Tek-Trol TEK-B ATCH 7900B User manual

Technology Solutions

TATCH 7900B

EK-B

Instruction Manual

NEMA 4X Large Display Batcher

Document Number: IM-7900B

www.tek-trol.com

© COPYRIGHT Tek-Trol LLC 2021

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum

product performance, make sure you thoroughly understand the contents before installing, using, or

maintaining this product.

For technical assistance, contact

Customer Support

796 Tek-Drive

Crystal Lake, IL 60014

USA

Tel: +1 847 857 6076,

www.tek-trol.com

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a

retrieval system, or translated into any human or computer language, in any form or by any means,

electronic, mechanical, manual, or otherwise, or disclosed to third parties without the express

written permission. The information contained in this manual is subject to change without notice.

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

1

Table ofContents

1Safety Instructions....................................................................................................................... 3

1.1 Intended Use ..................................................................................................................................... 3

1.2 Certifications ..................................................................................................................................... 3

1.3 Safety Instructions from the Manufacturer........................................................................................ 3

1.3.1 Disclaimer ........................................................................................................................................... 3

1.3.2 Product Liability and Warranty .......................................................................................................... 3

1.3.3 Information Concerning the Documentation..................................................................................... 3

1.4 Safety Precautions............................................................................................................................. 3

1.5 Packaging, Transportation and Storage.............................................................................................. 4

1.5.1 Packaging............................................................................................................................................ 4

1.5.2 Transportation.................................................................................................................................... 4

1.5.3 Storage ............................................................................................................................................... 4

1.5.4 Nameplate .......................................................................................................................................... 5

2Product Description.....................................................................................................................5

2.1 Introduction ...................................................................................................................................... 5

2.2 Specifications .................................................................................................................................... 6

2.3 Dimensional Drawings ....................................................................................................................... 9

2.4 Popular Models ................................................................................................................................. 9

3Installation .................................................................................................................................. 9

3.1 Mounting ........................................................................................................................................ 10

4Wiring Connection..................................................................................................................... 10

4.1 Wiring Connection........................................................................................................................... 10

4.2 Batcher Wiring ................................................................................................................................ 11

4.3 Rate or Total Wiring ........................................................................................................................ 11

4.4 Wiring in Hazardous Areas............................................................................................................... 12

5Operations................................................................................................................................. 13

5.1 Front Panel Operation Concept for Run Mode ................................................................................. 13

5.1.1 General Instructions ......................................................................................................................... 13

5.1.2 Ratemeter or Totalizer Operation.................................................................................................... 13

5.2 Batcher Operation ........................................................................................................................... 15

5.2.1 Batcher Configuration ...................................................................................................................... 16

6Setup and Programming ............................................................................................................ 18

6.1 Setup Mode..................................................................................................................................... 18

6.1.1 Mode Changes.................................................................................................................................. 18

6.1.2 Submenu GROUP NAVIGATION........................................................................................................ 18

6.1.3 Item Selection................................................................................................................................... 18

6.1.4 Numeric Entry................................................................................................................................... 18

6.1.5 Text Character Entry......................................................................................................................... 18

6.2 EZ Setup .......................................................................................................................................... 18

6.3 Menu Setup..................................................................................................................................... 20

6.4 Submenu Setup ............................................................................................................................... 21

6.4.1 Flow Equation Selection ................................................................................................................... 22

6.4.2 Setup Indicators Total ...................................................................................................................... 22

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

2

6.4.3 Setup Indicators Density .................................................................................................................. 23

6.4.4 Setup Indicators Rate ....................................................................................................................... 23

6.4.5 Setup Indicators Temperature ......................................................................................................... 24

6.4.6 Setup Fluid Properties ...................................................................................................................... 24

6.4.7 Setup Pulse Output........................................................................................................................... 25

6.4.8 Setup Analog Output........................................................................................................................ 25

6.4.9 Setup Relays ..................................................................................................................................... 26

6.4.10 Setup Relays ..................................................................................................................................... 27

7Menu Tree ................................................................................................................................. 28

8Troubleshooting ........................................................................................................................ 29

8.1 Response of Batcher on Error or Alarm ............................................................................................ 29

8.2 Diagnosis Flow Chart and Troubleshooting ...................................................................................... 30

8.3 Error and Warning Messages ........................................................................................................... 31

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

3

1Safety Instructions

1.1 Intended Use

Tek-Batch 7900B NEMA 4X Large Display Batcher satisfies the instrument requirements for various

flow meter types in liquid batching applications.

