Tecnoma ECO User manual

Operating instructions

Job computer ECO

990267EN

SEPTEMBER 2014

Read and follow these operating instructions.

Keep these operating instructions in a safe place for later

reference.

Imprint

Operating instructions

Product: Job computer ECO

Document number: 990267EN

From software version: SPRECO1: V619a; SPRECO2: 629a

Original language: German

Document

Contents

3 990267EN ind. A

Contents

1 For your safety 7

1.1 Basic safety instructions 7

1.2 Layout and meaning of warnings 7

1.3 Layout and meaning of alert messages 8

1.4 User requirements 8

1.5 Intended use 9

1.6 EC declaration of conformity 9

1.7 Disposing 9

1.8 Safety sign for the field sprayer 9

1.9 Safety sticker on the product 10

2 About this operating manual 11

2.1 Target group of these Operating Instructions 11

2.2 Illustrations in these operating instructions 11

2.3 Layout of operating instructions 11

2.4 Layout of references 12

3 Product description 13

3.1 Performance description 13

3.2 System requirements 13

3.3 Understanding manufacturer's plates 13

4 Mounting and installation 15

4.1 System overview 15

4.2 Connecting job computer to the basic tractor equipment 16

4.3 Fitting multi-function joystick (MFG) 17

4.4 Mounting the gyroscope 18

4.4.1 Mounting the bracket for the gyroscope 19

4.4.2 Using the gyroscope 20

5 Basic control principles 21

5.1 Switching job computer on and off 21

5.2 Initial start-up 21

5.3 Job computer in the terminal selection menu 22

5.4 Browsing between screens 22

5.5 Inputting data 22

5.6 Screen structure 23

5.6.1 Work screen with a field sprayer 23

5.6.2 Spray data area 24

Contents

4 990267EN ind. A

5.6.3 Selectable area 1 25

5.6.4 Boom terminal area 26

5.6.5 Selectable area 2 28

5.6.6 Function icons 29

5.6.7 Layout of additional screens 29

6 Preparing job computer sprayer for use 30

6.1 When should you configure what? 30

6.2 Entering field sprayer parameters 30

6.3 Options activation 33

6.3.1 Setting sections switching type 34

6.3.2 Setting filling type 34

6.3.3 Setting joystick type 34

6.3.4 Setting manifold type 34

6.3.5 Establishing CAN connection type 35

6.4 Calibrating the flow meter 35

6.4.1 Calibrating the flow meter with the tank method 35

6.4.2 Calibrating the flow meter with the nozzle method 37

6.4.3 Manually entering the number of pulses per liter for the flow meter 39

6.5 Calibrating the wheel sensor 40

6.5.1 Determining pulses per 100 meters 40

6.6 Configuring sections 41

6.6.1 Entering the number of sections 41

6.6.2 Entering the number of nozzles per section 42

6.6.3 Switching off section permanently 42

6.7 Configuring nozzles 43

6.7.1 Layout of the "NOZZLE/PRESSURE" screen 43

6.7.2 Selecting nozzle type 43

6.7.3 Calculating theoretical application rates 45

6.7.4 Calibrating nozzles 46

6.7.5 Configuring wide area nozzles 47

6.8 Tank filling 48

6.8.1 Filling up the tank manually without additional systems 48

6.8.2 Filling up the tank with TANK-Control 49

6.9 Setting sprayer geometry 49

7 Operating job computer sprayer on the field 52

7.1 Controlling boom 52

7.1.1 Locking boom 52

7.1.2 Folding boom in and out 52

7.1.3 Raising and lowering boom 55

7.1.4 Sloping boom 56

7.1.5 Tilting booms up and down 56

7.2 Controlling application 57

7.2.1 Setting rate 57

7.2.2 Changing application mode 57

Using Automatic mode 58

Changing application rate in manual mode 59

Contents

5 990267EN ind. A

7.2.3 Starting spreading 60

7.2.4 Stopping spreading 60

7.2.5 Operating sections 60

Activating corner nozzles 61

Operating wide area nozzles 62

7.2.6 Switching foam marker on and off 63

7.2.7 Dealing with weed infestations 63

Work screen in localized mode 63

Preselecting and switching off sections in localized mode 64

Activating localized mode 64

Multi-function joystick in localized mode 64

7.2.8 Operating PWM regulation 65

7.3 Documenting work results 66

7.4 Operating the multi-function joystick 67

7.5 Operating additional functions 67

8 DISTANCE-Control 68

8.1 Safety mechanisms 68

8.2 Mode of operation 68

8.3 Configuring DISTANCE-Control 69

8.3.1 Calibrating DISTANCE-Control 69

8.3.2 Configuring work height 72

8.3.3 Configuring clearance height 73

8.3.4 Selecting work mode 75

8.4 Operating DISTANCE-Control while working 76

9 TRAIL-Control 77

9.1 Configuring TRAIL-Control 77

9.1.1 TRAIL-Control parameters 77

9.1.2 Calibrating TRAIL-Control 77

Teaching-in the middle position and end stops 78

Calibrating the hydraulics of the proportional valve 80

9.2 TRAIL-Control – Using drawbar and axle steering 81

9.2.1 Steering the trailer device 82

Steering in automatic mode 82

Steering in manual mode 82

Steering the trailer device against the slope 83

9.2.2 Preparing TRAIL-Control for road driving 84

Locking TRAIL-Control 84

10 Cooperation with other applications 86

10.1 TaskManager 86

10.2 SECTION-Control 86

11 Maintenance and technical data 87

11.1 Preparing system for winter rest 87

Contents

6 990267EN ind. A

11.2 Technical data 87

11.2.1 Technical data for the job computer 87

11.2.2 Field sprayer technical data 88

11.3 Checking the software version 89

11.4 Fault diagnostics 89

11.4.1 “Simulated speed“ function 89

11.5 Multi-function joystick button assignment 90

12 Alarm messages 92

For your safety

7 990267EN ind. A

For your safety

Basic safety instructions

Please read the following safety instructions carefully before operating the product for the first time.

