TeMec Drive AZ2 User manual

AZ2

DC MOTOR DRIVE

USER MANUAL

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

2 / 52

Read carefully this manual before using the drive.

TeMec Drive reserves the right to change the information reported in this manual without prior notice

because the product is in continuous evolution.

No part of this manual may be howsoever reproduced without previous consent by TeMec Drive.

REVISIONS INDEX

Rev.

Par.

Description

Date

R

V

A

0.0

-

First release

04/03/2016

1.0

-

Update. Independent with encoder functionalities added.

01/03/2019

2.1

9

Corrected troubleshooting for yellow error

11/11/2020

RZ

R = Redaction

V = Verification

A = Approval

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

3 / 52

Index

1. SAFETY PRECAUTIONS.....................................................................................................................5

1.1. Operating limits................................................................................................................................. 5

1.2. Handling............................................................................................................................................. 5

1.3. Transportation and installation......................................................................................................... 6

1.4. Wiring ................................................................................................................................................ 7

1.5. Operations......................................................................................................................................... 8

1.6. Modification of advanced parameters.............................................................................................. 8

1.7. Maintenance and inspection............................................................................................................. 9

1.8. Disposal.............................................................................................................................................. 9

1.9. CE conformity and applicable standards........................................................................................... 9

2. GENERAL INFORMATION............................................................................................................... 10

2.1. Technical characteristics.................................................................................................................. 10

2.2. Board overview................................................................................................................................ 11

2.3. Ordering codes ................................................................................................................................ 11

3. INSTALLATION AND WIRINGS........................................................................................................ 12

3.1. Installation environment................................................................................................................. 12

3.2. Mechanical installation.................................................................................................................... 12

3.3. Mechanical drawings....................................................................................................................... 13

3.4. External power supply connections ................................................................................................ 14

4. OPERATION OF TWO INDEPENDENT MOTORS WITHOUT ENCODER................................................ 15

4.1. Connections and commands ........................................................................................................... 15

4.2. Ramps.............................................................................................................................................. 18

4.2.1. Advanced parameters ............................................................................................................. 18

4.3. Current limits................................................................................................................................... 19

4.3.1. Advanced parameters ............................................................................................................. 20

5. OPERATION OF TWO INDEPENDENT MOTORS WITH ENCODER ...................................................... 22

5.1. Connections and commands ........................................................................................................... 22

5.2. Homing function.............................................................................................................................. 25

5.2.1. Advanced parameters ............................................................................................................. 26

5.3. Normal run ...................................................................................................................................... 26

5.3.1. Advanced parameters ............................................................................................................. 27

6. OPERATION OF TWO SYNCHRONIZED MOTORS ............................................................................. 29

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

4 / 52

6.1. Connections and commands ........................................................................................................... 29

6.2. Trimming mode ............................................................................................................................... 30

6.3. Homing function.............................................................................................................................. 30

6.3.1. Advanced parameters ............................................................................................................. 31

6.4. Normal run ...................................................................................................................................... 32

6.4.1. Advanced parameters ............................................................................................................. 33

7. ERRORS AND DIAGNOSTICS........................................................................................................... 35

7.1. Global errors.................................................................................................................................... 35

7.1.1. Advanced parameters ............................................................................................................. 36

7.2. Motor specific errors....................................................................................................................... 37

7.2.1. Advanced parameters ............................................................................................................. 38

8. PARAMETER TABLES ..................................................................................................................... 39

8.1. Digital inputs and outputs ............................................................................................................... 39

8.2. Ramps.............................................................................................................................................. 40

8.3. Current limits................................................................................................................................... 40

8.4. Synchronism - motor 1 and motor 2 ............................................................................................... 43

8.5. Synchronism - global ....................................................................................................................... 45

8.6. Independent with encoder.............................................................................................................. 45

8.7. Global errors.................................................................................................................................... 45

8.8. Motor specific errors....................................................................................................................... 47

9. TROUBLESHOOTING...................................................................................................................... 49

10. MAINTENANCE AND INSPECTION.................................................................................................. 51

11.DISPOSAL ..................................................................................................................................... 51

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

5 / 52

1. SAFETY PRECAUTIONS

Read carefully the following items so that you can safely use the drive avoiding causing injury to the

operators, damaging the mechanic components driven by the drive or other objects in the area.

Make sure you that all warnings are correctly observed.

Safety marking legend:

MARKING

Meaning of the marking

!WARNING

Indicates that errors that may lead to death or serious injury.

!CAUTION

Indicates that errors that may lead to injury to people or damage

objects.

MARKING

Meaning of the marking

Prohibition. Do not do it.

!

Obligation. Follow the instruction.

!

Warning.

1.1. Operating limits

This drive is designed for the open loop control of one or two linear actuators driven by direct

current motors for synchronous or independent operation. Do not use for driving other electrical

loads or motor types without first contacting your TeMec Drive distributor.

Use the drive only in industrial application; do not use it where a possible fault can cause serious

injury to human life, like nuclear plants, aviation, safety device, entertainment, medical.

Use the drive only where a possible fault of the drive does not cause serious accidents or

damages or use it only where safety equipment is applicable or a backup circuit device is provided

outside the system.

1.2. Handling

!WARNING

Do not disassemble, modify or repair. This can cause electrical shock, fire and

injury.

Do not touch the electronic drive components when power is on. This can result

in electric shock or other injury.

Do not allow water or any other fluid to come in contact with the drive. This can

result in electric shock or fire.

!

Turn on the power only when the drive is closed in a proper insulating cabinet to

avoid electric shock or other injury.

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

6 / 52

If the drive begins to emit smoke, an unusual odour, or unusual sounds,

immediately disconnect the power. Continuous use of the drive in such a state

may cause fire. Call your TeMec Drive distributor for assistance and/or repair.

Always turn the power off if the drive is not used for long time. Leaks, dust and

other material may cause malfunctions and if power is left on with the drive in

that state, it may result in fire.

!CAUTION

Do not touch heatsink fins or discharge / braking resistors. These parts may be

hot and can cause burning if you touch them.

1.3. Transportation and installation

!WARNING

Do not install or operate the drive if it is damaged. This can result in electrical

shock or fire.

Do not place any inflammable objects near the drive. If an accident occurs in

which flame is emitted, this could lead to fire.

Do not install in any location where the drive could come into contact with water

or other fluids. This can result in electric shock or fire.

!

Install the drive being sure that no metal part is in contact with the bottom side

of the board. The contact with the exposed tracks may cause electric shock or

fire.

Operate under the environmental conditions prescribed in this instruction

manual. Operations under any other conditions may result in malfunction.

Install an emergency stop device that fits with system specifications. The drive

alone cannot stop operation immediately, thus resulting in an accident or injury.