1.2 Certifications

CE Approvals.

1.3 Safety Instructions from the Manufacturer

1.3.1 Disclaimer

The manufacturer will not be held accountable for any damage that happens by using its product,

including, but not limited to direct, indirect, or incidental and consequential damages.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer has the right to modify the content of this document, including the disclaimer,

at any time for any reason without prior notice, and will not be answerable in any way for the

possible consequence of such changes.

1.3.2 Product Liability and Warranty

The operator shall bear authority for the suitability of the device for the specific application. The

manufacturer accepts no liability for the consequences of misuse by the operator. Wrong

installation or operation of the devices (systems) will cause the warranty to be void. The

respective Terms and Conditions of Sale, which forms the basis for the sales contract shall also

apply.

1.3.3 Information Concerning the Documentation

To prevent any injury to the operator or damage to the device it is essential to read the

information in this document and the applicable national standard safety instructions This

operating manual contains all the information needed in various stages, such as product

identification, incoming acceptance and storage, mounting, connection, operation and

commissioning, troubleshooting, maintenance, and disposal.

1.4 Safety Precautions

You must read these instructions carefully prior to installing and commissioning the device. These

instructions are an important part of the product and must be kept for future reference.

Observing these instructions can ensure optimum protection of both personnel and the

environment and safe and fault-free operation of the device.

For additional information that is not discussed in this manual, contact the manufacturer.

Warnings and Symbols Used

The following safety symbol marks are used in this operation manual and on the instrument.

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

4

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in

death or severe injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

NOTE

Indicates that operating the hardware or software in this manner may damage it

or lead to system failure.

1.5 Packaging, Transportation and Storage

1.5.1 Packaging

The original package consists of

•Tek-Batch 7900B NEMA 4X Large Display Batcher.

•Documentation

NOTE

Unpack and Check the contents for damages or sign of rough handling. Report

damage to the manufacturer immediately. Check the contents against the packing

list provided.

1.5.2 Transportation

•Avoid impact shocks to the device and prevent it from getting wet during

transportation.

•Verify local safety regulations, directives, and company procedures with respect to

hoisting, rigging, and transportation of heavy equipment.

•Transport the product to the installation site using the original manufacturer’s packing

whenever possible.

1.5.3 Storage

If this product is to be stored for a long period of time before installation, take the following

precautions:

•Store your product in the manufacturer’s original packing used for shipping.

•Storage location should conform to the following requirements:

1. Free from rain and water

2. Free from vibration and impact shock

3. At room temperature with minimal temperature and humidity variation

•Properties of the instrument can change when stored outdoors.

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

5

1.5.4 Nameplate

The nameplate lists the important information, such as design details and technical data.

NOTE

Check the device nameplate to ensure that the device is delivered according to

your order. Check for the correct supply voltage printed on the nameplate.

2Product Description

2.1 Introduction

The Tek-Batch 7900B NEMA 4X Large Display Batcher satisfies the instrument requirements for

various flow meter types in liquid batching applications. It also provides multiple flow equations

and instrument functions in a single unit with several advanced features. The large digit

alphanumeric display shows measured and calculated parameters in an easy-to-understand

format. Measurements and display scrolling can be accessed with a single key. The versatile Large

Display Batcher permits various functions within the instrument’s attractive wall mount package.

The multiple hardware inputs and outputs can be “soft” assigned to meet different common

application needs. While configuring the instrument, the user “soft selects” the use of each

input/output. The isolated analog output can be set to follow volume flow, corrected volume flow,

mass flow, temperature, or density through a menu setting. This approach can be used to assign

most hardware characteristics. The user can use the standard RS-232 Serial Port for data logging,

transaction printing, or connection to a modem for a remote meter reading. Remote metering

software is available. A Service or Test mode is available to help the user during system startup by

monitoring inputs, exercising outputs, and reporting system configuration.

