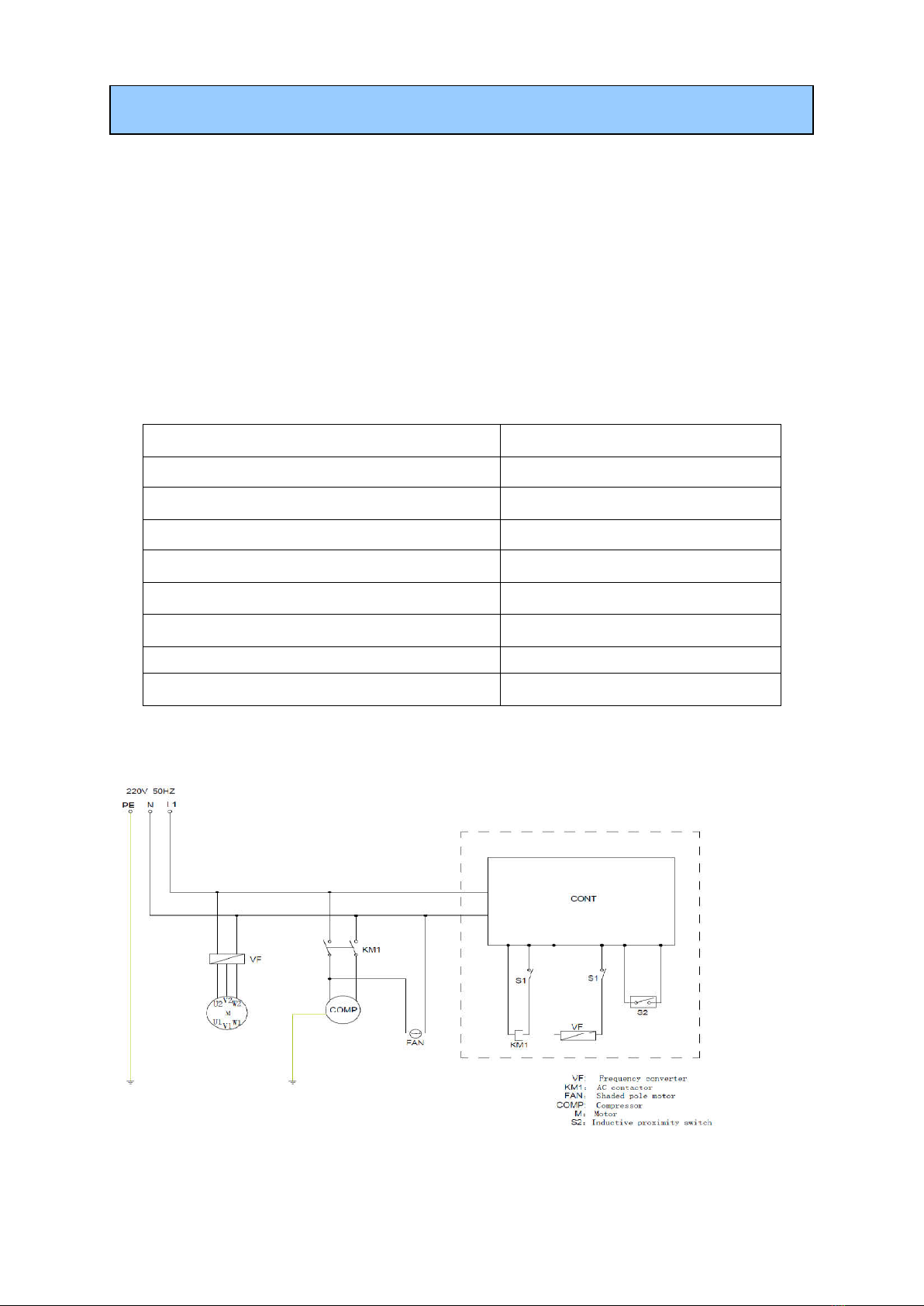

1.3 CIRCUIT DIAGRAM

1 CHARACTERISTIC AND TECHNICAL DATA

2

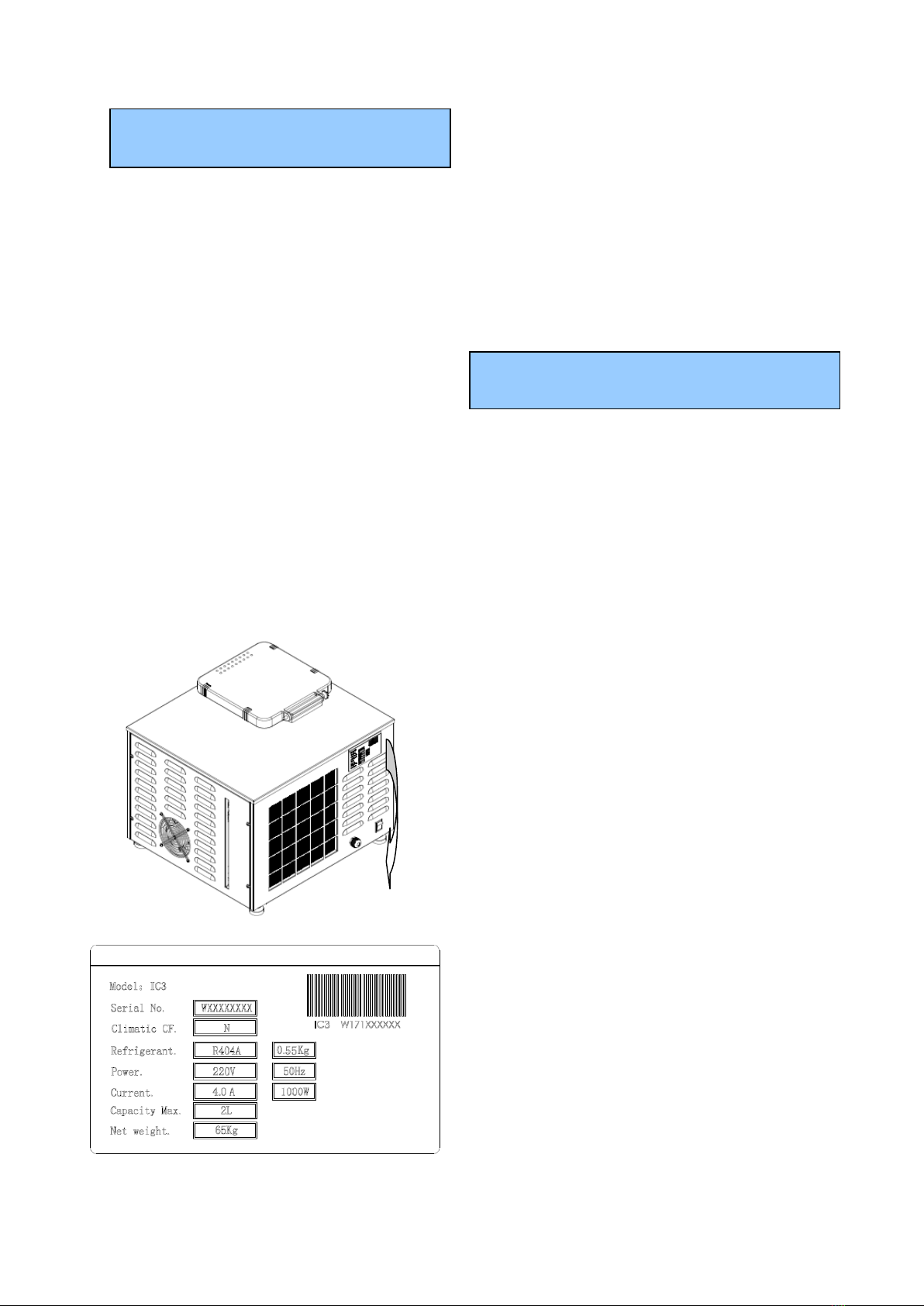

Nameplate is mounted on the ice cream

Vertical Batch Freezer as an indication specifying

the model and series information before being

packed up.

Check if the instruction manual corresponds

to the ice cream Vertical Batch Freezer referred to.

If any further information or technical

assistance is required, in addition to the model and

machine type, you must also indicate the serial

number.

2.1 POSITION OF NAMEPLATE

The nameplate is accreted on the rear section

of the ice cream Vertical Batch Freezer indicating

the detailed identification information such as

model and serial number ect.

2.3 THE MAIN COMPONENTS OF

NAMEPLATE

The nameplates of all the components that were

not manufactured directly by EASY BEST (e.g.

compressor, fans etc.) are mounted on the

components themselves in the position in which

they were originally placed by the respective

manufacturers.

3.1 INTENDED USER OF THE

INSTRUCTION MANUAL

This instructions manual is intended for the

following personnel:

· shipping, loading and unloading staff

· operators

· installers

· maintenance personnel

3.2 OBJECTIVES OF THE INFORMATION

IN THE MANUAL

The purpose of this manual is to indicate how

the machine should be used based used design. It

will also indicate its technical features, offering

instructions on how to move, install regulate and

use it.

It will also guide you in maintenance work

and facilitate spare parts orders.

3.3 LIMITATION ON USE OF THE MANUAL

It is important to remember that the

instructions manual reflects the techniques current

at the time the machine was purchased. Thus, the

manufacturer has the right to update the manual

and the equipment without updating the manual or

any prior production, with the exception of unusual

case.

2 ICE CREAM BATCHER FREEZER

MARKING DATE

3 HOW TO USE AND PRESERVE THE

INSTRUCTION MANUAL

3

This section provides the basic information for

the ice cream Vertical Batch Freezer’s main

function and the limited environment.

Damages caused by handling errors are not

covered by the WARRANTY.