▪Before you leave the vehicle cabin, ensure all automatic mechanisms are deactivated or manual

mode is activated. In particular deactivate the systems:

– TRAIL-Control

– DISTANCE-Control

▪Keep children away from the trailer device and from the job computer.

▪Do not make any unauthorized modifications to the product. Unauthorized modifications or use

may impair safety and reduce the service life or operability of the unit. Modifications are

considered unauthorized if they are not described in the product documentation.

▪Never remove any safety mechanisms or stickers from the product.

▪Carefully read and follow all safety instructions in this operating guide and in the field sprayer

operating instructions.

▪Observe all applicable regulations on accident prevention.

▪Follow all recognised safety, industrial and medical rules as well as all road traffic laws.

▪Before charging the tractor battery, always disconnect the tractor from the job computer.

▪Use only clear water when you are testing the field sprayer. Do not use a poisonous spray during

the tests or when calibrating the systems.

Layout and meaning of warnings

All safety instructions found in these Operating Instructions are composed in accordance with the

following pattern:

WARNING

This signal word identifies medium-risk hazards, which could potentially cause death or serious

bodily injury, if not avoided.

CAUTION

This signal word identifies low-risk hazards, which could potentially cause minor or moderate bodily

injury or damage to property, if not avoided.

NOTICE

This signal word identifies actions which could lead to operational malfunctions if performed

incorrectly.

These actions require that you operate in a precise and cautious manner in order to produce

optimum work results.

There are some actions that need to be performed in several steps. If there is a risk involved in

carrying out any of these steps, a safety warning will appear in the instructions themselves.

1

1.1

1.2

For your safety

8 990267EN ind. A

Safety instructions always directly precede the step involving risk and can be identified by their bold

font type and a signal word.

1. NOTICE! This is a notice. It warns that there is a risk involved in the next step.

2. Step involving risk.

Layout and meaning of alert messages

While working with the field sprayer, an alarm message may appear.

The alarm messages have the following purpose:

▪Warn – They warn the operator if the current state of the field sprayer could lead to a dangerous

situation.

▪Inform – They inform the operator that the current state of the field sprayer or the configuration

is not correct and can lead to faults in operation.

On the following diagram, you can see how the alarm messages are structured:

Layout of alarm messages

Type of alarm Name of the component that caused the

alarm.

"ALARMS" message Problem description and solution

What the exact cause of an alarm message is

or how you rectify a fault can be read in the

section "Alarm messages [➙92]"

Type of alarm

There are three types of alarm:

▪Info

The status of a sensor has changed. If applicable, you must do something.

▪Error

An error has occurred.

▪Danger

Faults that are dangerous. With these alarms, break off work immediately, find out the cause and

rectify the problem.

User requirements

▪Learn to operate the product in accordance with the instructions. Nobody must operate the

product before reading these Operating Instructions.

▪Please read and carefully observe all safety instructions and warnings contained in these

Operating Instructions and in the manuals of any connected machines and farm equipment.

Example

1.3

Purpose

Illustration

1.4

For your safety

9 990267EN ind. A

▪If there is anything within these Operating Instructions that you do not understand, please do not

hesitate to contact us or your dealer. Müller-Elektronik's Customer Services department will be

happy to assist you.

Intended use

The job computer is used to control field sprayers in agriculture. The manufacturer shall not be held

responsible for any installation or use that goes beyond this.

Intended use also includes the adherence to the conditions for operation and repairs prescribed by

the manufacturer.

The manufacturer cannot be held liable for any personal injury or property damage resulting from

such non-observance. All risk involved during improper use lies with the user.

All applicable accident prevention regulations and all other generally recognized safety, industrial,

and medical rules as well as all road traffic laws must be observed. Any unauthorized modifications

made to the unit will void the manufacturer's warranty.

EC declaration of conformity

This product has been manufactured in conformity with the following national and harmonised

standards as specified in the current EMC Directive 2004/108/EC:

▪EN ISO 14982

Disposing

When it has reached the end of its service life, please dispose of this product as

electronic scrap in accordance with all applicable waste management laws.

Safety sign for the field sprayer

If the field sprayer is fitted with drawbar steering or with axle steering, everyone approaching the field

sprayer must be warned of possible dangers. For that reason you receive a safety sign.

1. Stick the safety sign in the appropriate place.

The following rules apply to attaching safety signs:

▪Safety signs must be attached at a visible location so that they can be seen by everyone

approaching the danger zone.

▪If the danger area can be approached from several sides of the machine, attach the warning

signs on all machine sides.

▪Regularly check the safety signs for completeness and legibility.

▪Replace damaged or unreadable signs with new ones.

1.5

1.6

1.7

1.8

For your safety

10 990267EN ind. A

Safety sign Where to attach Meaning

Close to the bend area, between tractor

and trailer device

Do not stay in the bend area

during operation.

Safety sticker on the product

Sticker on the job computer

Do not clean with a high-pressure cleaner.

1.9

About this operating manual

11 990267EN ind. A

About this operating manual

Target group of these Operating Instructions

These operating instructions are intended for operators of field sprayers. The field sprayers must be

fitted with the System Sprayer Controller Midi.

Illustrations in these operating instructions

The role of the diagrams on the software interface is to serve as a reference. They help you in finding

your way around the software screens.

The information shown on the screen is dependent on various factors:

▪the type of field sprayer,

▪the configuration of the field sprayer,

▪the condition of the field sprayer,

For this reason the diagrams in these operating instructions may show different information from the

terminal.

The instructions were written for the operation of the job computer on terminals from Müller-

Elektronik. If the job computer is operated with other ISOBUS terminals, the screen layout and the

information represented may differ from the diagrams in this operating manual.