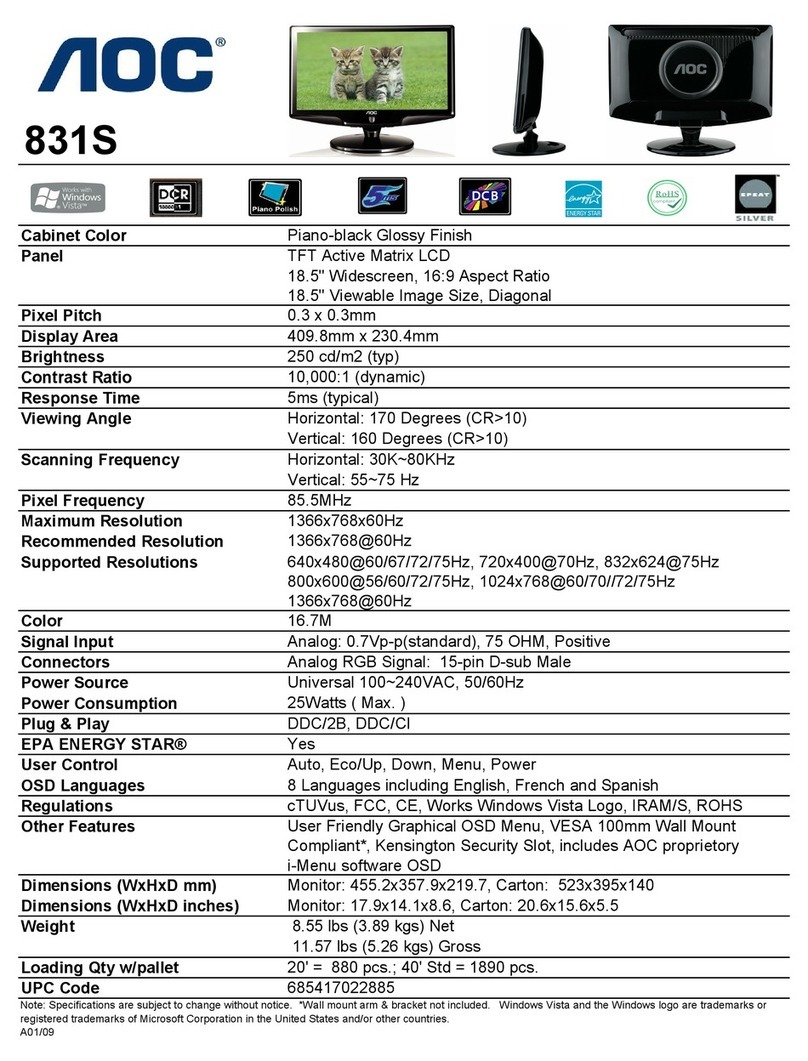

Fig 1: Tek-Batch 7900B NEMA 4X Large Display Batcher

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

6

2.2 Specifications

Accuracy

0.02% FS at 20 ° C

Ranges

Voltage: 0-10 VDC, 0-5 VDC, 1-5 VDC, Current: 4-20 mA, 0-20 mA

Flow Meters and

Computations

Meter Types: All linear and square law meters supported including

vortex, turbine, magnetic, PD, target, orifice, venturi, v-cone,

Coriolis, and many others.

Linearization: Square root, 16-point table or UVC table

Computations: Volume, Corrected Volume and Mass.

Fluid Computations: Temperature, Density, Viscosity and API 2540

for petroleum.

Operating Temperature

32°F to 122°F (0°C to 50°C)

Storage Temperature

-40°F to 185° (-40°C to 85°C)

Humidity

0-95% non-condensing

Extended Temperature

-4°F to 131°F (-20°C to 55°C)

Display

UL/C-UL Listed (File No. E192404), CE Compliant, Type: 2 lines of 20

characters, Types: Backlit LCD, Character Size: 0.35”

(8.3mm) nominal user programmable label descriptors and units of

measure

Keypad

Membrane Keypad with 16 keys

Type

NEMA 4X

Materials

Plastic, UL94V-0, Flame retardant Bezel: Textured per matt finish

Real Time Clock

The Tek-Batch is equipped with a battery backed real time clock

with display of time and date.