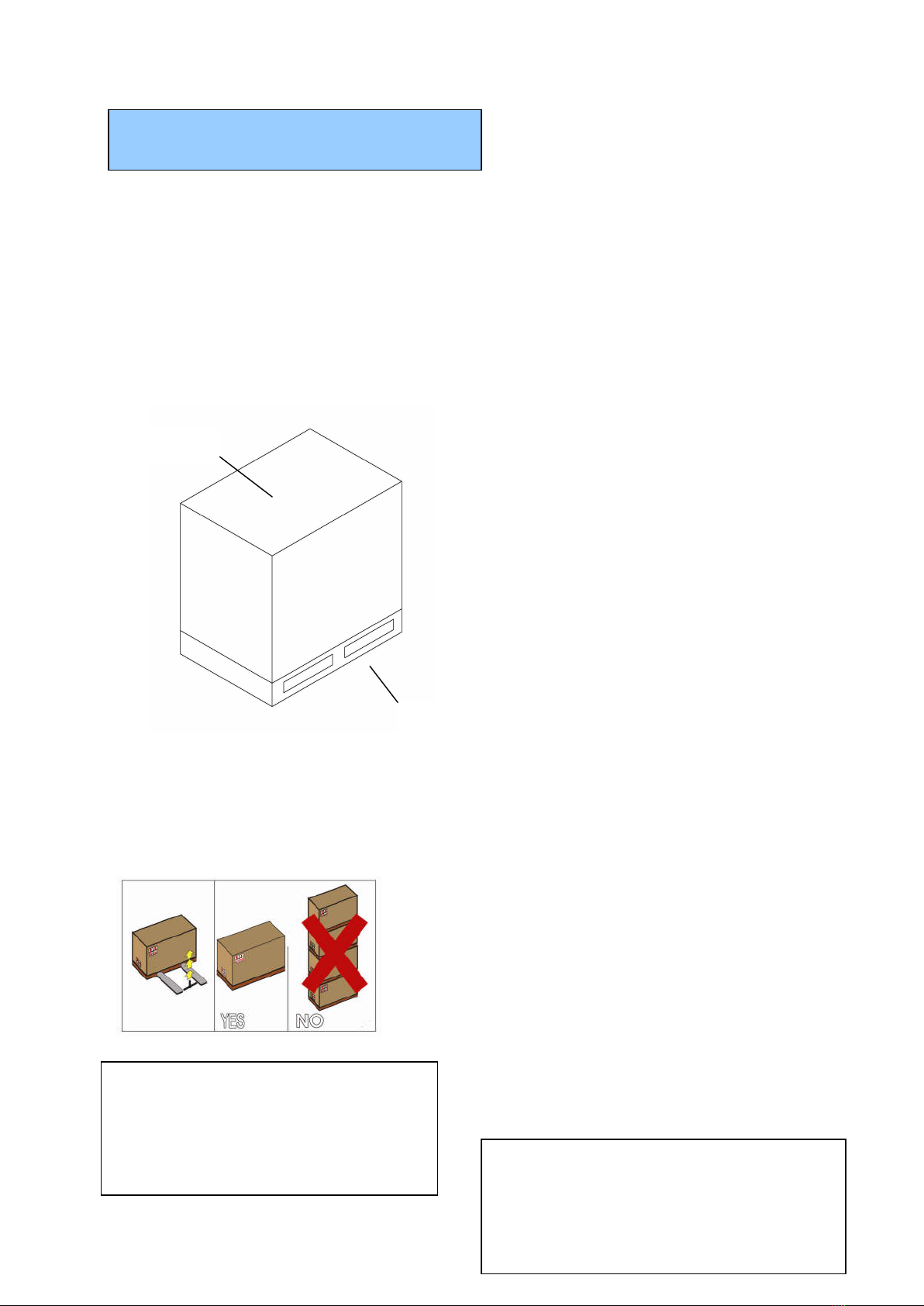

4.1 RECEIVING ICE CREAM Vertical Batch

Freezer

The ice cream Vertical Batch Freezer is

packed to protect it during shipment and/or storage.

Principal components:

·multiple wooden pallet

·multiple wooden case

The following figure shows the standard package

4.2 UNLOADING OPERATION

The orientation of the ice cream Vertical

Batch Freezer must comply with the indications

listed on the pictograms and the writing on the

outside package.

4.3 CHECKING THE PACKAGE

Before deliver the machine from the shipper,

check the conditions of the packing. If it shows

obvious damage on the outside, the machine could

be damaged. In this case, unpack the ice cream

Vertical Batch Freezer in the shipper’s presence.

Any damage caused by incorrect handling and

storage is not the manufacturer’s responsibility.

In this case:

A) Contact your area representative

B) Draw up written report

C) Send a copy of the report to the

manufacture or area representative

4.4 PACKING MANAGEMENT

All the unpacked materials can be

recycled in order to dispose of according local

legalization. Be sure to destroy plastic

components to prevent any hazards (suffocation)

to children.

4.5 PERSONNEL REQUIREMENTS

We recommend that the operations to move

the ice cream Vertical Batch Freezer should be

handled by personnel accustomed by using hosting

equipment, in full compliance with safety

standards in force.

4.6 UNLOADING REQUIREMENTS

Ice cream Vertical Batch Freezer should be

lifted with a fork-lift truck or with any other

suitable equipment with a minimum capacity of

twice the weight of the display case (see the

specific nameplate). Operators running the hoisting

equipments must remain at an adequate distance

from the hoisted part and must ensure that no

people or property is exposed to danger if the ice

cream Vertical Batch Freezer drops.

Movements must be slow and continuous to

prevent the case from tipping over etc…

4 MOVE, LOADING AND UNLOADINGG ICE

CREAM VERTICAL BATCH FREEZER

Case

Pallet

Important: Remember that since

cardboard packing is used, it is subject to the

action of atmospheric (rain, snow). Therefore,

the ice cream Vertical Batch Freezer must be

stored in a dry indoor area.