!CAUTION

!

When installing make sure that the fixing holes are spaced correctly within the

tolerances indicated in this manual. Otherwise the drive may bend and be

damaged.

Pressing too hard on the screwdriver may irreparably damage the drive.

Always turn the power off when removing the drive from its support. After

wiring is complete, be sure to replace the unit into its case.

If braking is necessary (to hold motor shaft), install a mechanical brake. The

function brake on the drive will not function as a mechanical hold, and if used

for that purpose, injury may result.

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

7 / 52

1.4. Wiring

!WARNING

Do not connect in parallel the two power outputs to increase the total current

that can be imposed on a single motor. This can result in electrical shock or fire.

Do not change encoders’ connections after the successful execution of the first

homing. Any change in one of the two encoders’ connections may lead to

instability in the operation that may cause accidents or injury.

First shut off input power and wait at least 5 minutes before touching terminals

and wires on equipment (MCCB) that is connected to drive power side. Touching

the terminals and wires before that time could result in electric shock.

!

Use a protection diode on the positive terminal of the drive power supply to

avoid damages on the supply circuitry in case of regenerative braking of the

motor. The use of the diode is required in case of parallel connection of more

than one drive or connection of other loads in parallel with the drive.

A qualified expert must do electrical construction work. Connection of input

power by someone who does not have that expert knowledge may result in fire

or electric shock.

Connect output terminals (motor side) correctly. If the polarity is incorrect, the

motor(s) will operate in reverse and that may result in injury.

Do the wiring after installation. If wiring is done prior to installation, that may

result in injury or electric shock.

The following steps must be performed before wiring:

1. turn off all input power;

2. wait at least 5 minutes and check to make sure that the on state LED1 is no

longer lit;

3. use a tester that can measure DC voltage (60V DC or more), and check to

make sure that the voltage to the DC main circuits (across +V and 0V) is 45V

or less. If these steps are not properly performed, the wiring will cause

electric shock.

Tighten the screws on the terminal block to specified torque. If the screws are

not tightened to the specified torque, it may lead to fire.

Check to make sure that the input power voltage is within the limits of the rated

power voltage written on the nameplate, with the tolerance indicated in the

manual. If the input power voltage do not respect these conditions, this may

result in fire.

!CAUTION

Do not attach devices with built-in capacitors (such as noise filters or surge

absorbers) to the outputs (motor side) terminals. This could cause a fire.

!

Use a protection diode or set longer decelerating ramps in case of regenerative

braking. Such phenomenons may cause overvoltages and damages to the

external components that constitute the supply circuitry.

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

8 / 52

1.5. Operations

!WARNING

Do not overload the drive over its capabilities. The use of the drive over its

maximum service factor may cause serious accidents through overheating and

fire.

Do not touch drive terminals when electrical power is going to the drive even if

the motor is stopped. Touching the drive terminals while power is connected to

it may result in electric shock.

Do not touch the drive when the hands are wet. Such action may result in electric

shock.

!

Execute a homing procedure after the power reset, enable parameter SG01 or

use limit switches to avoid overtravel that may cause an accident or injury.

Make sure that operation signals are off before resetting the drive after

malfunction. If the drive is reset before turning off the operating signal, the

motor may restart suddenly, resulting in injury.

If incorrect set, the drive may has some damage or unexpected movement. Be

sure to set the setup menu correctly.

!CAUTION

!

Use a motor that conforms to the specifications of the drive and power supply.

If the motor being used does not conform to those specifications, not only will

the motor not rotate correctly but also it may cause serious accidents through

overheating and fire.

1.6. Modification of advanced parameters

!WARNING

!

Do not modify advanced parameters before reading carefully this manual or

contacting your TeMec Drive distributor. An incorrect set of the parameters can

cause injury or accidents.

Do not disable the soft start function if not strictly necessary; always contact

your TeMec Drive distributor. A possible fault with the drive in such a state may

cause fire.

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

9 / 52

1.7. Maintenance and inspection

!WARNING

Do not replace parts. This could be a cause of electric shock, fire and bodily

injury. To replace parts, call your TeMec Drive distributor.

!

The equipment must be inspected periodically. If the equipment is not inspected

and maintained, errors and malfunctions may not be discovered and that could

result in accidents.

Before inspection, perform the following steps:

1. turn off all input power to the drive;

2. wait at least 5 minutes and check to make sure that the on state LED1 is no longer

lit;

3. use a tester that can measure DC voltages (60V DC or more), and check that the

voltage to the DC main circuits (across +V and 0V) is 45V or less.

Performing an inspection without carrying out these steps first could lead to

electric shock.

1.8. Disposal

!WARNING

!

If you dispose of the drive, have it done by a specialist in industry waste disposal

(*). If you dispose of the drive by yourself, this can result in explosionof capacitor

or produce noxious gases, resulting in injury.

(*) Persons who specialize in the processing of waste and known as "industrial waste

product collectors and transporters" or "industrial waste disposal persons”. Please

observe any applicable law, regulation, rule or ordinance for industrial waste

disposal.

1.9. CE conformity and applicable standards

The AZ2 drive complies with the following standards:

EMC CE-Emission of interference according to EN 61000-6-4: 2007

EMC CE-Immunity to interference according to EN 61000-6-2: 2005

The drive is a component to be used in a second environment (industrial environment) and category

C3, together with specific EMC filters. When used in the first environment (residential / commercial

environment), drives may produce radio-frequency interference dangerous for other equipment: the

user must implement additional filtering measures.

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

10 / 52

2. GENERAL INFORMATION

AZ2is a full electronic motor drive designed for the control of two DC motors in low voltage

applications. The power stage is based on MOS transistor technology, controlled by a pulse width

modulation (PWM). A digital signal processor (DSP) elaborates the control data, generates the output

waveforms and manages the communication interfaces.

The user can exchange data and commands with the drive using the digital I/O and a Modbus

interface. The last one is mainly used for communication with the PC application through which the

user can change parameters, monitor the status of the drive and read diagnostic information. The

use of the Modbus interface in a fieldbus system needs an optional transceiver board, to adapt the

voltages levels from the board to the fieldbus physic level.

The board is also capable to acquire both the output currents, the supply voltage and the board

temperature. More than ten auxiliary I/O are available on the board and can be used for custom

applications or future purposes.

The AZ2drive is designed for the open loop control of linear actuators driven by DC motors but its

use can be extended to any application involving the control of DC motors. For this reason in the

following manual the terms motor and linear actuator, forward/backward and open/close are used

as synonyms.