Layout of operating instructions

The operating instructions explain step by step how you can perform certain operations with the

product.

We use the following symbols throughout these Operating Instructions to identify different operating

instructions:

Type of depiction Meaning

1.

2.

Actions that must be performed in succession.

⇨Result of the action.

This will happen when you perform an action.

⇨Result of an operating instruction.

This will happen when you have completed all

steps.

Requirements.

In the event that any requirements have been

specified, these must be met before an action

can be performed.

2

2.1

2.2

2.3

About this operating manual

12 990267EN ind. A

Layout of references

If any references are given in these Operating Instructions, they will appear thus:

Example of a reference: [➙12]

References can be identified by their square brackets and an arrow. The number following the arrow

shows you on what page the chapter starts where you can find further information.

2.4

Product description

13 990267EN ind. A

Product description

Performance description

The system may consist of one or two job computers depending on how many of the field sprayer

functions are to be controlled via the terminal.

Job computer F1 has the following functions:

▪Up to nine sections switchings with main section switch

▪Manual and automatic control of the spread rate

▪Display of current speed

▪Display of current spread rate

▪Display of remaining workable area

▪Display of the current tank content

▪Documentation of work results

▪DISTANCE-Control – automatic control of the boom height.

▪Raising and lowering boom manually

▪Sloping boom manually

Job computer F2 has these functions:

▪Several hydraulics functions. For example: Sloping the boom, folding the boom in and out.

▪TRAIL-Control – automatic drawbar and axle steering.

System requirements

For the job computer to be used, the tractor must meet the following requirements:

▪For ISOBUS systems:

– The tractor must be fitted with basic ISOBUS equipment.

– The terminal must be ISOBUS-compliant.

▪For ECO systems:

– The tractor must be fitted with basic ECO equipment.

– An ECO terminal from Müller-Elektronik must be fitted to the tractor.