4

The major function of ice cream maker is

freeze and turn the disinfected raw material into

low temperatured hard ice cream, therefore only

disinfected material is allowed to be placed in the

processing area in order to guarantee the quality of

the ice cream。

5.1 AREAL NAME

Proper training process needs to be

undertaken before operating the ice cream maker

please read the following content carefully:

5.2 SAFETY RULES

Operators need to be very cautious when

using the ice cream Vertical Batch Freezer

Necessary observation and precaution may

assist in avoiding most of the accidents.

To prevent accident from occurring, please

read the following items carefully before installing

and switching on the ice cream Vertical Batch

Freezer.

No one without appropriate understanding

on the manual will be allowed to operate

the Vertical Batch Freezer.

It has been stipulated in the legalizations

of many countries that all the ice cream

Vertical Batch Freezer operators must be

properly trained before operating the

machine.

Please read the instruction manual

carefully before using the machine.

Operating without complying with the use

regulations might case the occurrence of

accident.

Accurate installation of all the

components and accessories must be

ensured, and verified feasible for the

proper use of the ice cream Vertical Batch

Freezer.

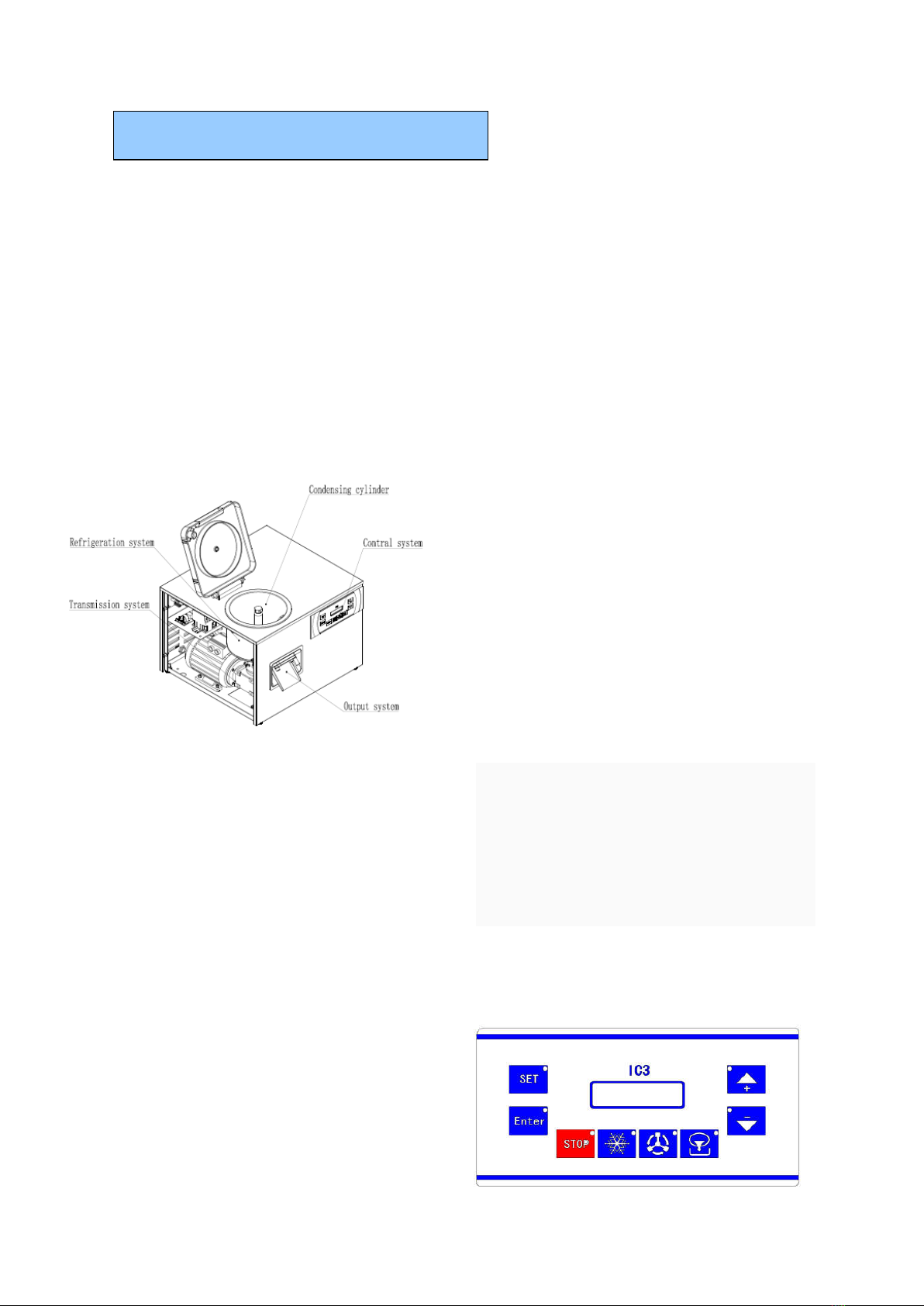

5.3 COMPONENTS INTRODUCE

Condenser unit

The Condenser unit is located in the down of

ice cream Vertical Batch Freezer and all the

components required for machine operation are

positioned in this unit.