Format: 12- or 24-hour time display; Day, Month, Year, date display

Power Input

The factory equipped power option is internally fused. An internal

line to line filter capacitor and MOV are provided for

added transient suppression.

110VAC Power: 85 to 127Vrms, 50/60 Hz

220VAC Power: 170 to 276Vrms, 50/60 Hz

DC Power: 2VDC (10 to 14VDC), 24VDC (14 to 28VDC)

Power Consumption: AC: 11.0VA (11W), DC: 300mA max

Basic Measurement

Resolution

16 bit

Update Rate

4updates/sec

Automatic Fault Detection

Signal over/under-range, Current Loop Broken

Calibration

Software Calibration (no trimmers) and Auto-zero Continuously

Extended Calibration

Learns Zero and Full Scale of each range using special test mode

Fault Protection

Reverse Polarity: No ill effects

Over-Voltage Limit: 50VDC Over voltage protection

Over-Current Protection: Internally current limited protected to

24VDC

Pulse Inputs

Number of Flow Inputs: one with or without quadrature or pulse

security checking

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

7

Input Impedance: 10 KΩ nominal

Pullup Resistance: 10 KΩ to 5 VDC (menu selectable) Pull Down

Resistance: 10 KΩ to common

Trigger Level: (menu selectable) High Level Input

Logic On: 3 to 30 VDC, Logic Off: 0 to 1 VDC Low Level Input (mag

pickup)

Sensitivity: 0 mV or 100 mV

Minimum Count Speed: Menu selectable

Maximum Count Speed: Menu Selectable: 40Hz, 3000Hz or 20 kHz

Over voltage Protection: 50 VDC

Auxiliary / Compensation

Input

The auxiliary/compensation input is menu selectable for

temperature, density or not used. This input is used for the

compensated input when performing compensated flow

calculations. It can also be used as a general purpose input for

display and alarming.

Operation: Ratiometric

Accuracy: 0.02% FS at 20° C

Basic Measurement Resolution: 16 bit

Update Rate: 1 update/sec minimum

Automatic Fault detection: Signal Over-range/under-range, Current

Loop Broken, RTD short, RTD open, Fault mode to

user defined default settings

Fault Protection: Reverse Polarity: No ill effects, Over-Voltage Limit

(Voltage Input): 50VDC

Available Input Ranges: Voltage: 0-10VDC, 0-5VDC, 1-5VDC,

Current: 4-20mA, 0-20mA, Resistance: 100 Ohms DIN RTD

100 Ohm DIN RTD (DIN 43-760, BS 1904)

Three Wire Lead Compensation

Internal RTD linearization learns ice point resistance 1 mA

Excitation current with reverse polarity protection

Temperature Resolution: 0.01 °C, Temperature Accuracy: ± 0.25 °C

Control Inputs

Switch Inputs are menu selectable for Start, Stop, Reset, Lock,

Inhibit, Alarm Acknowledge, Print or Not Used.

Number of Control Inputs: 3 Control Input Specifications

Input Scan Rate: 10 scans per second

Logic 1: 4 - 30VDC, Logic 0: 0 - 0.8VDC

Input Impedance: 100 KΩ

Control Activation: Positive Edge or Pos. Level based on product

definition for switch usage.

Excitation Voltage

Menu Selectable: 5, 12 or 24VDC @ 100mA (fault protected)

Relay Outputs

The relay outputs are menu assignable to (Individually for each

relay) Low-Rate Alarm, Hi Rate Alarm, Prewarn Alarm,

Preset Alarm or General-purpose warning (security), low

temperature/high temperature.

Number of relays: 2

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

8

Contact Style: Form C contacts

Contact Ratings: 5A, 240VAC or 30VDC

Serial Communication

The serial port can be used for printing, data logging, modem

connection and communication with a computer.

RS-232: Device ID: 01-99

Baud Rates: 300, 600, 1200, 2400, 4800, 9600, 19200 Parity: None,

Odd, Even

Handshaking: None, Software, Hardware

Print Setup: Configurable print list and formatting.

Print Out: Custom form length, print headers, print list items.

Print Initialization: Print on end of batch, key depression, interval,

time of day, control input or serial request.