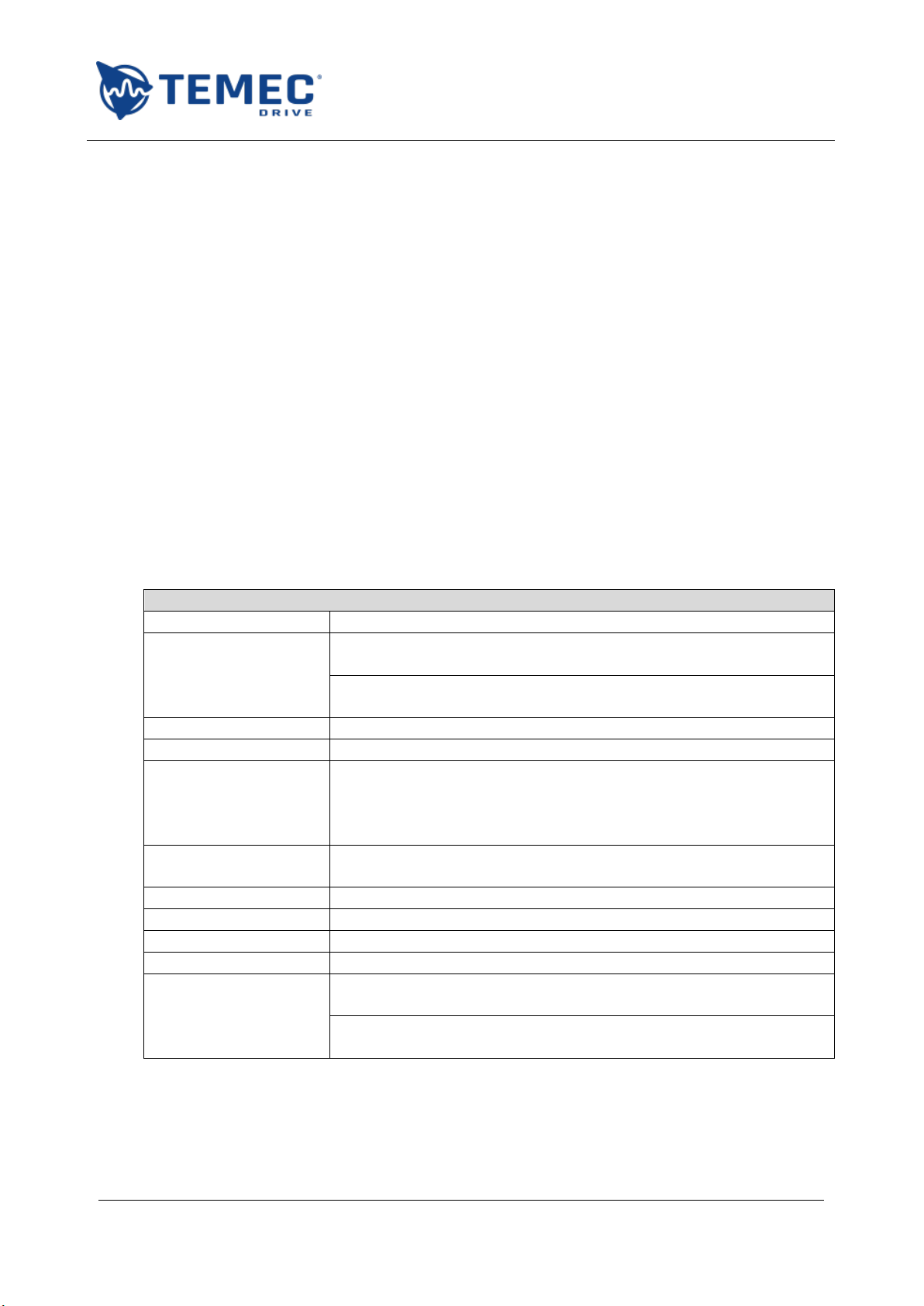

2.1. Technical characteristics

TECHNICAL DATA

Supply voltage

12 V to 48 V DC, maximum ripple 20%

Output current

Code AZ2048D01000000:

Maximum 10 A / motor, S3 –30% –5 minutes service factor

Code AZ2048D01500000:

Maximum 15 A / motor, S3 –30% –5 minutes service factor

PWM frequency

10 kHz

Quiescent current

50 mA @ 24 V DC supply

Inputs (not isolated)

1.7 –12 V DC ON, 0 –0.7 V DC OFF

8 inputs for commands and limit switches

4 inputs for pulse signals (max 1 kHz)

Pull-up/down (10 kΩ) settable for each input type

Outputs (not isolated)

2 NPN open collector (max 50 mA –24 V DC)

One for general fault and one with programmable function

Output auxiliary voltage

12 V DC, maximum 50 mA

Diagnostic

Blinking codes using a multicolour LED

Operating temperature

-20°C …+60°C

IP grade

IP00

Dimensions and weight

Code AZ2048D01000000:

86 x 72 x 36 mm (LxWxH); 67 g

Code AZ2048D01500000:

86 x 72 x 43 mm (LxWxH); 130 g

Table 1: AZ2technical data

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

11 / 52

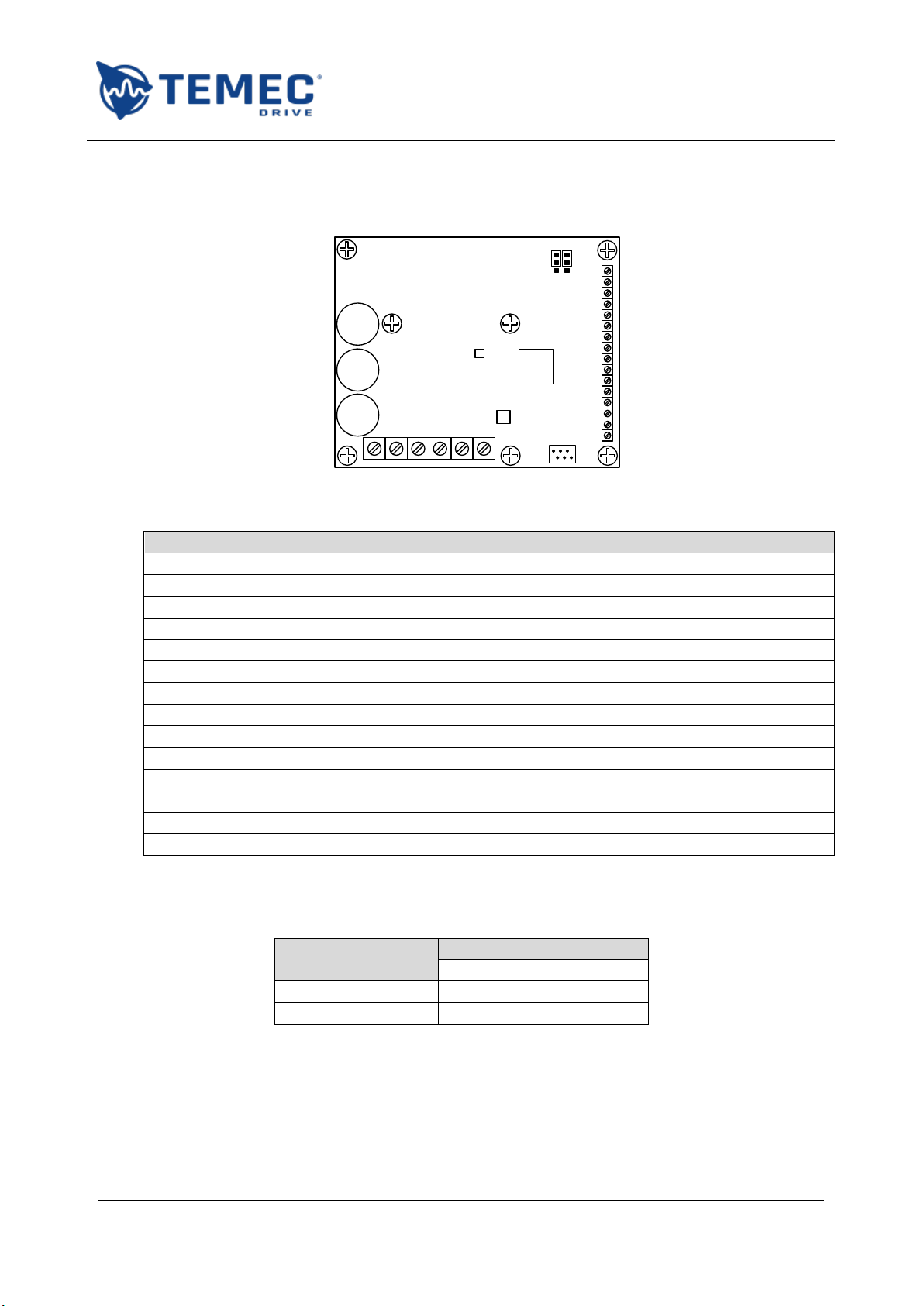

2.2. Board overview

Figure 1 shows the main board components while Table 2 explains the functions associated with

them.

+V 0V M1+ M1- M2+ M2-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

DSP

LED1

LED2

S1

S1

S1

S1

S2 S2

S3

X1

X2

X3

J2J1

Figure 1: main board components

Component

Function

X1

Power terminal for power supply and motor output connections

X2:1 - X2:8

Signal terminals for inputs

X2:9 - X2:12

Signal terminals for pulse inputs

X2:13

Fault output

X2:14

Configurable output

X2:15

Auxiliary voltage GND and inputs GND

X2:16

Auxiliary voltage +12 V

X3

Connector for communication with PC application or fieldbus interface

J1

Jumper for inputs 1-8 pull-up/down configuration

J2

Jumper for inputs 9-12 pull-up/down configuration

LED1

DSP red LED

LED2

Diagnostic red/green/blue (RGB) LED

S1

Holes for mounting screws

S2

Holes for heat sink mounting screws

Table 2: main components

2.3. Ordering codes

The following table reports the ordering codes:

Code

Options

Output current (per motor)

AZ2048D01000000

10 A

AZ2048D01500000

15 A

Figure 2: ordering codes

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

12 / 52

3. INSTALLATION AND WIRINGS

!

Read carefully the safety precautions reported in 1.3 and 1.4 before installing the drive!

Follow the instruction reported below to install the drive and integrate it into your system.

3.1. Installation environment

Remember that the drive is an electronic device; check carefully that the installation environment is

appropriate:

do not install in any location with high temperature, high humidity, moisture condensation and

freezing;

avoid installing location where there is the possibility of exposition to water, large amounts of

dust, metallic fragments or corrosive gases;

operate in areas where the temperature is within the limit temperatures reported in Table 1;

do not install in any location that can be subject to large amounts of vibrations.

3.2. Mechanical installation

Install the drive being sure that no metal part is in contact with the bottom side of the board.

The contact with the exposed tracks may cause electric shock or fire.

With reference to Figure 1 and Table 2, use S1 mounting holes for the mechanical installation.

Install the drive in vertical position, with the power terminal on the bottom side and so that the

fins of the optional heat sink result in vertical position.

When installing the drive, leave at least the distances shown in Figure 3 so that the wiring can be

made easily and the drive can dissipate the heat generated during the operation.

In case of multiple installations align the drives horizontally, leaving at least the distances shown

in Figure 3.

AZ2AZ2

5 cm

5 cm

5 cm

3

cm

Figure 3: minimum distances for mechanical installation

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

13 / 52

When wiring the drive use the following tightening torques for the terminal blocks:

Terminal block

Tightening torque [Nm]