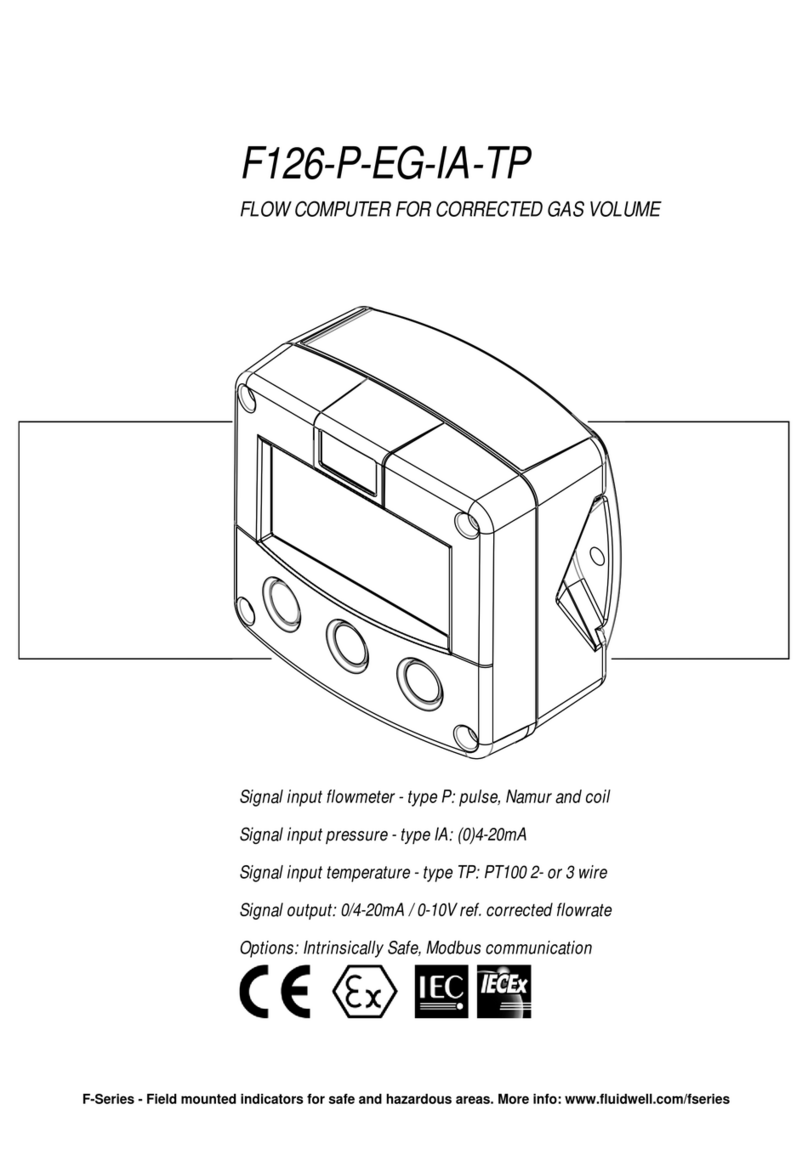

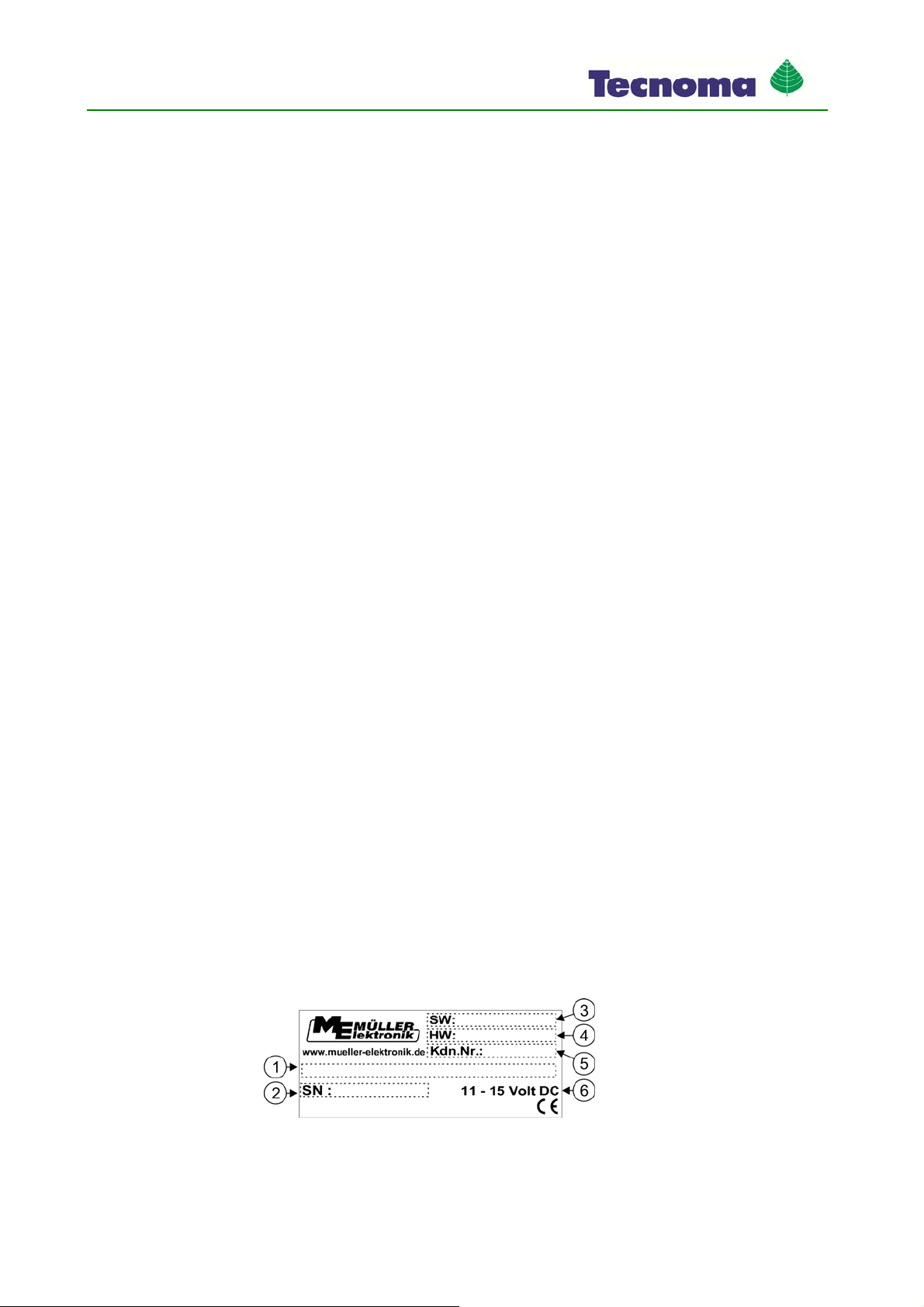

Understanding manufacturer's plates

On the job computer you will find a manufacturer's plate in the form of a sticker. On this sticker you

can find all the information you need to clearly identify the product.

Have these details ready when you contact Customer Services.

Manufacturer's plate on the side of the job computer

3

3.1

3.2

3.3

Product description

14 990267EN ind. A

Item name

In the name you can see whether the job

computer is F1 or F2.

Hardware version

Serial number Customer number

If the product was manufactured for an

agricultural machinery manufacturer, the

agricultural machinery manufacturer's item

number will be shown here.

Software version

If you update the software, this version will no

longer be up-to-date.

Operating voltage

The product may only be connected to

voltages within this range.