RS-485: (optional 2nd COM port) Device ID: 01-247

Baud Rates: 2400, 4800, 9600, 19200 Parity: None, Odd, Even

Protocol: Modbus RTU (Half Duplex)

Data Logging

The data logger captures print list information to internal storage

for approximately 1000 transactions. This information

can be used for later uploading or printing. Storage format is

selectable for Comma-Carriage Return or Printer formats.

Isolated Analog Output

The analog output is menu assignable to correspond to the

Uncompensated Volume Rate, Corrected Volume Rate, Mass

Rate, Temperature, Density, Volume Total, Corrected Volume Total

or Mass Total.

Type: Isolated Current Sourcing

Available Ranges: 4-20mA, 0-20mA

Resolution: 12 bit

Accuracy: 0.05% FS at 20° C

Update Rate: 1 update/sec minimum

Temperature Drift: Less than 200 ppm/C

Maximum Load: 1000 ohms (at nominal line voltage) Compliance

Effect: Less than .05% Span

60 Hz rejection: 40 dB minimum

Calibration: Operator assisted Learn Mode

Averaging: User entry of damping constant to cause a smooth

control action

Isolated Pulse Output

The isolated pulse output is menu assignable to Uncompensated

Volume Total, Compensated Volume Total or Mass Total

Pulse Output Form: Photozmos Relay

Maximum On Current: 25 mA

Maximum Off Voltage: 30 VDC

Saturation Voltage: 1.0 VDC

Maximum Off Current: 0.1 mA

Pulse Duration: 10 mSec or 100 mSec (user selectable) Pulse output

buffer: 256

Fault Protection Reverse polarity: Shunt Diode

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

9

2.3 Dimensional Drawings

Fig 2: Bottom View Fig 3: Front View

Fig 4: Side View

2.4 Popular Models

Model

Description

7900B-LDB

NEMA 4X Large Display Batcher

3Installation

This section covers instructions on installation and commissioning. Installation of the device must

be carried out by qualified trained, specialists authorized to perform such works.

CAUTION

•When removing the instrument from hazardous processes, avoid direct contact

with the fluid and the meter.

•

All installation must comply with local installation requirements and local

electrical code.

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

10

NOTE

There is no need to remove the meter from its case to complete the installation,

wiring, and setup of the meter for most applications.

3.1 Mounting

The Tek-Batch 7900B NEMA 4X Large Display Batcher should be located in an area where,

atmosphere is clean, dry, shock and vibration free.

4Wiring Connection

CAUTION

•Use copper wire with 60°C or 60/75°C insulation for all line voltage

connections. Observe all safety regulations.

•

Electrical wiring should be performed in accordance with all applicable

national, state, and local codes to prevent damage to the meter and ensure

personnel safety.

4.1 Wiring Connection

Pin

Description

1

DC OUTPUT

2

PULSE IN 1 (Vin +)

3

PULSE IN 2 (Iin +)

4

COMMON

5

--------- (Vin +)

6

RTD EXCIT +

7

RTD SENS +

8

RTD SENS – (Iin +)

9

CNTR IN 1

10

CNTR IN 2

11

CNTR IN 3

12

COMMON

13

PULSE OUTPUT +

14

PULSE OUTPUT -

15

ANALOG OUTPUT +

16

ANALOG OUTPUT -

17

NC

18

COM RLY 1

19

NO

20

NC

21

COM RLY 2

22

NO

23

AC LINE

DC +

24

AC LINE

DC -

25

NC

26

COM RLY 3

27

NO

28

NC

29

COM RLY 3

30

NO

RS 232

RS 485

1

TX

4

TX/RC +

2

RX

5

TX/RC –

3

COM

6

GND 180REF

Table 1: Pin Description (TB-1)

Fig 5: Tek-Batch 7900B Pin Diagram

Table 2: Communication Port (TB-2)

*Note: * Power Terminals 23 & 24 used for DC Input only when

ordered with DC INPUT option

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

11

4.2 Batcher Wiring

Fig 6: Typical Batcher Wiring Fig 7: Optional Wiring for

Flow Sensor with Preamp

4.3 Rate or Total Wiring

Fig 8: Typical Rate/Total Wiring

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

12

4.4 Wiring in Hazardous Areas

Fig 9: Wiring in Hazardous Area with Flow Input

Fig 10: Wiring in Hazardous Area with Temperature Input (4 to 20mA Transmitter)