Minimum

Maximum

X1 –POWER

0.5

0.6

X2 –Signals

0.22

0.25

Table 3: recommended tightening torques

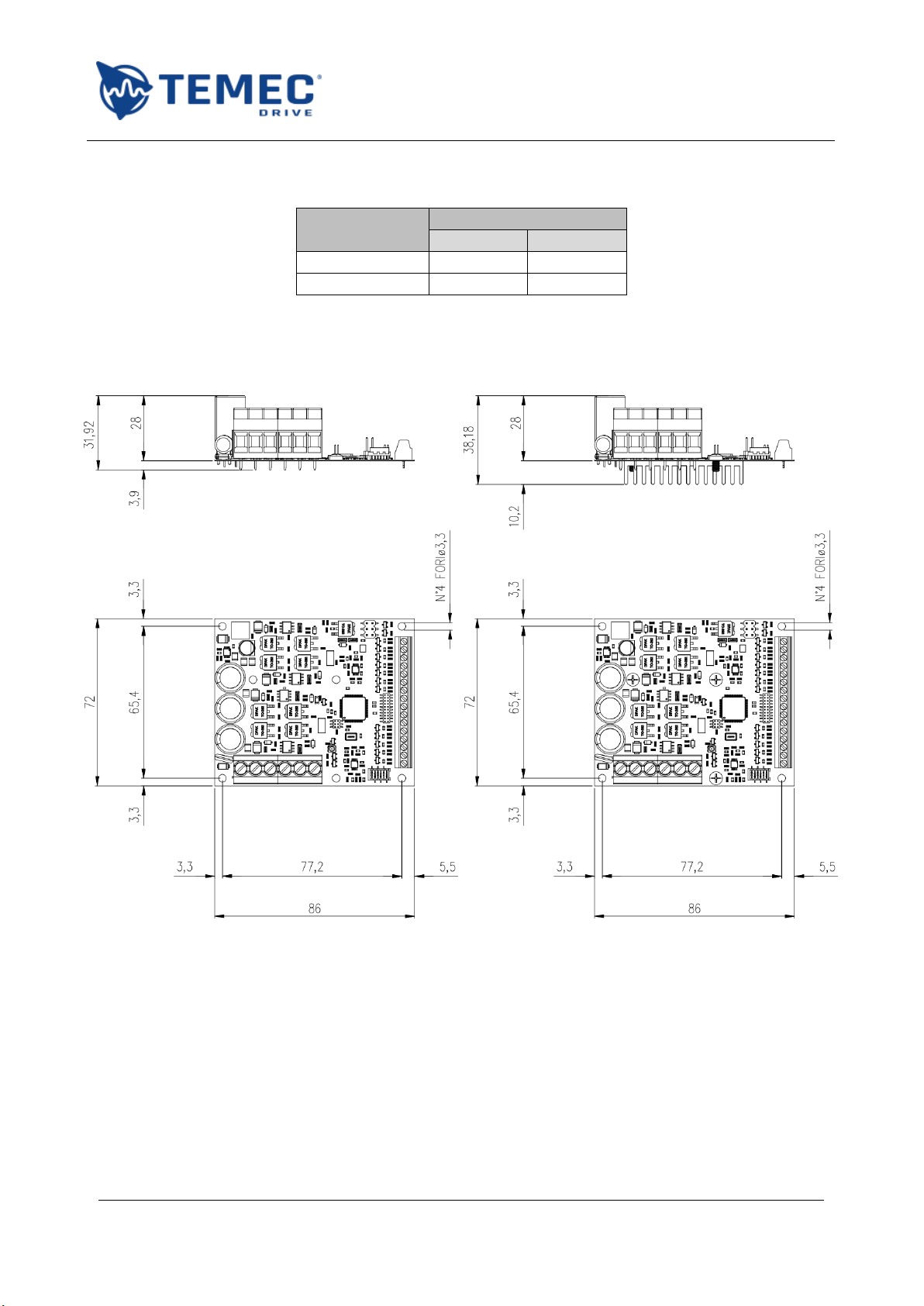

3.3. Mechanical drawings

All quotes are expressed in millimetres:

Figure 4: AZ2048D01000000 dimensions in mm

Figure 5: AZ2048D01500000 dimensions in mm

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

14 / 52

3.4. External power supply connections

It is strongly recommended to use a protection diode on the positive terminal of the drive power

supply to avoid damages on the supply circuitry in case of regenerative braking of the motor. The use

of the diode is required in case of parallel connection of more than one AZ2or connection of other

loads in parallel with the drive, as shown in Figure 6:

AZ2

+V 0V

AZ2

+V 0V

Generic

Load

DC

POWER

SUPPLY+

-

Figure 6: parallel connection of multiple drives

An example of diode that can be used is Infineon IDP30E60, adequately dissipated.

For the protection of the drive use a 25 A time delay fuse for AZ2048D01000000 or 35 A for

AZ2048D01500000.

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

15 / 52

4. OPERATION OF TWO INDEPENDENT MOTORS WITHOUT ENCODER

!

Read carefully the safety precautions reported in 1.5 before operating the drive!

In this operation mode, the drive can independently control the movement of two motors, by

applying on them the desired voltage and following the desired ramps, set by the user. The

movement stops when the relative limit switch signal goes high, when the current limit is achieved,

when the command is released or the STOP signal goes high.

All the parameters areset independently for both motors and for the opening and closing movement.

When the drive is not applying voltage to the motor, the terminals are short-circuited to ground.

4.1. Connections and commands

!

Read carefully the safety precautions reported in 1.4 before wiring the drive!

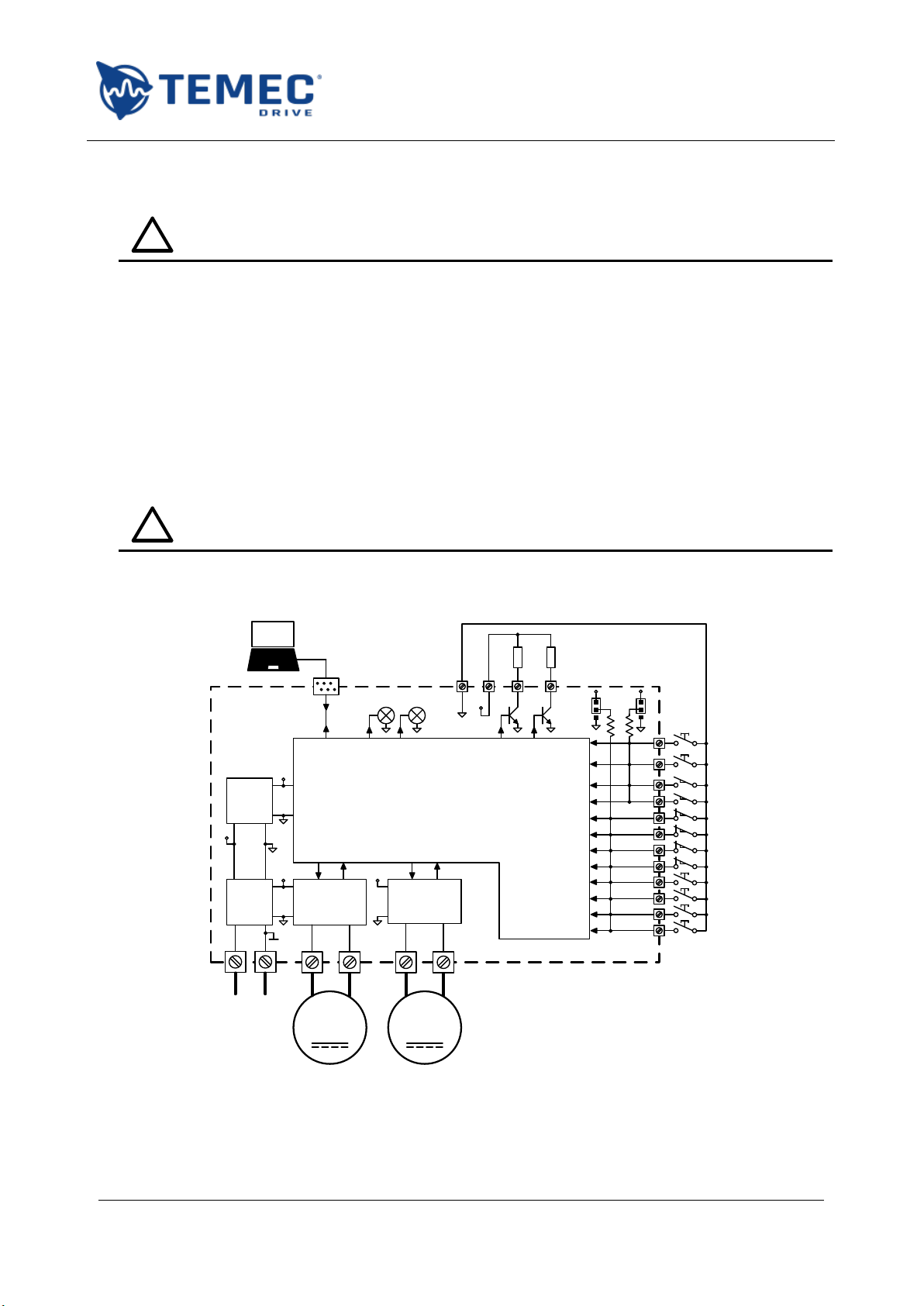

Below is a connection scheme showing all possible commands and devices that can be connected to

the board:

M

Power stage

&

Current sense

M

Power stage

&

Current sense

Switching

power

supply

12 V

DC

regulator

3.3 V

+V

3.3V

12V

12V

10kΩ

+

12V

12-48V DC

RED RGB

Modbus

interface

Inputs

Diagnostics

Motor

Drive

M1+ M1- M2+ M2-

1

2

3

4

5

6

7

12

1615

0V

13 14 J2

12V

OPEN-1

CLOSE-1

OPEN-2

CLOSE-2

OP-SW-1

CL-SW-1

OP-SW-2

STOP-2

Fault 11 STOP-1

8CL-SW-2

9INT-SW-1

10 INT-SW-2

10kΩ

+

J1

DSP

Figure 7: connection scheme example in independent mode

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

16 / 52

For each of the two motors:

Label

Function

OPEN

Open / forward command

CLOSE

Close / backward command

OP-SW

Open limit switch

CL-SW

Close limit switch

INT-SW

Intermediate switch

STOP

Stop command (errors reset)

Table 4: legend of external devices in independent operating mode

The user can set for every input from 01 to 12:

-the reversed logic working mode; set this bit following Table 5:

Normally

open contact

Normally

closed contact

Pull-up

resistor

Enable

reverse logic

Disable

reverse logic

Pull-down

resistor

Disable

reverse logic

Enable reverse

logic

Table 5: instructions for setting the reverse logic input mode

-a delay for the OFF to ON transition;

-a delay for the ON to OFF transition.

For example, digital input 1 parameters are (see 8.1 for the complete list):

Label

Function

Range

Default value

DI00

Reverse input 01 logic

ON / OFF

ON

DI01

Input 01 turn on delay

5 –500 [ms]

10

DI02

Input 01 turn off delay

5 –500 [ms]

10

Table 6: example of digital input parameters

The commands are configured as hold-to-run but can also work in one-press mode changing the

following parameter:

Label

Function

Range

Default value

DI36

Sets inputs in one-press mode

ON / OFF

OFF

Table 7: input mode parameter

The function of the digital output at terminal X2:14 can be set using this parameter:

Label

Function

Range

Default value

DI37

Sets function of output X2:14

See below

General Fault

Table 8: parameter for digital output 2 setting

The possible information that can be sent to OUT2 are:

-motor 1 or 2 Fault;

-motor 1 or 2 Open Limit Switch;

-motor 1 or 2 Close Limit Switch;

-motor 1 or 2 Intermediate Limit Switch;

-motor 1 or 2 Current Open Limit Switch;

-motor 1 or 2 Current Close Limit Switch;

-motor 1 or 2 Electronic Open Limit;

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

17 / 52

-motor 1 or 2 Electronic Close Limit;

-motor 1 or 2 Open Inrush Overcurrent;

-motor 1 or 2 Open Overcurrent;

-motor 1 or 2 Close Inrush Overcurrent;

-motor 1 or 2 Close Overcurrent;

-motor 1 or 2 Encoder disconnected;

-motor 1 or 2 Open Limit Loss;

-motor 1 or 2 Close Limit Loss;

-general Fault;

-power supply overvoltage;

-power supply under-voltage;

-board over-temperature;

-synchronism error.