Mounting and installation

15 990267EN ind. A

Mounting and installation

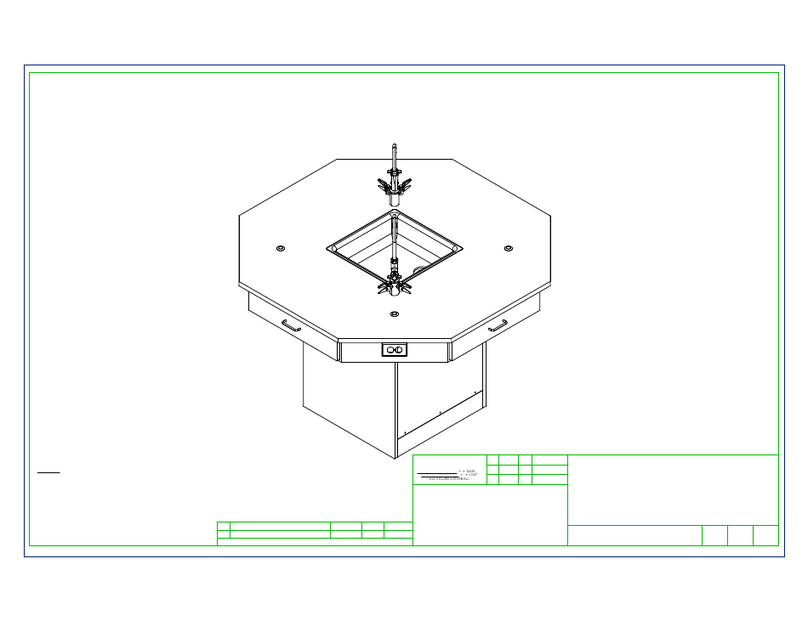

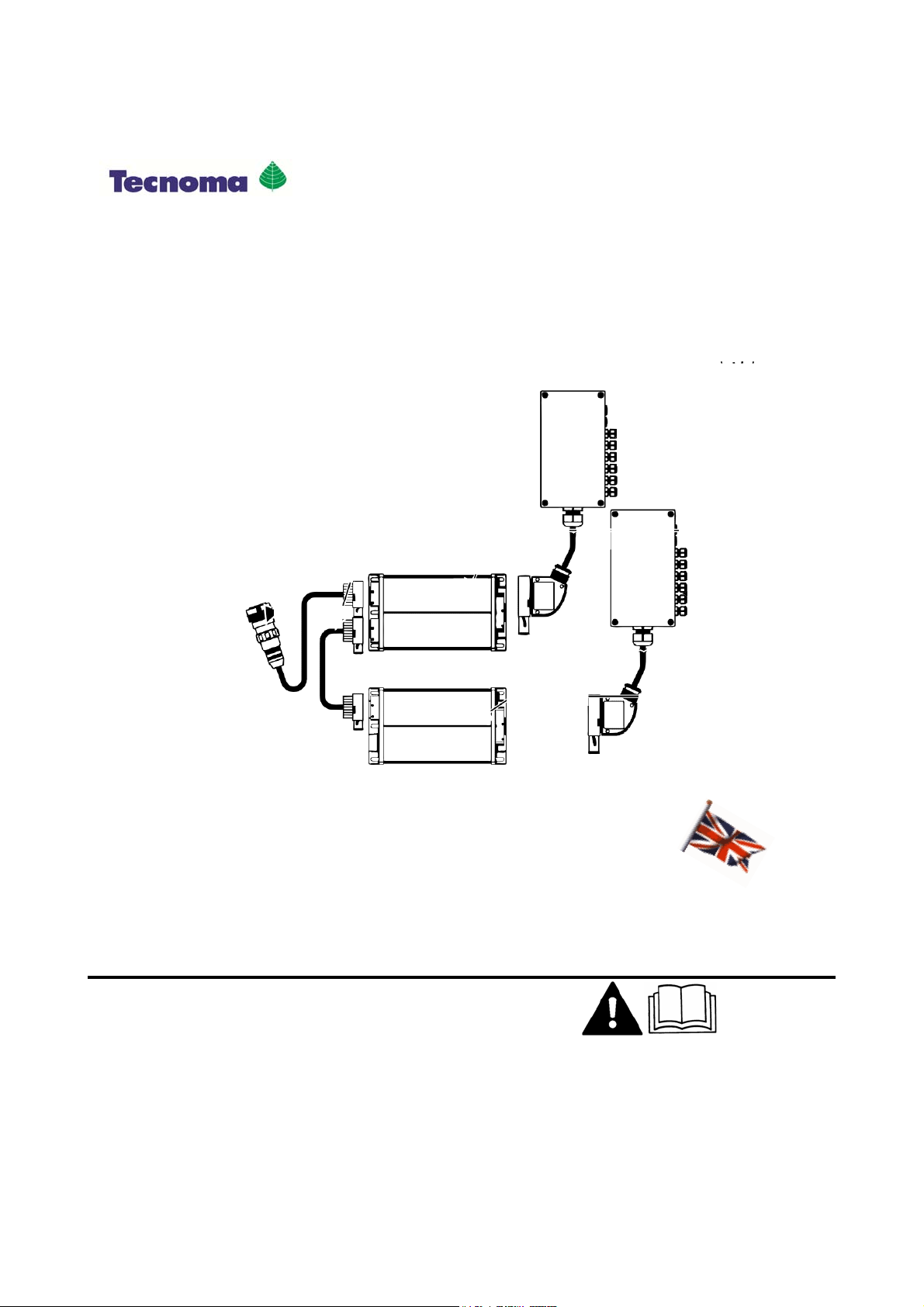

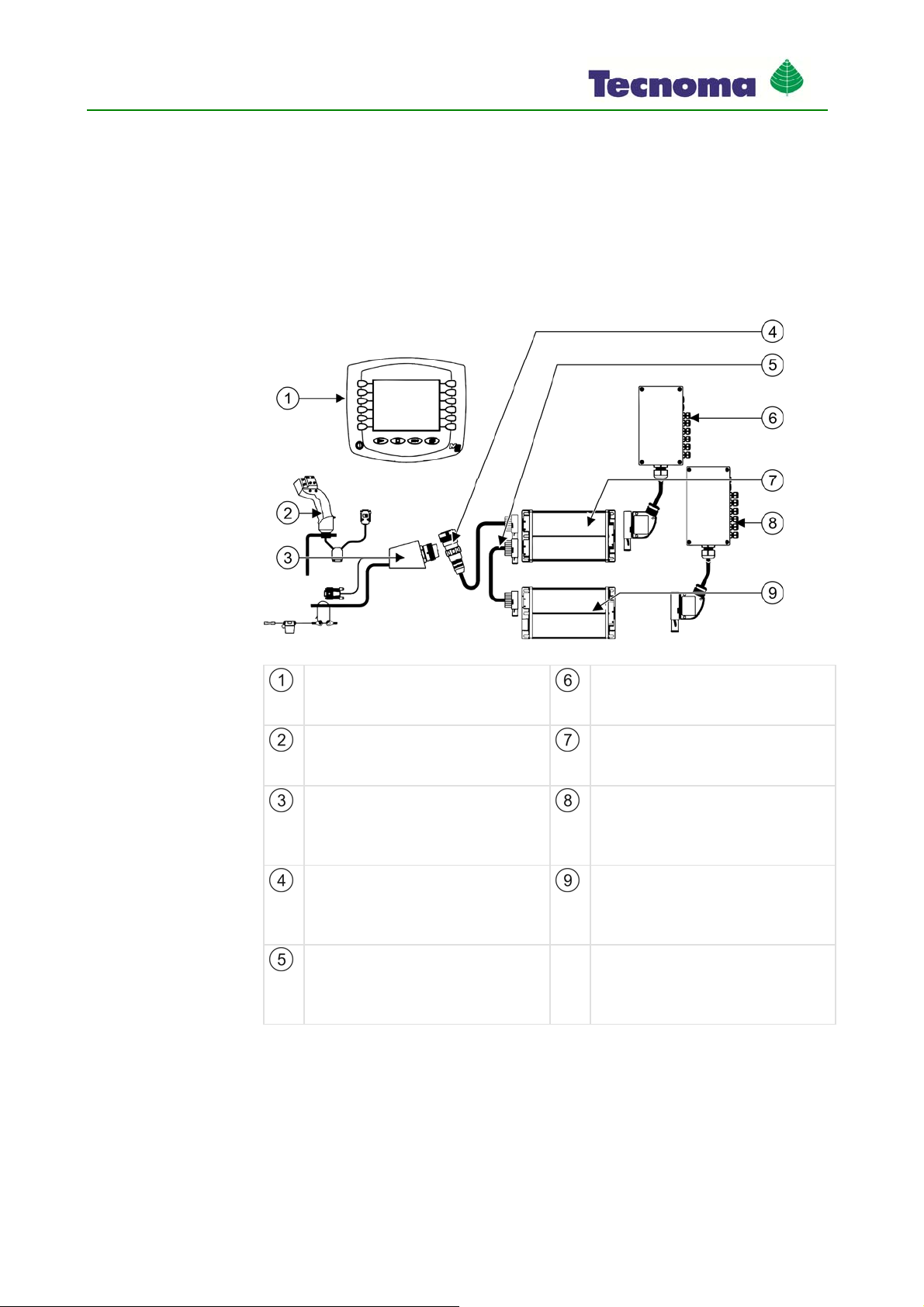

System overview

The job computers F1 and F2 are not sufficient on their own to be able to control and operate a field

sprayer.

In the following images you can see what components need to be fitted to your field sprayer and the

tractor.

System overview of job computer on a tractor without ISOBUS interface

Terminal

- ISOBUS terminal from Müller-Elektronik with

license "ISO11587 VT"

Cable harness and distributor for job

computer F2

Different configurations are possible.

Multi-function joystick

Optional

- Used to operate the field sprayer.

Job computer F2

Slave job computer

Different configurations possible

ISOBUS basic equipment

- Connects the job computers with the tractor.

- Supplies the job computers and the terminal

with voltage.