The motor compartment consists of

gas-liquid separator , compressor, air condenser

and so on.. In particular, during normal operation

no one is able to access it or moving things. Only

qualified technicians are allowed to access it,

observing safety and maintenance regulations.

Transmission system

Famous brand compressor and reducer, low

noisy but high efficiency. Smooth speed;

Professional frequency converter to realize low

speed refrigeration, high-speed discharge

two-speed operation, higher efficiency, more

professional.

Control panel

Control panel is used for ice cream machine

specific manipulation.

5 ENVISION USE

5

1, first of all, press set key, the number “1” in

“15:00 “ will be flashing on screen, press the + and

- keys, you can define your own time. Press set key

one time, the first number will be flashing. Press

twice, the second number will be flashing. And so

on, you can define your own time. After changing

all the numbers, you can press enter key to

confirm.

2, you firstly need to press the Cooling key when

made ice cream, next press the rotate button that is

at the bottom of the Cooling key, then start to

make ice cream. After production is completed,

you need to press the stop button and then choose

discharging button.

The position of ice cream Vertical Batch Freezer

is a very important issue that can compromise

proper machine operation. Correct positioning

influences the life of the ice cream Vertical Batch

Freezer and its spare parts. Above all, however, it

affects system operating expenses. We advise you

to follow carefully the instructions below.

Our technical servicing office can give you any

additional clarifications that may be needed.

6.1 Make sure that ice cream is put on the desktop.

Horizontal.

6.2 Make sure the normal heat radiation of the ice

cream Vertical Batch Freezer; nothing is to be

placed in front of the heat discharge panel.

side panel No things Side/back panel No things

These two methods are prohibited discharge.

Furthermore, please NEVER place the ice cream

Vertical Batch Freezer at:

·Door

·Window

·Sources of heat (e.g. heaters etc.)

.The ice cream Vertical Batch Freezer must

be protected from the direct irradiation of sunlight,

and never be placed outdoors in case it causes any

negative effects to the customers or operators.

Caution :

1)Do not place the power cable in a transit

area in case it harms people pass by.

2)Never touch the power plug with wet

hands.

3)Make sure the power mains network is

earthed in accordance with the regulations in force.

4)Never insert any adapters or multiple

plugs on the supply plug used to connect the ice

cream machine.

5) Never use extensions to connect the ice

cream machine.

6) Make sure that the mains voltage

complies with the data listed on the nameplate of

the machine (Maximum allowable variation ±6%.).

6 INITIAL STARTUP OF THE ICE

CREAM VERTICAL BATCH FREEZER

6

Before using the ice cream machine, water

and power sources need to be supplied.

7.1 Power supply

Firstly customer is suggested to have a

professional socket which has earth line. Yellow

green line is earth line.

7.2 Check the rotation direction of motor

Ice cream machinery motor has two rotations,

clockwise and counterclockwise. It is embodied in

the mixing components. When wiring, please make

sure the button on the control panel points in same

direction with rotation. Otherwise, it will affect the

cooling effect and discharging speed.

7.3 After connected power supply, should first test

motor steering is correct, if in the opposite

direction, should be adjust the socket or attachment

position, until the steering and motor signs in the

same direction.

7.4 Before switch on the ice cream machine, make

sure that no packaging pieces, and other impurities

in ice cream machine

The machine should be thoroughly cleaned before

use.

Before starting any maintenance work or

operator checks, you must:

Verify that the ice cream Vertical Batch

Freezer is turned off and it is disconnected

from the power mains.

Set up a sing indicating the work that is being

done.

If necessary, procure adequate lifting

equipment.

Verify that the operations to be done will not

injure person or damage machinery nearby.

8.1 CLASSIFICATION OF INTERNVENTIONS

Maintenance work falls into two categories:

Normal maintenance: defined as maintenance

work to the ice cream Vertical Batch Freezer under

normal operating conditions, i.e. without requiring

the replacement of any parts. This includes:

Maintenance within a few hours before the

operation

Weekly maintenance work

Work done every six months

Work done annually

Extraordinary maintenance:

Defined as work comprising:

Work required due to malfunction

Work to be done at long intervals, i.e. work

corresponding to the end of the work of a main

part and requiring the interruption of display case

operation.

8.2 REQUIREMENTS FOR MAINTENANCE

PERSONNEL

Maintenance must be conducted SOLELY by

qualified personnel specializing in working with

refrigerating systems.

The must know and understand the written

7 Installation and use of ice cream

Vertical Batch Freezer

8 Maintenance

7

instructions, laws and regulations.

The instructions are drawn up by EASY

BEST. Safety rules in this manual can be defined

due to local laws in different country and region

They must have had actual training on the

operations to be performed. Maintenance workers

must have read the instructions in this manual and

be familiar with all the commands so that they can

work in full compliance of the safety regulations

currently in force.

They must not be drug or alcohol abusers. A

technician who uses prescription drugs must obtain

medical advice on his ability to conduct certain

types of activities.

8.3 Clothing

Before starting any work operation,

maintenance workers must wear suitable clothing.

All the instruments that are used must be in perfect

condition and be type tested.

The maintenance worker must ALWAYS

check the supplied devices and replace them if

they are damaged or are not compliant.