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

18 / 52

4.2. Ramps

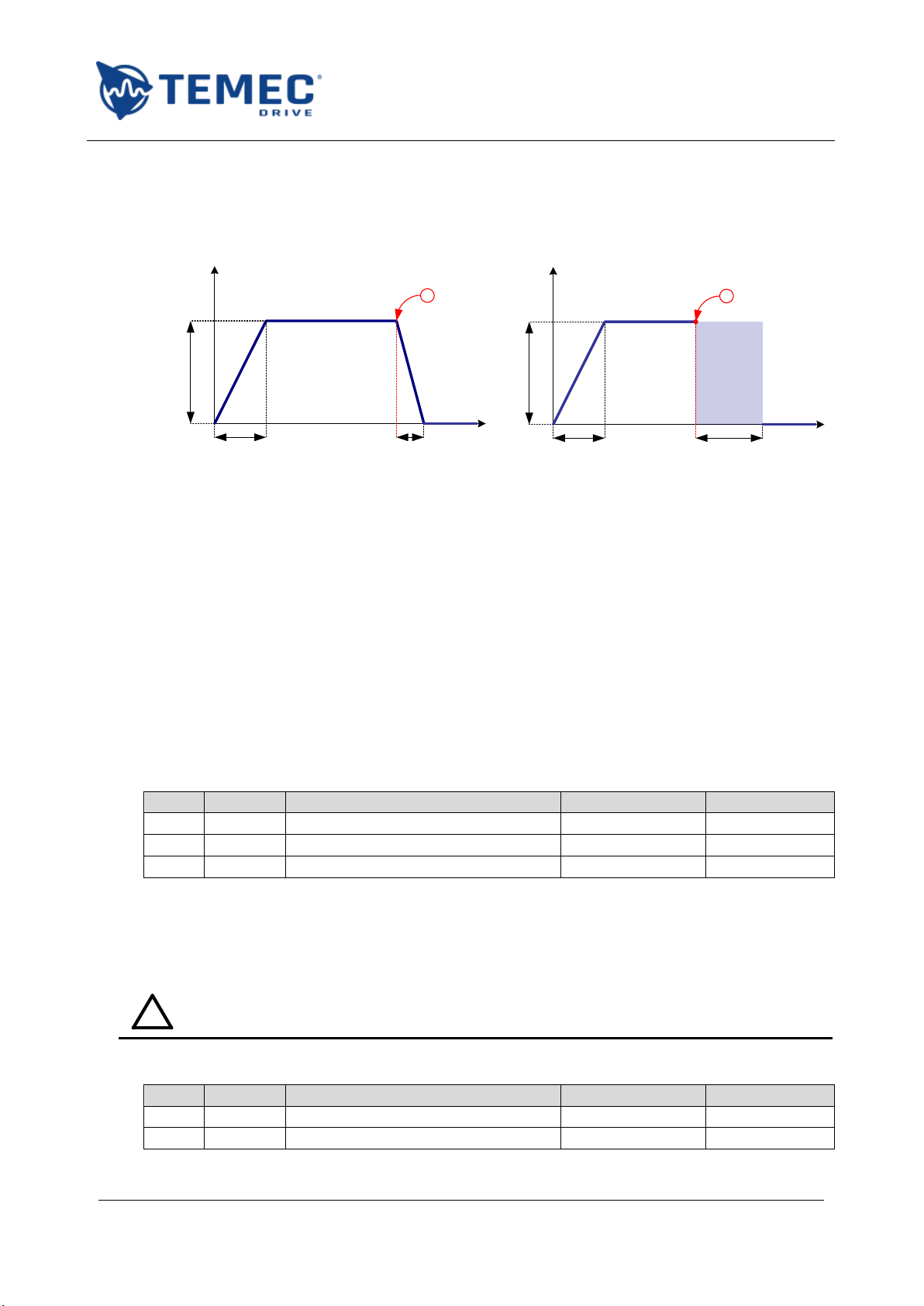

The following figures show how the drive applies the voltage to the motors. The example is the

acceleration and deceleration ramp for motor 1 during the opening movement with two different

stops:

V

t

V

t

M101 M102

M100

!!

High

impedance

M101 M106

M100

Figure 8: ramp waveform example in case of normal stop (left) and overcurrent (right)

In both cases the full voltage is applied gradually, following a ramp long M101 ms.

In the first case (Figure 8 - left) the motor stops because the drive reduces the voltage until 0 V, in

M102 ms. Excluding errors, this happens if:

the command is released;

the STOP command is pressed;

the limit switch is engaged.

When an overcurrent is detected the drive behaviour follows Figure 8 - right: the motor terminals

are disconnected from the power stage (no voltage applied) for M106 = 500 ms and the stop is

achieved by inertia.

The ramps applied to the motors are set using three parameters (see 8.2 for the complete list):

Label

Output

Function

Range

Default value

M100

Motor 1

Open voltage

10 –48 [V]

24

M101

Motor 1

Open acceleration ramp

100 –3000 [ms]

500

M102

Motor 1

Open deceleration ramp

100 –3000 [ms]

500

Table 9: example of ramp parameters

The user can set different ramps for the two motor and for each direction.

4.2.1.ADVANCED PARAMETERS

!

Read carefully the safety precautions reported in 1.6 before modifying any of the

advanced parameters!

In advanced mode the user can modify this further parameters:

Label

Output

Function

Range

Default value

M106

Motor 1

Motor 1 inertial braking time

500 –3000 [ms]

500

M206

Motor 2

Motor 2 inertial braking time

500 –3000 [ms]

500

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

19 / 52

Table 10: ramps advanced parameters

4.3. Current limits

The drive monitors the current absorption during all the motor movement using two thresholds, one

for the start phase and the second during the rest of the run as shown in this Figure 9:

I

t

C106

C102

C108

V

t

M101 M102

M100

!

Figure 9: current monitoring parameters

The first threshold is used for a time given by the sum of M101 and C106 = 1 s. The user can set the

nominal current threshold C108, while the inrush one C102 is calculated as 2 times the first value.

Either the drive can go in block state or not when the current limit is exceeded, depending on the

user choice. If the block is disabled (C107 = OFF), the drive will read the overcurrent as a limit switch

permitting only the movement in the opposite direction.

The parameters below configure the current limit functions for the opening movement of motor 1

(see 8.3 for the complete list):

Label

Output

Function

Range

Default

value

C107

Motor 1

Enables the block in case of overcurrent during

opening

ON / OFF

ON

C108

Motor 1

High threshold of nominal current control

during opening

1 –11 [A]

10

Table 11: example of current limit parameters

The user can set different current limits for the two motor and for each direction.

AZ2USER MANUAL

ST.TEC.003.EN Rev. 2.1

20 / 52

4.3.1.ADVANCED PARAMETERS

!

Read carefully the safety precautions reported in 1.6 before modifying any of the

advanced parameters!

In advanced mode, the user can configure independently the two functions of current monitoring for

inrush and normal run.