Cable harness and distributor for job

computer F1

Different configurations possible

Connection cable for ISOBUS basic

equipment

Connection of the job computers to the

tractor's basic equipment

Job computer F1

Master job computer

Different configurations possible

Connector cable

Connects job computer F1 and job computer

F2

Different configurations possible

4

4.1

Mounting and installation

16 990267EN ind. A

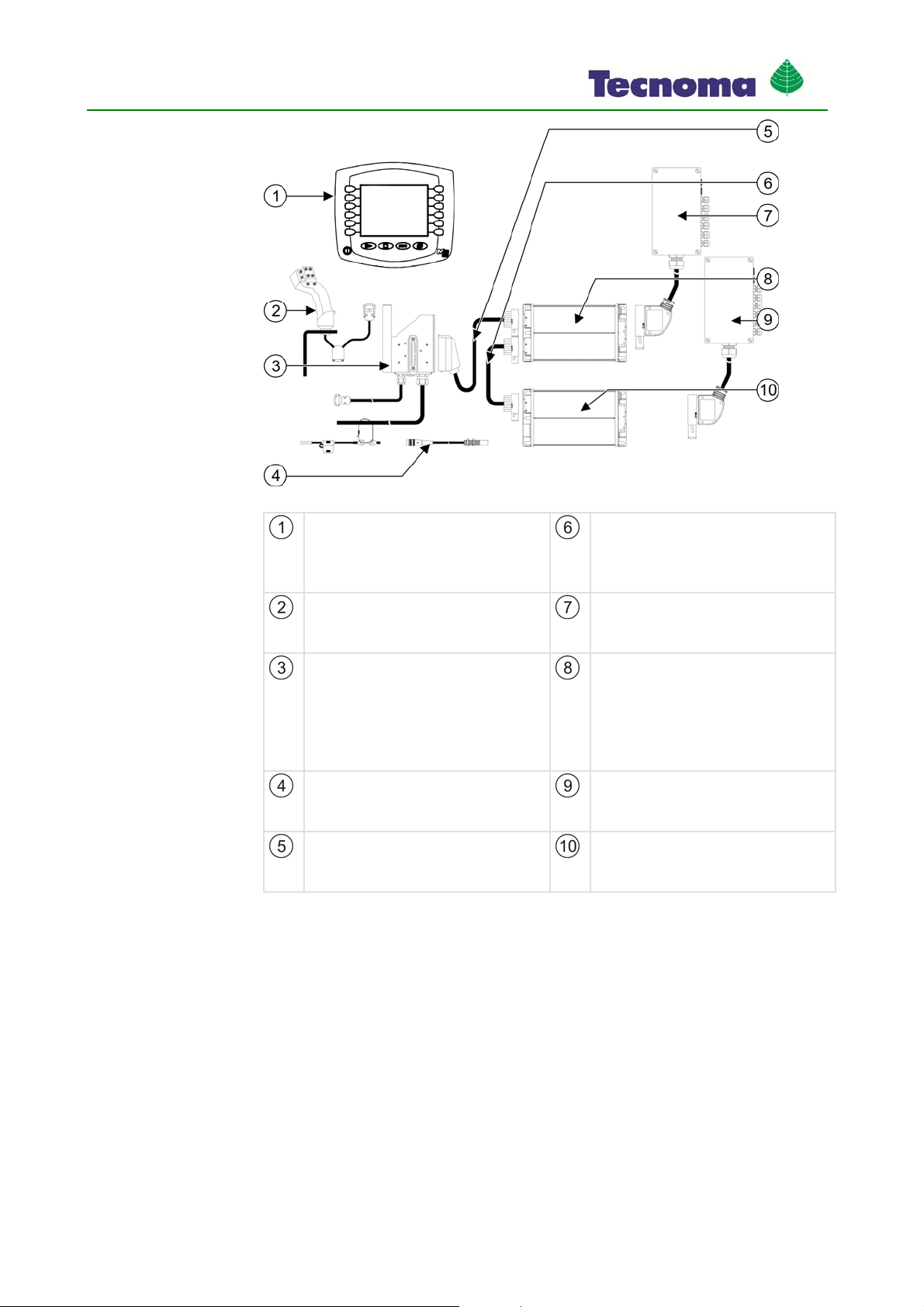

System overview of job computer on a tractor without ISOBUS interface

Terminal

Terminals from Müller-Elektronik Connector cable

Connects job computer F1 and job computer

F2

Different configurations possible

Multi-function joystick

Optional

- Used to operate the field sprayer.

Cable harness and distributor for job

computer F2

Different configurations possible

- Connects the job computers with the tractor.

- Supplies the job computers and the terminal

with voltage.

- Offers the option of connection of a wheel

sensor.

Job computer F2

Slave job computer

Different configurations possible

Wheel sensor Cable harness and distributor for job

computer F1

Different configurations possible

Connection cable for ECO basic equipment

Connection of the job computer sprayer to the

tractor's basic equipment.

Job computer F1

Master job computer

Different configurations possible

Connecting job computer to the basic tractor equipment

For you to operate the field sprayer with the terminal, you must connect the job computer to the

tractor's basic equipment. You need to use different plugs depending on the type of basic equipment

fitted to the tractor.

Tractor with ISOBUS basic equipment

This is how you connect the job computer to the ISOBUS basic equipment:

Tractor is ISOBUS-capable.

Job computer is fitted to the field sprayer.

Field sprayer has been attached to or is trailed by the tractor.

4.2

Procedure

Mounting and installation

17 990267EN ind. A

1. Pull cable from the field sprayer to the ISOBUS basic equipment socket.

2. Unfasten dust protection caps.

3. Insert ISOBUS plug into the tractor's ISOBUS socket and screw in.

4. Connect dust protection caps with one another to protect the sockets from dust.

⇨You have connected the job computer to the basic equipment.

5. Check whether the job computer is correctly connected by starting it up.

Tractor with ECO basic equipment

This is how you connect the job computer to the ECO basic equipment:

Tractor is fitted with basic ECO equipment from Müller-Elektronik.

Job computer is fitted to the field sprayer.

Field sprayer has been attached to or is trailed by the tractor.

1. Pull cable from the field sprayer to the ECO basic equipment socket.

2. Insert the plug of the ECO basic equipment into the socket.

First insert the hook on the tip of the plug into the opening in the socket :

3. Let the plug snap .

⇨You have connected the job computer to the basic equipment.

4. Check whether the job computer is correctly connected by starting it up.

Fitting multi-function joystick (MFG)

The multi-function joystick can additionally be connected to the terminal and is absolutely essential

for operation of the field sprayer.