WEAR PROTECTIVE GLOVES

WEAR GOGGLES (DURING WELDING

WORK

WEAR SAFETY SHOES

WEAR WORK OVERALLS WITHOUT ANY

LOOSE ENDS

8.4 Cleaning the ice cream machine

It is necessary to clean the barrel before and

after operating the machine. Furthermore, the

barrel must be properly cleaned up with warm

water after being disinfected.

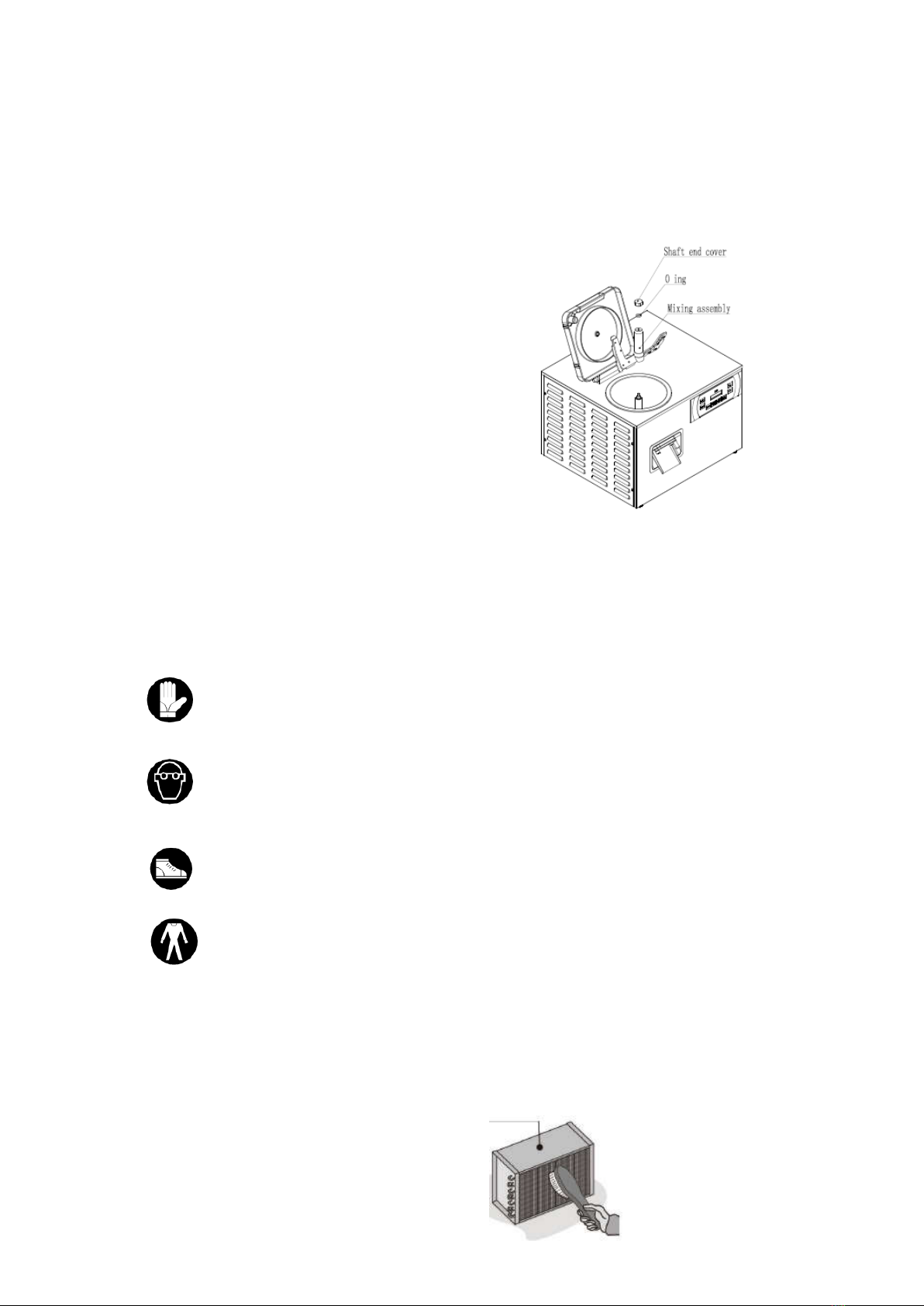

As shown in the picture below, every time

before or after making ice cream, the mixed part of

the machine must be screwed off and disinfected

properly so that to ensure the quality of ice cream..

(Screw off the nut on the top and then pull the

mixed part upwards)

For external cleaning, just use clear water to add a

few washing liquid such as detergent, soap, etc

ATTENTION

1. For the water to clean the machine, the ideal

temperature is 55 ℃. The water temperature

is no more than 60 ℃ and not be below

45 ℃. For spare parts removed, they have to

cleaned by hand and do not use the automatic

washing machine to clean

2. NEVER use inflammable or abrasive products.,

or will damage the spare parts and pollute

production area.

8.5 CLEANING THE CONDERSER

The condenser must be cleaned every 30

days maximum and this involves removing the

dust that collects in the fins.

IMPORTANT:

1).Disconnect power of the ice cream machine, to

clean the condenser side fin with a stiff brush.