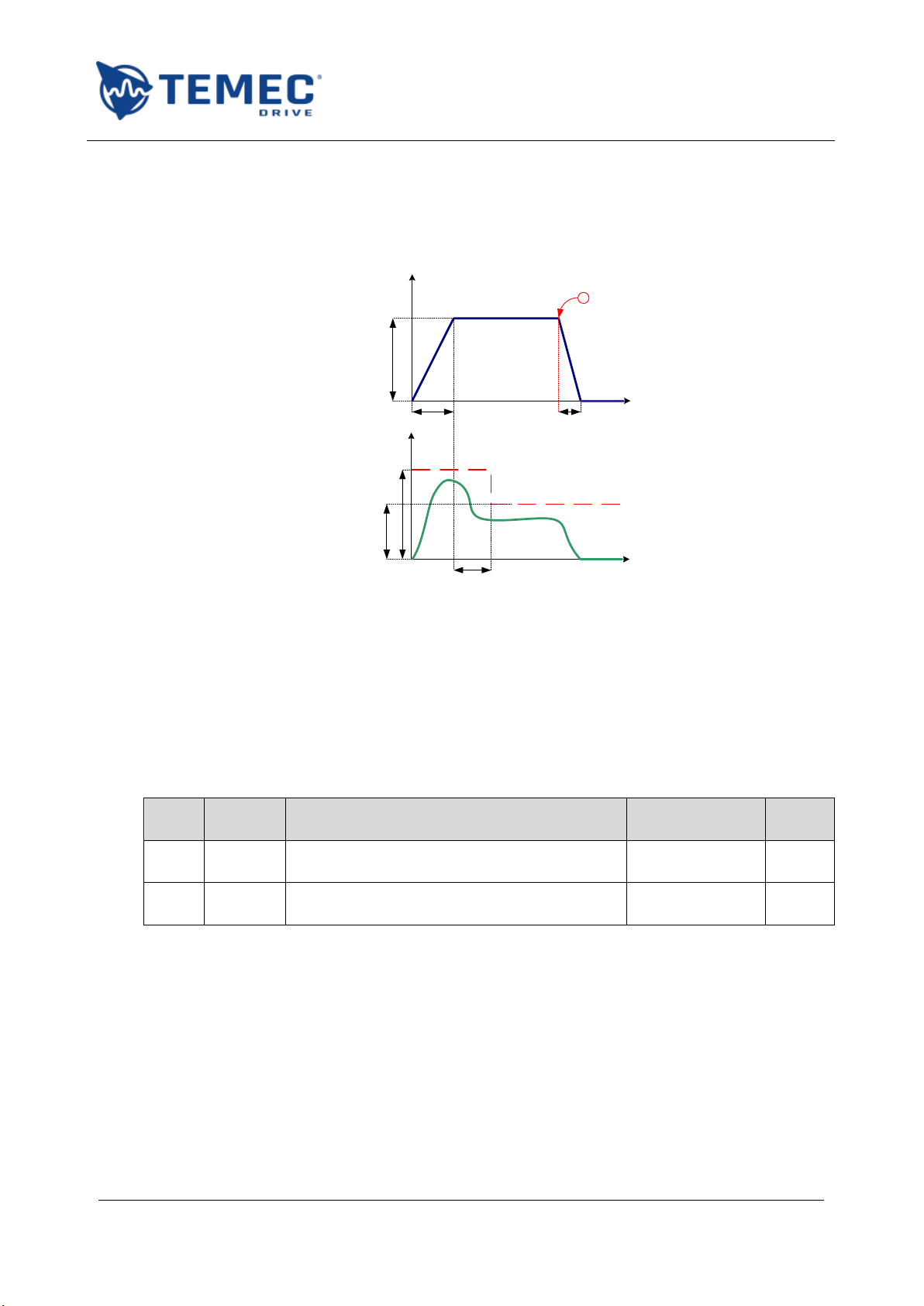

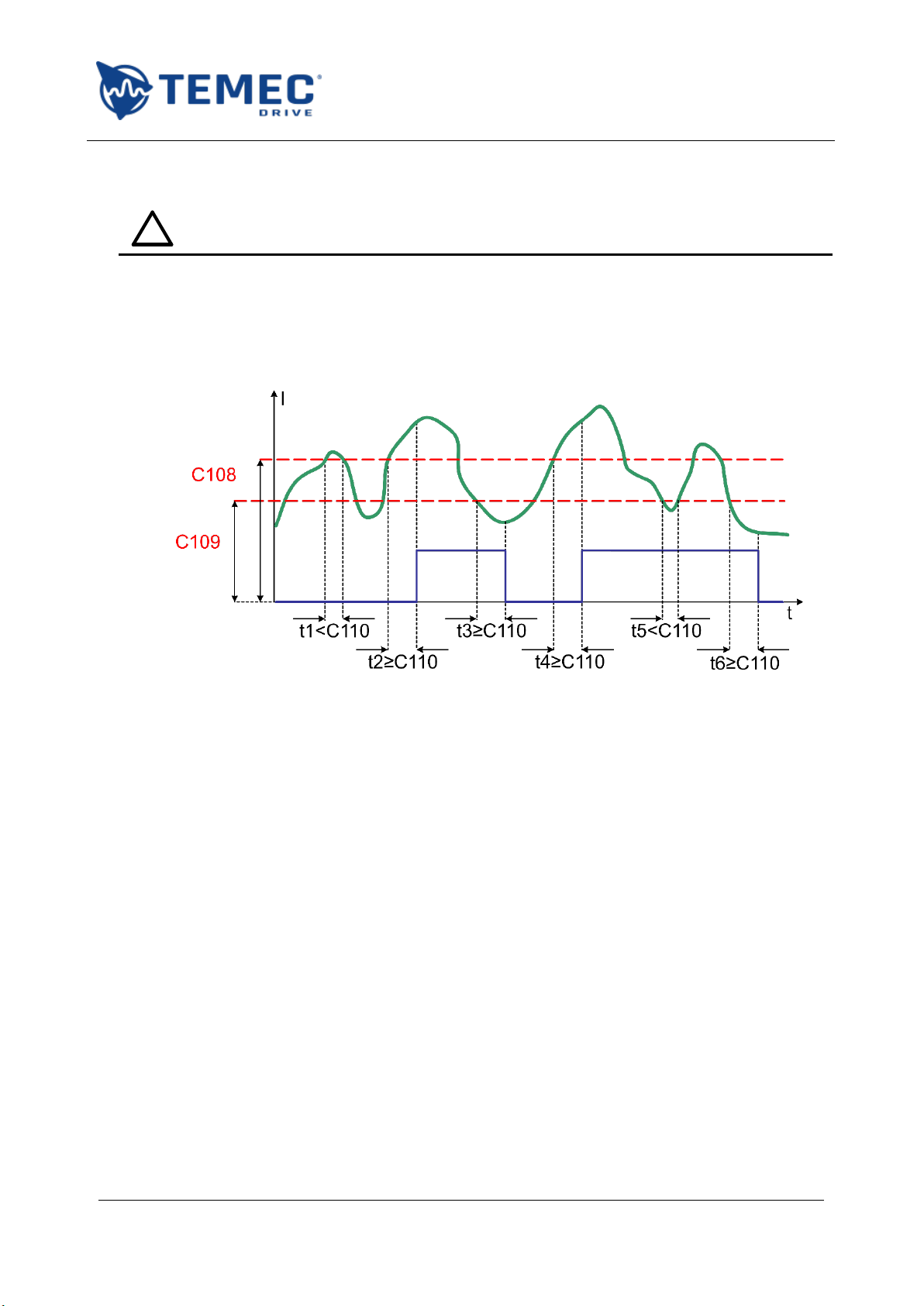

The Figure 10 explains the meaning of the parameters and is applicable to all the monitoring function

of analog and digital quantities; in particular, the parameters shown below are related to the

monitoring of motor 1 nominal current during opening:

Figure 10: example of analog quantity monitoring

The green trace is an example of controlled quantity (i.e. the current), in red there are the two

threshold and in blue the result of the check (high current over the limit).

The check is positive if the controlled quantity exceeds the high threshold for more than C110 ms (t2

and t4but not t1). The quantity returns into the limits (blue trace 0) if it goes down the lower

threshold for more than C110 ms (t3and t6but not t5).

Other changeable parameters are the ones that enable the soft start function (for example C100).

Table of contents

Other TeMec Drive DC Drive manuals

Popular DC Drive manuals by other brands

Invertek Drives

Invertek Drives OPTIDRIVE E3 user manual

Danfoss

Danfoss VLT AutomationDrive FC 300 Series Programming guide

FALK

FALK Ultramite UB Installation & maintenance instructions

Minarik

Minarik RG5500U user manual

KB Electronics

KB Electronics KBWS-12 Installation and operating instructions

ABB

ABB ACS355 series Quick installation and start-up guide