Fig 11: Wiring in Hazardous Area with Temperature Input (RTD)

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

13

5Operations

5.1 Front Panel Operation Concept for Run Mode

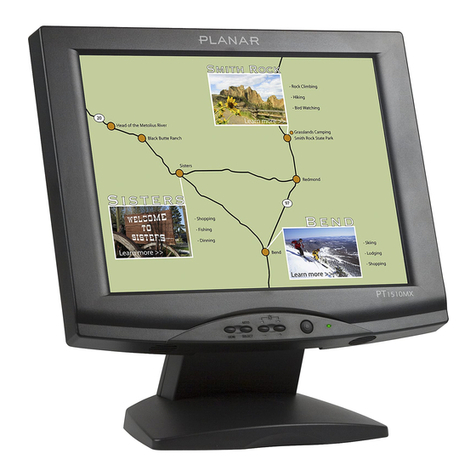

Fig 12: Display of NEMA 4X Large Display Batcher

Table 3: Display Key with its Function

Key Function

HELP On-line help is provided to assist the operator

Total

To clear the total

GRAND

To clear the grand total

PRE 1 & PRE 2

Used to view and/or change the preset

setpoints

SCROLL

To setup a display list

PRINT

Used to print on demand

START

Start Batches

STOP

Stop Batches

MENU

Used to enter the Setup and Test modes

ENTER

To acknowledge and clear alarms

5.1.1 General Instructions

•The unit can display Rate, Total, Grand Total, Temperature, Density, Presets and Time of Day.

•Even if you're using the Volumetric Flow Equation, you can see the temperature and/or

density (a Temperature or Density sensor must be installed).

•Using a temperature or density sensor, the device may compute Mass or Corrected Volume

equations (these equations can also be computed without Temperature/Density sensors

using user-defined default values).

•The unit can be programmed to perform Ratemeter/Totalizer or Batching functions (see

section SELECT INSTRUMENT Submenu).

5.1.2 Ratemeter or Totalizer Operation

The Ratemeter/Totalizer mode is primarily used to keep track of flow rate and total. The relays

can be used to trigger flow, total, temperature or density alarms.

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

14

5.1.2.1 Password Protection for Rate or Total Mode

•The device will be locked when an Operator and/or Supervisor have entered a password in

the setup mode (see section SETUP PASSWORD submenu). The unit will prompt the user

for the password when trying to perform the following functions:

oClear Total

oClear Grand Total

oEnter Menu

oEdit Preset 1 (PRE 1 Key)

oEdit Preset 2 (PRE 2 Key)

•Only supervisors should have access to the supervisor password. The supervisor password

will allow access to restricted areas of the Setup and Test menus.

5.1.2.2 Relay Operation in Rate/Total mode

•Alarm outputs can include up to four relays (two are common).

•The relays can be programmed to trip in response to rate, total, temperature, density, or

system alarms.

•Low and high alarms can be programmed into the relays. By tapping the PRE 1 or PRE 2 keys

on the front panel, you can quickly access Preset 1 (RLY1) and Preset 2 (RLY2).

•Presets 3 and 4 can only be accessed through the setup menu.

5.1.2.3 Pulse Output in Rate/Total mode

•Volume Total, Corrected Volume Total, or Mass Total are the menu options for the isolated

pulse output (open collector).

•The pulse output duration can be set to 10mS (50Hz max) or 100mS (5Hz max).

•A pulse output scale factor (pulse value) can be set to scale the pulse output.

•The pulse output is used to connect remote totalizers or other devices such as a PLC. Refer

electrical specifications section.

5.1.2.4 Analog Output in Rate/Total mode

•The analog output can be assigned to the Volume Rate, Corrected Volume Rate, Mass Rate,

Temperature, Density, Volume Total, Corrected Volume Total, or Mass Total through the

menu system.

•The analog output is used to employ strip chart recorders or other devices to track "trends."

5.1.2.5 RS-232 Serial Port Operation in Rate/Total mode

In the Operating Mode (Run Mode), one can use the RS-232 serial port to program (using the

Setup Disk), communicate with printers, and connect to computers.