2).Don't use liquid to clean the condenser

8

10.1 DISMANTLING FOR DEMOLITION

10.1 If the ICM is going to be scrapped, this

creates two separate problems:

10.1.1 Management

The competent public offices must be notified

that the machine is being scrapped so that the

documents they have about the machine can be

canceled.

The ICM comes with a set of legal

documents, such as the manual, the nameplate and

the various authorizations. Those documents must

be examined once decide to demolish the machine.

10.1.2 Handling of ice cream machine

It is essential that specialized disposal

companies or the manufacturer to do this work.

10.2 TO scrap the ice cream only can be

performed abide by above condition.

If the ICM needs to be moved after be

scrapped ,proceed as follows:

10.2.1 Before starting to disassemble the machine,

you are required to shut off the electrical supply.

10.2.2 All of this must be done by setting up

special signs to indicate what you are doing.

10.2.3 Disassembly must be carried out by

qualified personnel or directly by the manufacturer.

10.2.4 Being sure to separate and identify (mark)

all the components.

10.2.5 Perfect organization during disassembly

guarantees perfect and safe reassembly.

10.2.6 All the material must be kept in a dry area

that is protected against weather.

10.2.7 Before remounting the machine, check the

material thoroughly for any damage.

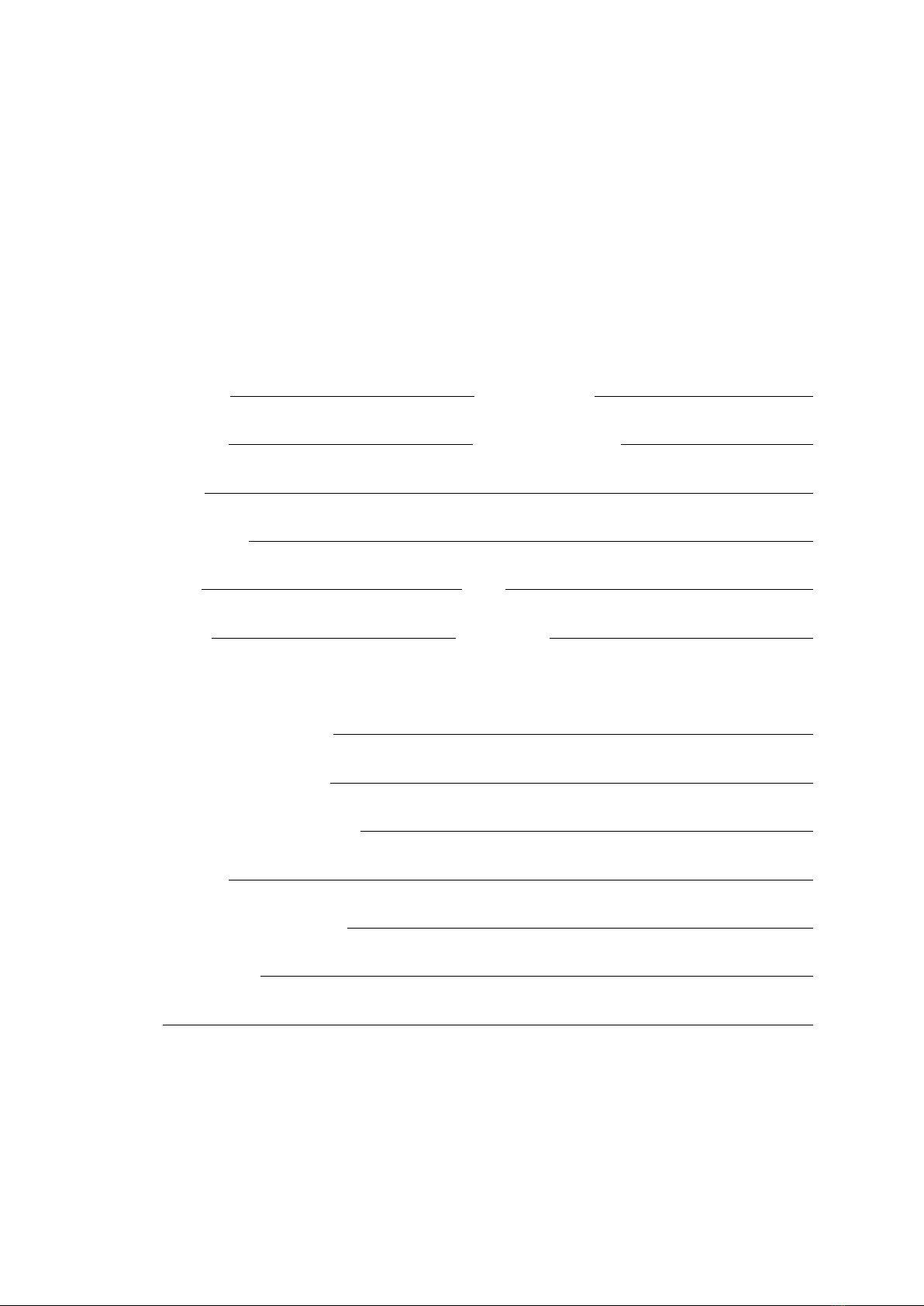

FAULT CAUSE SOLUTIONS

No supply voltage.

Main switch OFF.

Plug not connected.

Product exceeds loading

limits.

Product put in when too hot

or moist.