Procedure

4.3

Mounting and installation

18 990267EN ind. A

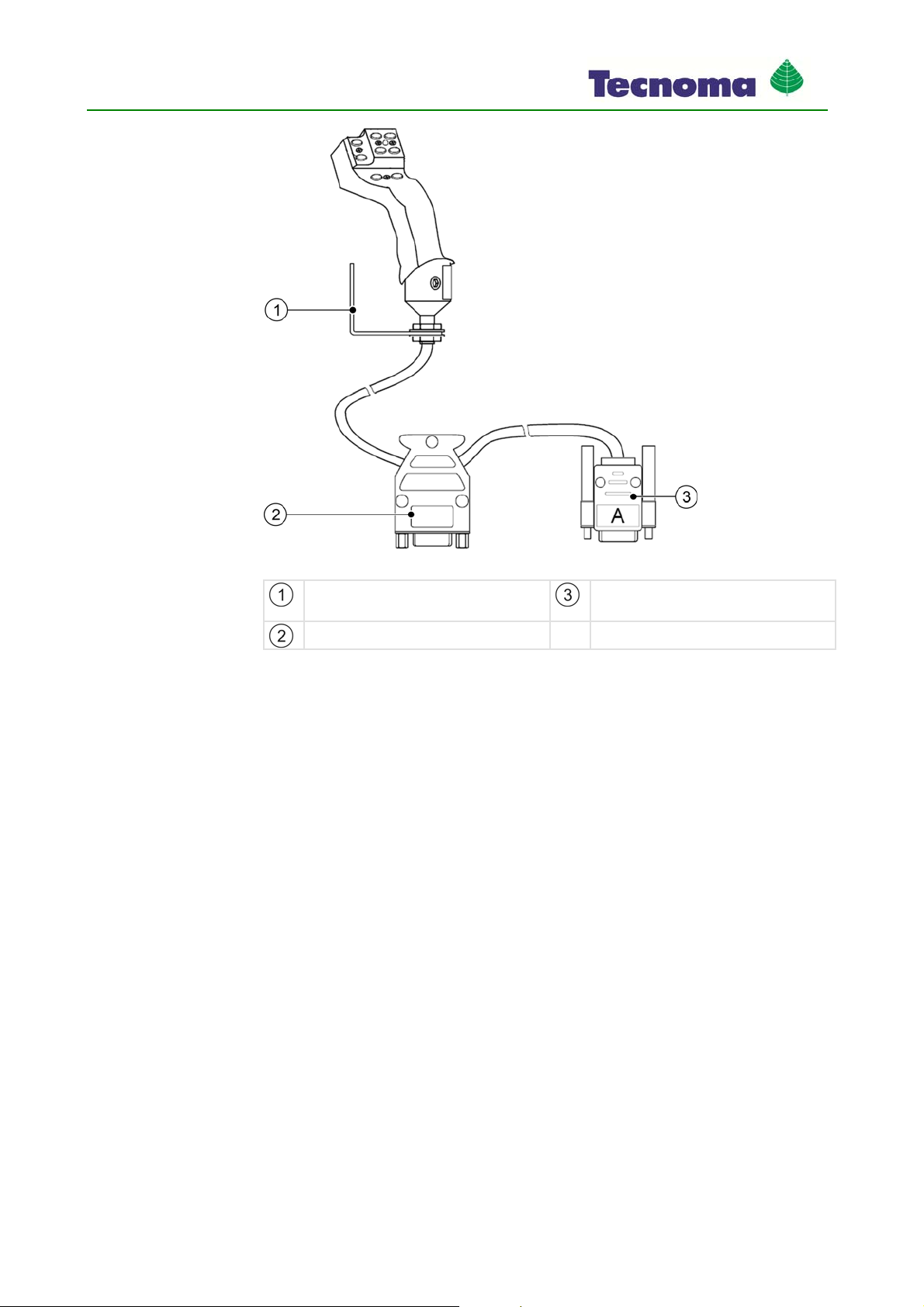

Connecting multi-function joystick

Mounting angle

For attachment in the cabin Connector for connection to the terminal

Jack for connection to the basic equipment

You fit the multi-function joystick as follows:

1. Fit the multi-function joystick next to the driver on the right.

2. Plug in the connector of the basic equipment to the jack on the multi-function joystick.

3. Plug in connector A on the multi-function joystick to jack A on the terminal.

⇨The multi-function joystick is connected between the basic equipment and the terminal.

⇨When the terminal is switched on, the LED on the multi-function joystick lights up.

Mounting the gyroscope

The gyroscope is a measuring device to determine the direction changes of the tractor.

To mount the gyroscope you must carry out the following:

▪Mount the bracket on the tractor

Procedure

4.4

Mounting and installation

19 990267EN ind. A

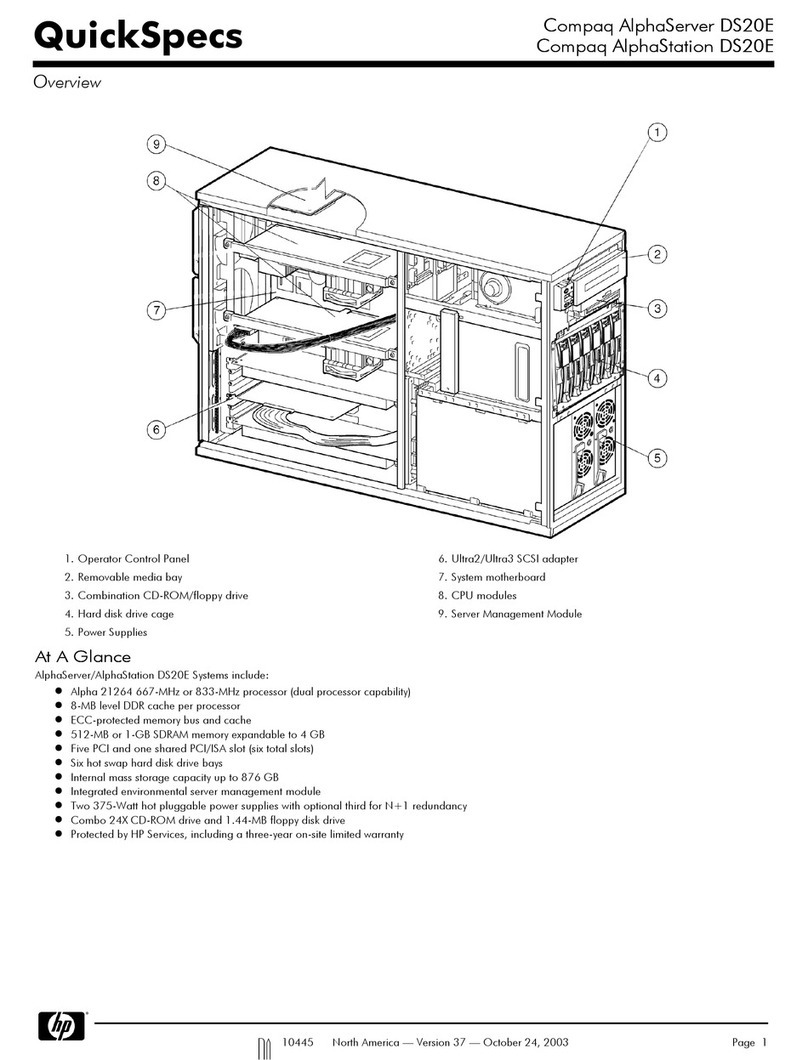

Mounting the bracket for the gyroscope

Bracket Gyroscope in the bracket

Mounting the bracket on the tractor

The bracket on the tractor is used for fastening the gyroscope to the tractor for the duration of work

on the field.

1. Determine the position for mounting the bracket on the tractor.

The bracket must be mounted vertically and without vibration on the rear of the tractor.

Make sure that the connection cable of the gyroscope does not become too taut when fastened

in the bracket.

2. CAUTION! Before drilling a hole, make sure that for drilling you do not damage any

cables.

3. Drill the holes for the screws.

4. Fasten the bracket.

The bracket must be fastened securely to prevent shaking while driving.

4.4.1

Procedure

Mounting and installation

20 990267EN ind. A

Using the gyroscope

1. Fasten the gyroscope into the bracket on the tractor and screw tight with the wing screw.

The side with the TOP-OBEN label must be on the top:

2. After work, fasten the gyroscope into the bracket on the trailer device and screw tight with the

wing screw.

4.4.2

Procedure

Table of contents