5.1.2.5.1 PC Communication

The Setup Disk allows the user to check the operating status unit including, Flow Rate, Flow

Total, Temperature, Density, Presets, etc.

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

15

5.1.2.5.2 Operation of RS-232 Serial Port with Printers

5.1.2.5.2.1 Transaction Printing

The user defines the items included in the printed document (Refer section SET DATA

OUTPUT, Select list). The transaction document can be started by either pressing the PRINT

key or closing the remote contact.

5.1.2.5.2.2 Data Logging

The user defines the items included in each data log (Refer SET PRINTER OUTPUT, Select list

section). The user can also select when (time of day) or how often (print interval) the data

log is to be made (see SET PRINTER OUTPUT, Configure section).

5.1.2.5.2.3 System Setup and Maintenance Report

The system setup and maintenance reports list all instrument setup parameters and usage

for the current instrument configuration. The audit trail information and a status report are

also printed. This report is initiated in the Test menu (Refer PRINT SYSTEM SETUP section).

5.1.2.6 RS-485 Serial Port (optional)

5.1.2.6.1 RS-485 Port Description

The RS-485 card utilizes Modbus RTU protocol to access various process parameters and

totalizers. The Relays can be controlled through Modbus. Additionally, action routines can be

executed.

For further information, contact the factory and request the RS-485 Protocol manual.

5.1.2.6.2 Operation of Serial Communication Port with PC

•The Batcher's RS-485 channel supports several Modbus RTU commands.

•Modbus RTU drivers are available from third-party sources for a variety of Man-Machine

Interface software for IBM-compatible PCs.

•The user reads and writes the information from/to the RS-485 using the Modbus RTU

commands.

•The Batcher responds to this information and command requests.

•Process variables and totalizers are read in register pairs in floating-point format.

•Time and date are read as a series of integer register values.

•Alarms are individually read as coils. Action routines are initiated by writing to coils.

5.2 Batcher Operation

•The Batcher mode is used to control the batches.

•The relay operation is the main difference between Batch and Rate/Total modes.

•The operator can "START" the unit through the front panel or a remote input in Batch mode.

The relays (RLY1 & RLY2) will energize and transfer electricity to a flow control device once

they are started (i.e., solenoid valve or pump).

•The total accumulation will begin when the unit receives a signal from the flow sensor.

•Relay 2 will be turned off when the Prewarn value (PRE 2) is reached (ideal for flow slow down).

Relay 1 will drop out and complete the Batch when the Batch amount (PRE 1) is reached.

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

16

•Several messages will be displayed during regular batch operation (i.e., Batch Fill, Batch

Stopped).

•The keypad is disabled for the duration of these timed messages (approx. 2 sec).

5.2.1 Batcher Configuration

Several batch operation options are available when the unit is programmed for batch mode.

Following are batch operation options:

•Up or Down Counting

•Maximum Batch Preset

•Batch Overrun Compensation

•Auto Batch Restart

•Time Delay

•Flow Signal Timeout

•Maximum Drain Time

•Slow Start Quantity

•Start or Reset/Start

•Stop or Stop/Reset

5.2.1.1 Standard Preset or EZ Preset

•Standard Preset is used for applications in which the batch amount does not change

frequently.

•EZ Preset is used in applications in which the batch amounts change frequently.

•The EZ Preset mode was designed to enter presets with minimum keystrokes.

5.2.1.2 Batch Count Mode

The Batch Count Mode allows the user to choose whether the unit will batch up to a preset

value or batch down from a preset value to zero.

5.2.1.3 Maximum Batch Preset

•The user can preset the Maximum Batch value that can be entered by the operator using

the Maximum Batch Preset.

•If an operator should try to program a batch higher than this value, the unit will not allow

the value to be entered and will prompt the user with an error message, i.e., Maximum

Batch Preset has been exceeded.

5.2.1.4 Batch Overrun

•The Batch Overrun is used for batch applications with slow responding valves and a

consistent batching flow rate.

•When the Batch Overrun is set, the unit will compensate for batch overruns by computing

an averaged overrun value from the last four batches.

•This average is used to adjust the batch setpoint to minimize overrun internally.