Electrical system fault.

Refrigerating system fault.

Floor unstable.

Contact with external objects.

Screws loose (e.g. glass

structure of grids).

No supply voltage.

Main switch OFF.

Plug not connected.

Product exceeds loading limits.

Product put in when too hot or

moist.

Electrical system fault.

Refrigerating system fault.

Floor unstable.

Contact with

external objects.

Screws loose (e.g. glass structure of

grids).

Check the supply cable.

Verify that the main switch is section ON.

Check the position of the plug.

Remove excess

product.

Check product.

(*)Contact a qualified technician or EASY

BEST.

(*)Contact a qualified technician or EASY

BEST

Use shims to stabilize the display case.

Remove any external

objects in contact with the display case.

Check screw tightness.

9 TROUBLESHOOTING

10 DISMANTLING

9

Please pass the page to Qingdao EASY BEST INT’L HOLDINGS CO., LTD

(Valid Fax: 0086 0532-89081177)

The FILE CARD FOR CLIENTS

Respectful Customer,

Thank you for choosing the product for Qing Dao EASY BEST INT’L HOLDINGS CO., LTD, which

is willing to supply further services for you, kindly hope you to fill in the following:

Product Name: Product Type:

Ex-work Code: Purchase Date:

Usage unit:

Detailed address:

Telephone: Fax:

Postal code: Contact Tel.

Besides the document accompanied the machine, if you need:

Further detailed technical data:

The latest product information:

Other product detailed information:

Your opinions::

The characteristic of the product:

All service after sale:

Others:

(Warranty time starts from the date which the product is ex-work, if the card does not come back the company)

10

address:Qingdao Industry Area,Cheng yang,China mobile:400-107-9989

T:+86-0532-89081119 E-email: easybestchina@qdtecmach.com

fax:+86-0532-89081177/79 Http:// www.easybest-tecmach.com

hotline:+86-0532-89089202 Http:// www. easybest-tecmach.cn

Due to the continuous improvement of the product, the type, shape, material and color of the album

are subject to change without notice

11

Table of contents

Popular Freezer manuals by other brands

Beko

Beko FSB720FF Installation, operation & food storage instructions

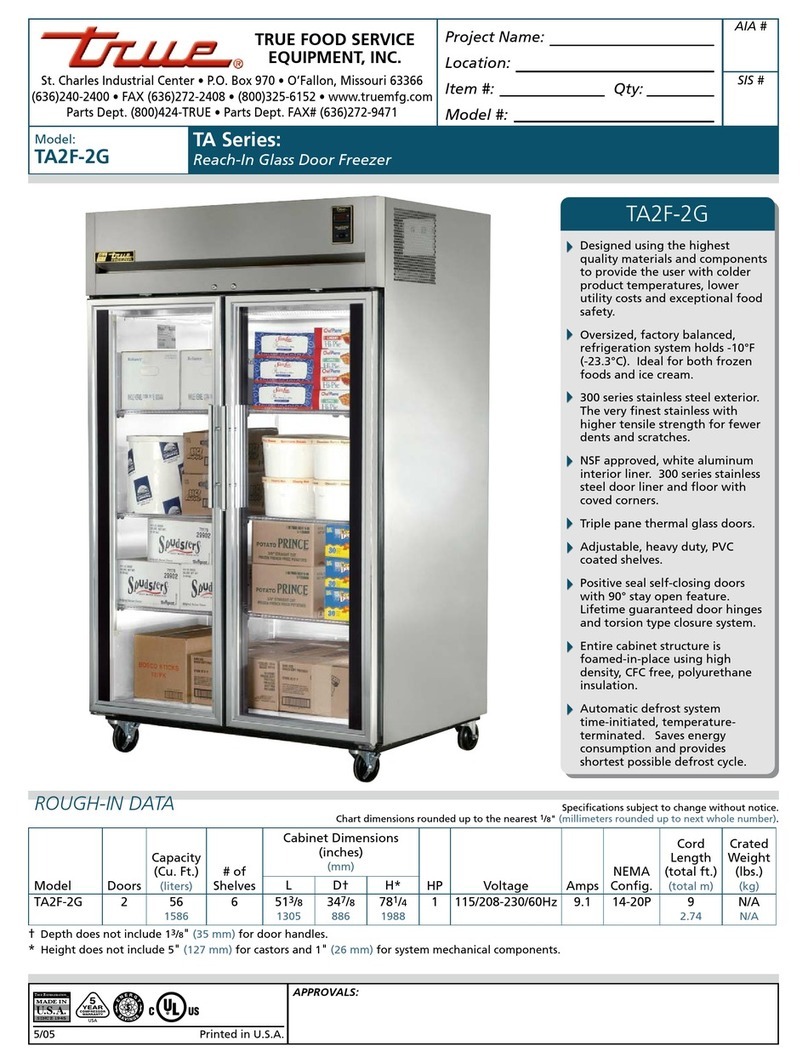

True

True TA2F-2G Specifications

MARVEL SCIENTIFIC

MARVEL SCIENTIFIC 4CAFX Installation, operation and maintenance instructions

Sanyo

Sanyo MDF-U74V instruction manual

True

True TS-49FG Specifications

Electrolux

Electrolux IK2685L user manual