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

17

5.2.1.5 Flow Signal Timeout

•The user can set a timeout between 0 and 99 seconds with the Flow Signal Timeout.

•If a batch is “Filling” and zero flow persists for more than the user entered time, the batch

will be aborted.

•Overflows caused by malfunctioning flow sensors and/or wiring are avoided.

5.2.1.6 Maximum Drain Time

•When the flow rate is equal to 0, the unit declares the batch is done.

•A flow rate may be present long after the Preset Relay de-energizes due to slow reacting

valves or leaky valves.

•The Maximum Drain Time allows the user to enter an amount of time (0 to 99 seconds) to

wait before declaring “Batch Done.”

•When the flow rate is “0” or the Maximum Drain Time has expired, the device will proclaim

“Batch Done” after the Preset Batch quantity has been reached. After that, the batch data

s

5.2.1.7 Slow Start Quantity

•The Slow Start Quantity function allows you to input an amount for a Slow Start up.

•This function necessitates the use of two-stage valve control.

•RLY 1 (slow flow) will activate for Slow Start, whereas RLY 2 (rapid flow) will activate after

the Slow Start Quantity is delivered.

•When filling an empty container, this reduces turbulence.

5.2.1.8 START, RESET/START and STOP, STOP/RESET

•When configuring the control inputs, Control Input1 is for START or START/RESET. When

the signal is applied to Control Input1 or the front panel Start key is clicked, the unit is set

to START and begins batching.

•A separate Reset signal clears the previous batch total.

•When the unit is set for RESET/START, is when the signal is applied to Control Input1 or

the Start key at the front panel is clicked, the unit will automatically reset then start

(provided that the prior batch was accomplished or completed).

•When a previous batch was stopped in the middle of a batch cycle, the unit would START

from where it was finished.

•STOP/RESET or STOP can be set for Control Input 2.

•When the unit is set to STOP, a signal is applied to Control Input 2, or the front panel Stop

key is pressed, the unit will stop batching.

•A separate Reset signal clears the batch total.

•When the STOP/RESET option is selected, a batch in progress will finish when a signal is

applied to Control Input 2, or the front panel Stop key is pressed.

•For Control Input 2, when a signal is applied, or the front panel Stop key is pressed, the

device will reset if it is stopped or after a finished batch

*Note: Applying a voltage level to Control Input 2 will disable all Start inputs in either mode.

Instruction Manual

Tek-Batch 7900B

www.tek-trol.com

Technology Solutions

18

6Setup and Programming

6.1 Setup Mode

6.1.1 Mode Changes

•Press the MENU key for RUN, SETUP, TEST selections.

•RUN is the normal operating mode for the instrument.

•SETUP offers various sub-menus used for instrument setup.

•TEST provides various sub-menus to test, calibrate and system start-up.

6.1.2 Submenu GROUP NAVIGATION

•When in SETUP or TEST mode, use the UP and DOWN arrow keys to browse up and down

through the Sub-Menu groupings.

•Press the ENTER key to enter a desired setup or test Sub-Menu group.

6.1.3 Item Selection

•The unit will frequently provide many options for a particular topic during setup.

•The topic prompt appears on the top line of the display.

•The options are displayed on the display's lower line.

•Press the key next to the option you want to choose an item.

•The selected option will blink.

•Press the ENTER key to accept the selected choice.

6.1.4 Numeric Entry

•Numerical values are entered using the keys labeled "0 - 9", "–", ".", CLEAR, and ENTER.

•A leading 0 will assume that you intend to enter a minus "–" sign.

•Press the CLEAR key to clear the current value and to enable editing.

6.1.5 Text Character Entry

•The user must insert text characters for some configuration elements (e.g., Descriptors,

Units Label).

•Press CLEAR to enable editing.

•The UP and DOWN arrow keys are used to scroll through the available character sets for

each character.

•Press the ENTER key to accept the character and advance to the next character.

6.2 EZ Setup

•The EZ Setup method allows you to configure the unit for the most regularly utilized

instrument functions quickly and easily.

•This configuration implies you are measured Volumetric Flow with a DC Pulsing flow sensor

at a high level. Many functions are automatically set in EZ Setup mode.

•This may cause any previously programmed information to be lost or reset.

Table of contents